-

Posts

7,218 -

Joined

-

Last visited

-

Days Won

39

Everything posted by Roman

-

Setting up flat shift works amazingly well, even on a synchro box. As on a normal up shift. Rpm needs to drop. But this will only happen when you have both slowly rolled off the gas, and rolled onto the clutch. Only when both of those things pass a certain threshold, will the motor start to dip rpm. This doesnt mean rpm is plummeting to target. Just that it has started dropping. So any disparity needs to be made up for by your synchro. So you have just wasted 1/10th of a second (or whatever) having your rpm hover higher than it needed to. Then added more wear to your synchro. If you setup flat shifting, your throttle pedal position (power generation) is no longer a variable preventing rpm from dropping. Your rpm will drop, then power engage again more like a square wave than a sine wave. Because the torque cut and reapplication is instant. Your motor drops to where it needs to be quicker, giving your gearbox an easier job. Then you spend a bunch less time rolling off and back onto the power. Only talking fractional gains that are probably worthwhile at a drag strip but maybe not track racing. But little things like this can all add up. The key to making it work well was having a variable position sensor on the clutch. When I'd tried in the past with just a clutch switch it was impossible to get right. There is a very sensitive zone where it either works well, or is cutting/engaging at the wrong time. Being able to adjust the point via software, rather than climbing under the dash with a spanner makes your life a whole lot easier haha. However, yeah. Feels like its an under utilized feature for synchro boxes, as it worked really well for me. A big torquey engine might need more careful reapplication of the power, with a softer introduction of ignition timing. But at least if the ECU is doing it, its exactly consistent.

-

Get with the times @fuel, current oldschool projects on this forum: Restoring JZX100s Showing off Barn Find Kanye West CDs

-

Another thing is that you can dip a toe into experimenting with final drive ratio to some degree, just by changing tyre size. In the echo, from my 14" wheel setup to 13" wheel setup, it was same difference in rolling radius. As though I had changed from a 4.3 to a 4.5 final drive. Yet as easy as just bolting some different wheels on. Unlike changing a FWD car's diff, which might take a week. I could have 2 or 3 sets of tyres that give different gearing speeds, and test them all on a single day. Something else worth mentioning. In a straight line like the post above all of those results are fairly the same. If I run those cars on a simulated track test that has some corners and braking. Again, they are all about same same. With one exception. The car with 50% more grip does a big steamy wee on everything else by 10 sec per lap. Then everything else is fractions of a second apart, 10 seconds later. It's funny when you see people with all of the awesome stuff like carbon bonnet etc. But then get absolutely trounced by someone who spent $500 on putting the car on some second hand slicks. Even if second hand, the right tyre makes an insane difference in terms of bang for buck. Which then also has that flow on effect. If you can hold more speed through some corners, you are less punished by falling into "valley of death" between lower gears or whatever.

-

One thing that I think is interesting, is that in our brains we build false equivalencies between various factors. As in. getting more grip, getting more power, having a more aerodynamic car, etc are all worth the same in how we emotionally or financially invest in them. Spend $5000 on a carbon bonnet, has to make your car equally as flash as spending $5000 on a new gearbox right? Yet, in reality. Something like adding 10hp might be fairly trivial, reducing drag coefficient by 0.5cd might cost you $20,000. Or not even be possible. You might spend $5000 on a carbon bonnet, that only saves you 15kg. Which has the same net effect as gaining 3hp. haha. So its interesting to take the same baseline car, and run it through the CarTest program. Even if just for the straight line stuff, results are interesting. Below I have setup different versions of otherwise identical car with +10hp, 0.5cd improvement, 50% more grip, and 50kg lighter. As I think these all show realistic possibilities from things like buying different tyres, adding carbon parts, taking out seats, or whatever. It's interesting to see that adding 10hp wins or equal best in every category except for 60ft time. I guess what I am saying is, if you adjusted the gains from each of these categories until the results were about even for all of them. You'd probably find that one will be impossible (improving .cd by a massive margin) Others will be insanely expensive or detrimental to the overall car (trying to lose 300kg) and others are comparatively easy (Spend an afternoon on dyno testing 5x different intake pipes)

-

This is an interesting point, because if you get that midrange beefed up, then it might feel like it doesnt need that final drive change, or the close ratio box quite so much. Then you get all this mileage out of the car using OEM parts instead of high maintenance dog box or whatever. Accumulative wins from getting the basics right, and vice versa.

-

I 100% buy into the idea that finding that sweet spot of price / effort / complexity / failure rate / etc is the main thing that can make a car fun or not. If you have a car that has dry sump which needs 1/2 hour of oil warming. A rollcage you need to climb over. Sparse interior with no comforts. Ear splittingly loud. and so on. You just super narrow down the conditions in which you could go take the car for a fun drive. And then the less you engage with it, the less you feel like it later. and so on. All just adds up to the point where there's so much admin work needed before you can go for a fun blat up the road. That you just leave it parked up instead.

-

The other thing that's great, if you want to get a more real life sort of feel about how the car will perform. Cars in Assetto Corsa can be adjusted by tweaking the values in text files. That just list things like gear ratios, etc. My gearbox has a really really awful shift from 1st to 2nd, and ideally I want to use the 3-4-5-6 gear stack. However to do this with lots of rpm would requre a 5:1 final drive, or higher. Putting the car together in Assetto Corsa, and driving it around Hampton or Taupo (there are really good maps for each of these now!) and it showed that it was just quite horrible with a 5 or 6 to 1 final drive. As you'd have to change gear mid corner so much. 4.7 final drive actually seemed to work well, and doesnt hugely compromise the cars ability to trundle along at 100kph etc.

-

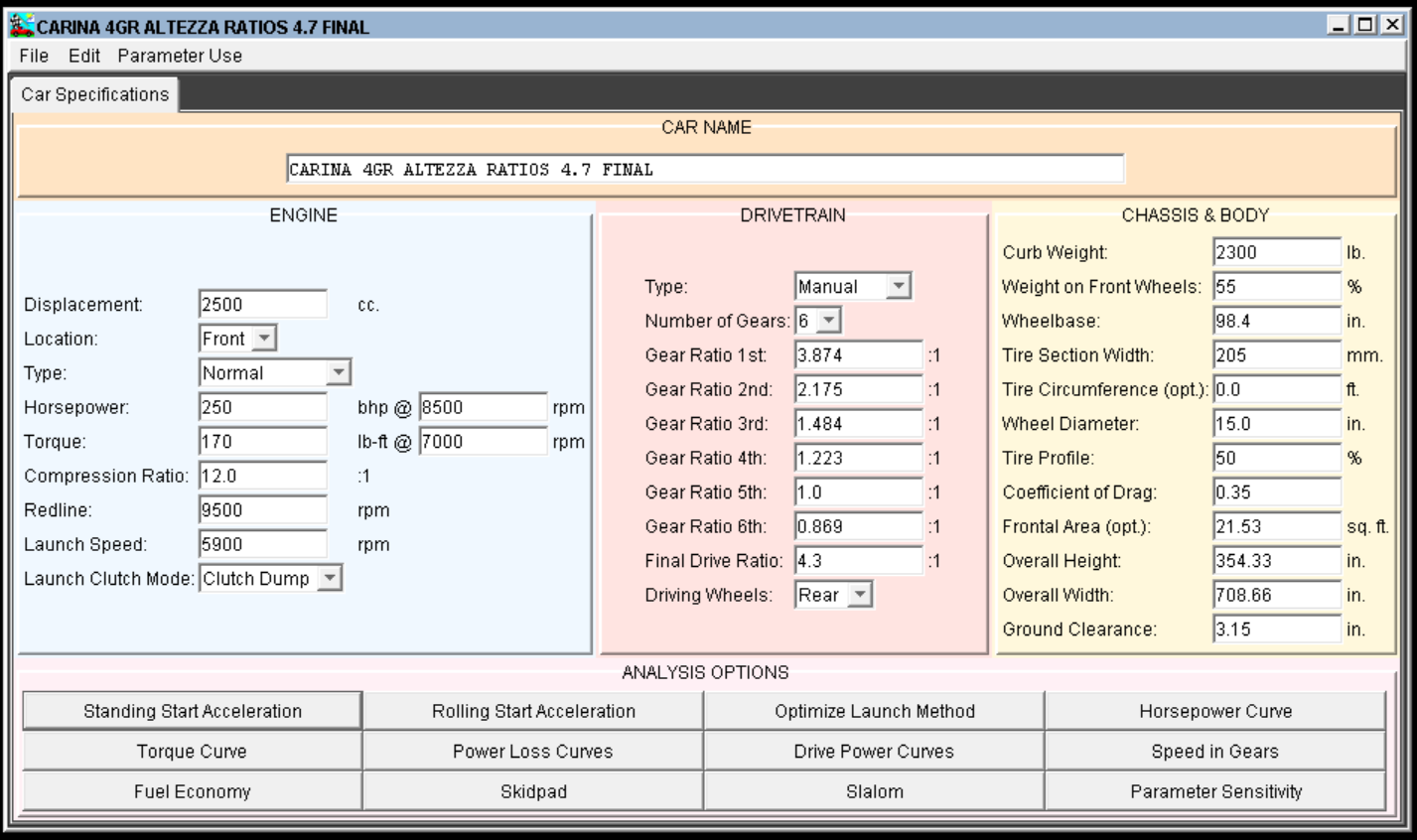

I've got a program called CarTest2000. It's pretty janky in terms of it's layout etc, but its really great. Basically you input a car's tyre size, aero, weight, gear ratios, all that. Like so: then you can run a bunch of performance tests. The great thing about it isnt necessarily that it's 100% accurate, so much as that you can isolate just a single variable perfectly, and see how it changes things. In saying this, before I'd turned a single spanner on a 1NZ, it predicted the Echo would run a 13.8 and 100mph. Which was not far off the money. Then it can output a variety of tests like this Or like this for comparative testing

-

Have you considered a... Son of a bitch! He did it! [Forum achievement unlocked]

- 417 replies

-

- 15

-

-

-

-

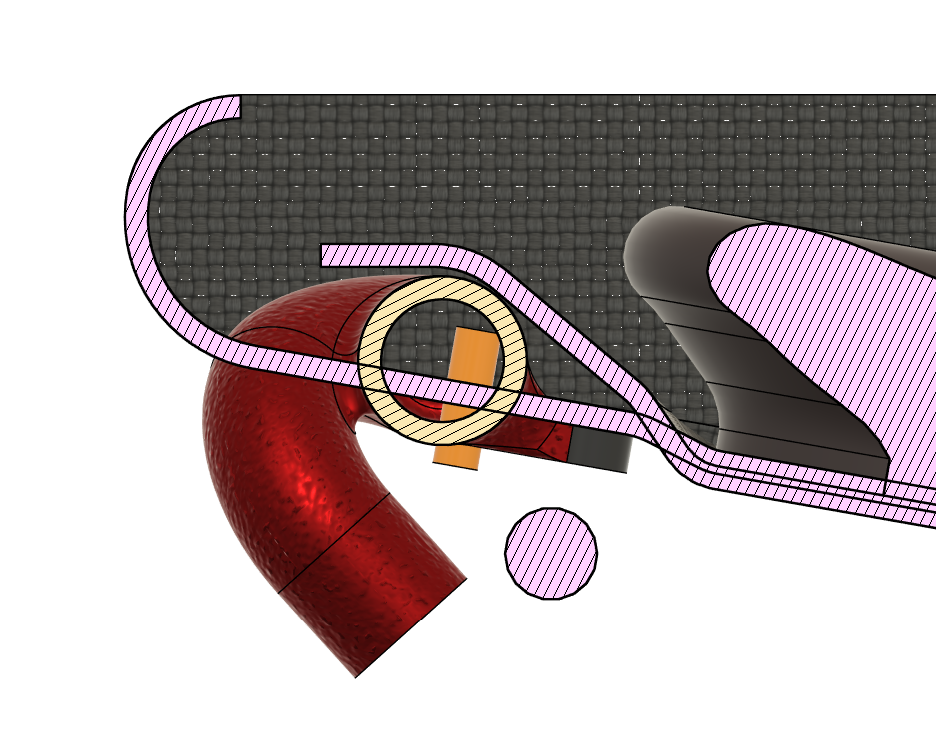

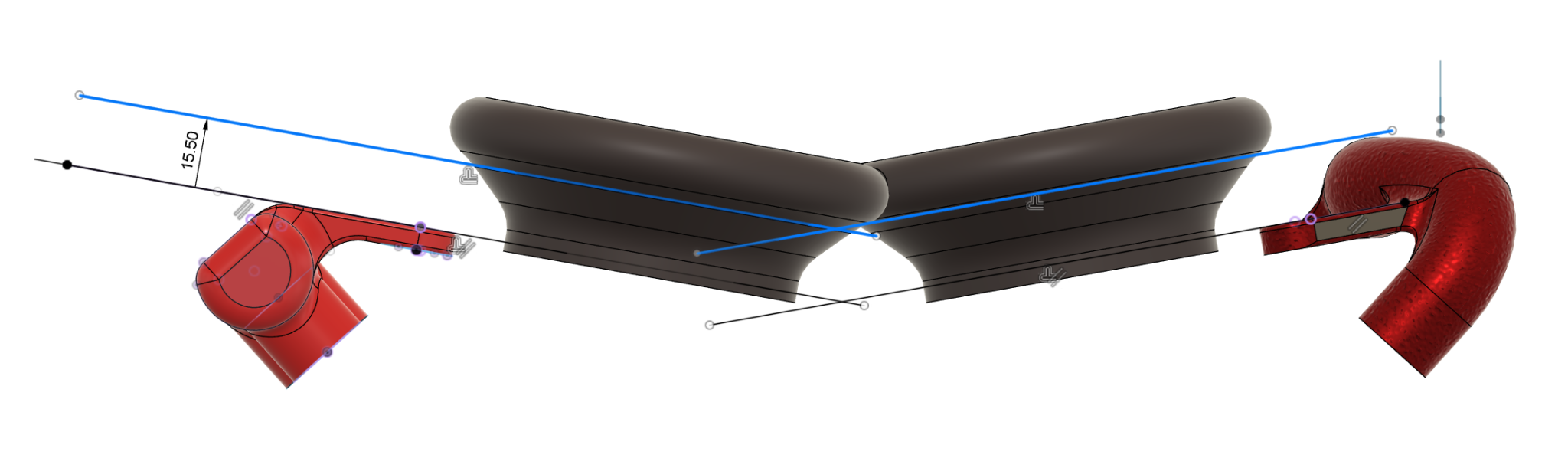

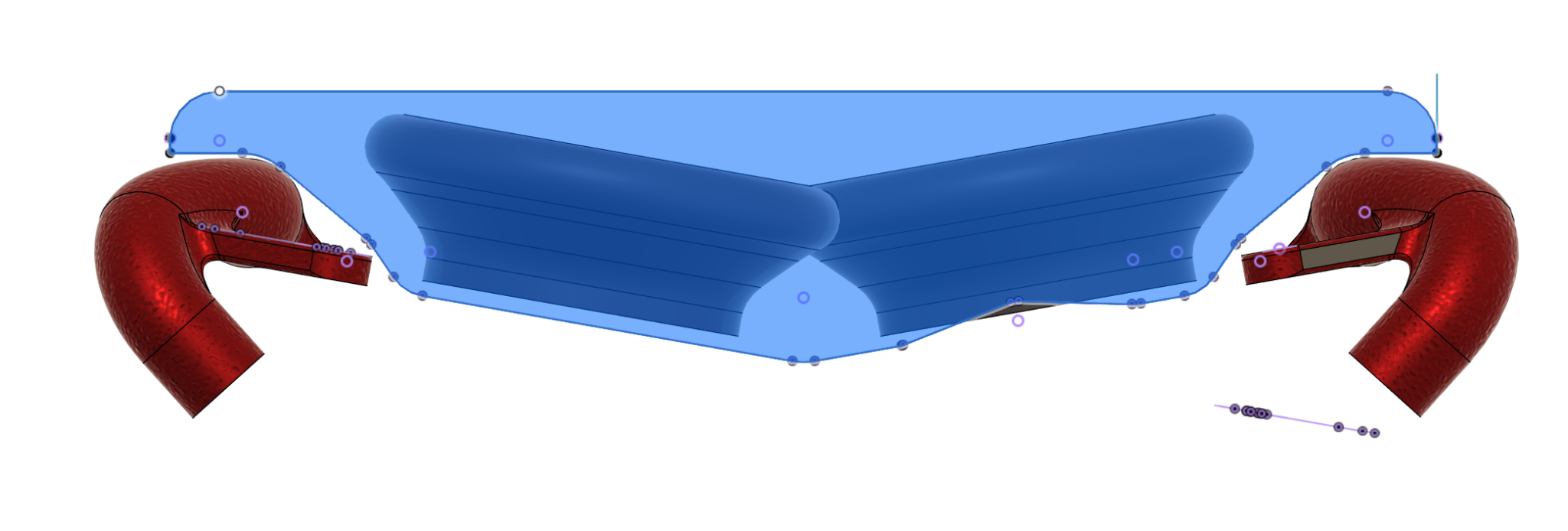

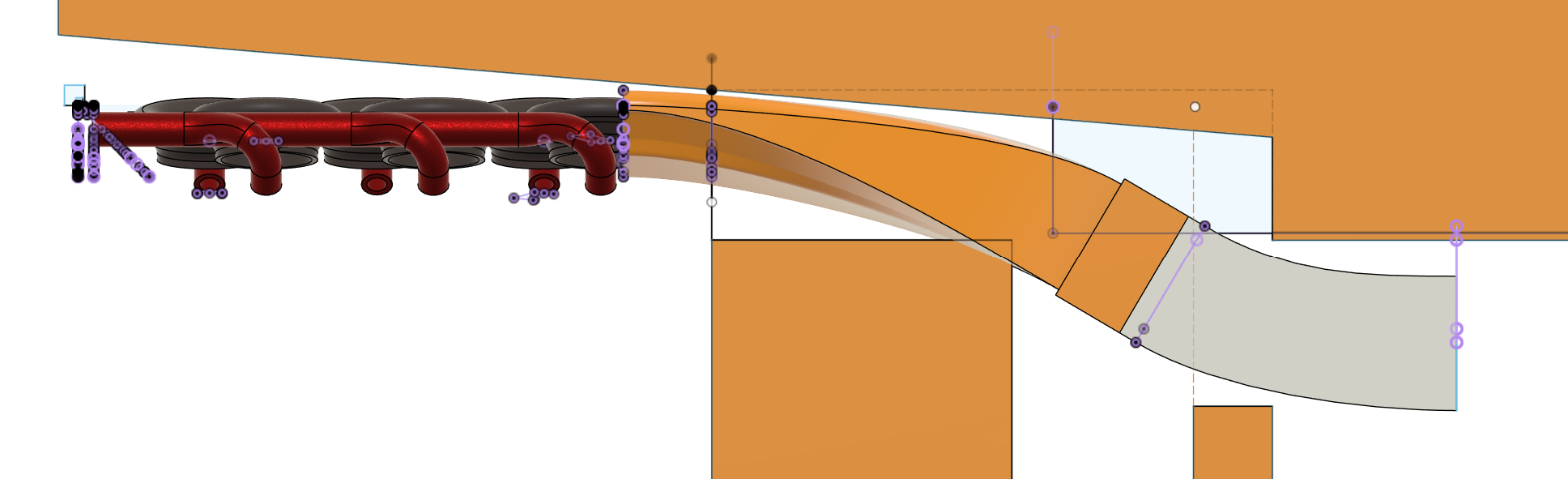

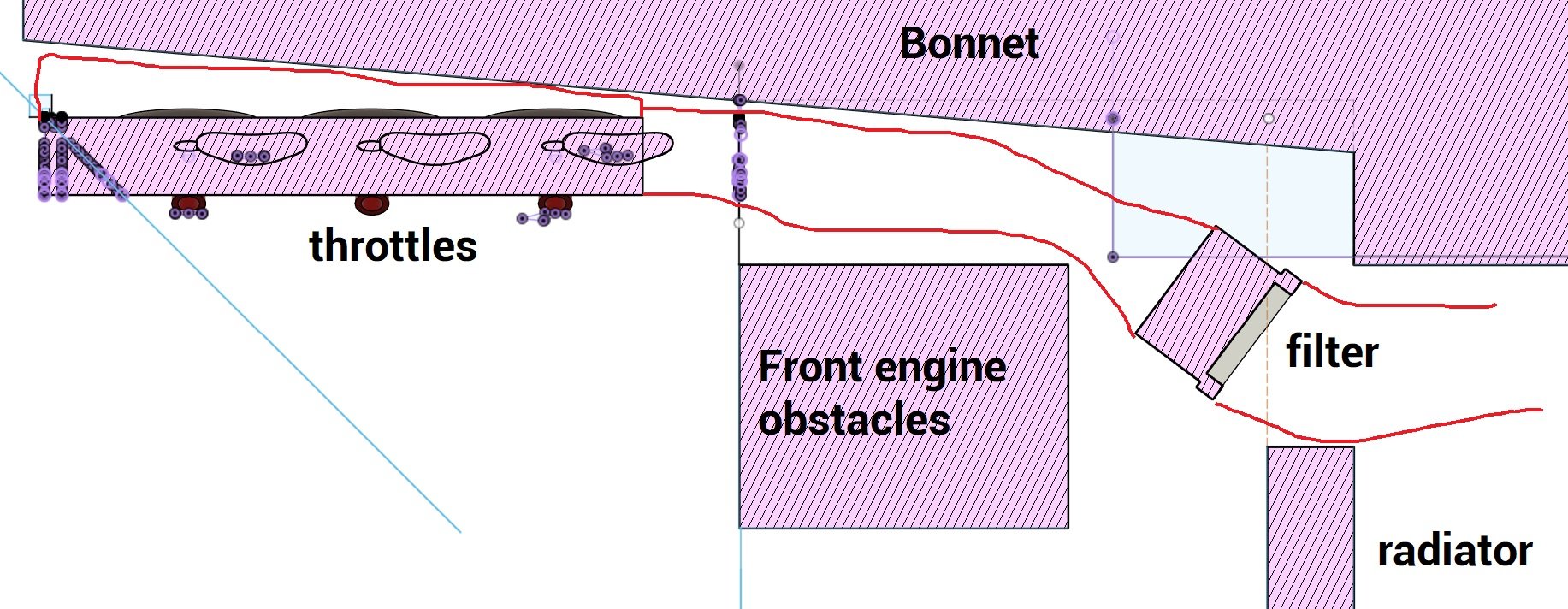

"This has been fun to make some fairly quick progress on for once." I just had to say it, didnt I? Okay as per chat thread, there's a bit of a change of plans to make everything work betterer. I dont have nearly as much bonnet clearance as I would have hoped. I've decided that remaking the fuel rails will help remedy this, but also solve a bunch of other problems at the same time. The existing fuel rails sit high, meaning the airbox has to be quite narrow. So it shrouds the trumpets a bit: So there are a few considerations for a version 2 version 3 fuel rail setup. -Last ones looked kinda cool when I modelled them, and I was excited to print some gratuitously bendy looking shapes. But ended up weird looking. I will keep it simpler now. -This time I will be more considerate for the person that needs to machine the fuel rail later. This means having a flat base that is perpendicular to the direction of drilling needed, so it's easy to clamp down. -The fuel feed fittings will now be on the same plane as the injector holes. Not located in the long end which makes it very difficult to secure to drill/tap. -I need to keep the fuel rail high enough that I have clearance for my cable pulleys to be able to move at least 90 degrees. -I need to keep the top of the fuel rail flush with the underside of a wider flatter airbox. -Make sure that fuel dampers can fit this time. I suspect this might solve some weird behavior with fuel at particular rpm/load combos. -I will add some fixing points so the airbox can mount on the rails. So all of the intake stuff locks together a bit and makes the whole assembly a lot more rigid. After some farting around juggling the above criteria back and forth. has ended up like this. New fuel rail shape is a bit simpler. It has some fixing points that I will fit studs to, for holding the airbox on. The throttle pulleys are a tight fit underneath, but will be able to rotate more than 90 degrees. It is kind of annoying to be redoing things, again. However this solves a whole bunch of issues so I'm happy to do it. Thankfully none of this impedes other progress. As there's lots I can carry on with while still having no airbox and using the current fuel rails.

- 130 replies

-

- 29

-

-

Like Meth?

-

Yep 100%, can keep plodding along with this while also getting other things sorted. Still got a to-do list that's a mile long to get car sorted for cert. My metal printed linkages parts to hopefully finalize my ethrottle setup should be arriving in a few days hopefully. That's the main thing I need done, to carry on tuning the car. I've had a fairly bodgey way of mounting the e-throttle motors currently (cable ties were involved) and this means the PID isnt great. B theres a little bit of slop in everything, it tends to undershoot or overshoot by a bit. Once everything is solidly sorted, hopefully the bank to bank targets will be really good. I've also been thinking that may some of my wacky fuel results, like wanting 85% VE at 5% throttle at 800rpm. Is due to lack of a fuel damper. I originally designed the rails to accomodate these, but with the final version they slightly hit on the lip on the firewall. So might be a reason to redo the rails anyway. For the next iteration I'll put everything that needs to be machined on the same plane. Injector holes and the fuel hose fitting all facing the same way, and on the opposite side of a flat base. It will give a whole heap more space around the throttles.

-

Yeah I can probably figure out something like that. Just having another look at the engine bay, there's another simple way to improve the situation whether it ends up front feed or side feed which will unshroud the throttles a bit. Which is redo the fuel rails. I thought they would look cool with the swoopy sort of design but they look a bit strange when on the motor. I could easily remake them so they are only as low as the flange that mounts them to the throttles. Then I can run a wider airbox all the way back. Then they will be hidden so wont matter what they look like. So will just make them easier to machine this time.

-

-

The longer filter is only 85mm tall instead of 100mm, so might be the better pick given the constraints.

-

Yeah these filters are not a solid plastic housing, its like silicone rubber or something. So could definitely make it curved if that works better or whatever. It's easy to test though, even without a dyno - Two back to back runs, with the filter in or out. (and/or airbox off) It looks like I might need to rethink my plans anyway. I have just been doing some bonnet measurements and it's a lot worse than I would have hoped. I've just cut the center brace out of a spare bonnet, so max clearance possible. Even with that gone there's only about 20mm clearance from the top of my lower manifold part to the underside of bonnet at the worst point. So I might need to run some side feed inlets on it instead of coming straight out the front. Or make it a lot wider at the pinch point, so cross sectional area is still alright.

-

Stop being provocative, he clearly doesnt like having a painted floor. Although he hasnt told us what sort of carpet he's going to put down instead Great work Sheepers this car is going to be absolutely ace. I look forward to seeing it some time.

-

Whoa! Looks awesome

-

Yeah that's a fair point. Itt looks a decent size in person. But looking up the car's that it fits, it's all fairly sedentary Peugeot stuff. It's 330x100mm with 50mm deep pleats. So it's still considerably considerably more filter area than nearly any pod filter I guess.

-

Found an easier option I think. Rather than running the super long wide filter, and having it directly over radiator. I guess it's easier to put it a little close to the motor, and then any flexi join etc that's needed, isnt critical to sealing filtered air in. I found this other filter in my bucket, which looks like a good size and means everything fits within my printer's width: So now I'm printing the front part to hold it on and dip it down a little. It looks like I've got more room around the radiator cap than I first thought, so will un-scoop some of that area. Might add some ridges that run front to back to add rigidity to the whole thing. But for now, make sure it all fits. Then figure out how much of a roof I can put on it, and how to hold it all together. This has been fun to make some fairly quick progress on for once.

- 130 replies

-

- 37

-

-

Sounds good, cant wait to see it!

-

Cool, do they let you use the dyno at work for beams related activities?

-

Are there any more events coming up soon @Truenotch ?

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

-

I have / had an Earth-X battery. Chose that brand because it had extra protections in it for short circuiting / overcharging / etc compared to some other options. But that was a while ago, they might be all same same now.