-

Posts

14,316 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

Nice! I like the colour

-

I spent a while googling trying to win your one million pound prize to no avail What company manufactured that vehicle? I've never seen one before

-

- 134 replies

-

- 42

-

-

-

Fuel hoses done, apart from a breather I borrowed a far superior brake pipe flaring tool from @RX FORD which made life a lot easier, and got all the brake pipes done. I'll get some brake fluid tomorrow and fingers crossed no leaks I wanted to keep the pipes as hidden as possible so are routed a bit different to original, the rf one goes across the firewall above the carpet on the inside of the car, to keep it from being cooked by exhaust. I'd welded some 6mm bolts on before it got painted to mount the pipe to

- 134 replies

-

- 21

-

-

DRZ problem solved, put it back together (with the head/barrel off) put it on trademe, sold, guy picked it up and didn't even haggle on price. Mint. While he was picking it up, @Ash-he came and picked up the passola as well so 2 bikes gone in one morning Now I can concentrate my 2 wheeled efforts on this one. Have ordered a complete exhaust which should be here early Jan. A system for a CB900RR is a bolt on with a couple of easy mods, headers are slightly different and gets rid of the twin mufflers and goes to a conventional single side muff which will tidy the bum up a bit

- 528 replies

-

- 18

-

-

Dumb. I'd noticed a light throttle knock in this which is one reason I bought another bike. It's always been a bit of a rattler, these things are well known for sounding like a can of rocks from new so it's a bit tricky to internet diagnose the problem. I intended to sort my license test on this and sell it I rode it for the first time in a while the other day and the rattle had not healed itself, and sounded worse, probably because the new bike is so quiet and I'm used to that one now I had a look in the oil filter and there was a bit of sparkly stuff in it... I didn't want to sell it knowing there was a potential for it to chernobyl shortly after selling it so I thought I'd have a look and fingers crossed it was something easy like just a top end rebuild. Based on the peppering of shit on the front side of the piston and very slight up and down movement in the big end of the rod I think the bearing /crank is goosed Sucks as it's only done 20,000km Not sure what I'll do yet. I don't really want to spend heaps of time and effort on it when I don't intend on keeping it

- 528 replies

-

- 11

-

-

Pretty cool that you rebuilt your own engine, good work While simple in theory compared to piston engines, I imagine there's a bunch of little tricks you need to know when assembling one So was it low oil pressure = fucked the bearing= shaft gets a bit floppy= stationary gear gets a hiding?

-

Nice. I know the stereotype you are referring to which I think unfortunately makes people look down on a pretty good car. Easy to get parts for, relatively light and compact for an American car, heaps of aftermarket mods available I'd like a 68 notchback and it would look as though it came out of a 90s car craft article on "budget 11 second streeters" or something like that.

-

FirstMate's 1964 AP5 Valiant discussion thread

cletus replied to FirstMate's topic in Project Discussion

Yes! Nice. Welcome to OS. -

you could make packers to fill up the gaps

-

Nice! Doesn't take much to make a big improvement cosmetics wise by removing things like the ugly seat I'd leave the tank bare, imo it looks cleaner without anything on it

-

Suggestion from a caveman who knows nothing about air flow dynamics What about a trumpet with a built in flat bit that directs air flow over the throttle blades in a more streamlined fashion?

-

I wondered if mounting the SUPER TORNADO STAR OF DAVID staggered up and down so they aren't sucking air next to each other might improve them?

-

@VintageSpecial have you seen this info sheet on the lvvta website? https://lvvta.org.nz/documents/infosheets/LVVTA_Info_02-2018_Modified_Production_&_Scratch-built_Low_Volume_Vehicle_Definitions.pdf

-

I wonder if that's why you had problems with the crank pulley coming loose? Having pistons and rods doing weird things with angles and speeds must make for interesting harmonics?

-

There are rules around stainless brake pipes, there is a list of approved manufacturers on the lvvta website. It's not a new thing, although there was an update recently on what sort of pipe can be used because like anything, China makes a cheaper version which is unknown quality so there is now a requirement to use quality pipe. As you say it's a prick to flare and bend properly, its easy to stuff it up and have fractures or leaks, that's why they have a list of approved people who can do it, who have supplied samples of their work to lvvta Hoses are a different story, as long as they have crimped end fittings and are good quality,attached correctly etc, they are fine

-

Can you clarify what you mean please? I'm not sure what you are referring to I'm not sure how qualifications would make any difference to any statement I have made , it's only my opinion

-

One of my bosses yarns that amuses me, was a number of years ago he went to look at a scratch built sports car for a couple of gents who were qualified engineers, who took a long time to explain how clever they were and how many qualifications they had, and how they had computer modeled the custom front suspension and how it had great geometry etc etc Boss asks "what rack are you using" They reply "ford laser" Boss "won't work. Will go the wrong way." Engineers "no its fine we computer modeled it and we are confident it is great" Boss grabs the steering shaft , turns it left, wheels go right. They had used a rear steer rack but mounted it in front of the suspension

-

I disagree. Someone who has been to university to study how to design a bridge or a dishwasher or whatever mechanical engineers do, who has no or minimal experience in the automotive industry, shouldn't be trying to figure out if a car is safe or not. much like I shouldn't be inspecting a house to say if that's safe, because I can't tell you what a nog or a dwang is Even if there was some sort of super engineer who could design bridges and dishwashers and also know heaps about cars, they would still have to pay lvvta $250 for the cert admin , plate etc, plus the super engineers time, so the cost would be the same or probably more because the super engineer has heaps of letters behind his or her name so can charge $500 an hour Unless you are meaning that the super engineer could have some sort of system where they make up their own requirements and cert tag system in competition with lvvta? I deal with stuff on an almost daily basis designed by engineers who are actually in the automotive industry and they STILL get things completely wrong

-

I don't know if there's an official set maximum number, but there is consideration given to how many there are in an area Probably because it's easier to keep on top of training and monitoring 100 certifiers nationwide instead of 1000 and to retain good certifiers If there was to be a flood of lower level certifiers who can only do the entry level stuff (which is the "bread and butter" work, ie coilovers in Japanese imports) then the more experienced certifiers would get stuck with dealing with the more difficult jobs all day= would likely lose the experienced certifiers

-

I don't get what you mean "Law maker" = LVVTA "Law enforcer"= lvv certifiers Certifiers are not employed by or paid by lvvta, they are all separate businesses. When a certification is issued, the certifier pays a fee to LVVTA. This is about $250 at the moment. The rest of the certification cost is to cover the certifiers time and business costs Do you mean there should be several different lvvtas with their own rules? Or any "engineer" should be able to certify a vehicle by following lvvta's rules?

-

A good example of this working is the last update of the wheel and tyre chapter of the CCM There was some wording around mud flaps that could have been difficult. I made a submission and encouraged others to do the same In the final version the wording was changed to something that will be much better for modifiers I have no idea how many people made submissions on that but LVVTA obviously took it on board and changed it. I think its great that they listen to the public's input The opposite of Auckland transports speed limit public consultation process, where based on what I saw, most people were making submissions saying leave the speed limits as they are Id bet they will still do what they planned on doing and tell everyone that "the public was overwhelmingly in favour of our action on speed limits"

-

Yes , if you restore the vehicle and it matches the declaration. But taking another complete registered vehicle, doing similar mods to it and swapping ID tags and plates off a car with a declaration? It would be interesting to see what the correct answer is, as you can legally replace the chassis on a ute for example, if the chassis is beyond repair. which then ends up with mismatched numbers, but that can be legitimate if NZTA is notified and it's recorded on landata as having a replacement chassis I doubt changing the body and chassis and redoing all the mods that were done prior to 92 in 2021, would be classed as "restoring" the original car

-

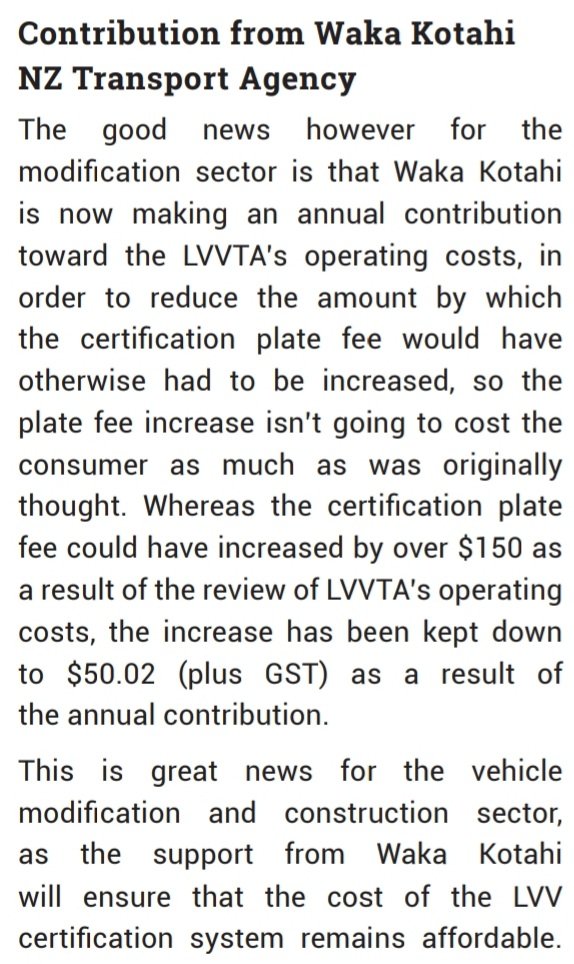

They are also receiving funding from NZTA now so I doubt they are going anywhere soon From newsletter last year