-

Posts

3,961 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by NickJ

-

Pretty sure I flipped one throttle shaft so the two short ends where facing each other to make mine fit and had to custom fabricate the linkage. But what I really don't understand, how can you balance the carbs and not test drive?

-

Karol Shusbands 72 Skyline. Discussion.

NickJ replied to CarolsHusband's topic in Project Discussion

Is that the factory exhaust position? Underside looks very similar to my 510 but the exhaust runs through the crossmember. Have wondered if that way would work but it always looked too close to the ground? -

fix it til it is?

- 26 replies

-

- 15

-

-

-

Ok cheers guys, I think the Datsun will get a short stay on stands while I scrape together some cash. As long as they aren't as loud as the mud tyres on the Niva, I think I can live with that

-

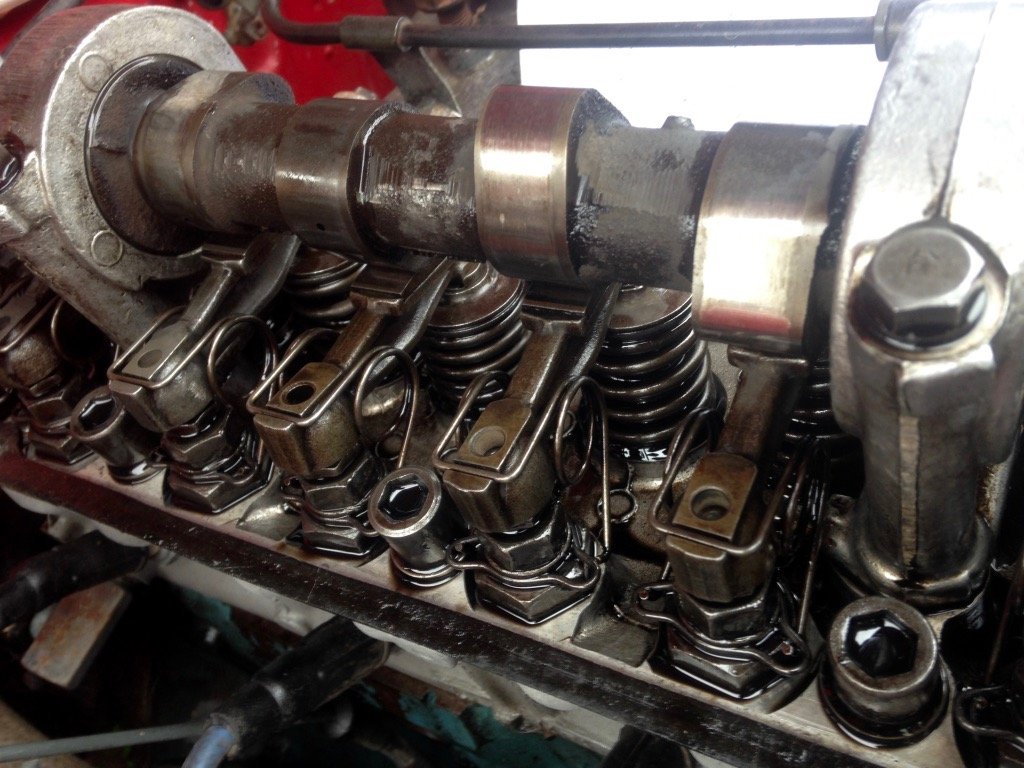

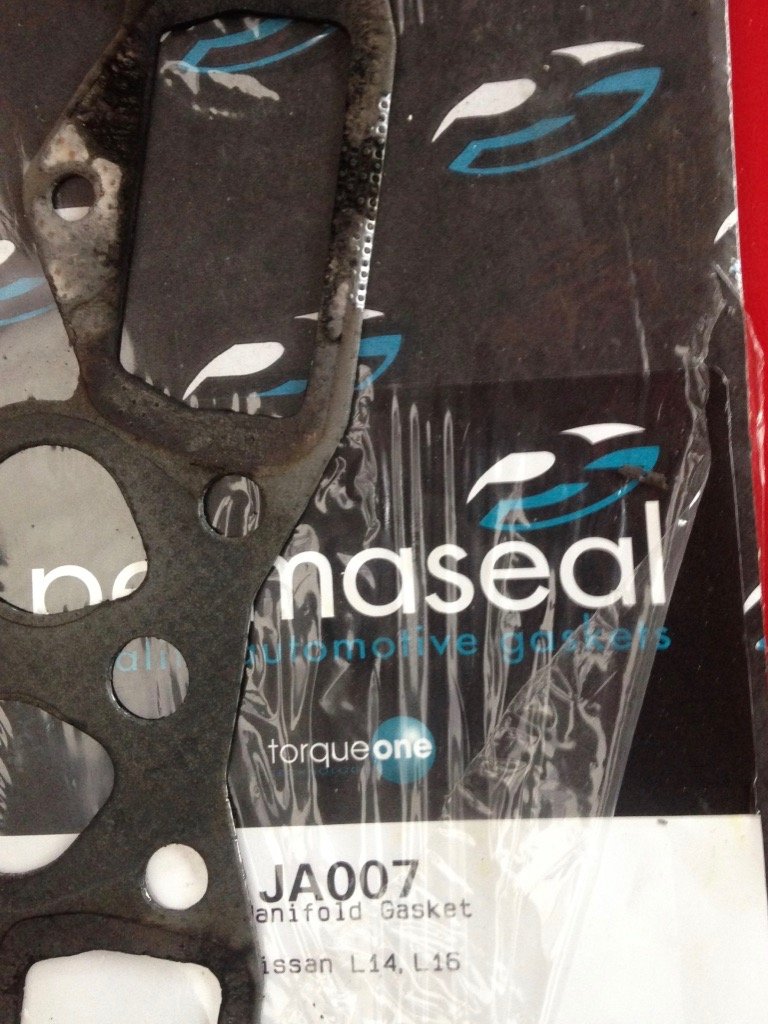

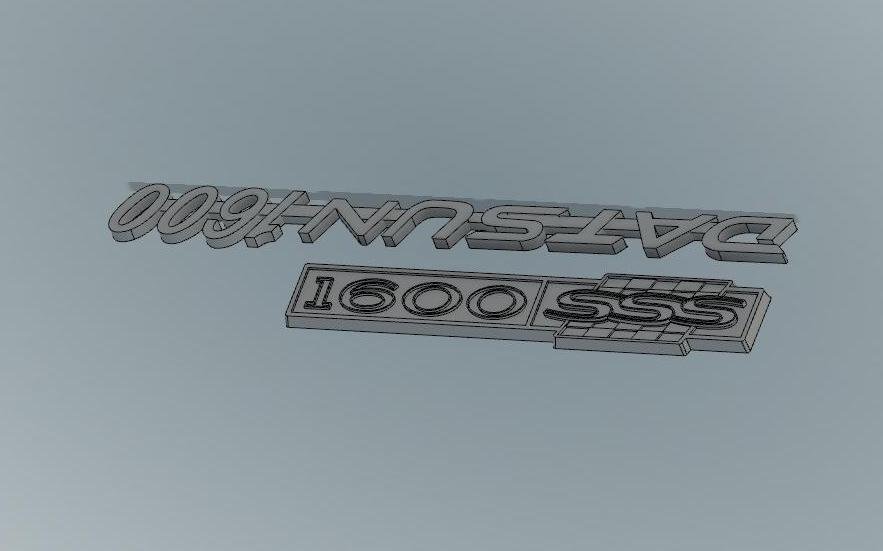

Electrical issue turned out to be worn brushes in the distributor, after a solid tour of Chch looking for a replacement brush housing I ended up finding a young fella at Repco who took one look and said, you need bush set xxx, see, they can be soldered in right there. Not often you find someone at a parts store that has the right knowledge, he set me off to another branch with stock and the repair was made in 5 minutes for less than $10 Valvetrain tick investigating time...... Once again, couldn't find much, but one lashpad and rocker had a burr which I took off, unsure if it really changed much. After some more driving and a worsening sound I rechecked the gasket, turns out the new gaskets don't have reinforcement around the exhaust ports, didn't last long! Put the old one back in with a helping of sealant, so far so good. Whats really odd is the tick is most noticeable in the cabin, with the bonnet up it is there, but is drowned out by general engine noise and you'd struggle to pick it up. I'm starting to lean further towards i'm just being paranoid. The only thing I am yet to do (and probably should have done first) is check clearances when hot, that might offer a different view. Went for a hoon down Central Otago way Was a bloody good drive, midweek and late afternoon meant little to no traffic through all the fun bits, until overheating at lake Pukaki on sunset, I topped up with water and limped into Wanaka, unsure to the exact cause as it drank quite a bit of water, wasn't down on power or using fuel and the oil was all good. Turns out I had blown a heater hose and thankfully the old L series is a tough beast, a quick visit to tractor services for some tube to bypass the split hose and she was all go again. However I no longer had a heater. Calling around the usual suppliers and Nissan didn't provide any replacements, the hoses are all listed NLA so to the parts shelf I went Generic Gates hose 01-0005 covers the heater feed behind the block and a Holden commodore hose Gates 02-0912 was just enough for the return line. While in the mood, next on the list was to get the 3.5 R180 diff into place. Standard R160 top, R180 bottom. Quick check up, close enough. Out with the old In with the new. Needed a pair of sump plugs which were happily provided by pick a part and their solid collection of R180 equiped Subaru wagons. This should bring the 100k rev limit down around 3200rpm, it may be at the cost of of the line go, but the car is more of a cruiser than racer now, its worth a go. During the process I cut my hand on the wheel, not sure if its from being old or due to damage, but a new set of tyres is now on the list. Bloody happy to have found it here and not on the Lindis! Have also sorted CAD files for the badges, currently waiting on some tiny carbide end mills to feed the machine, this is so I can keep the actual badges on the shelf and not be paranoid of them falling off. Numb nuts put them in the scanner opposite which is why one is upside down!

- 53 replies

-

- 20

-

-

Thats exactly it, when it's a car that I enjoy driving, why not put grip on it! How many Ks do you think you've put on them?

-

Not sure if we have a tyre tech thread? Swapped diffs out on the Datsun today and cut my hand on the tyre, glad I noticed it! Well the tyres are pretty old so no real loss. As for replacements, whats a good 205/60/13? Seems to be heaps of budget options, anything sporty other than semi-slicks? On that side, anyone run semi-slick tyres on a weekend car, do they last long? Bear in mind it's a Datsun and driving in the rain is a serious corrosion hazard!

-

Do as Alex suggested, you'll be able to file back 2mm more than accurate enough, the backlash in the distributor gearing will give more grief than careful filing.

-

Cheer mate, just tracking down all the bits so I can knock if over in a day, i'll be in touch

-

Will he then be offended when I turn up in an L series Datsun?

-

Hey guys, Anyone have a valve spring compressor poking about I could potentially borrow this weekend? Might be whipping the head off the Datsun to search the mystery click Cheers

-

One kit should coat the engine a few times over but remember it needs to be clean, fully degreased (serve a meal on it to the inlaws spec) for that kind of stuff i'd use water based degreaser for the bulk, dry fully (even bake off) then rinse off with brake cleaner before going through the steps. it really works best on machined surfaces, if there is a crack it will find it, however crack testing on a cast surface can be near impossible, hard to clean up the dye after application then the developer sucks it out of the surface porosity hiding any cracks, if the crack is in a corner of a journal between casting and machining you may need to do a few applications to convince yourself what is going on, take heaps of photos if you do multiple tests! Its been a while since I was using the stuff regularly, but from memory I left the penetrant on much longer than advised to be sure it got everywhere (searching fatigue initiation on stainless parts) we could find pretty small defects that otherwise were invisible to the eye. When cleaning off the excess penetrant, take you time and have heaps of clean rags on hand. Hopefully that makes sense? been a long day and i'm a few beers down

-

Going by the above are you off shore? one trick I read about but never have never tried is to mix kerosene and food colouring (pretty much all the dye penetrant is anyway) and substitute talc or climbing chalk for the developer, the trick will be getting it lightly and evenly dusted

-

We use rocol at work, pretty simple really, just follow the instructions, why the long wait?

-

Went for a hoon with some GCs up to Hanmer for the car show over the weekend, had a brief look around but realised I'd much rather be driving/tinkering/sharning than walking around a paddock looking at cars. There was a very tidy sss that I drooled over but came to the realisation that pristine cars aren't really my thing, presentable yes, but I don't want this to end up a shed queen i'm too scared to get dirty. On the way home as I dropped to third for an intersection the charge light came on, my first instinct was the fan belt had jumped off, so I pulled over and baled out fast expecting a run back up the road for a desperate recovery as multiple stock trucks ground it into the asphalt, sadly everything was in order, a quick shake of the main alternator wires and a check of the fusebox I shrugged my shoulders and finished the short drive home. Main suspect now is the fusebox followed by the mechanical regulator then alternator, place your bets! Have also been giving the valve train region click some thought, 500 miles since I really noticed it and no big change, odds are its not terminal/engine killing? I'm thinking a measure up of the rockers/seats might shed some light, so once the electrical gremlins are expelled, I plan to throw some feeler gauges in that general direction.

- 53 replies

-

- 11

-

-

Looks like we'll be heading up for the day

-

i'll have to check my spares and look into this, could be some fun learning Must admit I have been tempted to park next to the 1200 a few times

-

I have no idea, can the springs be swapped to alter performance?

-

I had the same thought, gasket has been replaced, I'm not quite ready to rule it out though as it is the most likely origin, now with a fresh gasket any leak should be obvious.

-

Haha, funny you say that, many years ago my father wanted a 125, turned out they were too expensive for him and he had to settle for a 1600....

-

Enough backstory, now for the car. As mentioned, I picked it up over the Christmas break from the family home up north, being that it has been used sporadically I put aside a few days to go over every nut and bolt to be sure the trip back to Christchurch would be uneventful. First up, a few small jobs... Sort the petrol smell: The original rubber joiner had given up years ago meaning the tank couldn't be filled past halfway, a crowd in the west island have reproduced them so out with old, in with the new Then came a tune of the engine, I had been nervous about this as i've never touched SU style carbs, turns out they're easy, plus my learning was made faster by having a full set spare to look at. The engine also has a mysterious click from about #2 or 3, I have adjusted the valves but it still doesn't change, oddly it comes and goes, is mildly engine temp dependant and there is good compression on all four, for sure something that will need more digging..... The eagle eyed 510 spotters will notice the brake master setup is not correct, having be swapped out for a different style for race duties. for now I will run with these until I get the original rebuilt and cleaned up. With mechanicals looking ready for a drive I moved onto the interior, how about the stolen dashboard you say? well as luck would have it, a history of writing off Datsuns racing had left my father with just enough bits to kit the car out as required, he even produced a full set of badges that I now have tucked away awaiting some modern technology for reproduction. The carpet was very much in fine race spec consisting of two or three coats of red paint, in order to prevent my girlfriend from running off halfway back I needed something to muffle the road noise, once again the family parts warehouse presented a front carpet in the most delightful shade of poo brown, matched with carefully positioned black mats to cover the tears a more suitable environment to conversation was produced. Yup, white interior, far better suited to summer! With everything packed and a torn bit of envelope to suppress the steering wheel vibration we headed south, we both held our breath over the Cook strait as the Datsun met salt air and stumbled on start up leaving the ferry, incidentally some muppet had forgotten to fully set the distributor after resetting the timing and had come loose, sorting that we drove on to Marahau for a bbq with Alex and Hannah. On stern advice we reluctantly drove over the Takaka hill, well actually I have been fizzing to do this for a long time and boy was it fun, even with 50km speed restrictions and road works its gotta be one of the best drives in the country polished off with an epic view. And that dumps us back home nice and safe. So plans from here? I was planning on a full restoration beginning this winter, the paintwork is pretty rough from being done for the track but i'm just enjoying driving it too much to take it off the road for any considerable time, there are a few things to start with: The engine tick, it may just be me but I want to dig further just in case I have a side draft manifold and throttle bodies, efi was also on the plans, but SU's just drive so nice and the fuel economy is pretty reasonable. Replace a broken shaft spring on the rear carb - this is causing the idle to not fully drop occasionally, no biggie, but sometimes irritating. Complete the CAD models of the badges and get some replicas made, this way I don't have to cry if they fall off/get broken. Get around to picking up a 5 speed or fit the 3.5 diff in the shed, 3500rpm cruise is a tad loud for my increasing age! Repair the split dash, irritates me a bunch looking at it Paint up a few potential rust spots. Actually decide what colour the carpets should be and source new front and rear Polish up the chrome Clean up the wheels Source new window rubbers so the window trims can be installed. While the list is long of potential performance upgrades, I'm not keen on going too far from factory with it and any modifications that can't be reverted to factory are off limits. Long term it really does need a repaint, but the BRE colours are growing on me and the aged look is reflective of why I brought it, for driving!

- 53 replies

-

- 42

-

-

More palatable than a rotary I guess

-

Project link: Discuss my impending wave of rust below

-

This car has been a long time in the making acquiring, but being the descendant of an original Datsun foamer, it could be said it was my destiny..... The car being a 1972 Datsun 1600sss, the back story? well, take a seat..... 20 years ago the car in question was owned by a young man in Palmerston North, being an easy target it was stolen and taken on a joyride, thankfully once they had had their thrills it was abandoned to be recovered by the boys in blue, but the good luck didn't last, while in impound some scrots jumped the fence and stripped her of all the fancy sss interior, with the badges, steering wheel and dash board gone, there was not much left to identify it as the performance upgrade intended by the factory. Being the Datsun man he is, when my father got word of it being up for grabs he beelined for the impound yard for a nosey, even though the interior had been stripped, the body was in fairly good shape and for a price that we'd all love to pay now, he loaded it onto a trailer and tucked it up under a tarp in the back lawn. At this stage he had a standard 1600 set up as a track car for competing in classic classes at Manfield & car club sprints, but with a teenage family, i'm sure restoration of the sss was still a long way off. Here's a younger me in the 1600 race car in the early 2000s during a carclub motorkhana, most likely the first time I drove a 1600 too! Somewhere in the mid 2000s the race car got close and personal with the tyre wall at the end of the back straight at Manfield, coming out very much second best a donor shell was required, with the sss being in pretty good shape it was quickly fitted out with all the bits and went on to serve race duties for a number of years, thankfully my father realised that sss body shells were getting hard to find and so when a standard shell popped up cheap, he brought that to convert to a more modern safety standard and the sss was reunited with standard parts and retired to weekend road duties. As all this unfolded, I left home, traveled the world, invested heavily in Ladas, eventually to settle in the Datsun capital of NZ, Christchurch. Two years ago the stars aligned on a SAR training exercise and while stocking up on pies in Fairlie, I spotted this wee beaut Sparking a deep down affection I followed it around the corner to where it stopped and of course I started chatting with the owner, turned out its been in their family for quite some time, and the lovely lady informed me that there was a Datsun club and that they had nationals on in Ohakune, even better was that year's theme, 50 years of the 510! Looking at dates they lined up and before I knew it I was hitching a ride north with our very own Datsun barry Runamuck to meet my father and other 510 foamers from around NZ. After a weekend driving around the central plateau I was convinced I needed a 1600 in my life and a plan was struck to purchase a dereg but complete vehicle that was tucked away, sadly after discussion with panelbeaters over the required rust work for re-vin the costs looked a bit daunting for my current plans. A few months later my father slipped up and offered the road legal sss to me, I rapidly agreed before he could back down, only downside was I had no leave left and a work schedule needing much attention, this meant I had to wait until Christmas break to pick up the car! For now it's late, but I shall dig out some more pics and tell more about the car itself and the mini and major plans ahead. Discussion thread here:

- 53 replies

-

- 40

-

.jpg.f987d0351014b1d90f87d960f0793792.jpg)