-

Posts

4046 -

Joined

-

Last visited

-

Days Won

1

Everything posted by mjrstar

-

Oooh I wonder if the coil stalks are the same length on different engines, might be able to extend the spring a little if the spark is having to take a jump to get to the plug.

-

I'd check the fuel rail for internal corrosion, if the car has a stock fuel rail which isn't anodised inside and has been run on ethanol it can cause pretty nasty corrosion and a partial blockage. I have seen a single piston meltdown in an evo caused by this. The piston has been torched somehow, and the edge of the valve recess is most prone due to material thickness, as mentioned before the head was pulled. So at some stage in its life that cylinder has seen more air (or more likely less fuel) than its other 5 Brothers. What you don't know is when this was.. First up is get yourself 6 milk bottles and take a leaf out of @Roman 's fuel injector science (cool idea) to rule out fuel delivery in its current condition. Does the car run ballast resistor for injectors? As dodgy impedance across one of those would affect duty cycle.

-

I would say over 5hrs of weld time depending on preferred flow rate.

-

How much gas do you think you'll use? Bunnings argoshield / mig gas was popular here, personally I run a 5kg owner bottle co2 for mig, and an F size ezyswap argon on my TIG ..

-

Good point, hadn't considered that but would be worthwhile.

-

OEM likely to be pretty meh at the rpm's you are talking... Quick Google suggests options for supra v series and Toyota c series. But nothing obvious for t or j. Maybe h pattern dog box is the option. https://www.jackstransmissions.com/transmission-parts/v160-supra-parts/1-6-carbon-fiber-synchro-set-v160

-

-

Clutch friction plate mass. My old evo freshly built box simply would not shift at high rpm,it had the "big" evo 9 clutch and flywheel. (junk) The less work the synchro has to do (by changing speed of clutch friction plate between gears) the quicker you will be able to rip a gear.. The other thing that helps is closer ratios - same deal, synchro is going less wok as the rpm change between gears is less.. So many people overlook the ability to rip gears at high rpm in thier race cars.. It's critical in my opinion. I run dual cone carbon synchros in my Honda box, coupled with a lightweight friction plate and close gearset, and it's at the point where people ask if it's running a sequential box, it's just so fast. Someone like ATS will a carbon clutch, which is basically a carrier hub, then a sheet of carbon with a spline inside it as the friction plate. Ultimate lightweight..

-

Have you actually taken a radiator temperature? If the radiator isn't scorching hot then airflow isn't the issue. Mates old lotus 7 replica thing had hot engine, but you could touch the radiator, so was clearly a coolant flow issue not an air flow issue.

-

^^it is starting to look like sheepers prediction, or maybe a bit of piston melting near the valve recess edge. Put air down the spark plug hole, with valves on compression stroke, see if air comes out the crankcase breathers or manifold.

-

To build an ap4 spec car you'd be throwing away a lot of the gr yaris, guards, suspension, gearbox, diff , axles, brakes, interior etc.. So perhaps it does?

-

I guess that'll be why he's still in the evo at the nzrc events.

-

Oh yeah look at all those doors! My mistake. I only caught the back half of the conversation at a recce for a rally stage a couple of months ago (he was running his evo at that event) , but I think it is destined for 3 cylinder treatment down the track?

-

Maybe he needs to send it to garage 4age and get some turbo delete and a 16v head with patented peach can or noodle induction system? Sure it's a 20v but I would hoon though..

-

Unless you are a very quick learner I'd suggest that a first attempt at aluminum tig on a radiator with made from scratch tanks, variations in thickness and the slightest pinhole likely to cause a major irritation is going to be tricky to say the least! Best of luck for whichever route you choose.

-

Took it back for a re-check, better but still not great... We talked about possible lsd effect and he then ran it up in single (awd) wheel mode and it came up within 2%.. What I don't know is if he 'helped' this figure with careful pedal pressure or not.. The car pulls up nice and straight as it always has.. But whatever it's now future Matt's problem in 365 days time.

-

Honda half size radiator and someone handy with a tig is where I would start. (if you are OK with an aluminum radiator) I reckon top and bottom tank modifications to an old soldered together mini radiator would be trickier than a fresh new aluminum rad. https://www.trademe.co.nz/a/motors/car-parts-accessories/ford/radiators/listing/3660448327?gclid=CjwKCAjw_ISWBhBkEiwAdqxb9sva4Chwm4_JJmyJQRUWO6KiiF6-Z774J2LBSsC1B8pxR5gNWCEO9xoCqhwQAvD_BwE&gclsrc=aw.ds Edit - clearly beaten by tori whilst I was finding a link.

-

Why 20v? The only reason I can think of is that at the time no-one had invented a clutch and bellhousing to run the sequential gearbox..

-

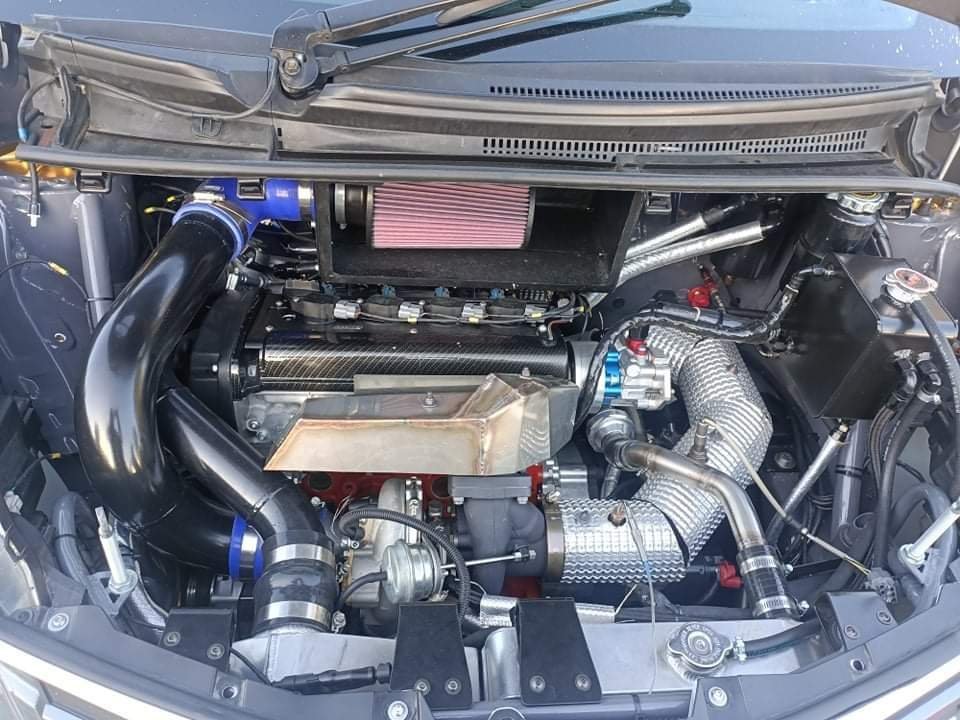

header progress is looking grand. Speaking of 20v, has anyone seen the 4age 20v turbo GR yaris rally car that Hayden Mckenzie has hidden away? I have nothing to add other than have you considered a 2zz or 20v turbo?

-

Probably last time at that testing station, mostly because they missed bulging tyre and a crack in the rim. Into the caliper strip.

-

For sure, this is a bloody good piece of advice, at this stage I need it next weekend to tow racecar either wof or no wof, so can't afford to immobilise the ute with a leaky cylinder. Very tempted to roll the dice on a strip down though... I think when I did my Honda calipers I had quite a fight getting the dust boot to play the game.

-

Gave the pistons a few cycles through the range, they didn't seem all that free for a start, then a bleed, and a side to side swap of the pads... Will go back for a re-check but if that doesn't fix it I'm going make it someone else's problem. Also emptied ~200kg of equipment out of the tray.

-

This is interesting, I haven't noticed a lever / height operated prop valve like the old hiluxs had, but that's not to say it doesn't have one..

-

Yeah had the same thing with an ae111 corolla, one rebuilt bias valve later it was happy days. It had huge performance on the rear on one side so was a bit easier to spot.