-

Posts

3,393 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by kpr

-

1 tooth per combustion event is all you need for dizzy. ecu sees trigger pulse and fires coil. dizzy sorts the rest. will need to setup the teeth so you have one of them pointing at sensor when engine is at tdc do you have any external vr conditioners. or vr straight into ms?

-

can you fit a hall sensor in there to read the orginal 20 tooth wheel? rather than vr.

-

Engine is going to be rebuilt with a few new bits Previous bottom end was a silvertop bottom end. Balanced with arp rod bolts and toda 82mm pistons. rest stock. This time: Same toda pistons : awaiting new rings Brian Crower rods: just some off the self rods. mostly because they are around 100gm lighter per rod than what was in there ARP mains Toda Oil pump gears The broken stuff; Crank seen better days. Block had some unrelated pitting in the bores, looks like it had water or something sitting around rings when it wasn't in use for some time. mostly at the bottom of the stroke, so probably wasn't loosing any power from it. Head: valves look ok, awaiting 2nd opinion from engine guy So yeh no more 20v parts, had a spare 16v ze block and crank, will be base for new bottom end. Suspect that the valves have been starting to float. so will be putting these fancy beehive springs in. at the moment it has supertech singles. which are borderline for what im doing No#3 toast

- 216 replies

-

- 26

-

-

-

Had same issue using stock toyota triggers with ms back in the day. my half assed solution was to run super tight clearance between trigger wheel and vr sensor. to get voltage up when cranking

-

guessing it depends what you are shooting for? economy or power or just science? will assume science. but if economy. would it not be better to go the other way to a point, less advance and higher throttle opening to get the same airflow. which would reduce pumping loss?

-

may a well get a 3s now and run all the bearings #bmw lyfe

-

So, it didn't make anymore power with the 52mm throttles. Same power everywhere. Then hooked up the new fuel rail and injectors. was way down on power. then nunga nunga... RIP 4age. ran a bearing on number 3. shiny bits on the piston are where its been hitting the head. and valves have been having a go too. Actually surprised its lasted this long. bottom end was built 10 years ago, its been n/a most of its life. was supercharged for a bit. was turbo in my ae85 for awhile. revved to 9000rpm every time its driven. pretty sure it proven itself that all that was no drama. thinking what did the damage, was when it had the issue with pumping oil up into the head and out the breathers. resulting in low oil pressure and giving the bearings a bit of a hiding. just been a time bomb from then onwards. it broke on the dyno, so zero chance was suffering from oil surge at the time. probably wasn't ready for all this power anyway

- 216 replies

-

- 26

-

-

-

As mentioned above. trying to keep everything the same apart from throttles and adapter. But also didn't want to cut up my 20v setup. just in case this doesn't work. Found some thick wall ali pipe, that just happened to have the same 60mm od, as trumpets on the 20v setup and also 52mm id, which is the same as the bmw throttle inlets. so all i needed to do was machine a taper into the pipe from 52mm out to 53.5mm. Went and used the old boys lathe. found this hanging around his shed. gentle hint maybe...? test fit seems good, same length and top half as the 20v setup. which is plenty big, the taper was pretty aggressive before, possibly little too much. few more little things to do, then will be good to go

- 216 replies

-

- 32

-

-

-

So yep, those are bmw 52mm throttles. I wouldn't suggest running out and fitting them to your average 4age. have had to do a lot of little mods, to get them close enough together for the port spacing. right down to having to anneal the throttle shaft, as i had to re-drill it and mr bmw hardened the shit out of one part where the bearing ran. Anyway attempted to teach my self how to cad. sent it to @niswhale who cut me a template/test run out of mdf Amazingly i drew it right first go. and i was about to resort to hole saws and angle grinder.. After a lot of dicking around all the throttles fit on the flange. Have half made a fuel rail for some massive 980cc injectors i brought when was going to try outboard injection. To start with they will be just there to bung the holes. later on if all goes well will switch to them and retune. but for now changing as little as possible other than throttles, in the name of proper @Roman science. Hello tempted to run with mdf.. but this part is on its way from @Stu (cheers cnt) Since metal isn't fun anymore, its made from acetal. aka fancy plastic.

- 216 replies

-

- 30

-

-

finally a 4age with the right amount of valves

-

too many dave's, im out

-

Hmm yes you're right. I was still thinking 4age with a few more revs to spend before rods exit block. The ports must be pretty long huh.

-

if you want to make it better with what you have. swap that 2.25 out with same design, but a 3". keep pipe after muffler 2.5" and shouldn't be much if any louder But yeh if you are going to build a whole new system, with turbo a possibility. what you have in mind should be good. probably want to run a baffled muffler at rear supercharged to keep noise down. swap it out for a straight though if go turbo. turbo stuff is easy to shut up actually, just put a turbo on it to start with

-

agree on about 50mm. maybe a little smaller will work on stock cams. length im gonna say 380mm from valve to bellmouth

-

Placing money on both throttle body size and trumpet length

-

reso and baffle type mufflers will cut out different noises, so always good idea to have one of each, to try avoid having drone or rasp. depends how the 200hp is being made. something na with big cams and overlap is going to work best with least exhaust pressure possible. otherwise 2.5" will be plenty. 2.5" bit easier to make quieter, although 3" doesn't have to be loud if done right. if going with a baffled muffler , i'd step up the muffler a size or 2. as pretty much none of them will flow as much as the pipe size they are made for. no point running big tube then putting a cork in the end of it to try shut the starlet up with 3" system, i run 2 reso style straight throughs,, then an oversized baffled muffler at rear to keep flow up.

-

Will be louder. So yeah put something in its place if it only has one other muffler in the system

-

There are better ways to make it quiet than putting a straw on it

-

Map signal issue is usually at the other end of the scale. will pull good vac at low throttle opening. its up near wide open throttle that is the issue.. numbers depend on setup and revs, but lets say 70% throttle; it will hit atmospheric pressure and flat line from there. so yeh you're stuck with the same fueling numbers from 70% to 100% throttle. so got to deal with a rich spot or lean at wot noise gets the approval though

-

Have never bothered with ecu knock detection for mostly the same reasons. Would be nice to have something that works properly, rather than ignition timing on the conservative side and putting your engines life in the hands of your petrol company of choice. but in saying that, if an engine is tuned that close to the edge, maybe pump gas isn't for you. or shouldn't be lending your car to some monkey who fills it up with 91 @Roman What does the rpm signal look like on your link? and on timing light? did toyota step up there game on the beams triggers? Also wouldn't think you would have any knock issues on your engine?

-

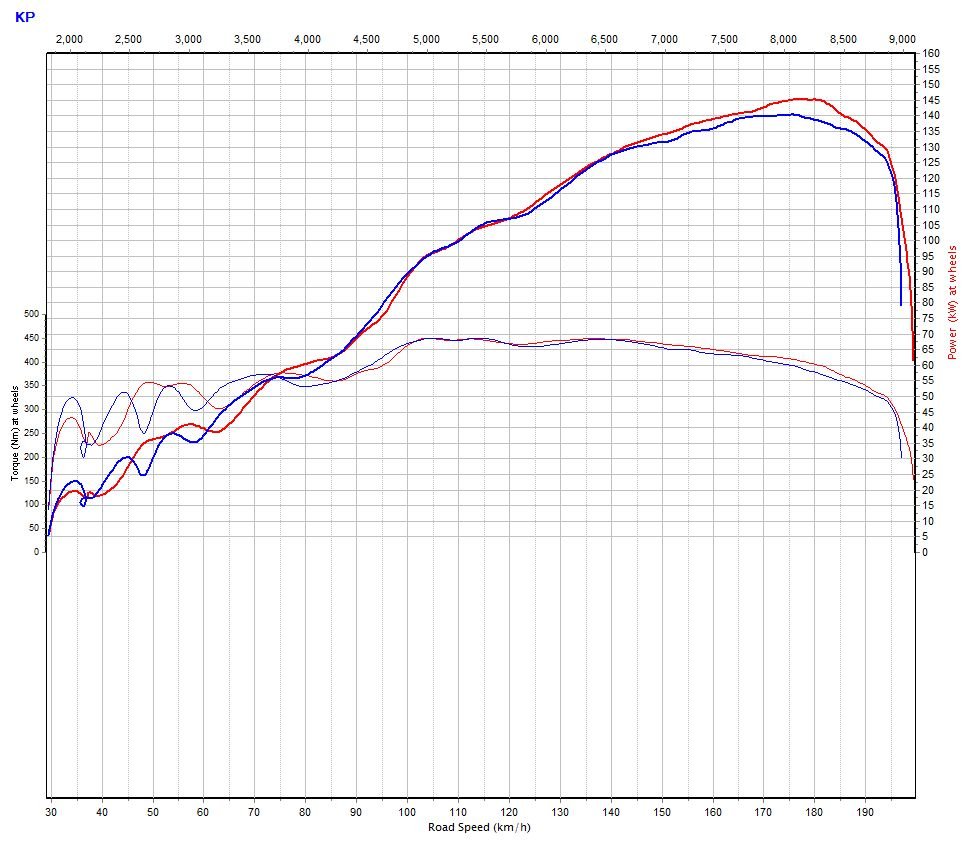

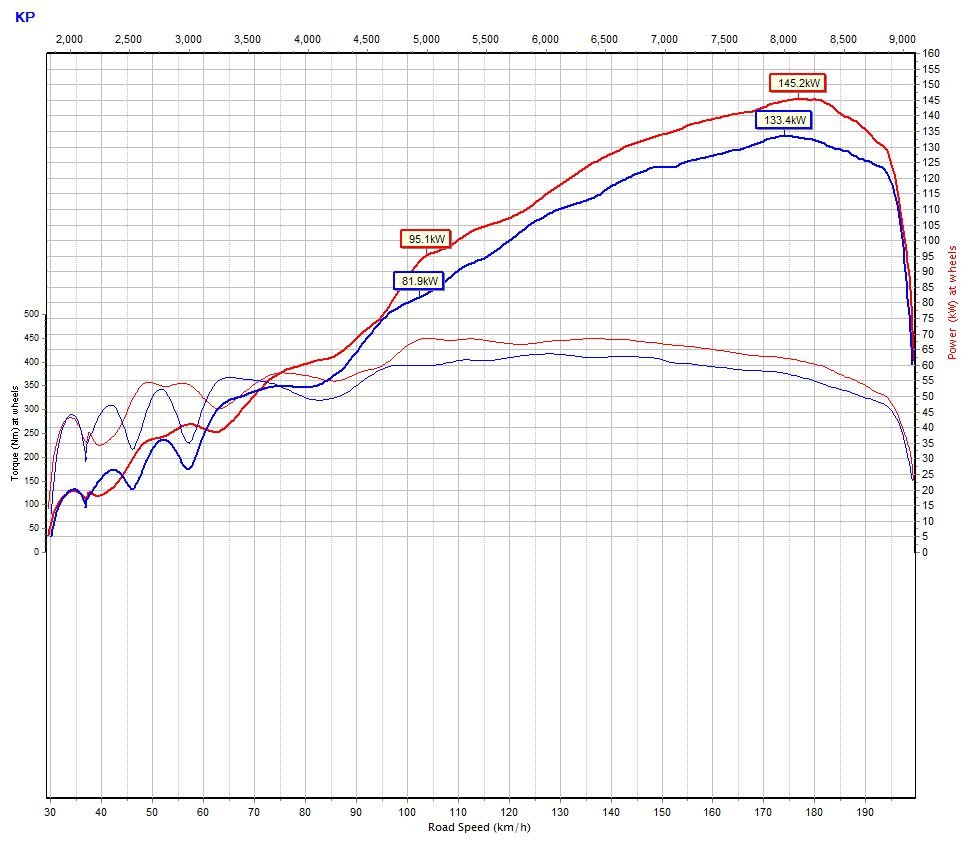

more dyno stuff.... Had to finish the tune after swapping to the small headers. Tried a few things while it was on there. First up; some time ago read something on the internet, that throttles may flow better/make more power just under 100% open rather than 100% open. Yeh nar; blue: 96% open, tried 98% as well same deal just a bit closer to red (100%) line. Maybe it needs even bigger throttles? they are 47mm Next is with the trumpets removed. the below removed all together was expecting some big losses, but not quite like this! over 10kw through the whole powerband.

- 216 replies

-

- 13

-

-

Moving pictures and loud noises version of last post. Got some decent sound quality this time

- 216 replies

-

- 19

-

-

-