-

Posts

7,219 -

Joined

-

Last visited

-

Days Won

39

Everything posted by Roman

-

Yes that can happen but I'm skeptical that temperature is the actual issue. I think there are two possibilities. Temperature related, it all overheats. But it's all stainless? The injector is completely enclosed in the aluminium head which is a great heat sink. Aluminium will start melting before stainless does. There is a teflon ring on the injector but it's well into the head and isnt exposed to combustion temps or close to it. Or: The lack of fuel pressure is the problem The fuel pressure stops the combustion pressure from pushing the injector pintle open. Apparently direct injection runs somewhere between 100-300 bar, which is why it needs the mechanical pump. Then peak combustion pressure is somewhere around 35-70 bar. So when you have the fuel pressure, you have 230 bar pressure differential, working in the direction of holding the injector closed. Without the fuel pressure, you have 70 bar (~1000psi) working in the opposite direction. Trying to push the injector open and nothing to stop it except for the small spring inside the injector that pushes the pintle to the home position. The only instance that I've heard of the injectors blowing their guts out, was with a BMW/Supra engine where they were aiming for ~1000hp and were stuffing a zillion pounds of boost in it. So my thoughts are that if I just mechanically lock the injector in its closed position & give the pintle return spring an infinite rate (fill injector with high temp epoxy) then it's going to be fine with an NA motor where combustion pressure isnt going to be mega. I filled the injectors yesterday. Had to pull the filter baskets out, fill with a small syringe, and use the heat gun on the injector body to thin the epoxy to help get the air bubbles out. Now this might not work and it may indeed be that high temps make the injectors blow their guts out. But will see how it goes.

-

Daves new school holden shambles. (Is this project oldschool yet?)

Roman replied to Muncie's topic in Other Projects

Wow, that would be awesome! Didnt realize you were stuck with an rpm limit like that. Extra rpm helps heaps at the drags, will be well into the 13s if you can stretch it to 7500 or so.- 742 replies

-

- 2

-

-

The driver's side bank is still okay. But the passenger side took a hammering for a variety of reasons. I dont think I will reuse them though, but they will still earn their keep in other ways. Being able to mock things up with a motor outside of the engine bay can be very handy! I really need to figure out some sort of airbox, so I'm considering just enclosing the entire lot of stuff in the top in the box. From the heads up.

-

I got a new motor! A real nice one this time, 90,000km on it. This is from a Gen 2 Mark X, which supposedly had some improvements to the PCV system and piston rings. Soit ends up with less shit all over everything in the intake. The state of the valves/ports was MUCH better than the earlier engine from last time. Hard to even know what's there, with all the shit on top as it comes from factory: It's been time consuming to get it ready to go, because it needs to be stripped down to a bare block. I've done a few things a little differently this time but the to-do list: -Swap to front sump setup -Remove heads, fit Kelford valve springs and retainers -No porting the heads this time (Will be interesting to get a base line with standard vs ported later on) -No plugging the DI holes time (Will leave factory injectors held in place, filled with resin so they cant blow open) -Swapped intake/exhaust -welding the rocker pins -Fitting BMW hydraulic lifters with Barra rocker clips -Adding the VVT cover plates, and loctiting all of the VVT pulley bolts. I've finished one side, and the head is bolted back on. Just need to finish the fiddly job of refitting the valve springs, then the other head can go back on. Exciting!

- 130 replies

-

- 60

-

-

-

Interesting that they use a scavenge only setup! I remember when TRS first started, in 2004-2005ish and some of the cars started blowing up the oil pumps. (It was a brand new / unknown issue at the time) Because I had my motor in at the same workshop that built / rebuilt them all. I suddenly got pushed way to the back of the queue as they had a stack of motors to diagnose and fix. I never understood how that could have been blowing up the factory pump, if they had a dry sump - but that all makes sense now.

- 417 replies

-

- 1

-

-

Dry sump can introduce as many problems as it fixes. Blame user or installer error if you like, but i think ive seen as many trackdays come to an early end from oil leaks, oil flying out, oil spills, belts flying off, etc from dry sump issues as much as anything else. Also max irony points when someone loses oil pressure because of a sandwich plate coming loose that was only there for sake of monitoring oil pressure.

- 417 replies

-

- 7

-

-

-

-

All of the fucking around to dry sump it will cost you at least another year of not driving your car. Bolt in option and gooooo

- 417 replies

-

- 7

-

-

-

-

Could have been factory ECU as well perhaps.

- 417 replies

-

It really boggles my mind, that there was never an MR-S with the 2ZZ. Even if it was only a super limited run, come on! How does a Fielder wagon or a Toyota Will get one, but not the mid engined car haha.

- 417 replies

-

- 5

-

-

-

-

Out of interest @Hyperblade what is the project? I'm assuming car related 😃

-

Oh wow, didnt know that. Thought everything of that era was mostly steel block. But might just have my Toyota hat on... Sorry/not sorry for spam

- 417 replies

-

Have seen some aftermarket braces that are only 2 point. Then the there is the Vitz RS with its bluetooth strut bar. Has the end plates but nothing in between... Some of the 2ZZ cars have a super wacky one from factory... Just how much are they expecting the struts to flex?!

- 417 replies

-

Also full alloy engine now. Probably a bit lighter than B series.

- 417 replies

-

- 2

-

-

Absolutely awesome milestone man! So stoked. Cant wait to see how it goes once VVT is sorted. At the very least I can assure you the intake will get a LOT louder yet when you start bringing in some overlap. Haha. What do these weigh when stock? I would have thought a rollcaged one would be kinda in the 1000-1100kg range. Will be absolutely wild to drive once motor is sorted, if its in the 900s.

- 417 replies

-

- 1

-

-

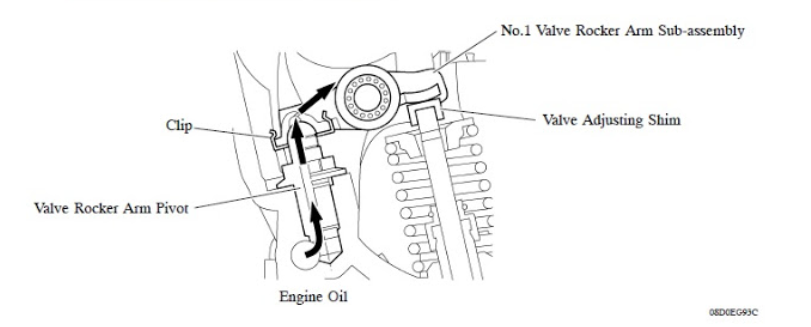

This is a Toyota GR engine rocker, BMW N52 hydraulic lifter, and a clip from a random 4 cyl Peugeot at pickapart. Whatever works, right? haha. The BMW stuff came with rockers, lifters, and clips. However they have a longer rocker, and the clip is like thin wire rather than a sheet. So it wont fit on the shorter 4GR rockers. However it was worth getting them for the lifters that accept the clips. The peugeot clips work nicely with both, with just a small zing on the end of the rocker to let the clip seat nicely. Looks like a workable combination, just need more of the clips. It looks like Barra or similar Ford I6 engines have clips that are largely the same. So I'll try find some of those, as they're probably a lot more common than Peugeot stuff. If anyone's got a broken motor sitting around with a bunch of clips that look like that, let me know!

- 130 replies

-

- 24

-

-

-

I've had really random looking trigger issues from it not liking the arming threshold settings. Could be worth a try bumping them up. Also if the VVTI is stable you could try advancing the cam and see if it goes away when the cam moves out of that zone.

-

the lift on the actual cam is only tiny, like 7mm but it has a 1.7 rocker ratio that ends up being 12something mm pushing the valve down. Kelford spec sheet shows some info from both.

-

Oh yeah I'm wrong about that spring height anyway. It's actually ~14mm As it's 36.3 - 22.35, not 22.35 total

-

Yeah not a bad idea!

-

Haha! Well, assuming I stick with the sub 13mm lift cams (as thats all that is available) If you put a spacer in that squashes up these kelford springs, the new seat pressure would likely be too high. But the factory springs might end up around the seat pressure of the kelford ones if you squashed them up. If you put a spacer at the bottom, then it's not adding any reciprocating weight either. I'm mostly wondering if high rpm makes the lifter squash down. As there's no way to really see if it's happening. If the lifter is squashing down then it means the valve isnt going down instead. So you lose heaps of duration and lift. I'm not sure if there's really any way to know, short of installing a camera or something. So going to a solid lifter might just be best idea either way.

-

They bind at 22mm lift, so are miles off thankfully. The lifters only compress by maybe 5-6mm absolute max from their free length. I havent measured yet but I assume they are partially compressed to some extent when installed. Someone pointed out that due to the way the lifters work, they need "some" compression before the check ball thing locks them in place when the cam turns. So having the hydraulic lifters gives you slightly less duration and lift than a completely solid setup. So might be worth going to a completely solid setup just for sake of that.

-

Still waiting for $$ for another motor. But have been doing some side-scheming. It seems that the rocker and lifter geometry is not necessarily a Toyota specific thing. Measuring up the hydraulic lifter, and it seems like nearly everything else with a similar setup (BMW, VW, GM, etc) uses the same stuff, or at the least largely the same dimensions. As in, they are all 12mm diameter and then just vary height slightly based on application. Then some of the rockers look the same too. In order to use the clips that clip the rocker onto the hydraulic lifter though. You either need to cut some slots into the top of the lifters, or swap them out. The aftermarket kits for the 2GR look to just be OEM lifters and clips from the Coyote 5.0 V8 which has a near identical looking valvetrain. Some guys are revving these Coyote motors to big rpm so that's good news I guess. They're fairly expensive to buy 24x lifters and rockers brand new though. So I've been having a look around for a second hand set. The N52 BMW engine is a straight 6 with 24x lifters which are already circumsized for the clips. 2GR vs N52: The BMW lifters are 2mm shorter, which I dont think is an issue - as I've also been looking into the idea of shimming the underside of the lifters, so the hydraulic action is doing the absolute minimum. As people have mentioned that doing it this way works just as well as completely solid lifters, but you dont need to do the incredibly fiddly job of setting the valve clearance by swapping out the valve stem tips. Although, that is another option. The 2UR motor, which is basically a V8 version of the 2GR. Shares quite a large amount of the geometry between them. They use the same length/dimension conrod on both engines. The rocker arrangement is largely the same. But the 2UR has a fixed pivot point, rocker clips, and then shims the clearance with valve stem caps that you can buy from Toyota in varying sizes. So that's another option perhaps. I've bought one of the solid pivots to test with my spare head. It looks like it will need some machining to make it work though. Unfortunately in the parts database it doesnt list the clips on their own. Only the rocker or the pivot. If the BMW lifters/clips fit onto the toyota rockers, that would be most excellent as it was quite cheap to get a 2nd hand set of 24x. Which should be arriving today or tomorrow hopefully.

- 130 replies

-

- 31

-

-

-

Daves new school holden shambles. (Is this project oldschool yet?)

Roman replied to Muncie's topic in Other Projects

Can confirm that it looks mean.- 742 replies

-

- 2

-

-

Adrenalin R sells packing material by itself. But it's just rolls of stainless wool as well I think.

-

Well, need to keep in mind that they're not spring chickens anymore! An R32 GTR is now as old as a Mk 2 escort was, when this site first started. Any car of this vintage can be really nice if you're lucky, but is likely in need of some repairs and maintenance. It's funny though how your brain can still think that cars like this are new-ish though. Gone are the days of "Is my car oldschool if it has plastic bumpers" Now we're on to "Is my car oldschool if it has Advanced Total Traction Engineering System with Electronic Torque Split - But only the early version?"

- 129 replies

-

- 20

-

-

-