-

Posts

7,218 -

Joined

-

Last visited

-

Days Won

39

Everything posted by Roman

-

One thing that has definitely changed, is vitz peoples perceptions of C56 boxes. It used to be that if I didnt go grab one out of the car from pickapart, it would stay in there and be crushed with the car. The most recent manual vitz RS to land at pickapart, was not even off the forks and someone was there to grab the box. haha. Although, not so many coming through these days, think I was right on the tail end of the bulk of NCP13s lifecycle through pickapart.

-

I parted it out, and no one wanted the shell so it got towed away by the wrecker. Done and dusted! Carina will be cool though maybe

-

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Hey I was talking to an Imp guy, and mentioned that you'd added some weight in the back with the reflectors. He said no worries, just pop an extra brick in the front and you'll be right. Hope that helps -

What's been happening with the carina in the 5 weeks since last update? Absolutely fuck all I've been busy putting the garage up, and have been away on some work trips. But then have also been off/on sick for nearly this whole time. However I've finally reached a turning point. The shed is up! and weather tight, or, close enough. Still work left to do, but good enough to biff the carina in there. So now I can at least work on it at night time and on rainy days. I've decided not to fire the motor up yet, because its fairly distracting from getting any other work done. Instead I will work on all of the peripheral issues that prevent me from driving it. So I took the front guards off, and all of the interior out so I've got a clear working space for a few things that need doing. The people who replaced the roof on our house were kind enough to leave a pair of tin snips out somewhere. The guy didnt want them back, as they'd started to rust. Some CRC later and they're pretty good again. It turns out these are pretty good at cutting firewall metal without any of the aggro that a grinder causes spraying metal and dust everywhere. So I trimmed the firewall hole a bit bigger so it's a little more all on the same plane, and back far enough that there's still an okay amount of room behind the motor. The main thing here, is that there is a rear water outlet on the motor that connects both of the heads to a coolant return pipe that runs back up the vee to the front. It needs to slide backwards a fair bit, to remove it. If you cant remove it, then you cant get the heads off. So I've been thinking about whether or not I care about this. Since so much of the motor has to come apart to remove the heads anyway (sump off, front cover off) I'd rather do that out of the car anyway. It's not much work to remove the motor, and I'll always opt for that over trying to work on something in a confined space. It's not like I'll ever be in a situation at a track day, where pulling the heads off is a solution to a problem that can be fixed same day. So I think I'll just make sure I can do all of the nuts and bolts up, reach the coolant hoses but not worry about being able to get that coolant outlet off. I got the fuel rails all connected up, and tested them with some fuel pressure. The rear fittings were hosing some fuel out, and needed to have the faces sanded flat. After that they sealed fine. Everything is now holding pressure with no leaks. Main things to do at the moment are try sort the firewall, and swap over the brake MC and booster to the smaller KE70 units. Realistically I'm at the point of pushing shit uphill to try get everything sorted by drag day. As I need a few more trips out of town for work between now and then. But I will do my best.

- 130 replies

-

- 33

-

-

-

Daves new school holden shambles. (Is this project oldschool yet?)

Roman replied to Muncie's topic in Other Projects

Shit yeah! Thats awesome to be WOF'd. Are there any enrichment settings in ECU you can play with? Might need a tad more on throttle stab- 741 replies

-

I guess an intetesting datapoint is that if you look at almost any motor that transitions from cable to ethrottle. They end up with bigger throttle(s) As you can just reshape the opening rate to get around drivability issues at low rpm. Where 30% throttle might give you 90% of airflow.

-

Daves new school holden shambles. (Is this project oldschool yet?)

Roman replied to Muncie's topic in Other Projects

More displacement will just turn your drivetrain into a noodle by loading it up with low rpm torque. Maybe a little bigger cam, bit more boost will acheive same thing easier? There's so many headaches associated with engine machining work, that can often go wrong even if you get the best people involved. I reckon there's bound to be a sweet spot for you with factoryish block and the right bolt on stuff. Do you have any guesstimates for drag day time / MPH / etc? I think I'll be somewhere in the 14s on first shakedown and with standard cams. (assuming I make it)- 741 replies

-

- 4

-

-

Matching the pedal and throttle body doesnt matter, as they both communicate to the ECU completely separately. So find a pedal that best fits rather than what matches the motor. Some good options for e-throttle pedals from commonish cars. Prius/Aqua/etc has a pedal that's easy to get. RX8 pedal is a nice unit if it fits. The prius/350z/etc sensor is like a TPS with a little lever arm on it, so you might be able to weld something up to just adapt this to your factory pedal.

-

A lot of the expensive looking aftermarket options that do the same thing as you're suggesting (Jenvey, EFI hardware etc) Look to just be a Bosch ethrottle unit with the guts put into a CNC'd housing. I think the chopped up factory throttle body is a good plan, might need to retain something to support the far end of the throttle shaft though. This is only 2 wire which would suggest it's just a regular DC motor but not sure how it would work in reality. Says 24 volt so not sure if it would work okay on a 12 system, guess so? Might work too slowly though, dunno. https://www.aliexpress.com/item/1005006106982472.html EDIT: This one might be good, good price too. https://www.aliexpress.com/item/1005007988405812.html

-

The bulldozer throttle setup wasnt suitable, I also bought a cheap cruise control cable unit. However I found that it housed a stepper motor not a DC motor, so too much of a pain to get it working. Would have been a nice solution if it was a regular DC motor.

-

E-throttle is just an H bridge controlling a DC motor... So you can literally use any DC motor that is within its torque and rpm range with the available juice (~14v and 2 amps or something like that?) A lot of the ethrottle setups have a lot of internal gearing to step down the motor speed by roughly 10:1 - 20:1 kinda range. I'd definitely not reccomend removing any of the springs from the throttle bodies though, probably wont pass wof/cert/etc, and it's also very dangerous if your motor fails and there's nothing to bring them to home position.

-

It's quite common to see a step between the head and the flange, as there's no downside to it being slightly oversized. Acts to reduce reversion a bit. But unlikely to be worth the effort of the extra welding etc steps halfway down the pipes for a manufacturer.

-

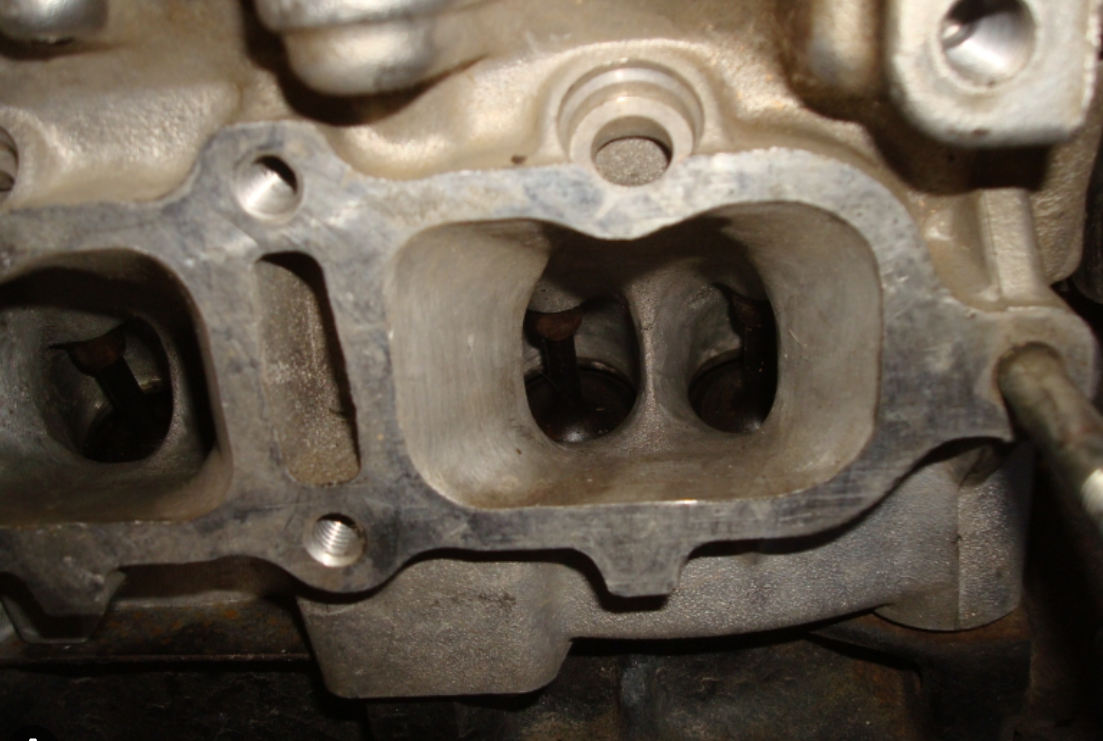

I cant find a beams motor comparison @Truenotch, you able to snap a pic of intake port for comparison? As it's a really interesting before/after of a VVT motor. Early 3SGTE port was wide to accomodate TVIS then absolutely pinched up like crazy. Disgusting. haha.

-

Ahhh yeah I agree 100% ! The things that need to be taken into consideration at an OEM level are insane. And all of the constraints applied, and then trying to make it a sellable product with a warranty that lasts 100s of thousands of kilometers. We're lucky as DIY tinkerers to have the freedom to do whatever the hell we want. I guess the point I was trying to make, is that "old info" on the internet has a loooooonnnnggggggg lifespan. And that generalizations about port size and so on, are only relevant metrics compared to other similar engines. The graphs that @BiTurbo228 posted are really interesting because they show what a huge variation there is on what some people might consider to be a hard and fast rule. For example, some testing that David Vizard might have done in the 70s or 80s, about optimizing a 2 valve carb motor. Studied port sizes, ratios, runner lengths, and so on. This information is absolutely 100% valid, in that context. So for example, for that motor having good air speed is absolutely critical. Or you're getting fuel puddling in the engine. But then on some EFI engines some dyno testing shows that runner diameter just isnt a critical factor anymore. Going too big has virtually no downsides, and going too small absolutely kills it. (or whatever) Yet some people will spend $$$$$ on an EFI motor and choke the hell out of it with tiny throttles or whatever. Because they've applied irrelevant generalizations to their particular engine. I've seen enough formulas, theories, etc absolutely fall on their face when it comes to emperical testing. That apart from following some very loose rules about how things should be (no super sharp edges on inlet runners) I think it all just comes down to testing testing testing. Some people pick a formula, decide that's the best possible thing, then test it and just accept the results good or bad. Rather than testing more iterations to validate their concepts. So thats why I'm itching to get to that point, this current part sucks and I apologize to everyone who's been reading my drivel this long without seeing any interesting results for better or worse yet. Hopefully though I'm close to the finish start line

-

Here's my take on why we've seen wildly different sizes on things like exhausts, ports, valve size being "ideal" as tech has changed and we've progressed through the timeline. Carb era In the 60s or 70s when carburetors were common. You've got a situation where the carb is mounted fairly far from the head, and suspending the fuel as it's transported to the combustion chamber is an absolutely critical aspect of the engine performance. So you need small port sizes, small runner sizes in order to keep airspeed up. Even at low rpm. Then your fuel pressure is really low. If there is only 3-4psi of fuel pressure, then having any sort of pressure wave in the intake manifold can hugely affect the fuel delivery. If at some rpm point there is a harmonic wave that adds or removes 2psi of pressure, then you've just lost or gained 50% of your fuel pressure differential. So as a general rule ports were small, valves were small, runners were small, and exhaust manifolds tried to avoid causing any massive peaks or troughs in the intake pressure. Compression ratios were low, in order to avoid issues with knock as there was no computer control over ignition. So very little cam duration, and tuned lengths somewhat avoided. Cast exhaust manifolds quite prominent. 2 valve heads common. Possibly because a 4 or 5 valve head, it was impossible to realize the benefits of the extra valve area when airspeed needed to be high all of the time. Early EFI era In say the 80s, EFI changed the game a bit by having a much higher fuel pressure and injectors mounted right by the head. So now you didnt need super tiny intake runners to suspend the fuel with high airspeed. The fuel is delivered straight down by the valves ready to go. So now runners an get bigger, ports can get bigger, valves can get bigger. You can realize the benefits of a 4 valve head, because you can have larger runners to match the higher valve area. The higher base fuel pressure also means the motor is considerably less sensitive to differential fuel pressure changes from positive or negative tuned waves from intake or exhaust. Having a tuned length exhaust manifold could be beneficial where it helps pull gas out, with comparatively little detriment when it's out of phase. As it's not disrupting the differential fuel pressure like with a carb. So it's not going to cause stand off. So now you could have a bit more cam overlap / duration without any downside. Usually had fixed valve timing, basic ECU & injection, and still a reasonably low compression ratios on NA motors. When you have a motor with a static compression ratio of say... 9:1 or 9.5:1 theres a still room in the head for residual exhaust gas to reside in the cylinder once the exhaust stroke is finished. So these motors were really sensitive to the benefits of having good extractors, and EFI made them insensitive to the downsides. So even really dunga motors like a 4AFE had a really nice 4-2-1 extractor setup. While the carb version of the same motor made in the same year, just has a cast manifold instead. EFI was the change at this point that allowed the removal of a lot of constraints on design for things like tuned exhaust. That had a root cause of fuel delivery issues. The Medium EFI era Then we move to about the 90s. Still usually fixed cam timing. But it seems like manufacturers were trying to maximize the powerband a bit more, and ECUs can deal with knock etc a little better. So we still see the decent 4-2-1 exhaust manifolds on everything, and more effort to try beef the powerband everywhere and improve economy. So there's a range of different variable intake geometry coming out on motors. Things like varaible plenum volume, variable runner designs, and so on all gave decent benefits. Compression ratios generally getting a bit higher into the 10s. Motors were making more power but also getting better fuel consumption without knock issues. Port sizes, tuned lengths etc could now be based around what the variable geometry systems, with fewer downsides than before. So everything could get a bit bigger. Power levels go up, as yet more of the design constraints of low rpm drivability were loosened. VVT Era Late 90s / early 2000s when variable cam phasers came in, it tipped the existing rule book on it's head again. The cam phasers largely made any variable inlet geometry like TVIS obsolete. As it's diminishing gains having more than one variable system in place. Cam phasers became the simplest and cheapest way to broaden a powerband, so the rest of the stuff got the boot. It also seemed to allow engines to have port sizes and valve sizes to suit their peak power requirements, with even less detriment to mid range or low rpm. A motor could now have heaps of overlap when it's beneficial, and not when it's not. Cam duration and lift became more aggressive, ports and valves could get bigger with no downsides. So looking at a beams 3SGE engine which has VVTI, for example. It has absolutely monstrous ports compared to earlier fixed timing heads. Crappy exhaust manifold Era Move to the early/mid 2000s and we're in an era where ECUs control and knock strategies etc are so effective, that compression ratios can go even higher. So ordinary to see 11:1 or more, even on economy engines. When the compression ratio gets higher, and VVT is present. The motor is less sensitive to exhaust design (citation needed, just my observation) So the motors can be made simpler and cheaper by putting a garbage manifold on, without any downside. So we're kinda back to the carb era of exhaust stuff, where we're not relying on a tuned length system anymore. Despite some absolutely disgusting exhausts, motors of this era are making better overall power/torque/economy/etc than earlier designs that were heavily reliant on a tuned 4-2-1 system. Direct Injection Era Then Direct Injection comes along, which was another technology that just tipped everything on it's head like VVT or EFI did. D.I caused a renaissance for the long abandoned variable intake geometry designs. As to get stratified charge working at low rpm, there needs to be lots of swirl in the chamber. Which you cant do with a 4 valve head and the huge valve area. Now the 80s style TVIS block off plates are back in vogue. Total intake port area can be huge, because it gets cut back in half by the TVIS type systems when needed. Based on the above I dont think there's any hard and fast rules around what works, because everythings works or does not work within the constraints of the surrounding tech level of the engine. As a motor can be highly dependent on a tuned exhaust manifold, or, not. (carb era engines, or late high comp EFI engines) Or highly dependent on airspeed, or not (carb era engines, or DI engines, but not anything else in between)

-

Things like bigport 4AGE and the early 3S engines had the huge port area, but then the TVIS system a little bit upstream that shuts off a runner to counteract it. I guess if you looked at the "pinch point" when one of the runners is shut, it would go way to the other end of the graph. The 4GR originally has this similar system as well, to make the DI stuff work at low rpm. Also I think the 2.5 and 3 litre GR engines (3GR and 4GR) share the same intake manifold, so the 3 litre engine has the same entry shape but less taper down to the bigger valves. So again, probably a shit way to design a 2.5 litre engine but just works out well for manufacturing reasons. It seems that in the era of fixed cam timing, there was a trend back towards smaller ports. But then as VVT emerged, it's back to having little downside to having a larger port again. If you look at a 2ZZ the ports are absolutely huge, because I think the cam timing magic nulifies the major downsides of a bigger port. I guess with a direct injection engine where there's no need to consider "wet flow" at all, there's potentially different constraints on port size/shape/etc. Either way, hopefully not toooooooo long until I can quit the speculation, and move on to the excuse making stage. Been too long off the road already. Hoping to have garage weather tight by this coming weekend but have also had some miserable weather lately.

-

I probably need to have an engine hold its guts in for more than 3 minutes at a time first. haha. Hopefully I'm past the worst of it and can start getting to the good part... (drawing graphs and posting them on the internet) He's got very different objectives to me, so I dont think a collaboration video would make much sense. As he's running a business and looking for the cost/benefit point of making parts and so on. So ultimately his videos are promotional material for his business which is cool. I think it's awesome he's able to do that as a full time gig. I dont really add any value to that equation. One thing that I'm keen to test though, that he's pointed out as a flaw with factory cams. Is that he says there is a bank to bank imbalance because of the way the rockers work. I am thinking that this imbalance likely completely goes away once you have one bank's home position advanced slightly ahead of the other. Rather than assuming that the zero degree "hard stop" is each cams zero point in relation to each other. However that's just my theory and he's done a lot more testing than I have, so I could be totally wrong on that one.

-

Kelford biggest are 242mm @ 1mm, 12.3mm lift Vs 225mm and 11mm lift for the Frankenstein ones. So Kelford still the best option for biggest possible cam at the moment. Also considerably cheaper. I'm using the direct injection only motor, so factory injector information isnt relevant here as I'm using BMW ones mounted in the throttles. I'm anticipating it'll have some fairly gross transient throttle response, as you always do when they're mounted high up. When I do a version 2.0 motor I will drill the underside of the ports and run 2x injectors per cylinder, one into each port. So then I can run some nicely small injectors and get a really good spray pattern from 32 nozzles total (or whatever) and then less ugly shit up on top of my motor too. That will be cool! I mean it's not a known weakness at this stage, but probably a good idea. I dont know why everyone with a 2GR is so shy about revving them. 86mm stroke engines (basically every 2 litre 4 cyl motor) have no problem doing 8500rpm all day long. Beams motor was happy doing that. Only an 83mm stroke on a 2GR and I think they have a better rod ratio too. To further throw a spanner into the works of my already stupidly compressed timeline to try get to the drags. I've been absolutely dead with the flu for about 2 weeks, only just getting better. So I'm back on the mission to get my garage finished but its blowing a gale today so cant put any more cladding up for now. Hopefully by next weekend the garage is all finished, which leaves me.... fuck all time to work on carina haha.

-

Stu's 4agte 85 EP71 Starlet and 4age 84 AE86 Levin

Roman replied to Stu's topic in Project Discussion

20v Jokes aside this car has come together awesomely, great work. Cant wait to see it / hear it! Are you going to do anything further apart from fix the exhaust when someone gives your welder back -

Stu's 4agte 85 EP71 Starlet and 4age 84 AE86 Levin

Roman replied to Stu's topic in Project Discussion

Here's a little song I've written in tribute to the 20v, set to the tune of What's my age again by Blink 182 Nightspeed drags, on a Friday night Put helmet on to get the feelin' right We started burning out, we started spinning cranks But then the car it stalled on me And that's about the time VW walked away from me Nobody likes you when you're twenty-vee It's got too many valves and it shows What the hell is 16V? My friends say build 4age again build 4age again? build 4age again? Then later on, on the drive home I called my mom from a payphone I said my silvertop it handles like on rails But I took a drag based sodomy And that's about the time that bitch hung up on me -

When I was looking for a filter idea for echo (and future purposes) I did a sort by price on the repco website, and did a click and collect on 1x of everything that cost less than $2 on clearance sale. You're welcome to borrow the magic box if it's helpful hahaha You might be able to fit two of the Mercedes ones on top of each other if you want a long/skinny. https://www.repco.co.nz/parts-service/filtration/air-filters/k-n-performance-air-filter-33-2193/p/A1269832?rgfeed=true&cid=google-shopping&utm_source=google&utm_medium=cpc&gad_source=1&gclid=Cj0KCQjwsc24BhDPARIsAFXqAB1pM7TxCwegKJMgkEs4hOjCtq_VJ0QGd-1Uymoj8q0MXa8xR7-WTRMaAiFIEALw_wcB

- 417 replies

-

- 5

-

-

-

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Yeah I remember this one guy had this real crazy idea and shit got wild -

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Worth noting that the gist of the article is that poor manufacturing tolerances were mostly to blame. You cant compare what those notoriously sloppy and imprecise Germans are up to, to the finest Scottish craftsmanship! It's only a rumour, but apparently some of the cars were actually assembled by people who were partially sober -

Daves new school holden shambles. (Is this project oldschool yet?)

Roman replied to Muncie's topic in Other Projects

The only way I'll win is by firing all my pistons at his car. Likewise, super keen to see your car again! Has had a huge amount of development since last year, keen to see how it goes. 30% more trap speed this year? haha- 741 replies

-

- 2

-