-

Posts

298 -

Joined

-

Last visited

-

Days Won

1

Everything posted by vk327

-

Fittings are pretty cheap, would have to figure out sizes, can get straights 45s and 90s crimp on hose ends, would need to get it debased somewhere I haven't got the gear for that, I can vac down and regas tho Edit, grab an overall pic and draw up what ya thinking for relocating and il see what fittings would work

-

Been smashing thru the jobs, brakes and clutch all bled up, had the dash out and back in to refit the ac core with new tx valve, finished all the ac lines and pulled vacuum so that's all ready to gas up. Powered up and configured the new ecu, tested everything from the ecu and sensors all working. Flushed and pressure tested the fuel system, dump pipe off the turbo all welded and wrapped. just leaves the rocker cover to fit and exhaust to build Speaking of Rocker cover, I just picked up that and the rest of the bits from pin striping

- 40 replies

-

- 17

-

-

easiest way is prob fit weld on insert oring fittings to the receiver and make up new hoses that splice onto your existing hoses but rerouted

-

I have the tooling to crimp custom lines, can get a huge variety of different fittings and even weld on ends

-

cable feed is sized to suit the fuse feeding it(fuse is there to protect wiring not the injector/end device), the injector limits how much current can flow and the ecu trigger side only has to carry the current of a single injector. in reality 20 awg/0.5mm is fine for injectors, I normally splice all injectors to a common feed of 14awg or similar

-

beware of the mace memcal they are spotty at best for actually being tuned, definitely throw a wideband o2 at it and check fueling is safe, going off prior experience will have bugger all timing in it as well

-

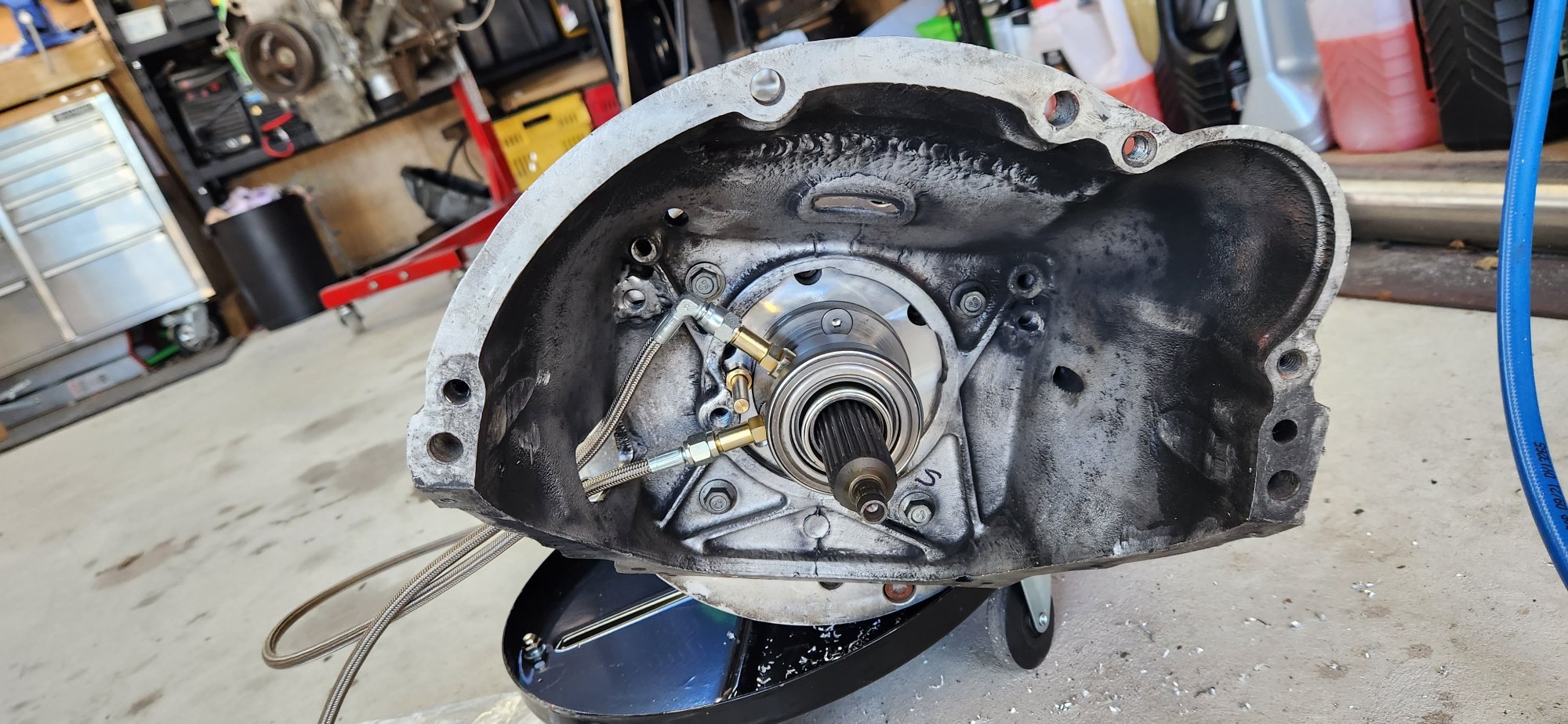

iv got a 28 spline harrop/eaton truetrac in the HQ 10bolt salilsbury works well, i snapped a factory axle a little while ago so that needs some billet axles to beef that up , aiming to be somewhere around 7-800rwhp, will be a different engine combo tho

-

yeah scott at elite motor trimmer made it up, the original was pretty manky , will be doing the rest of the interior next year, theme of 80s couch more brown vinyl & lots of brown velour

-

VL v8 lsd disc brake diff, will be getting upgraded to trutrac center soon and 31 spline axles to handle future plans for big power (might shorten it 30mm each side as well), will also be getting a macdonald bros 4 link and viking coilover setup. currently has 3.23:1 gears, thinking about dropping in the 3.45s i have, give it a bit more off the line

-

Been chipping away at the massive list of jobs still a heap of little things to finish up but... new headliner in, fitted all the seals and in with the glass, trims and interior back together, just finished off all the plumbing and wiring tonight just the AC lines left to finish once I fit the evap core. Getting close to firing it back up again as soon as I get the rocker cover & taillights back from pinstriping. then I'd better get onto assembling the pile of stainless I have here into a new exhaust. Hopefully have it all sorted an back on the dyno for tune tweaks all before drags

- 40 replies

-

- 30

-

-

-

this right here... 3D print a cover for all the e throttle and put a decoy 4 barrel holley on top

-

looks like the estima might be the go then, been looking at using an r31 disc or similar and a mazda 3 caliper with the integrated handbrake since r31 calipers are old and people want silly money for them

-

slight thread hijack on the diff topic @Roman what f series housing/axles/brakes are you running? iv got an estima diff i was gonna shorted and make brackets for the st140 corona but looking at any better options that are already 4 stud and brakes that fit behind 14" advans (have an altezza center to go in it to match the 3sge & J160)

-

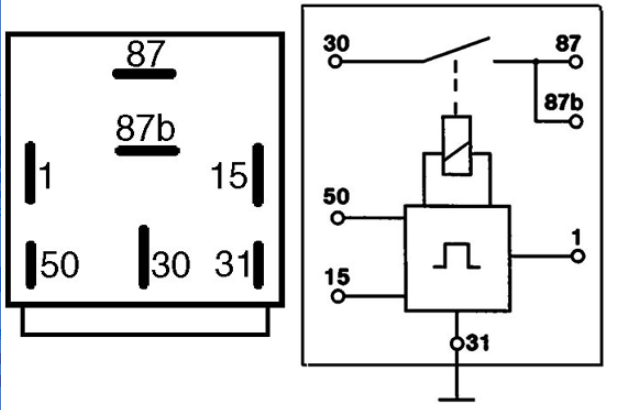

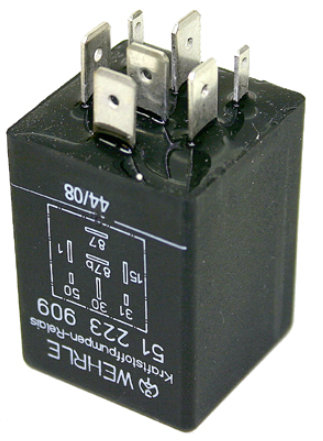

tachometric relay is the best setup for safety common in alot of 80s efi cars (bosch jetronic era) the tachometric relay is used to supply battery voltage to the entire EFI system and it does this via two different methods. Initially when the engine is cranking, supply voltage from the starter circuit is used to energise the relay. When the engine is running the relay contacts are held closed by sufficient primary ignition signal pulses delivered directly from the ignition coil negative terminal. Having the relay energised in this way also acts as a safety precaution because if the engine stops, the fuel pump and EFI system power supply would then be turned off. The tachometric relay consists of seven terminals, which are connected and marked as follows: Relay Pin 30 – Battery supply: Connect to battery positive usually via a fusible link. This circuit should have battery voltage at all times. Relay Pin 15 – Ignition supply: Connected to ignition key on circuit. This circuit should have 10-12 volts whenever the ignition is on. Relay Pin 1 – Ignition coil signal: Connected to the ignition coil negative terminal & is used to hold the relay contacts closed when engine running. Relay Pin 50 – Starter signal: Connected to the starter circuit and is used to energise the relay when cranking. Should have 12 volts when starter is engaged. Relay Pin 31 – Relay earth: Connected to ground and voltage should be less than 0.3 volts at all times; with a resistance to ground of less than 5 ohms. Relay Pin 87 – Power supply to EFI system: Connected to all EFI related components, which require a 12 volt, supply. Whilst cranking or running, battery voltage should be present. Relay Pin 87b – Power supply to fuel pump: Connected to the positive terminal of the fuel pump. With the engine cranking and running, battery voltage should be present. common part numbers Bosch: 0280230005, 0280230006 Wehrle: 51 223 909

-

More progress happening slowly,engine wiring all finished and engine bay plumbing/assembly coming along, still have to wire up under dash and add the water meth wiring, got the gearbox and drivshaft back in with the new concentric slave setup. Finally had a nice day to get it out in the sun and see how the new paint looks

- 40 replies

-

- 34

-

-

as others have said 3 channel bosch igniter 0 227 100 203, I can supply huco(hitachi) version new fairly cheaply iv used quite a few of these for wasted spark 6 cyl with an AU1 coil pack https://www.efihardware.com/products/374/igniter-triple-channel-HUCO

-

2002 ford mustang idle valve is easy to fit and works well https://www.rockauto.com/en/catalog/ford,2002,mustang,4.6l+v8,1385670,fuel+&+air,idle+air+control+(iac)+valve,6072

-

Slowly getting time to work on this between customer jobs and the 2 kids my spare time is pretty stretched, super happy with the 2 tone colours

- 40 replies

-

- 25

-

-

-

Just a couple weeks ago got it back from the painter looking super sharp in BMW pyrite brown, and running the lower trims and bumpers in vl MX grey, onto the fun task of putting a fresh painted car back together https://oldschool.co.nz/index.php?/topic/61662-vk327s-1986-vk-royale-with-boost-discussion/

- 40 replies

-

- 38

-

-

-

Decided more power was required so new sonic injection intake manifold & new turbo manifold built to fit, also upgraded to a new g4x monsoon ecu so built a concentric twist mil spec style wiring harness and decided to put ac back in so have put alternator back where it was originally it's tight around the wastegate but it just fits

- 40 replies

-

- 14

-

-

Stripped all the old dulux dulon gold off back to bare metal on advise of my painter got it in epoxy primer and enlisted help of a panel beater to make it straight

- 40 replies

-

- 11

-

-

Well been a few years, but time for an update on the old vk, been a busy (and expensive) last 6 months with stripping this thing down rust repairs changing up the motor a bit and getting it repainted on the slow task of putting it all back together now Rust repairs around the rear window & boot lip, gave it a nose job with a New old stock radiator support to replace the buckled twisted one

-

wouldnt worry about secondary injectors on a 3.8 , modern injectors work well at low pulse widths so not hard to get an engine to idle with a set of 1000cc or 1350cc injectors (at this point you'd lose resolution on the stock delco ecu fuel tables tho) , youd have to be pushing 20 plus psi of boost to even get close to needing that much fuel even with e85 and could run 60psi base pressure if needed a bit extra, more viable option would be a water meth kit which typically run a single nozzle into the intake, either the fancy AEM kit or have done a basic water meth kit before using an AEM nozzle with a solenoid and a tank with an efi pump and regulator on it and a hobbs pressure switch turns on the solenoid as boost comes on

-

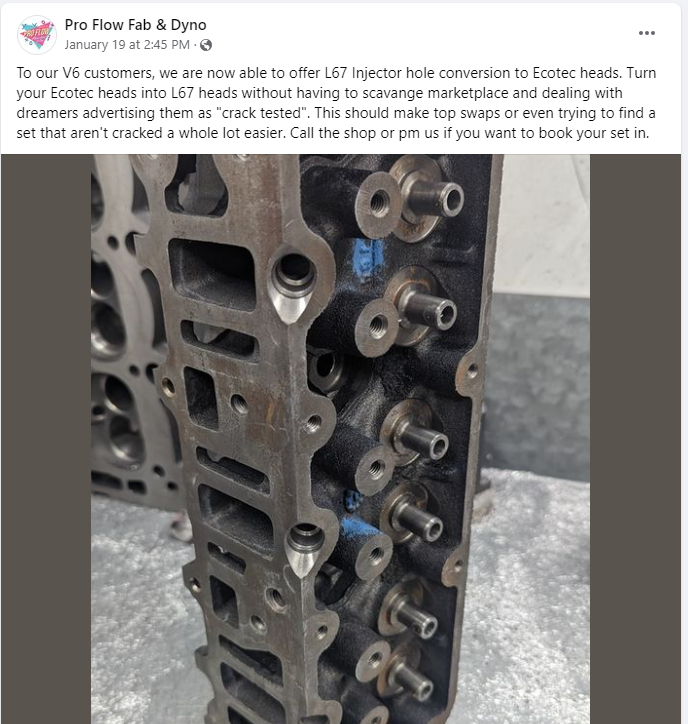

proflow fab in aussie are machining l36 heads to work as l67 heads now if you get stuck finding a decent replacement

-

3sge beams altezza engine, fairly compact 6 speed manual rwd , can run on the factory ecu standalone, can pickup a crashed altezza fairly cheap