-

Posts

1010 -

Joined

-

Last visited

-

Days Won

3

Everything posted by dmulally

-

All the rust? This landy is odd. Absolutely rusted to shit but has a galvanized chassis that looks brand new.

-

I picked up a spares land rover S3 with a diesel. Anybody know what it is? Dead reg and no plates so no way for me to tell.

-

I recall those two batteries under the seat. What a great car. I owned one many years ago and it was built like a tank. Very easy to weld in any patches.

-

She looks like a beauty! A 3.5 diff will make it much more livable.

-

For any big Chev parts I used Charlton Auto from Gore. I have bought gearboxes from them before. If you have a short diff then get a T56 and if the diff is in the 2's then I would go 4 speed. For carb choice I got 7 litres saved per 100km with a quadrajet over an edelbrock. Everything is expensive these days however marketplace prob the cheapest place to look. https://www.facebook.com/marketplace/item/1536298060551851/?mibextid=dXMIcH https://www.facebook.com/marketplace/item/6964925783630541/?mibextid=dXMIcH

-

Thanks to @yoeddynz not copywriting his shifter set up I copied his. Came out reasonably well I thought. The centre shaft bearing is a little sloppy but Ill see how it drives before replacing it with a rose joint. Maybe with the engine vibration it needs a little play. Ill have to confirm the shifting pattern when I get the half shafts back too. Really unhappy with how my welder is performing so before I do any more welding I need to purchase a new one. It'll do for this job however. I had a wire feed problem that I have fixed but it is temperamental. Sometimes it produces a nice weld and others it just blobs right up to the tip. Frustrating. The shifter is a VW shaft slid down inside the stock Imp shifter and rosette welded in a few places as well as round the collar. Still need to make the cover for it that will fit under the seat yet but I'll get onto that asap.

- 90 replies

-

- 13

-

-

-

Not sure if you're keeping the running gear as is but resist the urge to move to a 700r4. Don't be like me. Love this car.

-

So I finally got the engine mounted into the Imp with the freeway flyer gearbag. A lot of installing and uninstalling to see what works best where. As usually with these things it is a case of compromise and the least shit option which is to be expected. With the adapter plate and the VW being a bigger box I thought it would push the engine past the rear crossmember. Turns out that it's actually a shorter box and the engine was back towards the front by several inches. Therefore the carbs were hitting the firewall. Did not expect that one! So I had to make up a new gearbox mount bracket that pushed it rearwards 50mm. It will make the hump under the seat easier to make and possibly the linkage. New one installed here with me holding up the old one. The one issue this cause was that the output shafts on the gearbox are now further back. Annoying but seeing as there was always an angle to them it isn't that big of a deal. Except now the half shafts foul the exhaust. They had to come off and Ill have to cut a bit of length out of them. So out the pipes came and I got to chopping off the ends of the half shafts to line them up. I lined them up as best I could and scribed them for the engineer. I scribed them at full CV range with the wheel side at suspension stock level so I assume the engineer will weld it in the middle. He is a clever guy and I didn't want to tell him how to do his job so I'm interested to see what he comes up with. I took them in at lunch and he'll get around to it when he can. He promised to tack them up and I'll double check they fit ok before he finalises it.

- 90 replies

-

- 21

-

-

Ta. Looks like they are sold from that tool shop just past ITM in Masterton.

-

I rarely have my MIG set up higher than 50% power (Cebora 200) anyway so I'm not that fussed about heavy duty. I think the last heavy welding I did was on my dozer and I used stick for that and just poured in the rod. Fnar fnar. I was just looking up the BOC Smootharc actually. I think it is a direct competitor for the Cigweld. Does your smootharc lay a flat bead on the beefier stuff (say 3mm) and goes low enough for patch panels?

-

Time for me to get a new mig. I used to have a Lincoln 180 which I loved but gave to a mate (who promptly sold it) when I left Oz. I bought a Weldtech 200 from Proline which seemed ok but shat the bed and Proline werent interested in diagnosing or helping me repair it. Binned it. So I got a second hand Italian Stag 196 which has been good but it doesnt lay a smooth bead. I'm forever having to tinker with it and clear stoppages. I was threatening to get a 3 phase welder but Im limited to buying second hand. Can anybody recommend a 200 amp or so brand that lays a smooth bead before I get another Lincoln? Budget around 2-3k. Eyeing off this also as darkhorse but have never used a Cigweld. https://www.boc.co.nz/shop/en/nz/cigweld-transmig-185-ultra-multiprocess-welder-w1006185-p

-

Economy of effort only using two. How many hot flaps do you need to open anyway...

-

How about this? https://www.trademe.co.nz/a/motors/car-parts-accessories/ford/interior/listing/4511573754

-

With the adapter plate re-machined Im pretty sure it is ready to go. There were quite a few odds and ends in the kit left over that I couldn't tell what they were for so I'm hoping I either didnt need them or they were from the wrong kit. It's all torqued up now anyway so the next time I'll know it's wrong is when I test drive it. Quite a few things will need to happen before then however. Such as cutting a hole in the floor for the box, sorting a shifter, and custom made half shafts.

- 90 replies

-

- 20

-

-

Ended up getting it machined locally. Frustrating but what can you do really. Can anybody let me know if the rear main seal is the correct way round please? I'm second guessing myself. The hollow part faces the front of the engine.

-

I havent really considered it as it looks like it needs an ecu. Ill have a look. Edit: they have quite a large front sump hump which would foul the crossmember sadly. Im open to anything excluding the 6.2/6.5 detroits.

-

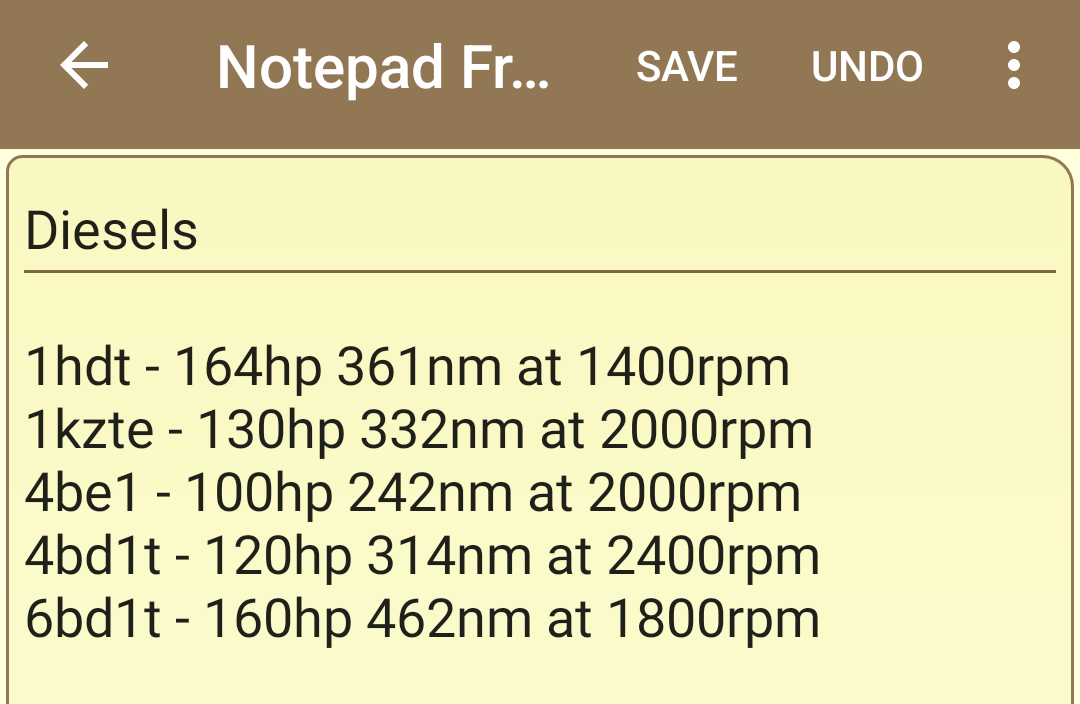

Some homework. The 6cyls will need some mods to fit. The 6bd1 is the length from the current radiator to the fw as it is. Would be great for towing but I dont tow as much these days.

-

I hope you wore the brown undies that day!! I did a bit of research and it looks like the mechanical pump is from a 2.4 with some mods required to increase fueling. Still looking up 2wd manual gearbox options.

-

This is fantastic feedback thanks @square. The last Hilux I had was the 2.4d and it was painful so I didnt even think about a later hilux engine. How did you go with wiring the 1kz with a mechanic pump and were any sump mods required? How did you find the a340? Did it need it's own controller to run like the 4l80e? The cummins stuff is so overpriced and oversized it didn't seem worth it. A 6BD1 could fit with some minor mods but will weigh similar to yours but with far less power.

-

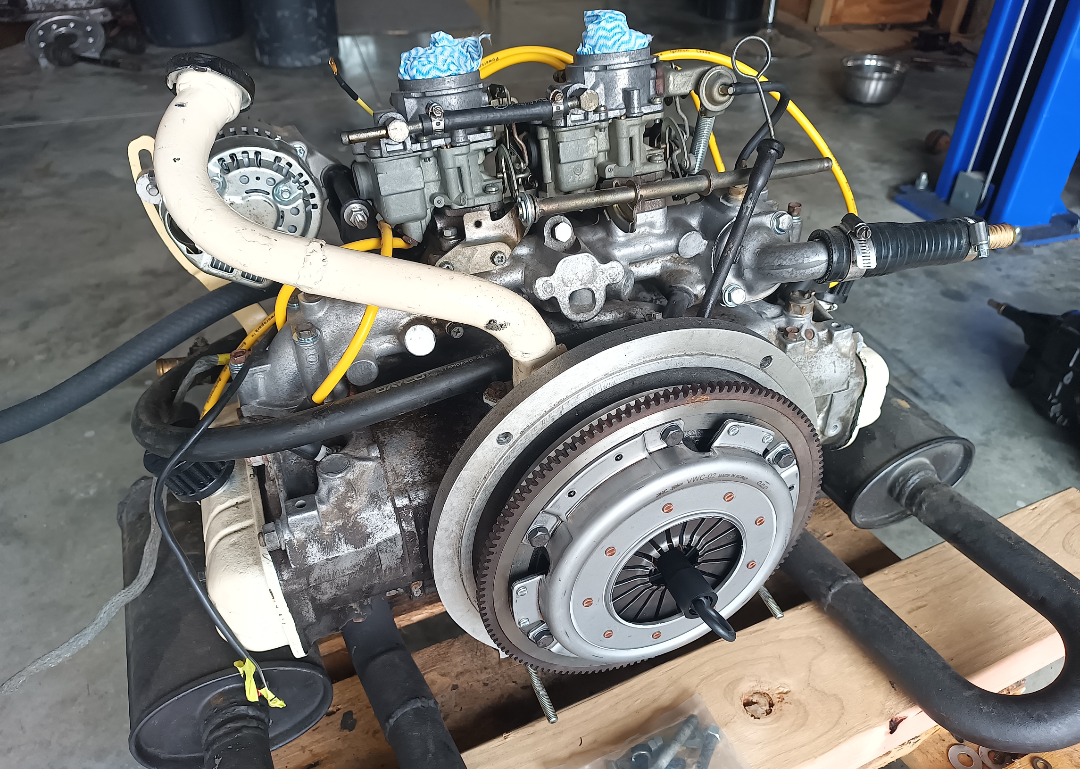

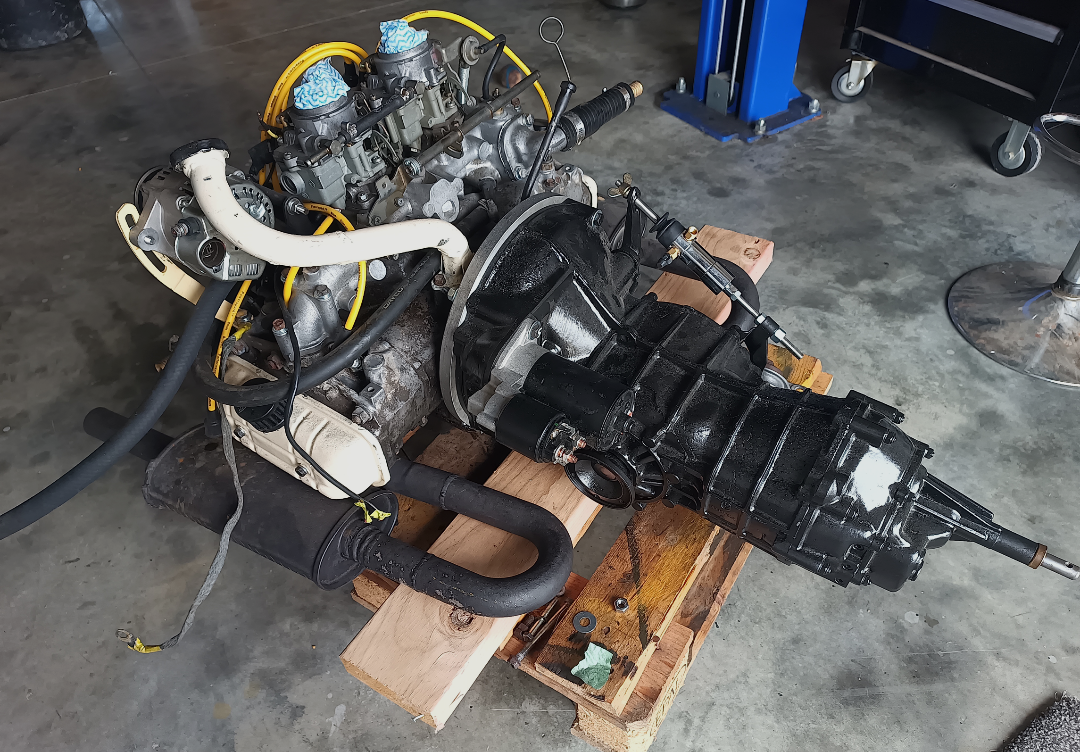

Hi All, Im a couple months away from taking my 66 C20 off the road to convert from a 350 with 700r4 to diesel. Mainly for fuel economy and reliability. I have all the stuff for an LPG conversion but Id still probably have to rebuild this engine and switch to a manual. I love the sound of the V8 and the power is quite adequate if not limited a little by the diff ratio of 4.56:1. I have a 4BE1 with a 5 speed box and a 4BD1 non turbo waiting in the shed. Both are pretty gutless but reliable. Ive looked for turbo bits for them for a while with no joy. Before I go down this path of no return, is there another non electric diesel engine worth looking at that isnt an LD28? The M57 has the dream specs but looks like a wiring nightmare and a lot of things to go wrong. I just sold my GMC 6.5td which had ok power but is another wiring ball ache. A detroit 353t would be fun but too rare. Also the size looks daunting. Open to ideas.

-

So old mate fucked up and forgot to counterbore the mounting holes. Ffs. Im one stubbed toe away from this being put under a car cover and put in the big shed at the back. This is how it was supposed to be done but I guess he forgot.

-

Thousand Dollar Supercar's 1988 Jaguar XJ-S 3.6

dmulally replied to Thousand Dollar Supercar's topic in Project Discussion

Yeah there is a wait. I booked it in ages ago. I was lucky that old mate who runs it was driving past my place on holidays and saw my s type outside and popped in to say hi. Not sure what tickling but will see how much effort is involved for the head gasket and if budget left over can see what else can be done. It was either that or put it to the back of the project queue for an engine and manual gearbox swap. Such a lovely car to drive. I miss it. Especially after driving a rattlely chev ute everywhere. -

Every one I have used has always been countersunk. This one isn't. I'll do a quick check for low profile screws/bolts but if nothing doing Ill just grind them down until it clears.

-

So having a bit of a drama fitting the adapter plate for the VW gearbag. The bolts that attach the plate to the block are fouling the flywheel. Am I missing a trick here? The holes aren't counterbored which would have solved that problem. I went to my normal bolt supplier and their low profile cap screws are the same height as a normal hex head at 5mm. Countersunk screws I'm not sure will have the surface contact area I need. I'm unsure if a button head screw would be too high a profile also. Google brings up space saving bolt head items from places in Asia which I'm not interested in as it'll take three months to arrive. Any ideas? Torque the bolts down and grind them lower in situ?

-

Thousand Dollar Supercar's 1988 Jaguar XJ-S 3.6

dmulally replied to Thousand Dollar Supercar's topic in Project Discussion

5k for an XJS with low kms and it didnt sell! Blimey. I might have to keep mine. It goes off to the Jaguar Workshop in a couple of weeks to get the 4.0 head gasket done and possibly tickled.