-

Posts

3,393 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by kpr

-

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

Also just looking back at your vct/vvti map. seems a bit low. yours should have the 50degree vct pulley. All the ones Ive done like more advance through the middle, pretty much max it out to 50. -

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

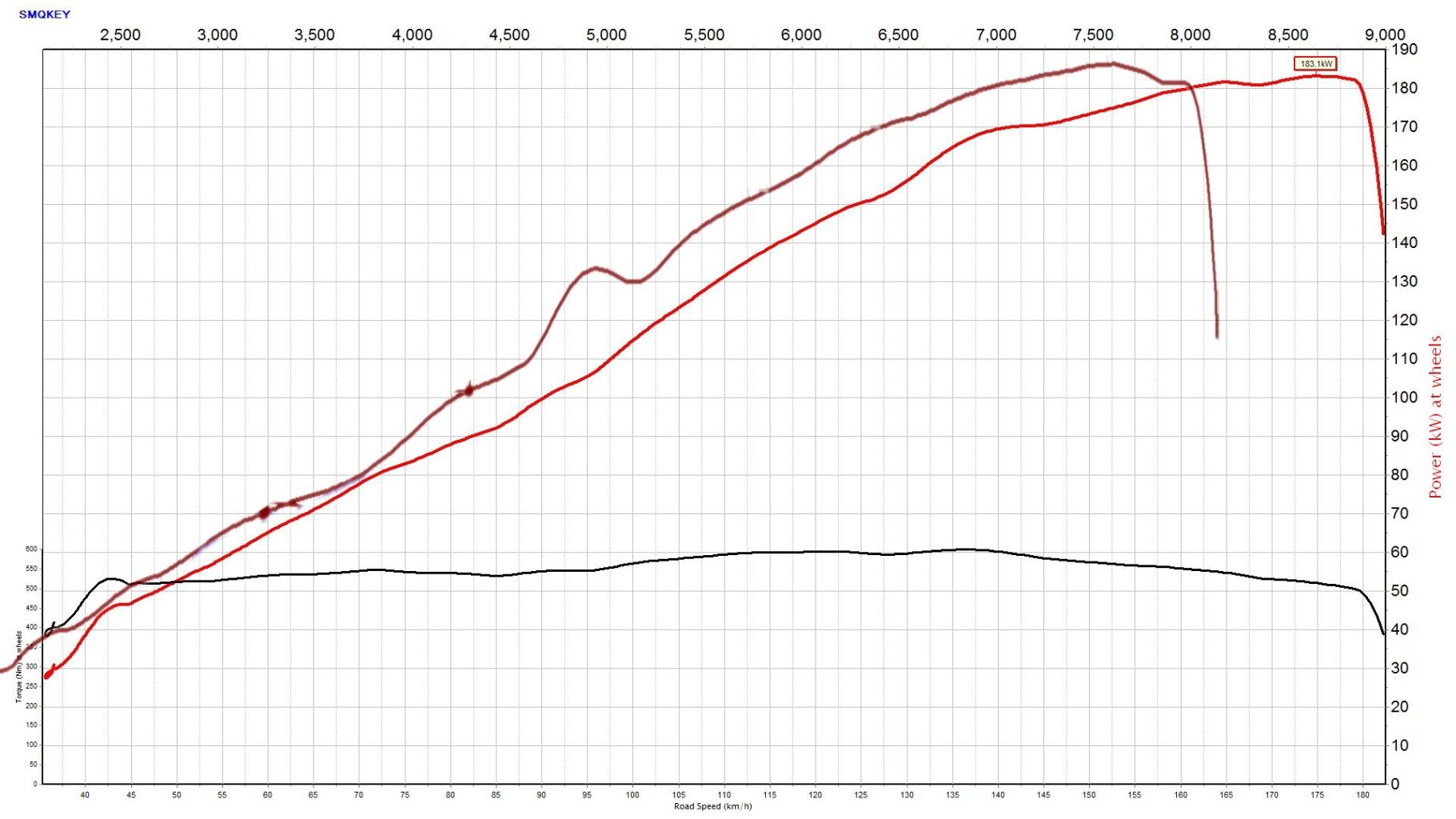

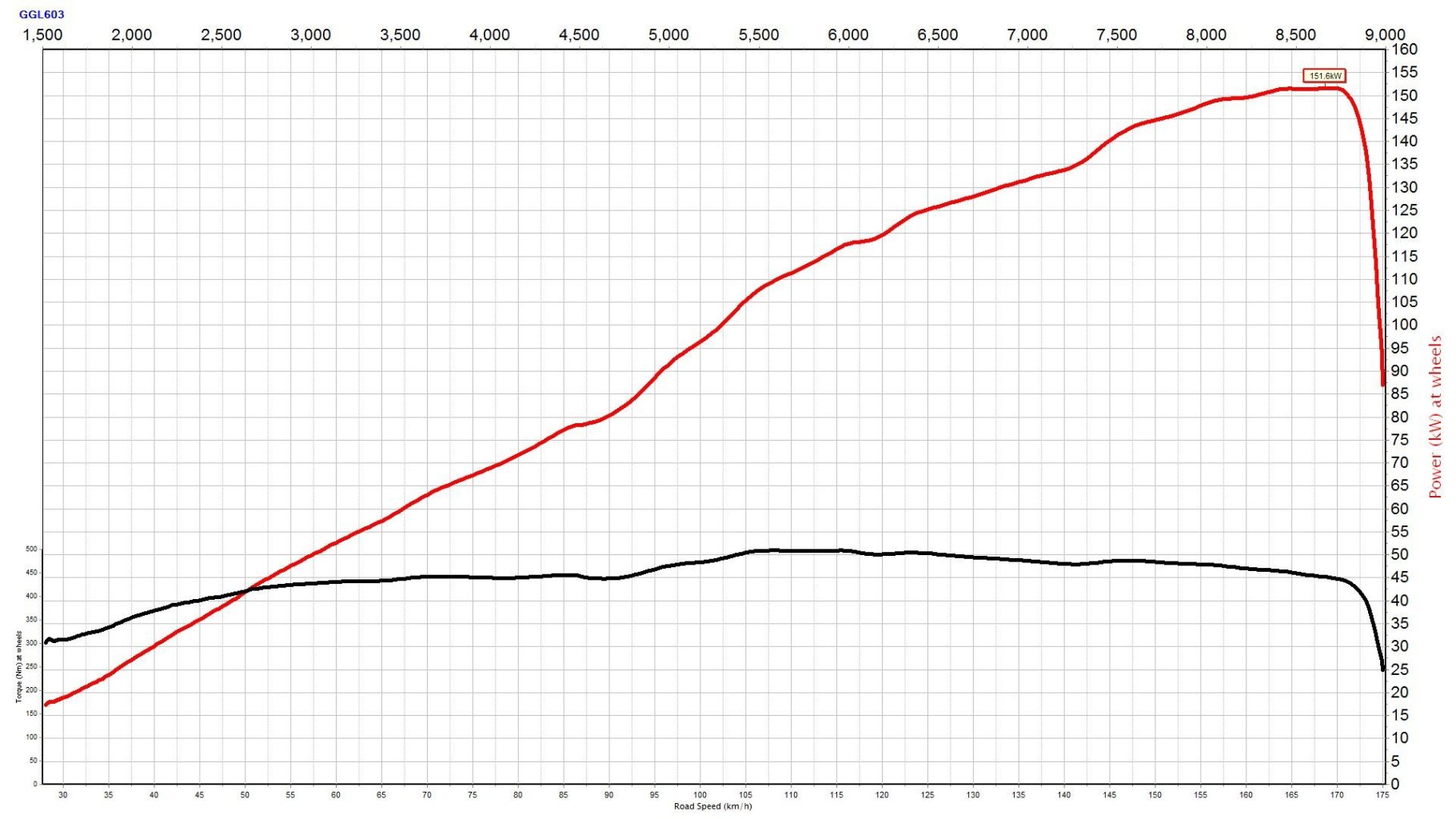

probably not, just come in for a tune. But i sold the intake off the ep3 , to another guy with a k24. k20 head and stage 3 cams, so better head and bigger cams. Done the initial tune on my dyno when it had a skunk2 ultra race? intake. which is the red below, and the ep3 k24 in brown. He lives quite far away, so remote tuned it to get the afr right when he swapped to my inlet manifold. had to add a lot of fuel through the middle and some up top. so probably pretty close to the ep3 power curve now. Don't see why the k20 wouldn't do the same thing. the heads flow good and have plenty of cam from factory, so good gains in getting the bolt ons right. this is the k20 -

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

probably fine long as the bends arent super aggressive. assuming you are still using the 47mm throttles. probably best to have them on the shorter manifold, then can taper up in diameter sooner Interestingly i just tuned a k20 on my dyno. had really short intake with big plenum and big short headers. done as expected. made 202hp and weak through the middle. -

one cap cant keep up.

-

yup, I think it runs even better than the other engine on stock cams, which had the inlet advanced a little. its even fixed my weak starter motor. since the cam is pretty retarded at the zero position, it has less dynamic compression and turns over faster haha. from memory it has from 0 to almost 5mm lift at tdc. the recommended setting for that cam is 2.7mm at tdc

-

Yeah most "turbo" cams are pretty tame. It definitely starts to hurt the spool up when get to a certain point though. If i put the matching exhaust cam in this, turbo comes on about 1000rpm later. But they are na cams. would be on the big end of turbo cams. It really just has the same effect as an na engine. the bigger you go, the more sensitive engine gets to whats attached to the exhaust side of the engine. get it right and big cams will work down to lower rpm than most people would think. get it wrong and everythings going to come out the wrong end

-

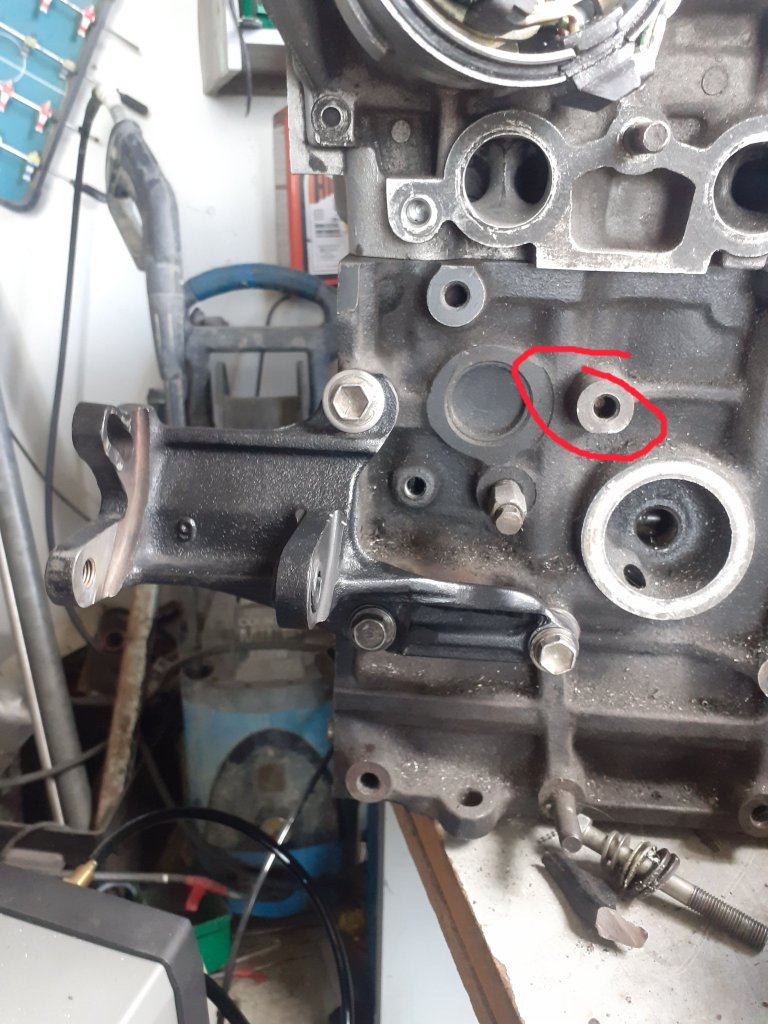

Still working through a few things. Also forgot to mention, the new engine still runs super nice with the big inlet cam and vvti. could daily drive it like a factory engine, smooth idle. doesnt stall out easy etc. would be pretty unsuspecting in a street car. Anyway since has to go in mud and stuff, been making the cambelt covers fit. which took some time, since has oversized pulleys and the 7a block is 15mm taller. made up a 3mm spacer between backing plate and the plastic covers plus a bit to fill the gap. had to nang a hole out for the vvti pulley to stick though. obviously covers arent going to seal off. but should keep most of the junk out some other stuff that had to do, that actually took pictures of. added an external oil drain to back head, between the to trigger sensors. since is bigport head. and this thing is mostly going up a hill when tapped out 7a block is missing a bolt hole which my butchered blacktop ps pump bracket bolts to. so did some illegal welding moves and made it attach to one of the lower bolt holes. also had some alignment issues making it spit the belt. which think i have solved cut 15mm out of the exhaust manifold, rather than modifying everything attached to the turbo. and yeah other stuff.

- 171 replies

-

- 28

-

-

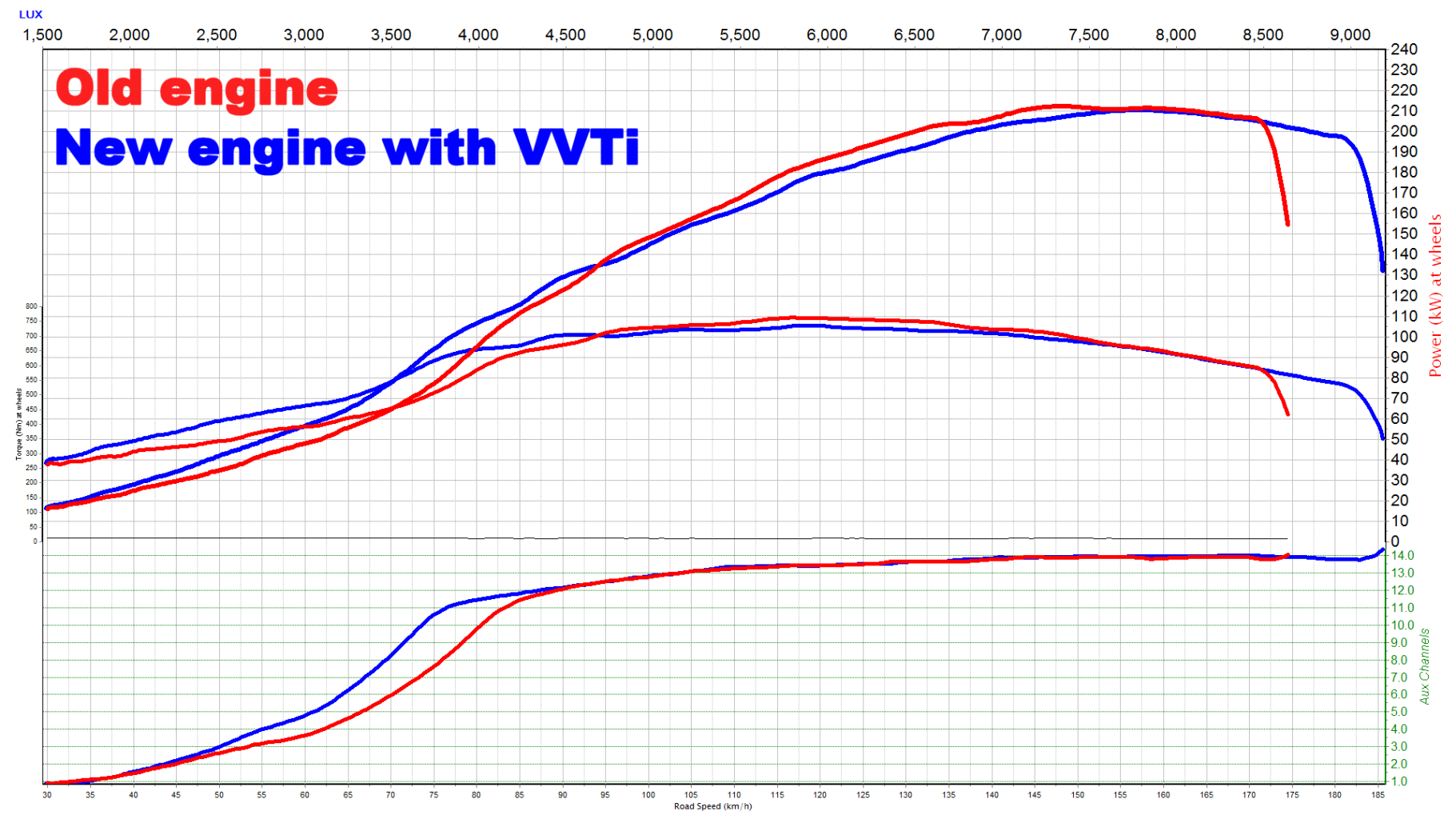

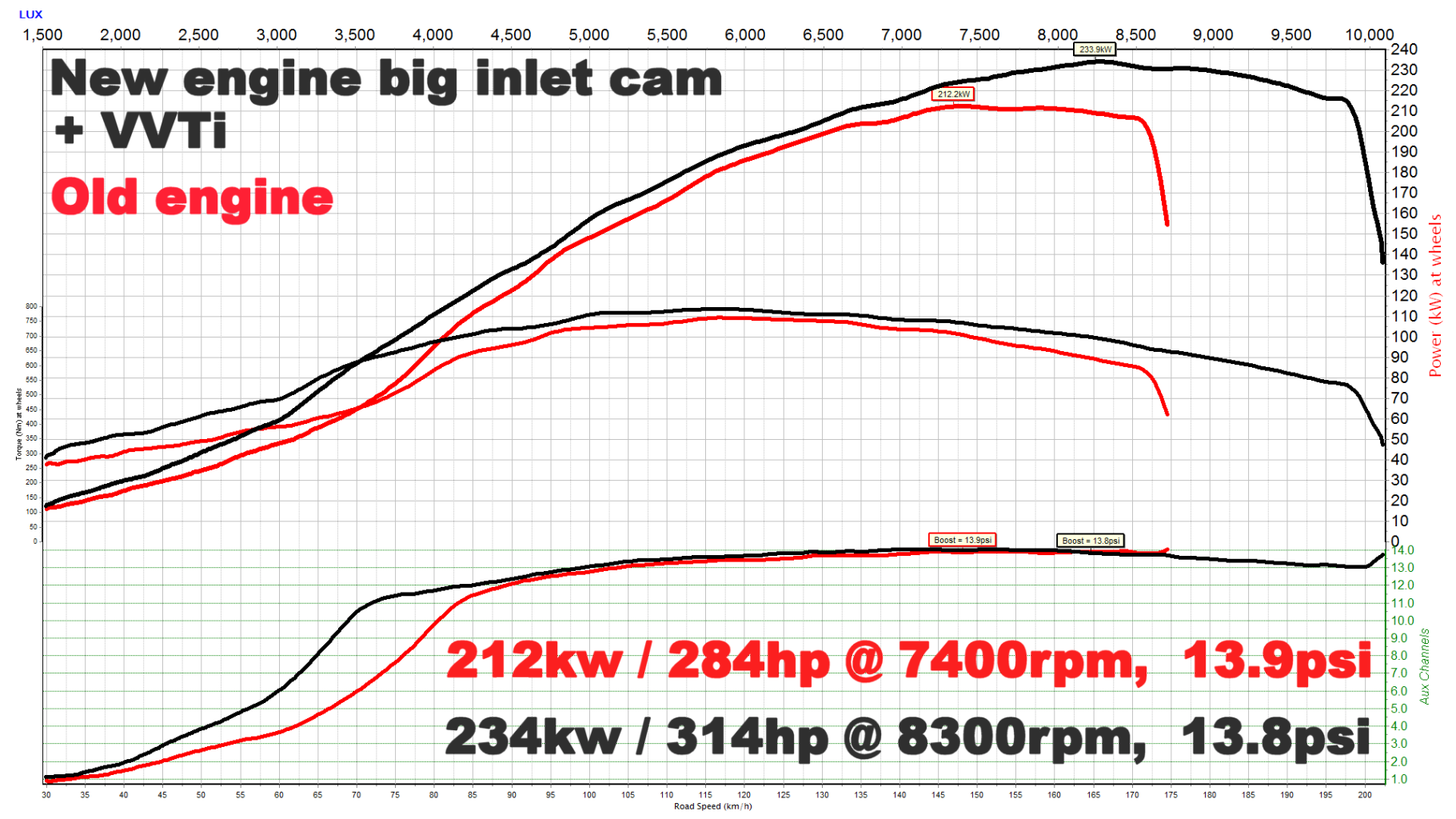

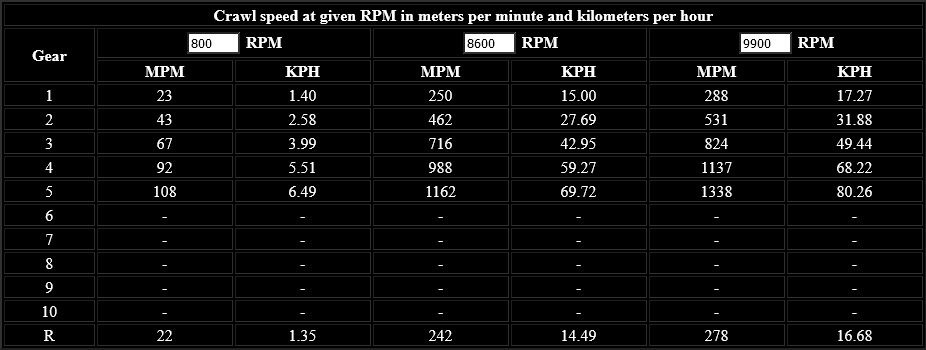

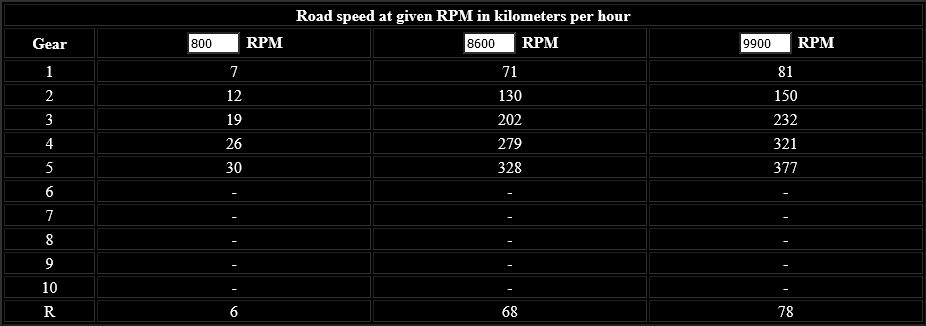

After working on this thing for 2 weeks solid, got it all together and running. Pretty much nothing was a straight bolt together, I think the only thing that went straight on was the plenum to intercooler pipes. everything else had to be modified in some way. but you get that when no 2 parts on this engine are meant to go together from factory Had a few little issues once running. but mostly plain sailing On stock cams the old engine made a little more jam (better head by the looks) but can see the vvti doing its stuff to hold the new one up. with boost coming on decent amount sooner The plan was always to swap to a bigger inlet cam and use the vvti to make it run nice for 4wding stuff. Was going to run with the stock cams for a bit, but had some oil leaks which i was down to the cams to fix. so didnt even make it off the dyno for a test run. Turns out the big inlet cam was the money as expected. is a 284 from 193b set. Pretty happy with it. It already had plenty of power for what it needed to do. but having more power and revs tagged on each end makes a big difference, especially in high range with the retarded gearing speaking for retarded gear ratio's. this is what 10k rpm, 4.88 diffs, w56, 4.7 crawler gears and 33" tyres gets you so my main mud bashing gear when you want to get places is 4th, old engine would do 8600rpm. new 9900rpm. so i can pull the same wheel speed in 4th as in 5th before, which was a bit too tall to get going in. but if you did it would zing. so 4th should be good now... High range is where it gets really dumb. If skip to the end of the video below i was in high range. chasing down cars driving down the road while in the paddock more graphs and noises in the vid. skip to the 7min mark at least.

- 171 replies

-

- 34

-

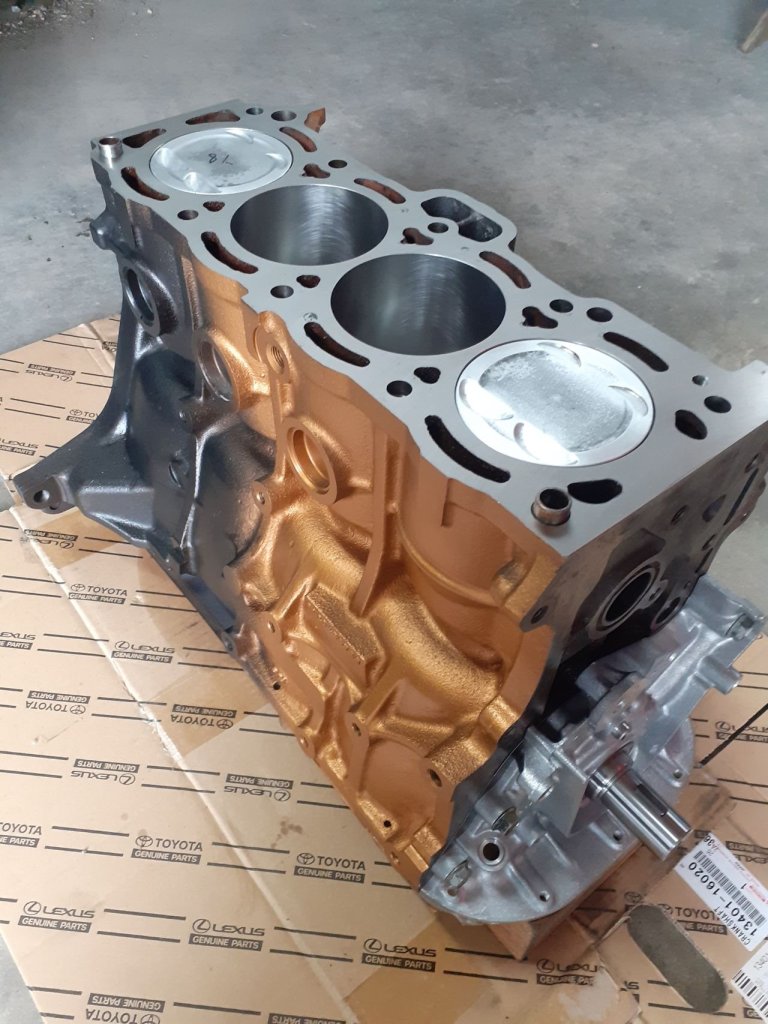

-

-

-

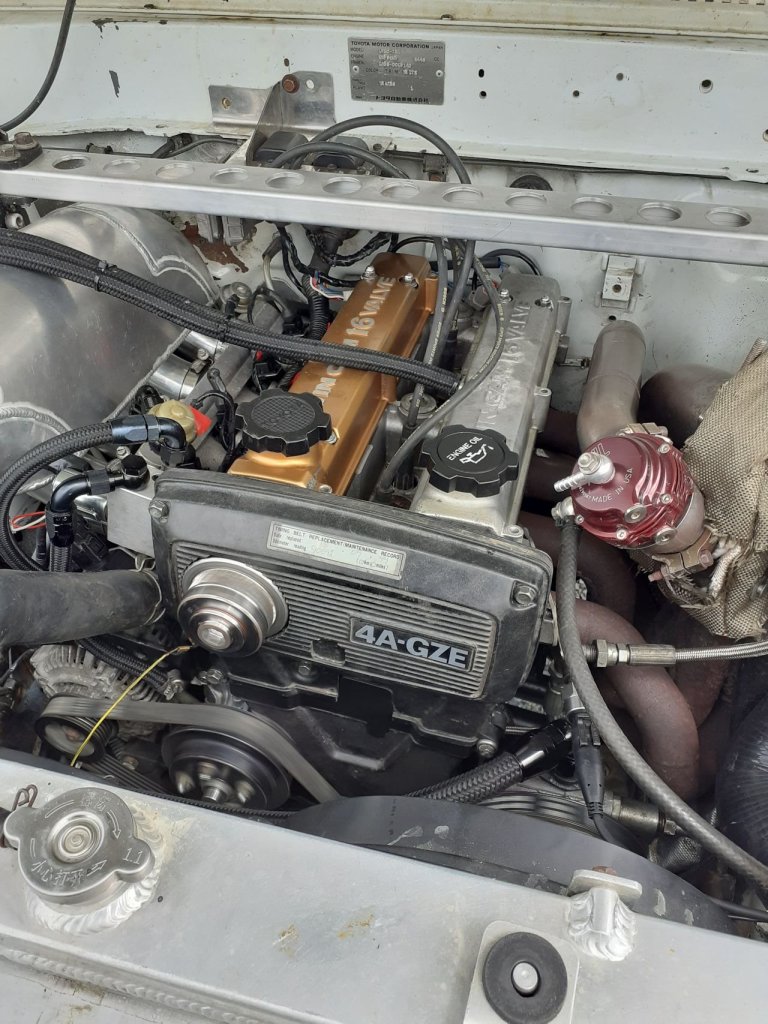

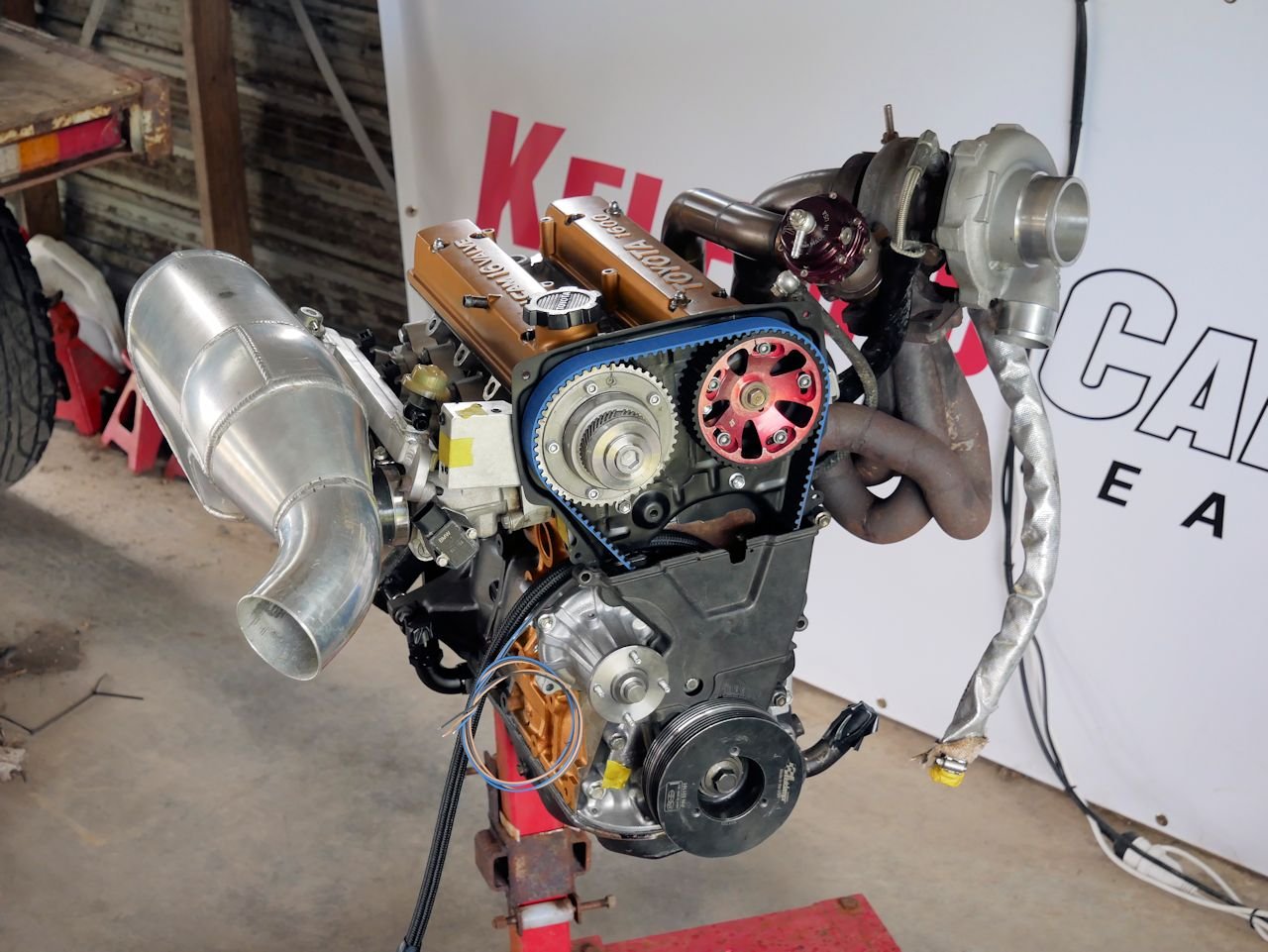

If you follow my youtube, you may have seen the teeboon 7a i tested in the starlet. It wasn't long for this life and ran a big end. Since 7age's are wet blankets. We come up with a deal, where i would acquire the 7a block and je pistons, leading to the following abortion, which combines these parts with the long rod test engine (frankenturd) So, 7a crank in the bin, bran new 4age crank, custom long rods and the je pistons First problem was 7a block had been decked .6mm or so, for the 7a with 4age spec pistons. 7a rods sit 4age pistons about .6mm down the bore. so the work around is to nang that amount off the block deck, to get zero deck height, cool. But my custom long rods are made to work with the factory height 7a block. After the block getting a fresh skim, that number was about .8mm. So skimmed .8mm off the pistons. pretty easy as they have a small dish and only the outer edge needed to come off The valve cutouts on the je pistons were on the wrong angle and pretty weak, plus they already had ate some valves. since was going to have to do the above butchery anyway, hit them with the die grinder to get clearance needed. sounds pretty rough, but i would rather buy new pistons then spend money on these old things. weight matched pistons and maxchina rods Installed with balanced crank, toda oil pump gears and a fresh gold fade Head is just sitting on the block at this point. But is getting the Turd head with the og vvti setup. Its modified bigport head, about far as can go on stock valves. from memory it made 120kw on stock cams, and 137kw on 193b cams in na form. Will just run stock cams to start with at least. Also made a new trigger setup, that mounts the sensors in the back of the head The intake cam 3 tooth is for the vvti, I'm just replicating what the jz runs here. Exhaust is single tooth sync/home for engine position. Will this horrible mess of parts make it to 10k rpm or fly to bits first? place bets now.. tl;dr hilux getting long rod, vvti, turbo

- 171 replies

-

- 25

-

-

-

Yeah, doesn't matter that much in most cases. some things and ecu's, the fuel equation is expecting a 1:1

-

If its map based tune, run vac to reg. if running itb's and tps tune (alpha n) that doesn't reference map, I would run a flat fuel pressure.

-

Back in the day.On an octane limited turbo 1500cc 95 was good for about 15psi boost. 98 20psi. Half avgas half 98 was good for 24psi. Around the 30kw mark for each jump. Pretty sure it was the full lead stuff not 100ll

-

you need argon for tig, co2 wont work

-

-

5e block with all the rod ratio i hope.

-

Tried some different angle megaphones. nothing really happened up top. but below 5500rpm some various wigglyness happened 5 degree - blue 6 degree - red 9.5 degree - green straight - pink full exhaust - black full exhaust seemed to be down a touch up top on the rest. the stand out was the 5 degree. not because it made any more power. but because it was the nicest curve in low revs. The flat megaphone i made on full exhaust sounds terrible when cruising. kinda expected it to do this, as have had the same problem before. seems to be an issue with the pipe not being able to hold its shape like a round pipe would. Also it was made to the equivalent of 7 degree round megaphone, going by inlet and outlet area. no idea if this would be the right way to do it, or if there is any way it would act the same as a round pipe. Have built a new one that should be 5 degree equivalent. Added a divider straight down the middle, to stop it flexing. unsure if will have any effect on the wizardry Yep the rest of the exhaust still has all the metals. stainless, mild and aluminum seems to have stopped making the horrible noise on a short test drive. haven't dyno'd it yet. will be happy if acts similar to the 5 degree in blue graph. The headers currently have this diverging cone setup on them pre the above stuff. probably should have be testing from the choke point back. but have a good results with this setup in the past, seems to get you most of the way there when combo'd with the right muffler. Also over crawling under the car.

- 216 replies

-

- 27

-

-

Ive done 2 with that same extrusion and injectors. both in drill press. pretty sure i done the same thing as @RXFORD suggested for the finish. no idea what drill size i used. just used a countersink tool for the entry taper. probably isnt the ideal angle but fine unless you hamfist it

-

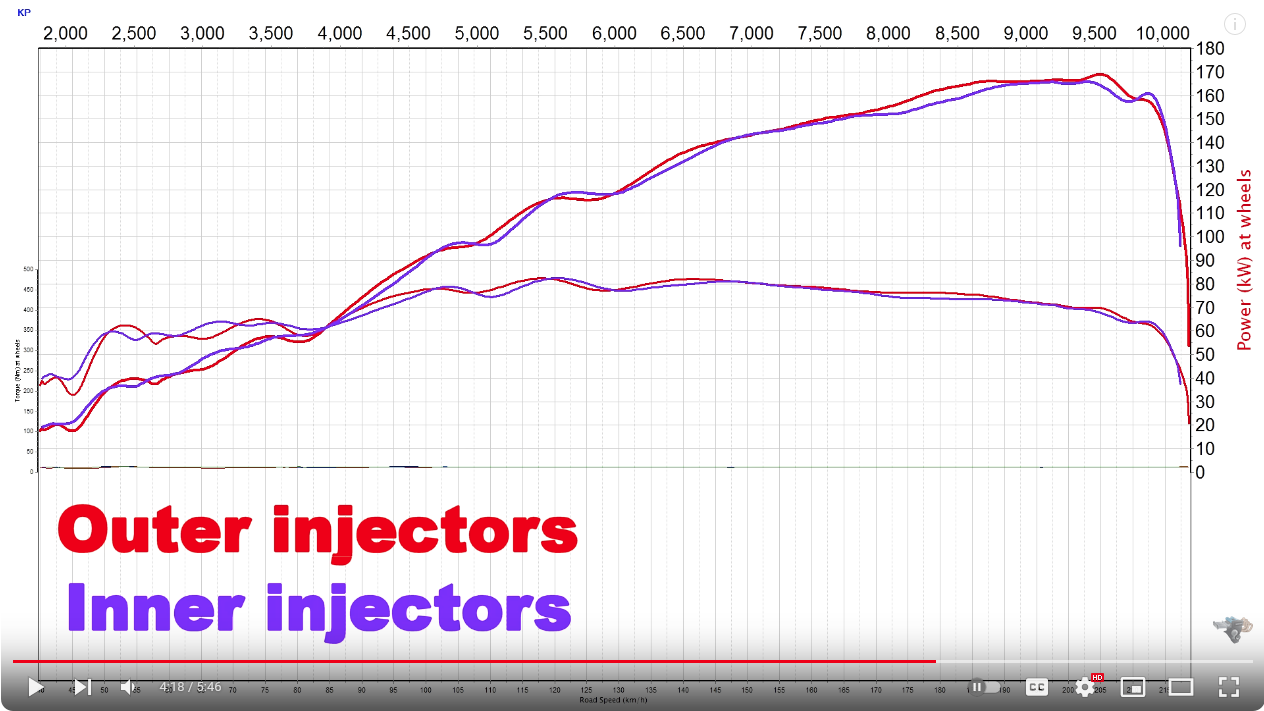

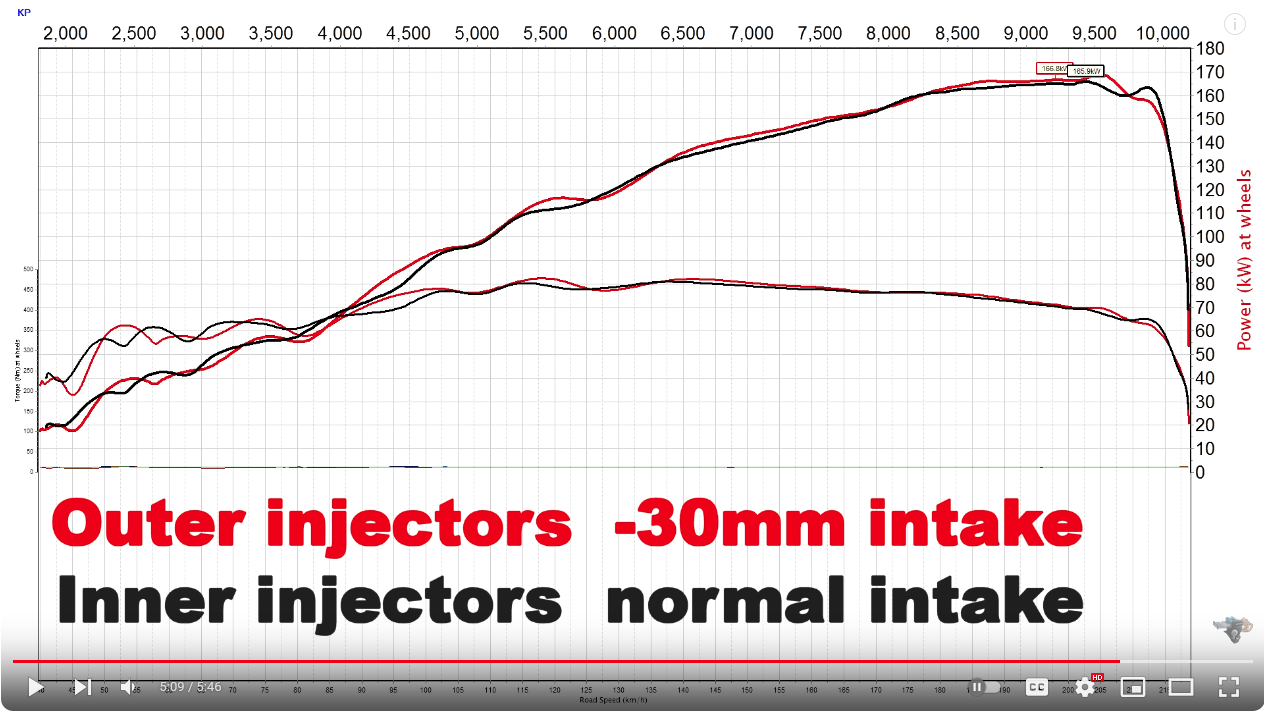

Other thing that seems to happen, is it moves the power curve around, by altering the effective intake length. can see the peaks and dips get pulled down in rpm with the injectors moved out. Im sure high end race car people know about this. But if average joe moves injectors on an intake that's slightly the wrong length. could be decent gains from this alone. So yeah, if the stars align and combo of things work together. probably looks to be big gains. If take all those factors out probably still little gains. If 1-2hp to be had. high end race car engine = yes make intake 30mm longer and the power curves start to line up

-

Thats a finger follower setup is it not. lighter than bucket setup. for all the rpms

-

The one on left worked bit better. but bad example of what would actually work best. as both kinda sucked for the application. too much duration. Can only go so much duration till it turns your engine into a turd. im running a 304/300 (262/258 at 1mm) combo. the 318/320 takes a massive hit in the bottom end for only little numbers up top Yep, kinda in the cam manufacturers hands on that one. too aggressive will just start breaking stuff.

-

would be interesting to see the whole curve on them. if the kelfords open the valve faster to the first mm. do they continue on accelerating the valve faster, getting to higher lift faster? This is an interesting pic that shows the numbers shown, only tell a small part of the story. left is a 318/11mm right is a 320/10.8mm pretty much same on paper with the advertised measurements. not so much when looking at them.

-

other than more stress on the valvetrain, more jam without any of the side effects of longer duration cam. so still runs like a nana car. but yeh not much of an upgrade if want to make decent power

-

doubt the 1nz cams were 264 @ 1mm. thats pretty massive. would be in the 300's @ 0.1mm. but yeah depends on the cam manufacturer what the "advertised" is measured at. sometime 0.1mm or 0.3mm on jap stuff. so possibly the 264's where at 0.3mm. But yeah, still can be vastly different that's why the 1mm numbers are a bit more relevant. the 4gr cams must have a slow ramp to keep the valve train happy. for them to be only 207/205 @ 1mm and 263/262 at 0.1mm. other cams in the 260's will be 220-230 at 1mm. short version get them big cams @Roman

-

A friend got me a deal on a strata advance tig. pretty happy with it so far

-

megasquirt lyfe.