-

Posts

298 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by vk327

-

Tyres on & bolted up for a look, reused the 235/40r18 nankang ns-20s that came on the front went with 245/40 matching nankangs for the rear, looks like I can do about 20-25mm off each side of the diff on the rear, front needs to come up about 10mm so I'm not clipping the guard all the time, shocks are a bit sad so good excuse of coilovers I reckon...

- 40 replies

-

- 15

-

-

-

-

Quick wash ready for rotokauri school car show tomorrow, better check those wheels again... tyres coming this week so will be able to measure up the diff mods soon. Gotta pull the manifold off again already blown out the exhaust gasket (shite pressed permaseal thing, got a copper one in from aussie to anneal and install, will double check flange face is flat while it's off should be good after that.

- 40 replies

-

- 14

-

-

Wheels have been making progress, painters has sorted the centers in a custom mix gunmetal with silver on the inner barrels, & RKM sorted polishing the outer lips looking sharp now, just gotta finish polishing bolts to assemble them

- 40 replies

-

- 19

-

-

1. Yes would normally resize rods with the arp bolts at least measure very carefully journal to crank and bearing clearance 2. depends on cam check with kelford 3. Depending on what power your aiming for a set of 731cc injectors from MSEL would give you plenty of head room at 3 bar base or 860 something at 4 bar pressure going boosted? , if NA the 371cc @3 bar ls3 injector would prob be adequate, MSEL have plenty of options

-

Iv setup alot of water meth kits now on various setups all boosted stuff, rotaries, 2jz, rbs and even a 6 port direct kit on a 6cyl bmw diesel. I have it in my own car along with spending alot of time on the dyno with Gav at High Performance rotaries getting these setup , pretty cool to see the benefit in almost instant air temp drop and the difference it makes to being borderline knock limited, especially when you don't wanna run e85 in a street car, as for setup on a link, in my vk im running the aem pump nozzle lines solenoid etc, except I have a hella ssr driving the pump driven by a pwm table and enable conditions on a GP output for the solenoid, I have a failsafe setup for low tank level to kill hi boost

-

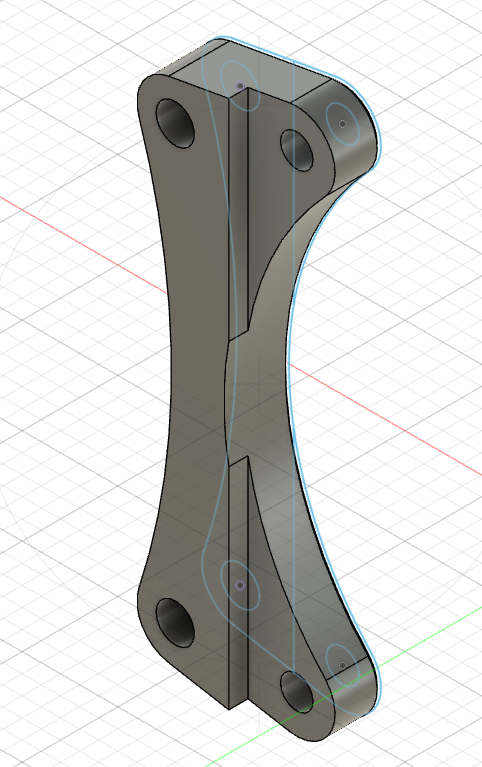

spent quite some time on this hence the several 3d print versions 1st, the rotor im using is a 320X32 vz thunder so same size & swept area as the factory evo rotor just a different hat offset height which suits commodore hub & gives good wheel clearance too , pad pretty much runs very near to the edge of the disc and almost to the inside diameter flat area so using maximum surface area possible

-

progress on the brake adaptors, a few chunks of 4140 now match my 3d printed models and fit spot on thanks to Moose design for sorting the machining, there's even hope to keep the corvette wheels it's super tight but they do clear in the 16"wheels

- 40 replies

-

- 21

-

-

further down the money pit worrmhole... got the wheels stripped of the old crusty paint by alistrip, then off to ACP and had them trued up, lips repaired & machined , now to sort out paint & final high polish for the lips. looking so good even at this point in bare metal

- 40 replies

-

- 19

-

-

Had a look at fitment on the rear looks like diff needs about a 25mm trim each side with a 245/40 tyre, plenty of room to the inside tub & suspension arms. fronts are pretty much flush to the front guard, will need to go up about 10mm in suspension height... oh damn now i need coilovers sorry not sorry wifey. Got the RS740s stripped apart that was a fun job getting loctited titanium bolts out of old alloy barrels. Being a 2 piece the barrels are blind hole threaded not nut and bolted like most 3 piece rims, great care & quite a bit of heat the barrel required to get them out without galling threads. Next up get the centers and barrels off to alistrip to be cleaned back to bare alloy for painting & polishing. I have drawn up & 3d printed an adapter to run 70mm BBS centers, that fits mint so off to CNC to be made in alloy & polished up to match the barrels, I'm off to pickup my bumper from being repaired (on the way to palmy swapmeet logging truck threw up a rock right thru the front lip, damn fibreglass bumper life), will have a look at some colours for centers while at my painters.

- 40 replies

-

- 11

-

-

Factory commodore hubs for hat rotors have bugger all from the od to edge of the stud basically just enough for the head of the stud on the back face

-

So since iv committed to the bmw style 42s iv gotta sort out narrowing the diff 25ish mm each side, now work out a suitable dark silver to paint the centers with... any suggestions to some factory paint codes that would go well with my colour scheme, one possibility is the gunmetal of @Rhyscars lexus might be a bit dark tho, thinking maybe something similar to the mx grey with a bright flake in it

-

Gav had it fired up all good on friday arvo sound healthy, I sorted out ya fan not working, (wires 87 & 30 were backwards on the relay) think he was gonna bolt it up to the dyno today, with the new LT10c you can wire in CAN from the wideband to the ecu if you want to setup fuel trim or just log it, are you gonna do anything for that god awful fuel pump whining away in the cabin?

-

Daves new school holden shambles. (Is this project oldschool yet?)

vk327 replied to Muncie's topic in Other Projects

piece of glass or suitably flat surface glue on sand paper sheets & lap the the mating faces flat, work up from 240g is to 800g, will pretty quickly see where it isint flat, also cork will blow out under boost pretty quick- 747 replies

-

- 1

-

-

Well since the vette wheels ain't gonna clear the brakes, iv committed to go the hard way to some cool wheels, ex 7 series bmw, 2 piece 18x8 18x9.5 style 42s made by bbs,fronts are spot on flush to the guards at +20p, rears are gonna need diff given the chop chop about 25mm each side, should look pretty sweet in gunmetal or dark silver centers & high polished lips something like the pic with the bbs centers & show off the fancy brakes at the same time

- 40 replies

-

- 20

-

-

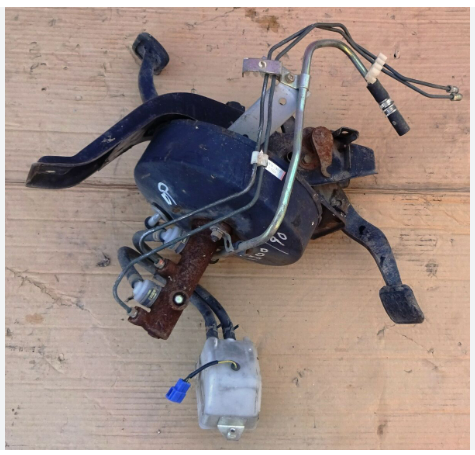

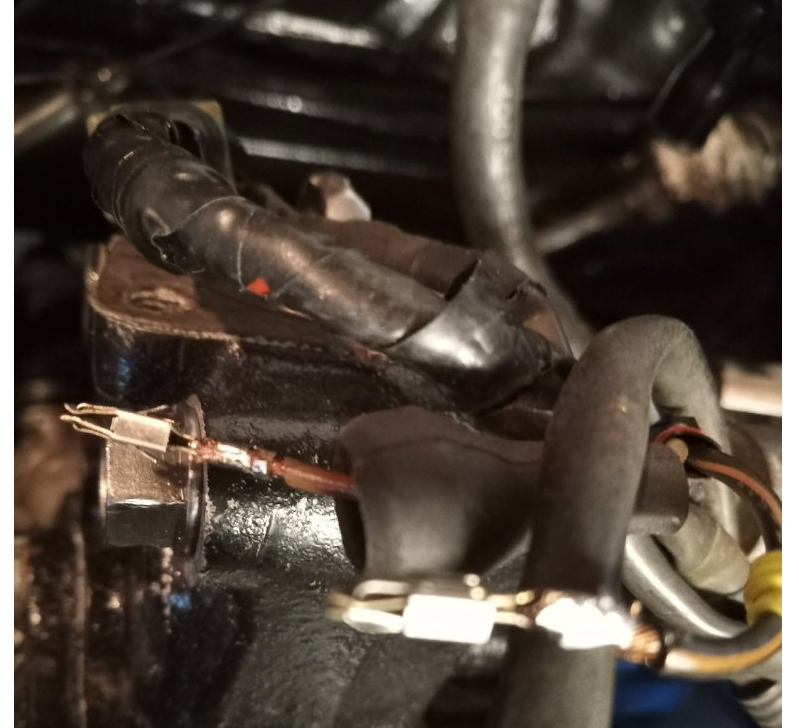

have seen an l300 setup under dash of a mk2 escort , yeah pedal throw acts to push backwards on the booster instead of forwards, another way is to engineer a bracket with a bellcrank mechanisim and have booster sideways under dash like these https://www.rrs-online.com.au/under-dash-booster-kits

-

I've seen van master/boosters used a few times where space is an issue , hiace or L300(pic), gets the whole assembly out of the engine bay, could be an option to give dual circuit boosted

-

Problem is the knockoffs all have dud offsets usually around +43- +50 to suit the gen 3/4 commodores, BBS can be worse in the low 20s for bmw which wont clear the guards, to get fitment i want/need worked on 18x8.5 +31 for the front & 18x9.5 +38 there is an option to custom order 1 piece om-1 simmons in offsets to suit,not to badly priced, would do gunmetal centers not gold style 42 look cool but pricey to buy and then need lips & barrels standard they are +21 ish offset in an 18 do makes for odd sized lips

-

So stoked with how the paint came out, my painter has done a wicked job , it was gonna be white over silver until i found the bmw brown, wanted to look like it could have been factory just a little bit flashier, fits with the 80s theme with the brown interior, looking at wheel options just incase the new brakes dont fit under the c4 wheels couple of contenders are OM-1 3 piece simmons, BBS LM or possibly bmw style 42 but would need custom lips/barrels

-

prob be best to get the microtech hooked up to a laptop and have a look at accel enrichment & injector/timing split before ya write off the microtech Gav at HPR is a bit of a wizard on them. I have had a run lately of bad microtech x4 igniters, have been deleteing them and going to ign1a coils. if ya do decide to go link let me know il sus you a good price and can sort repin of your existing loom although judging from that amount of tape usually means the loom will be hiding some gremlins, if its one thing iv learnt wiring modified rotaries, they are the top of the table for home job twist n tape & bad soldering

-

1st big outing since being put back together, 800km round trip to fielding and back via horopito for palmy swapmeet, cruising along averaging 12.4L/100km is better than when it was NA (although was boschs finest jetronic 80s fuel injection then) , love the torque curve this thing has now just rolling up on boost in 5th pulling up the big hills around taihape. such a mint day to cruise home on saturday

- 40 replies

-

- 43

-

-

-

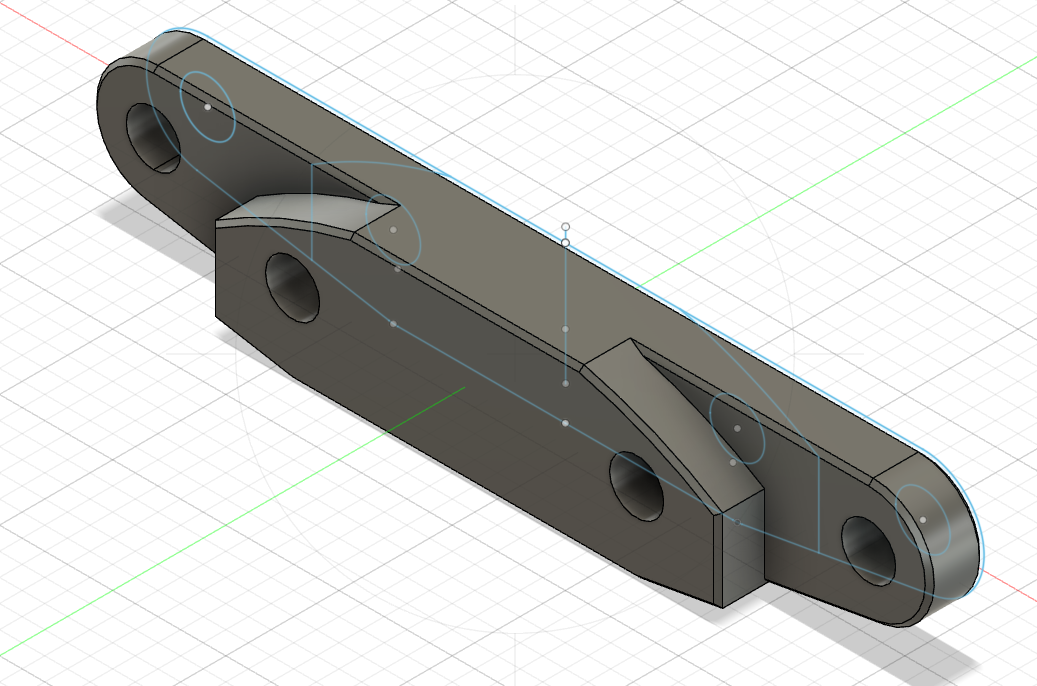

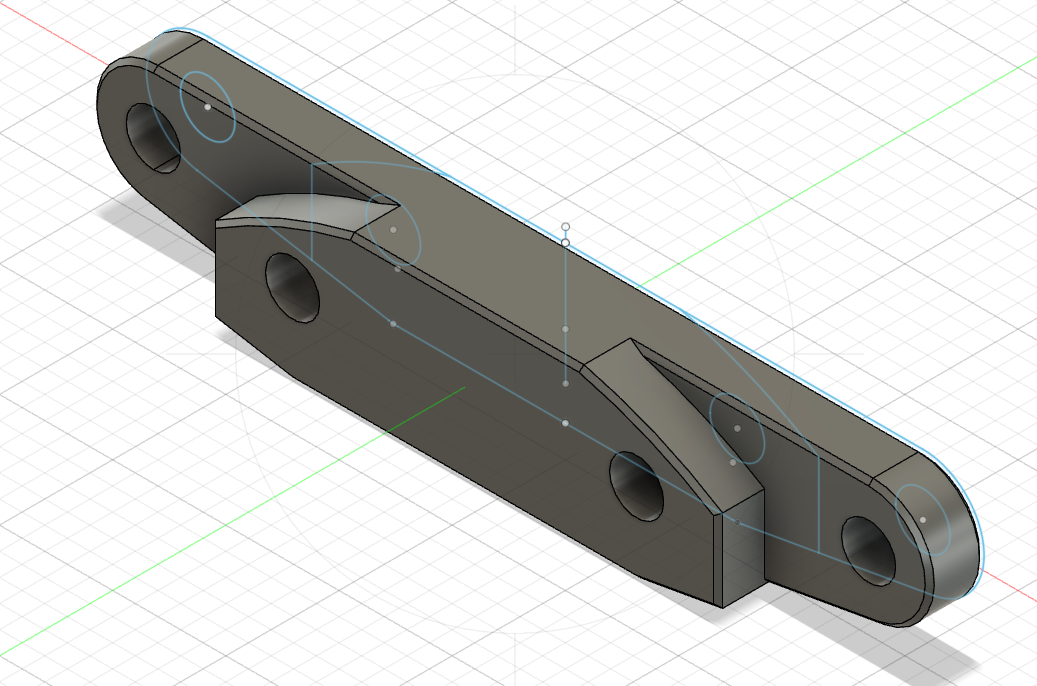

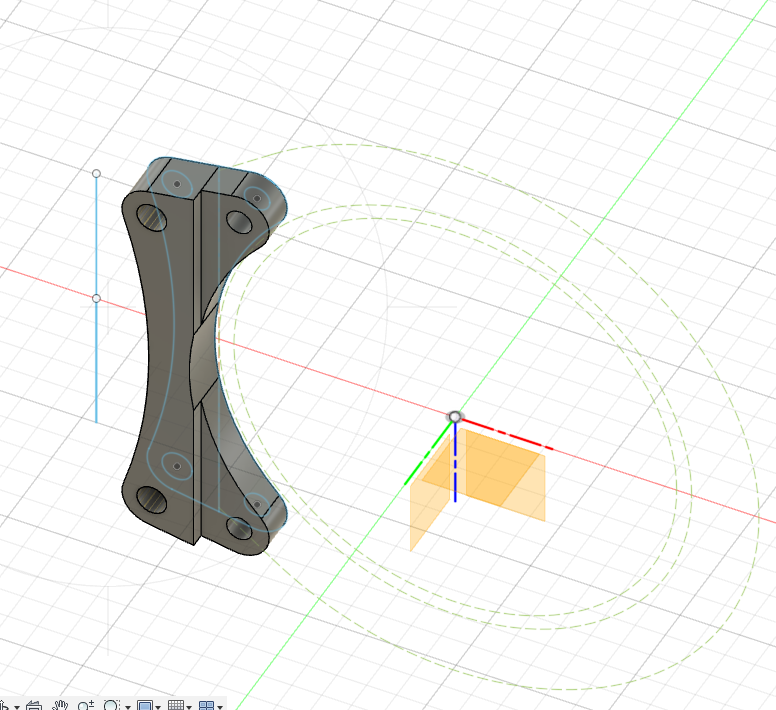

Fusion 360 is pretty easy to pickup, especially compared to autocad of old (i hadn't touched cad for nearly 10 years), has a few quirks but watch the basic how to videos on their website and you'll sus most of it, iv been able to sort it out well enough to get accurate 3d print prototypes sorted before I CNC machine them (downside for my wallet i now have a 3d printer)

-

New printer works pretty good, printed dimensions are spot on, now waiting on bolts to test fit and check what i measured is correct, probably not... but hey that's why it's 3d printed

- 40 replies

-

- 19

-

-

-

and down the rabbit hole of 3d printing i go... , brought an ender3 v3 se to have a play with got the adaptors version 1 ready to print when it arrives fronts for the evo brembos Rears to suit the z32 calipers & cutting the backing plate to fit

- 40 replies

-

- 18

-

-

Cool thanks i like the bolt on idea myself, just wasnt sure on cutting the backing plate mostly, I could weld and NDT easily, we have NDT capability at work, could get it done when I'm doing my front coilovers

-

@cletus interested on your option of this for brake setup, fitting z32 rear caliper to commodore diff, the aussies just cut and weld the plate to the backing (pretty sure not ok here) so drawn up this bracket, would be 17mm thick with a 5mm step on one side (still 12mm thick) to make mounting flush with existing backing plate for correct caliper to disc alignment. would need to cut back old mounting to red line and drill new holes would be threaded m10 same as factory caliper Will also check in with my local certifier once I have fronts modeled and 3d printed mockups to test fit as well