-

Posts

7,242 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Roman

-

Oh thank you! I was looking for those pictures but couldnt find them. I'm sure that from memory they were around the 250hp mark when restricted to 10:1 which is pretty sweet in itself. But they could very well be higher HP especially if higher compression or had a tickle up since leaving the race series (which was friggen ages ago)

-

Some more sharns without finishing anything. Possibly some repeats sorry. But here's a pic of the Altezza touring cars that did really well in NZ many moons ago: Notice the ITBs fitted to factory runners. Or I guess you could say, factory plenum fitted to ITBs. These had class limited 10:1 compression, no VVTI (Banned?), big cams, and ITBs welded/mounted into the factory plenum. They made around 250hp with this config. Not sure if it was just class mandated that they had to stick to the original plenum/intake, or if there were other reasons for this setup. I managed to track down one of the guys that helped make these and he had some yarns to share: Interesting that use of the standard plenum wasnt just because it was mandated. Although maybe that's why the factory throttle body is still in place. Race car rules can be weird haha.

- 165 replies

-

- 14

-

-

-

Love how clean it looks with those throttles! 20V stuff is so messy looking.

-

Stu's 4agte 85 EP71 Starlet and 4age 84 AE86 Levin

Roman replied to Stu's topic in Project Discussion

This is bloody excellent. -

Printed moulds are legit! User error/inexperience not bad tools. One of my previous ones (rear one) formed the bell shape just fine. I tried something different and it didnt work. So now I know what else to try instead. Even as per below it's just being bit of a fuss pot to get that full return on it.

-

So that was a win and a fail. It was a win because getting the moulds polished up from 360 grit up to 2000 made for a nice result and the moulds popped apart super easy and definitely reusable without any damage inflicted to separate them. It was a lose though because my design didnt work too well. Trying to fold the carbon fiber up around the radius of the bell didnt really work, this is where the sheet needs to kinda do some pleats to make the turn. So its hard to hold it all in place while trying to push the top down, which due to tight tolerances would then just want to squish it all back out the sides anyway. So I think I need something else which pushes in from the sides instead of just down from the top. So maybe split into 120 degree segments or something. Aaaaahhhhhhhh frustrating but learned something from it. Also with some further consideration I need to remake them a smaller size anyway. This is why I'm glad 3D printing exists, it would suck a whole lot more to make these moulds any other way then have to restart a bunch of times!

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

Roman replied to bonkas's topic in Project Discussion

+1 to that After all this effort please dont cook the head gasket or whatever, for sake of a water line! -

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Just had another geez through your thread, that section with all the mspaint pics was absolute gold. Love it. Car's coming along awesomely too! New paint looks great. -

I really like what you're doing with the new engine. But I think you may have gone a bit far with lightening the crank

-

Starting on a new mould for some 4AGE ITB trumpets but learning from some previous mistakes. Problems from the past are that I've had too little draft angle on some parts that are quite long. Also that some of the excess untrimmed parts end up folding over something and locking the part in place. Also trying to use only 2 pieces when theres no reason not to use more if it makes life easier. Annndddd I think it will be a good idea to add some tabs so I can twist the halves relative to each other to try get the part free. Previously I've damaged the moulds by needing to smash a screwdriver in (or whatever) to get the halves apart. Hopefully this will help! I'm hoping I can make at least four, or even eight from the one set of moulds. I'll also try drill some little holes in the moulds, fill them with wax and then so afterwards I can use some compressed air to blow the halves apart hopefully if they are stuck. The center part of the bell shape still needs to be dissolved out, but cant think how else to get that sweet sweet return angle on it. Worth it... Fingers crossed! Fingers crossed!

-

I've modelled some different bell shapes before, and compared to ideal they all get Vena Contracta a whole bunch more and reduced flow. But the flow rate at which it happens to a large degree needs to be very high. They way I figure it, if a cylinder is 500cc then an intake runner just needs to provide 500cc of air before the valves shut, then it has the whole rest of the cycle to "recharge" So a poor shape is probably less of an impact than if it was steady state flow like on front of a turbine or something. To be honest I have no idea if this will be any better or worse but that's the fun Thankfully in this case the numbers for fuel to reach AFR doesnt leave much to interpretation so its easy to compare. Especially if peaks and troughs move around. The idea is to have enough combos ready to try out that I can put together quickly for a dyno session to do some comparisons.

-

Thats some sweet power, love the airbox setup! Do you know how long your total intake length is, down to the valves? Also interesting that with an engine with totally different (everything) it still comes on power at around ~5300rpm.

-

Soooooo for a while now I've had an obsession with getting a "proper" bellmouth geometry on something. I successfully made a big one for the big single throttle but I really need a different radiator arrangement to make it work so its been on the back burner. But the geometry to give completely straight flow is massively massive compared to what is usually used, so its a problem when you have 4x throttles close together. With the space that is available, you have to trim down the sides of each trumpet by this much to fit 4 alongside each other. (Obviously dont need to trim front or rear but lazy modelling) So it looks like you lose most of the useful area of the bell... And looks like it would be prone to "stealing" air and maybe fuel from adjacent cylinders? Not so good. Probably better just having a smaller radius on each. Either way, I printed out a full sized bellmouth (without trimmed sides) so I can size it up in the engine bay. As it turns out that thanks to having a brake booster I've got zero room for a trumpet this big anyway on the rear and hitting the bonnet on the front will be a problem too. I've seen those cool kits where people have all of those parts you can clip together to help build an exhaust manifold. So I thought I'd try the same thing here but for an intake. So printed some parts so I can try some combos for a single runner. Base piece, a bell, 3 x straight 20mm sections and 3 x 10 degree sections. Also pictured is the bellmouth provided with the ITB kit, for an indication on how rediculous the bigger one is haha. Unlike those fancy exhaust kits though mine doesnt actually clip together because aint nobody got time for that. Also, turns out printing the straight ones was a waste of time as there's not even enough room for just the bends. Neither front or rear really fits. pooz. So I'm reprinting the bend parts with 15 degrees per segment and a bit tighter radius to see how much that helps. Based on what looks like will fit though, tipping the trumpets slightly towards the front of the engine bay is actually pretty cool because it allows more useful bellmouth area per runner. A lot more! Most of the air comes from around the sides rather than straight ahead so will be interesting to see how this goes. The question is, is the efficiency gain of the big bell worth the efficiency loss from the bend. And is the bend worth the extra runner length gained. And does any of this make a difference when you're trying to wheeze through a 45mm throttle. And the biggest question of all, will I actually finish making any of this? Some preliminary nerding seems to look like the bellmouth partially shrouding the entrance shouldnt be an issue so long as there's a bit of gap. The colour scale on this, red is 101.3kpa and green is 101.0kpa so pretty minimal loss hopefully EDIT: Just found what the factory BMW S14 engine runners look like, makes me feel like I might be on the right track. Even if the big bellmouth isnt necessary, perhaps there is a real life benefit to having them staggered to allow more clear air around each runner than you can get with straight pipes that are butted up to each other.

- 165 replies

-

- 23

-

-

Great stuff! Now the fun part begins

-

Hahahaha looking at some sweet sweet waveforms while driving. The dream

-

Yeah partly because this adaptor retains the first part of the intake manifold. So its ports > ali manifold > adapter > throttles > trumpet Which isnt a bad thing as that first part of the manifold handles the transition from circular shape to the port shape and does a nice job of it by the looks.

-

Current manifold lengths as follows: Valves to end of adapter: 205mm Throttle body height: 74mm Trumpet length: 83mm Giving a total current length from valve to bellmouth of 362mm Which is surprising! A lot longer than I expected. The standard intake manifold is approx 40-50mm longer than this (with a bend) Can easily go another ~70mm longer if I put about a 30 deg bend in the runners to avoid the bonnet. So will give this a hoon.

-

Just been thinking about this over last few days, even though I have comparatively heaps of space I want to try runners as long as I can so space is still an issue haha. Just been thinking, perhaps you could solid mount your airbox to the body of the car, and then just have some rubber gaskets around the trumpets so they can move relative to it? Thinking I might do something along these lines, probably easiest way to ensure theres enough space around the brake booster etc.

-

Thank you! Yours seems to have the 5500rpm curse as well. Haha. I think we have definitely established a trend here. Also I must disclaimer that since im using a redtop engine its lower comp, slightly less aggressive cams and no exhaust vvti. So its not exact apples for apples but results still applicable if not magnified for a dual vvti engine.

-

Without a throttle body in the way will also be interesting to try so different inlet pipe diameters and lengths. I think i remember glenn saying around 4" dia was best So much to do so little time! Start with the trumpets though

-

If you have two cars but largely the same except for engines, then they need to be different enough that its not a hard decision to take which one for a drive. I dont think a v6 turbo isn going to feel hugely different to a 1uz in terms of power delivery etc. Turbo rotary and then each car has its own completely different charm! or a high strung turbo hyabusa engine or something. Something as completely different to a 1uz as possible.

-

Yep im keen as to try staged injection again, as i can print some trumpets with injector bosses in them. 100% keen on a carbon airbox too, if a small enough pipe works nice to allow a maf it will be on there for sure! Then i just need one of those bmw ethrottle motors and ill be back in business.

-

That would be really intetesting actually, or even per cyl map sensor that can see when the pressure waves peak relative to tdc... might give some clues to best cam angle when a maf isnt available. Im hyped on some runner lenth experiments right now though! 17kw gain from runner lengthening is a crazy big improvement.

-

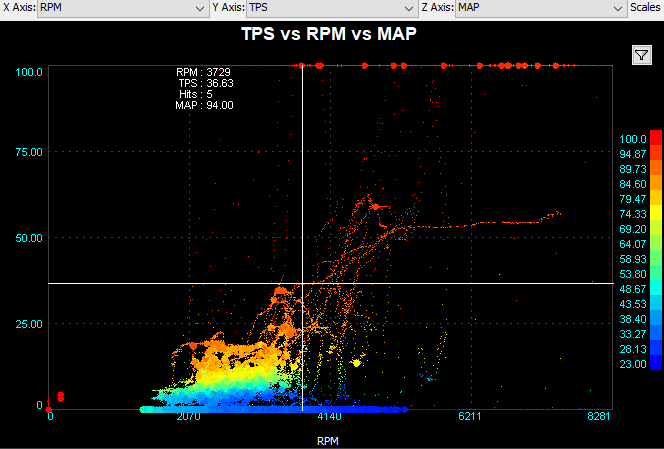

I still havent had much time to play with the tune more, but got it tidied up a bit. Basically it still just falls on its face at around 5500rpm. After refining the existing map a bit more though I am less convinced that cam timing is going to help that hugely. After its peak at 5500rpm it loses about 11% cylinder fill by 7500rpm, which is an uncharacteristically aggressive drop in torque. I'm getting more convinced the throttles themselves are a mass flow restriction, and this is why torque drops after this point. But it could be something else too. Possibly the stupid inlet/outlet shape on the blacktop throttles causing turbulence or something. So thought I'd head to the internetz and see if there are similar trends on other beams ITB setups using blacktop throttles. This is the first result I find... 180hp ATW with the peak torque at 5500rpm falling on its face after that. And comparatively garbage below 4000rpm too. Almost exactly how my setup has responded! I'd describe as "small to medium length" trumpets fitted on this one: Second result that I looked up looked almost identical to the above... Hmmm. Around about same length trumpets too. Found another link which didnt have RPM scale on the dyno, only KPH as was rolling road so cant tell what RPM things are happening at. But it looked to have initially results similar to the above. But then they put on longer and longer trumpets made more power everywhere. Ended up with a 17kw gain using 110mm trumpets after starting with 35mm. So I think I'll try print some trumpets as long as will fit. Will add a curve if need be. Another thing which is quite different to the plenum setup. On a stinking hot day with the air being drawn from right at the back of the hot engine bay it lost considerably more power to heat soak. Like, Virtual Dyno and fuel map says 25-30hp kind of loss. Really flat power from then onwards yuck. I'm not sure if that can be completely accounted for just from reduced air density, but somethings making it lose a lot of power when very hot! Is this all dissapointing so far? No way, all the indicators are there that there are good results to be found with some further testing. I know the engine has the cams etc capable of making max torque up to at least 6500rpm - There's likely just one variable holding it back currently. It might be the throttle ID, it might be the trumpet shape, it might be the overall intake tract length, or lack of airbox, or something else. All of these things I will be able to test and prove/disprove one by one. What a time to be alive / have a 3D printer

- 165 replies

-

- 15

-

-