-

Posts

3118 -

Joined

-

Last visited

Everything posted by d.p.n.s

-

mate i had a standard rear end in my mk1 van with a ca18det and it tramped like fuck.....slapped some dirty tramp bars in it and that solved everything......was like a rollerskate

-

I do have a Sierra front end sitting in the garage if you want the spings. And if you can get a capri crossmember in then just slap the mighty pinto in the bugger as well.

-

had a look mate .no calipers sorry. what else did you need/want.

-

I'll see what I've got sitting around this weekend.

-

Man 4age motors pop up all the time on facebook. Sometimes full rwd 4age setups.. The 4age would be the way I go.

-

Bike carbs work well mate... Rotary would work better.

-

Yeah That's awesome mate.

-

Holy shit Pete that is amazing.

-

-

there's been a lot of after market bias pedal box's not pass cert over here . even heard of a wilwood failing with very little explanation.

-

Brocky41's 1963 Ford Cortina MK1 - Discussion

d.p.n.s replied to brocky41's topic in Project Discussion

Sweet.... Seat looks perfect mate. -

found a use for an old diff housing and axles and made my rotisserie

-

fuck thats some heavy duty awesomeness

-

Apart from shocks that's every nut and bolt out..Build a rotisserie... strip the underseal off the underside..... then off to to be blasted.

-

The mk345 cortina are 4 linked.. but a panhard would help.

-

raided the off cuts bin and maybe not so off cuts pin today at work..and started making a rotisserie also postie turned up with the fuel pump im going to try and make work..... its from a 07 falcon ba turbo...so should pump enough gas.......going to try and reto fit it in the factory fuel tank. cheers

-

Na man.....I was sporting a good 4.5" chubby the 1st time saw it there ...in the field of shit.....in all its moldy yellow goodness. Mmmmmmmmmm

-

Or give me it

-

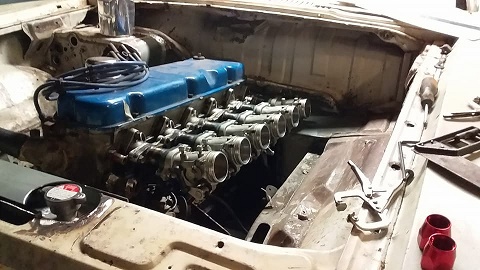

did a wee bit today . finally got the breather tank to fit. sorted out the rear of the engine bay (again) so the throttle body linkage does hit anything will have room for the Idle air controller and the trumpets will fit. and still cleaning bits on the motor.

-

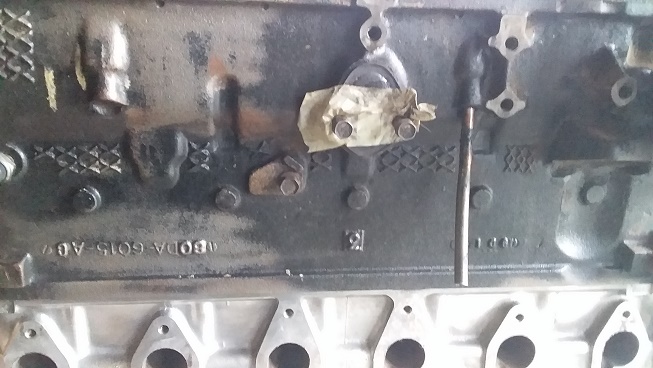

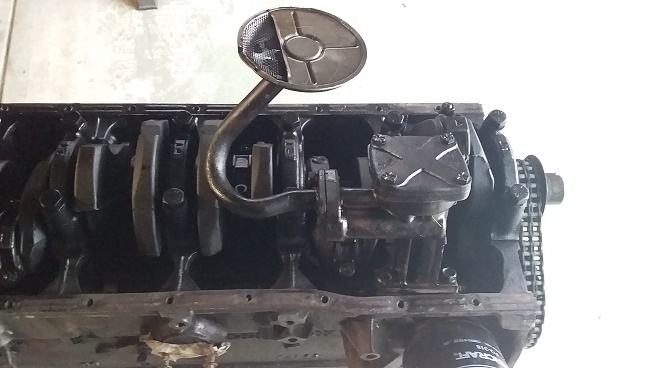

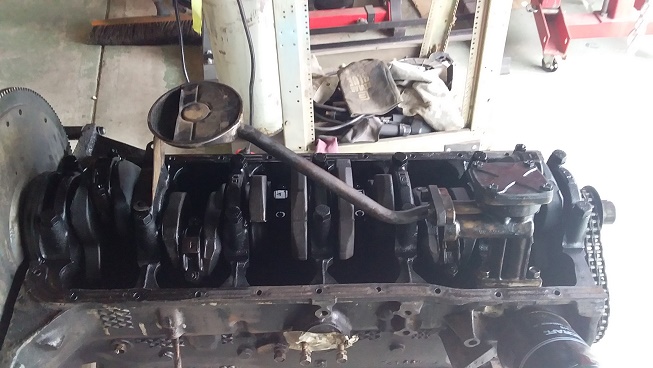

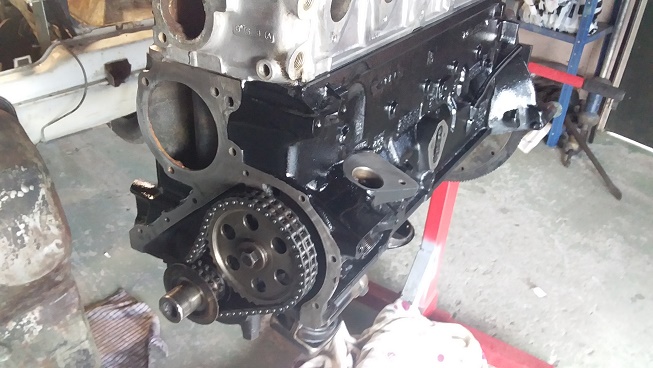

small update. all the measuring around the enginebay for the motor is all done now so i pulled the motor out for the last time...(next time it goes in it will be once the shell is all done and painted..like 20 odd years time lol) so i started playing with the motor. dip stick needed to be moved to the back as the cortina sump is a rear sump.(luckily the ford block has the hole already there ) just had to tap the bung out and swap them over . next up was the pick up had to be changed for the rear sump.(luckily i got the pick up with the sump.) but the 1st problem was the pick up didn't match the oil pump so it needed some modifying next problem was the pick up mount..the factory cortina 250xflow has 2 main cap studs that have longer heads on the studs and are drilled and tapped for 2 bolts.(but i dont have nor can i find any) so i pulled the cap off and folded up a tab to be cut and welded to the pick up.(could have made it 2 bits that bolt together but wanted to eliminate anything being able to come lose ) then i started to give it all a good clean up and thats it so far ...

-

-

6" pod filter adapters I'm wanting to use for trumpets finally arrived ... once they trimmed to fit 6 if them in there and molded into 1 and painted....... should be perfect... Only took 5 weeks on back order from summit racing.....2 days to get to NZ and 16 days to get to me from Auckland.... good old NZ ay. Now I can work out how much more to remove from the engine bay....pull motor and box out for clean up and build..and start welding all the holes in the engine bay up before mak8ng a rotisserie to do the underside.

-

d.p.n.s 1983 mk5 cortina Ghia..........yip pinthoe

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

-

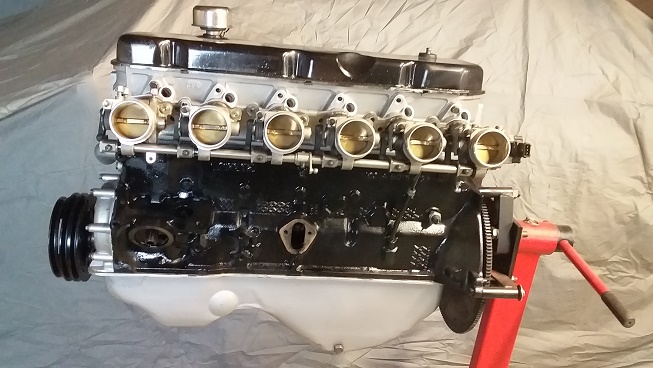

got a few more things done. mounted oilcooler got the electric water pump placed and plumbed then i made a bracket to mount the alternator around that. and then to cram it all together on one side made a panel to cap the gap at the top of the radiator off and all so help keep the radiator in place and last but not least ...got the ITB manifold back from surfab i had the flange cut off and flipped and welded back on and on a 5degree incline... had them flipped so that all the holes in the ITBs are on the underside as i would like to make a idle air control valve for it and all vacuum lines as well cheers