-

Posts

6,200 -

Joined

-

Last visited

-

Days Won

11

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Rookie

-

I hooked mine up to the original column shifter, the 722.6 only has PRND, so it fit well enough. I also have a computer sim shifter that I have wired up to the TCU for manual shifting when racing. If I was you I would try get it hooked up to the column and just get it to do PRND.

-

yea Maxx is all good they are definitely a strong force here in Scandinavia, but they are still quite locked in in terms of features, and development areas, also the price is up there. Here is the manual for Baldurs custom stratergies, have a look for yourself and see if there is something there for you. https://controls.is/manuals/customstrategy.pdf

-

I have separate engine and gearbox controllers, both are standalone units, I'm not sure what you plan is, or how the ecu for the m57s have been hacked these days? but for me it was a no brainer to go stand alone units so that there was no fuckery involved.

-

I saw your post about the dual lambda trim and such this morning, and thought you might like look at the BCS LPC8 ecu, I think there are a lot of features you would take advantage of, namely the custom strategies section where you can program whatever you would like directly in the ecu. https://controls.is/shop/ecu/lpc8gen2 https://controls.is/manuals/lpc8.pdf

-

That is the 6hp correct? If you didn't know then Baldur from BCS has written firmware so one of his ecus is a universal custom gearbox controller, I'm in the process of installing one in my truck as we speak, the results look promising.

-

@dmulally Good work dude, modern diesel swapped pickups are the best all round car ever, you are doing gods work. What gearbox are you using and what computers are you planning to run with?

-

@anglia4 Pretty sure it is a place holder for the 20b's thicker centre plate. They are rare and expensive so not having one in a mock up motor makes sense I guess.

-

As I see the current market atm, if money is no object get a Xona Rotor, don't even bother looking at a Garrett as they are similar priced and the Xona will out perform it every where. If bang for buck is key you really can go past a Holset. They are cheap new for a quality turbo and you can get them to do basically anything these days, they are short on compressor maps as Holset is, as a generalisation, a B2B company focusing on OEM. Borg is also good, but worse value for money than Holset, and don't perform as well as the big names. Also no to internal wastegates on petrol. Basically get a Xona, and if not read this and figure out which holset to buy. https://www.stavtech.co.uk/home/the-ultimate-holset-turbo-guide-probably

-

- 19 replies

-

- 16

-

-

-

Next on the want to have list was the caltracs. Originally we got it a bit wrong and couldn't use the top hole on the under diff mount because of the geometry. I drew it up in cad and got the scando version of sendcutsend to make me some new ones. Old Lameness: New hotness: They are on the truck now and all is good, just need to sort out the rest of it so I can test them.

- 19 replies

-

- 11

-

-

-

So I've been chipping away at this over winter, but pretty slow going when motivation and garage temps are at an all time low, but with sunshine comes energy, and with less than 3 months until the next Streetweek then things need to be whipped into shape. Obviously, I needed to start with the want to haves rather than the need to haves... So I built a new intake manifold. Started by chopping the flange off the stock one, some 4¨tube and bends, bit of plate and some Aliexpress trumpets: Port match the insides: Plate up the sides and drill some holes for the stiffeners: Weld inside and out and then add Aliexpress wiggins clamp, fuel lines, and sensors, then you are done:

- 19 replies

-

- 16

-

-

-

@Roman I'm pretty sure you just ran into the problem that dictates almost every dual bank itb setup uses push/pull rods. I think if it was me I would spend a little more time working on that solution as a stop gap. Hell, my BMW motorbike has two throttles that aren't mechanically linked and only one TPS and it runs mint hahaha we all know afr (within the right range) has almost nothing to do with power output. Good work on the doorts though, A++ would trade again.

-

Its pretty funny as I was going to mention it as a cheaper alternative, as I remembered that Billzilla from performance forums back in the day made a big write up about doing it that way with his beams powered Fraser, makes sense if the factory pressure pump is up to the job I suppose. Also makes sense looking at Markku's photo why the pump is driven by a multivee belt, as its only scavenge any slippage isn't as devastating. Anyway, crack on good chap!

- 418 replies

-

- 2

-

-

I really can't agree with you there. There is a reason why every form of professional motorsport relies on it, and it is because it is better in every performance metric. I can however agree that if it is put together with substandard parts, by someone who is unqualified to do the job, then there is a high likelihood of it being a failure. Loss of oil pressure for any reason is a day ender, and can be easily mitigated with an ecu safety cut, which we should all have installed as a par for the course, dry sump or not. @Rhyscar, if it was me mate, I would dig into what is actually causing the pressure drop off before ordering parts, whether it is the oil cooler, or cavitation due to the higher rpm, it would be nice to know before spending any money. Start with bypassing the oil cooler and see what happens.

- 418 replies

-

- 6

-

-

Dry sumps aren't cost prohibitive if you have a bit of nous, I built one for my Lotus 7 and all in I was under $1000, mind you that was 10-15 years ago. The trick is finding a pump for a reasonable price, for what we are doing you can basically build any design sump and tank and they work somewhere between ok and excellent, so there really isn't much to think about there. I found that waiting to the end of the Nascar season and looking at Ebay USA is pretty good, find a good brand like Dailey or Auto Verdi, Auto Verdi are good because they keep records of what the pump was used for and which team etc and you can write to them with the serial number and find out the history. For example Auto Verdi Pump To me at least spending $1000 on a dry sump more than paid for itself when compared to engine reconditioner bills for run bearings.

- 418 replies

-

- 6

-

-

-

Re Valve bind, I listened to HPA interview Mitch Pullen, and one thing I took away from it was that he was talking about how he sets up his high rpm LS engines to be a gnats cock away from spring bind at full lift, with the theory being that it is much harder for the spring to get uncontrollable harmonics in it when it basically self dampens every cycle, that and something about better heat dissipation, but that part I'm a little doubtful on. Sounds like you need custom cams with 21.9mm of lift...

-

Have you considered teflon pin buttons? Use the gsr pistons and the china rods, machine up some teflon pin buttons and keep with the cheap and cheerful plan.

-

DID1 will do a 1kd, pretty sure there is even a base map for them. https://controls.is/shop/DID1

-

I run the Baldur Control Systems DID1, it works for solenoid injectors, he has been working on Piezo injector driver for sometime now and it is apparently close to market. So depends on what engine you want to run?

-

Depends on the hill, but it mostly doesn't down shift on cruise control, it definitely doesn't slow down. You can also over take up hills if want, much to others surprise hahaha

-

- 19 replies

-

- 15

-

-

If you do end up pulling the trigger I would be interested to hear how it goes, like I said, I found them but never ended up buying or using one.

-

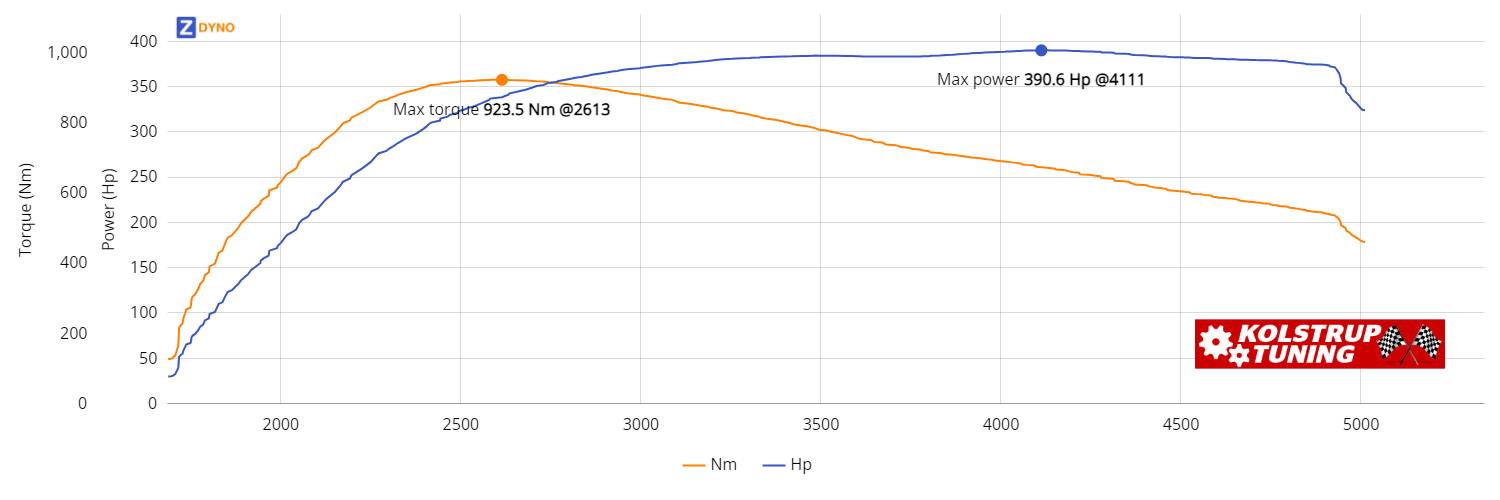

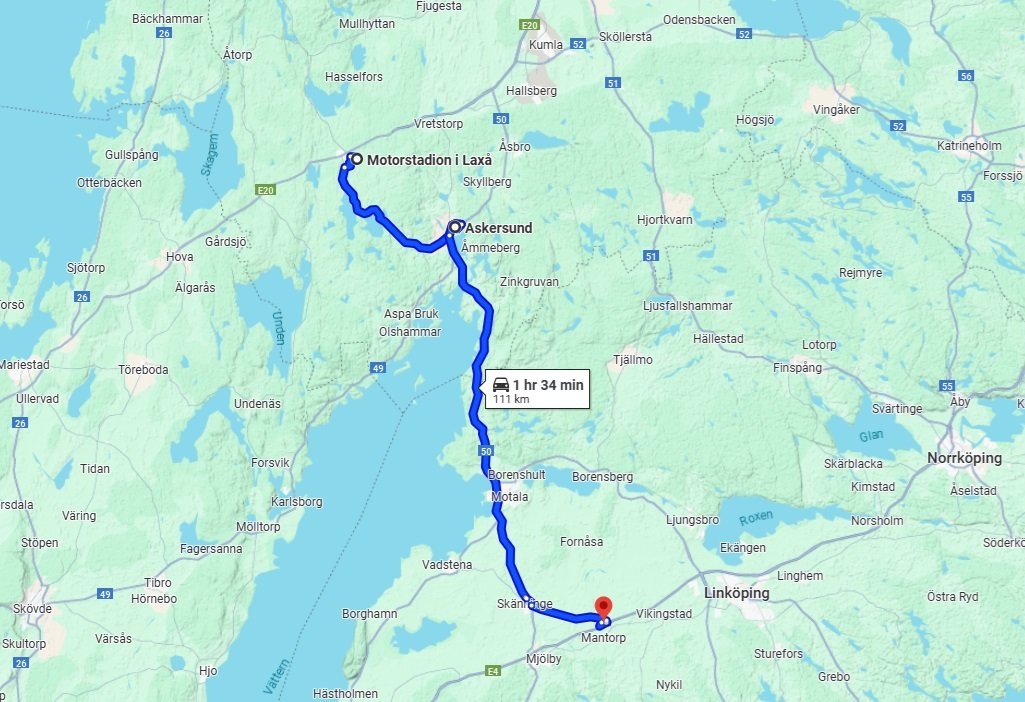

So once I got home and decompressed a bit I got to thinking about the compound setup, It didn't work quite as I would have guessed. Bypassing the small turbo just meant that the small turbos compressor became a restriction to the big turbo, not only that but then you ended up with much less bottom end than possible, The small turbo is the stock 320cdi item and as such is a vnt, this ment that I actually already had very good control over the exhaust, So I ended up plumbing all of the boost to the top of the wastegate to hold it closed. It was around this time I listened to the HPA podcast with ShaneT talking about the mazworks compound drag car and he found the same thing with that, so at least we had a direction to head in. Around this time I heard that the local tuning shop was running a dyno day so I got to fiddling, and with a bit of street driving and tuning I managed to get the boost table to the point that there was effectively no error, and a peak boost of 3.7 bar in the Race mode. So with that done I headed to the dyno day, I had a feeling at Streetweek it was around 350whp, because it ran 130 in the 1/8 and I guessed it weighed in at 4250 lb, but now it had an extra bar of boost in it and seemed noticably quicker, expectations were high. When I got there is was the usual mix of euro trash that show up to these events, with a couple nice volvos and a w124 I wouldn't mind owning, but I put it on the dyno and it was a bit of a mess, the torque is pretty brutal so it flashes the converter pretty hard, basically once you get on it it just jumps to 4000 rpm and then it pulls from there, but old mate didn't know what to expect so he stopped the run at 4400 rpm, so then I told him to go again, but now the intercooler was reasonably heat soaked and I think he got a fright be cause the next run he only gave it 80% throttle... Anyway it put down 390 hp and 924 Nm at the wheels at only 3.4 bars of boost which I thought wasn't too bad. Recently I have been fighting low rail pressure, but I think I found it yesterday, the hp fuel pump in the surge tank wasn't running because the nuts on the bulk head connectors had come loose after 2 years. I think over winter I will rebuild the manifold in mild steel to try and combat the warping and to remove the wastegate, that and fit a real intercooler because the chinese one isn't good. Oh, and I bought a nitrous system...

- 19 replies

-

- 25

-

-

-

Ill just leave this here... https://www.autoreservejaguar.com/jaguar-parts/air-and-fuel-delivery.html/s-type-xj-xf-2-7-diesel-2004-2010-throttle-body-actuator-motor.html Part number: C2S51097 I found the jaguar items long ago and they were pretty new then, I have never used one but it appears as if they have the right number of pins to do what we need it to.

-

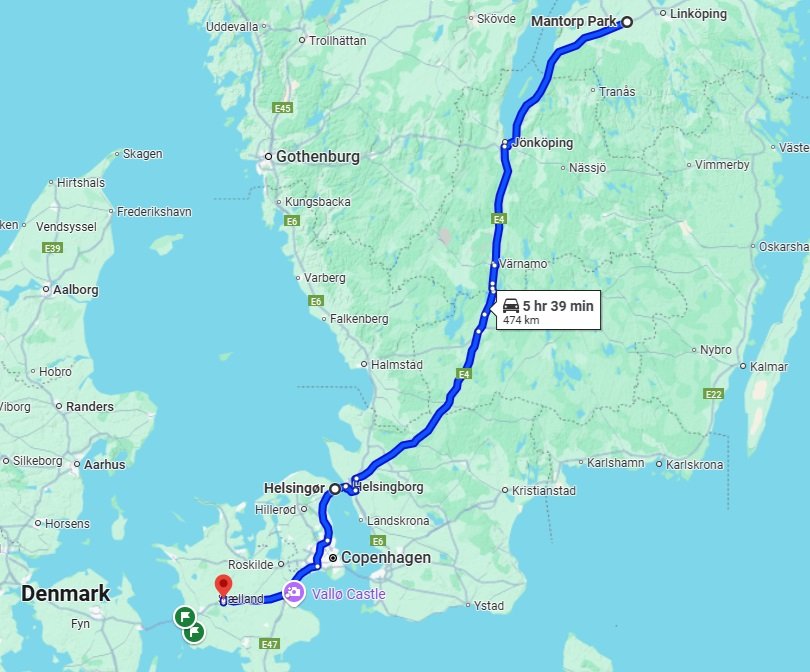

Day 7: Mantorp So we packed up and hit the road to get back to the starting point, there was a prize giving and sit down dinner. TBH it was a bit of an anticlimax after the week we had endured but it was sweet to finish up the week in one piece. In the end we came away with an award for the best transport car setup, the organisers loved that we were carting the house around with us, and we were the first truck camper setup that had competed in Street Week, so while we didn't come away with a place we did come away with a bunch of memories and a hell of a good time, as well as the new friends we made along the way. After dinner we hit the road and knocked out the last 6 hours to get home. To say work on monday was a drag is an understatement...

- 19 replies

-

- 39

-

-