-

Posts

3,248 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by d.p.n.s

-

More than happy to help if o can man

-

This does make me happy mate.. You have done well to keep this so long and still be going ahead with the ca18det..... bloody champion

-

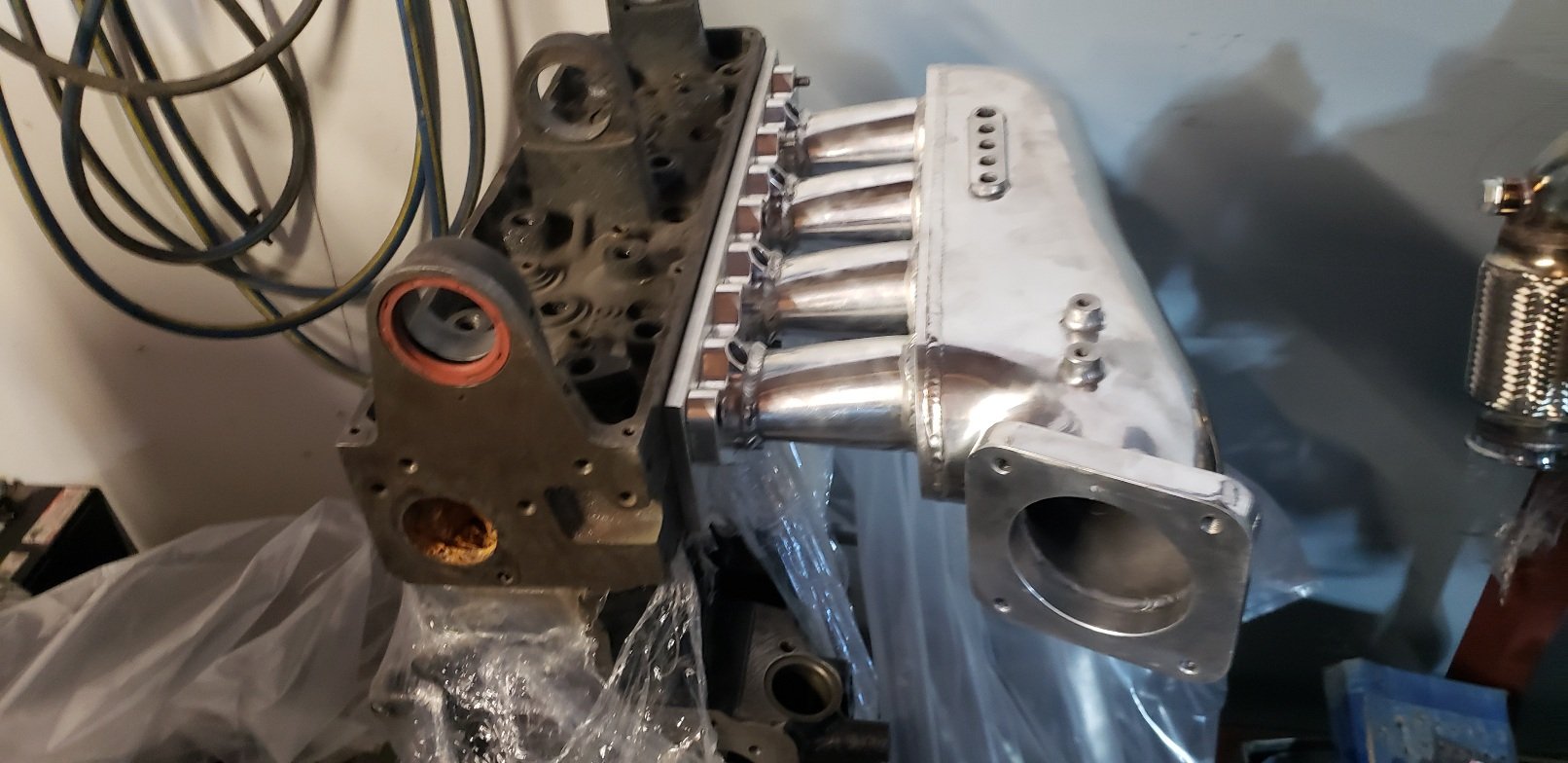

Ive adapted a evo 4-9 manifold to the old pinto now and just going the 1 main DBW TB.. The ITB TB actuator i made really struggled down low at just opening or low throttle input while I was playing with it

-

my new problematic daily....its a mk1 focus st170

d.p.n.s replied to d.p.n.s's topic in Other Projects

They can fetch good money... but no one has any at the moment. Ive seen them sell for $4 grand. I bought my car back for $500 .and got paid out insurance..so I bought it back so others could get the parts.. I advertised the motor for $1800 and it sold in less than a minute 😆 -

my new problematic daily....its a mk1 focus st170

d.p.n.s replied to d.p.n.s's topic in Other Projects

Yeah mine was 210000 when ut git written off.. was bloody great to drive. But I know there can be issues.with so much of the stuff on the motor.. -

my new problematic daily....its a mk1 focus st170

d.p.n.s replied to d.p.n.s's topic in Other Projects

Great cars....just have some issues. There's a bunch of vaccume lines on these ..pays to check them all.as they get brittle and crack. The other main issue is the inlet runner control.... I looked at making someone replace this at one point.. but never did it. ... my plan was to sell the st170 motor and buy a stadrd 2.0 zetec and turbo it... -

my new problematic daily....its a mk1 focus st170

d.p.n.s replied to d.p.n.s's topic in Other Projects

Thats all the normal shit to check. The timing could still be slightly out.. even spark plugs man... mine ran like shit .put a new set in ..ran better ... gapped them perfectly to spec....fixed it. -

D.P.N.S my 1979 CF bedford ambulance (Norman)

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

Ahhhhh Norman the ambulance. (Bit of a read sorry ) The diesel motor and parts get picked up this weekend (I believe).. I hope the guy the bought them gets it all going and it lives for ever.. definitely not the motor for me.. I think I'm just out of my depth with them. So what's the plan for Norman you ask. I was on the hunt for a XD XE XF 4.1 (carb motor ) and trans... And I found a good running low k one in chch for $1500.. But ive had a thought in my head i cant get rid off.. I know any ford motor going in will need a sump reworked or even remade completely and also a re cert. And if I went with the 4.1 i woild still need to find . Everything ..IE radiator, fan,trans cooler, exhaust,find a way of matching auto to factory speedo. Ect ect and its all old. Or I can buy an BA falcon for $1500. And thats where I'm at .. its the original plan Ive allways thought off and use to actually think about it looking at it in bogans shed. So the plan is BA barra and 4 speed auto, the factory parts like rad ,oil cooler , full wiring loom ,fuel box ,all the electric controls and even the dash ,..bring the whole van into the 2000s .. Thats not and easy job and a bigger program planed .. buy I tried the simple and I didn't like it ...infact I told my nephew I feel nothing for it ..no excitement. So Norman is going into storage till my mk3 and nephews mk5 are done.. then ill build Norman while doing my other mk3. That's the plan Cheers- 22 replies

-

- 17

-

-

-

I think I still have some EFI parts left over from bits I bought for the 4.1 in my cortina...(put ITBs on that). But I think 4.1 and keep it carb is the way to go for this old girl

-

Not sure.. at this point. What ever j get i have to remake a sump so ..im leaning more toward xd e f 4.1

-

I have wondered if the cf ambulance would be too heavy . Fiberglass body ..but it will have a bed and some basic shit in it.

-

Was actually thinking supercharged pinto... but probably not enough torque

-

Thanks mate.. but it won't be hard to do..I'll wait till ive found the motor and auto i end up using

-

Definitely ford 6 cylinder mate

-

I can't get the IP to prime and be honest with you mate ...dont really care for it.. I was only really going with the LD28 as its certified for one .. but I thought I could just slap a running LD28 and auto in and go for a wof... But I've allready done more than I wanted too and its still not running .. So I'm not willing to waste anymore of my time on it and just going to do what I should have done in the beginning. I also still have all the spare karts from the 2 motors if you want them.

-

D.P.N.S my 1979 CF bedford ambulance (Norman)

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

-

D.P.N.S my 1979 CF bedford ambulance (Norman)

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

I'm fucking over it... time for take 2. Anyone after a cheap ld28 message me. ..will be going on Facebook market place soon. -

How about this one

-

D.P.N.S my 1979 CF bedford ambulance (Norman)

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

Sorry been pretty busy doing house stuff so havnt done much with the LD28. But on Sunday I got it to the point I can try and fire it up.... Annnnnd it won't....fucking thing!!! The fuel cut switch that was on the pump that came with the motor that was in the rover .. had no plunger (fuck knows what its actually called ) ..it was just the top part. So I put one out of another pump I have here in . I pulled the pipes off the injectors to bleed the diesel through but I was just getting a dribble at maybe 4 of them. So I pulled the pipes of at the pump its self and swapped the fuel cut switch to the one that was in the pump (no plunger thing). And while cranking ( even bought a big heavy duty battery). It just spitting st bedt out of maybe 4 of the 6. Is it likely to be the pump itself?. Or a bleeding issue? https://youtube.com/shorts/dryOLrbjqEg?feature=share -

What about glow plugs... just 12v?

-

Nope I'm not putting it in till I've heard it run. I don't want to run it long I just want to make sure I've out it all together. Then once I'm happy ....then it can go in the van.

-

Thanks man.

-

D.P.N.S my 1979 CF bedford ambulance (Norman)

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

Ok Whats needed to start the ld28 on the engine stand .. Just want to see if it runs. *Flex plate is on *And can bolt a starter motor to it.and add power to the starter *can run a hose from a bottle of diesel to pump What else do I need to do? Cheers -

Probably been sitting for ever

-

Yeah I understand