-

Posts

17475 -

Joined

-

Last visited

-

Days Won

134

Everything posted by yoeddynz

-

I used a carbide tipped lathe tool to cut a mirror for the Viva wagon. It was messy but it worked. Discovered however that I cant do corners... so I rounded them with the angle grinder... even messier. Rtv hid the edges....

-

It looks so lush. I was very tempted by this myself but.... no spare coin. Maybe one day.. but by then they will finaaly be hit with Mazda tax and out of reach.. Anyway- I have this that I'd bought in the UK at some random swap meet. Might be of help! I want to keep it but totally happy to post it up to you. You use it/copy it and when finished post it back. PM me your address.

-

Just roll down the window, leave it in second gear and cruise. Wave friendly happy waves at the angry people. It's what I do in my wagon. Smile. Tis no time to be angry... we'll get there eventually.

-

Awesome!!!! I love this sort of money saving. I always look at tool chests that cost anything over several hundred to thousands and wonder who would spend that sort of money on a bloody tool box on wheels. Rich folk I guess. Good job man. Looks so tidy! You blatantly need a bright red F40 to park in there for sweet photos.

-

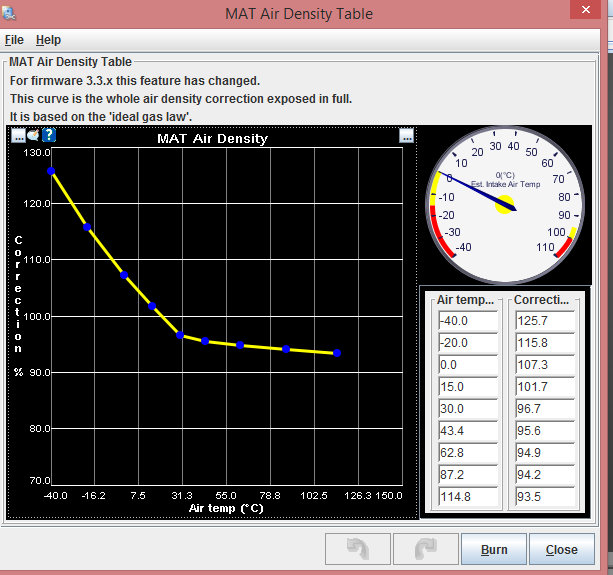

^ This...I think might possibly be happening. I have now got the setup returning from the rails to the tank and the over flow on the surge also returning to the tank. We took the car for a drive to the big smoke that is Motueka. Nothing really wrong with performance and every thing is smooth but with noticable noise from the main pump. I thought it might be low tank volume as I only had 7 litres left. Filled the tank up and noise still there. Got home and climbed under car with engine running. Surge tank is only jus warm to touch so that problem was solved. However the main pump has a noisy cavitation sound. So as much as I thought my Carter lift pump was the boss and was pumping heaps of good volume, the main pump can obviously pump even more. But why the cavitation sounds when the tank is full??? Is the main pump for want of so much fuel that the lift pump cant supply that it then starts to draw air through the overflow pipe which enter the tank nearer the top? Well luckily its going to be a piece of piss to re-route the rail return back to the surge and then block off the extra inlet I had added onto the fuel tank. With this done I am hoping that the surge tank wont get so hot either, having discovered the blocked filter and replacing it which will should give the lift a new lease on life. Plus in other news, related to the above as I thought it was the hot fuel issue causing it, I have fixed the heat soak surging. 1 minute of table changing on that Mat correction thingee before we took off and it seems to be sorted. Having left it outside the steel merchants while I picked up supplies and then outside the supermarket later on and neither time did it lean out after startup. Sweet! I will play with it some more as I think I can get it even better. Interesting to watch the air temps changing with use too. Anything from sitting at 25 degrees when driving along to around 45 degrees after the car has sat for a while turned off. The new table here...

-

Yeah Ive been reading up about this and it seems that heatsok is a common problem for IATs. This is my setup- the sensor is under that big pipe just down from the elbow (ooooohhhhh...about right above that big black hot radiator thingee..).. The sensor, a GM one from a V6 commy, was originally in the airbox on the commowhore. I figure they do that to avoid heatsoak issues. Smart. So yeah.. I could move it away but I might try playing with the table first as its easier. Plus I like the fact the sensor along with its wiring is hidden (which is why I put it there in the first place)

-

Going back to my long term problem of lean out surges after a hot start.. OK I have had another look and scratched my chin. I think I have worked out how the Mat correction thingee works! This is my current table... So what I think is happening is this.. Say I drive to the supermarket. When I arrive I turn the engine off and go do my shop for the finest sausages and beer one can buy. Meanwhile as I'm inside picking between dark malts and Ipas the heat inside the engine bay soaks into the big alloy tube between the filter and the TB. The IAT sensor positioned just down from the TB gets warm itself (even though its plastic its still going to warm up). I return with my goodies and start the car. The ECU now sees a much higher temp than what is actually getting drawn into the engine and pulls some fuel out. Lets say it thinks the inlet temp is 50 degrees. According to the MAT correction table above it will pull 10% of fuel. Hence the engine runs lean for a minute or so until the pipe and the sensor cool down. Then it slowly returns to normal. So If I play around with that table and alter the graph so it doesn't pull so much fuel I should see improvement. Considering my car is N/A and we never get much above say 35 degrees on the hottest days here then I should be fine doing this. Is this correct? I will try it out and see.

-

As promised... look at that paint dry.... Battery box is all done. Forgot to take photo of wooden lid and a strap to hold it down, made from the nylon belt from some old endura bike shorts. I knew it would come in handy one day.. I couldn't resist..I had to cut open the filter for a look. Wow.. Ok.. so yeah.. that'll be a bit blocked then... I refitted the tank, added a new line so now the fuel rail return runs straight to the main tank and the overflow from the surge tank runs into the other new tank fitting. I ran the system through to clean it before connecting to main rail feed. Started car.. ooohhh. Much quieter and seems a bit smoother. Popped the car outside and plugged the laptop in. Watched it warm up and waited till it was off the warm up enrichment. Idle was tad out so a tweek here and there. Its better but more importantly it should remain consistant. I still have the lean out idle surge in the first half minute after starting the hot engine when its been sat a while. I have suspected for a while that this might be due to heatsoak from the hot bay/radiator area into the inlet pipe where the inlet temp sensor sits. Maybe it sees a much higher temp and alters the mixture? I dont know? The temp sensor is plastic bodied and insulated from the alloy by some foam. Hmmm. I need to work this out as its annoying. Some one suggested ages ago to turn off the 'use inlet temp at startup' feature.. but that would only affect the fist startup and few seconds after? Its starts fine as is, hot or cold, but just starts to stumble up and down for a half minute. Any ideas? You can tell me here... Anyway.. I decided that the car was a bit dirty and was due a wash. The evening was warm so Kevin the cat and I gave it a clean. Kevin actually only played in his bowl of water, chasing sticks. I cleaned the car. I might even apply some wax on it in the morning since its so clean...

- 131 replies

-

- 20

-

-

Its 1/4"- same as the stock return as what was in the mazda the engine came in. Anyway- its all much betterer. I'll update the thread

-

Nathan right. The lift pump, being able to flow more than the main pressure pump, should fill the surge tank and then over flow back into the fuel tank. There should be no pressure build up within the surge tank.

-

I'll have to draw a picture. But not right now.. its late and I have a movie to watch.

-

Yep. This. Tank did have some crap in it. But my dumb fault for not checking filter earlier. I have learned.. Tank now clean and cleared out. It does show sign of light corrosion so at some point I'll buy some tank seal stuff and seal it.

-

Yeah the carter flows way more than the main pump. It's just a low pressure job but lots. I'd bought it from green brothers racing as they recommended it to feed my carb fed 12a turbo.. which I definitely wanted to make sure was well fed. Bart.. can you draw me a picture of what you just said? Make sure it includes a little datsun sideways on a port hills road.

-

Ok.. so after having typed all that the night before and having had some good replies in the tech thread I decided I needed to bench test it and do some chin scratching. I'm glad I did. I found the main problem. out from car and jury rigged up on bench... I discovered that the lift pump was hardly dribbling anything out. Hmmmm. Whats that pre filter like then??... oh.. I removed the filter and wow- proper flow again. I'm amazed the engine was able to run at all!!! So Hannah was heading to town (the big smoke) and would pick me up a new filter. I then decided that while the pumps were out I might as well pull the tank out and add a second return so I have options. First thing was to make things safe before I touch the tank with items of spark or flame. I taped the tank filler onto the trusty old Hiace exhaust and ran it until the tank was purged out of traces of fuel or vapours.. I machined up a little fitting with a nice flat thin section that would provide a good surface area for solder.. I soldered that in place and sat the tank aside. Now since the tank was out I thought it might be a good time to get rid of the horrible large ugly plastic battery box taking up space in the boot and do a similar recessed box like I did on the wagon. I measured the battery and made a box.. Then I cut a big hole out of the boot floor. I did it in that order because my Co2 bottle is about empty. I did not want a large hole that I could not fill. The box is in place now and just needs some paint. I'll continue this very exciting update tomorrow with a photo of some paint drying

- 131 replies

-

- 10

-

-

Hi.. its been a while. I blame a rusty old Hb wagon and a needy cat taking all my attention. So i had been discussing some fuel issues with this car in the DIY fuel injection thread. I'd found the main problem but Ive continued on with some other work so an update was possible. (Please ignore the next wall of text if you'd already read the stuff id written in the above mentioned thread over the last two days.) Well then..back to this old thing. Here comes lots of words... For ages, actually since I put the V6 in, my current fuel pump arrangement has been like this... But for quite some time it has been a bit noisy especially when its hot outside. One time when arriving at my parents place in Blenheim on a stinking hot day (maybe 35 degrees..not Aussie hot but hot enough! ) and moving the car about on their hot asphalt the engine started idling lean. I felt the surge tank and it was really bloody hot. What I figured back then was that the hot fuel returning from the fuel rails was going back into the surge tank and the engine was not drawing enough at idle to bring in fresh cold fuel from the tank. This is possibly compounded by the fact that the surge tank is filled by a low pressure high volume Carter pump I had been using when the car had the Rotary. So on that day I ended up making the fuel table richer at idle to compensate and that worked fine for when the day was hot as but usually it just means the idle is too rich. I finally had got around to putting the Viva up on the hoist and having a look at things. I decided to add a tee to the return line went from the regulator on the rail to the surge tank. I then ran a line direct to the the return on the main tank and connected the overflow from the surge into the spare input on the tee. This did not work. In fact the pump was way noisier and engine ran lean. So I tried running the return straight back into the main tank and blocked off the overflow. I figured the surge tank would still fill up as any air would get drawn through. But no.. air does not sink... So that didn't work either. I've connected it back the way it was as I was in dire need to go for a strop over the hill to show off the car to my cousin. I took a photo and this what its currently like- you can see the brass tee I'd added when mucking about... After doing more research (that would be looking at stuff on google..) I have noted that almost all surge setups are like mine. So they all have the same potential issue of rising fuel temps within the surge tank. To me it makes more sense to have the return to the main tank.. so long as you have a lift pump that will always keep up with demand and keep the surge tank full. But the surge will still require a overflow to purge air out and that needs to go to the same return pipe on the main tank. I don't think I can run the return from the rail into a tee on the overflow line that goes from the surge to the tank because the higher pressure would override the lift pump pressure and prevent it filling the surge. Man that's a tricky one to type..or picture. I figured I could add a second return into the main tank and run the rail return into that? All I know is that I need to stop the hot fuel going back into the surge. I don't really require a huge surge tank as the car does not see any D1 hardcore action. But if the main tank is low its nice to know I wont get any starvation out of a tight set corner heading up Takaka hill for example.

-

I was wondering.. bloody poverty spec ecu. .. But I reckon I could still fit a 12volt stabiliser to the pump feed before the relay. Have it so the pump always sees a set voltage must surely help in consistency ?

-

Yeah its always awesome when ya find a proper fault and an easy fix. I honestly don't know how it managed to run like that..but no wonder the main pump was making all sorts of sucky cavitation sounds. Glad I'd fitted a filter but the maintenance man needs a kick up the bum.... Still going to play about with fitting a return back to the tank and see if it drops the temp however I bet with good flow now the surge might stay cooler. Plus interested in digging out more info on pump voltage stabilisation and that 'proper width monkey' stuff Dave was talking about. Moral of the story is..don't rely on your cat to maintain your fuel system because it obviously doesn't work.

-

Technology scares me Dave.. it was a bold step going this far. But yeah- actually I never realised my MS has a pwm to control the pump. I'm pretty sure all my outputs are used plus are the pwms able to handle the current of a fuel pump? I need to learn more. The pump was is a Fuel miser(misery) replacement for a commy, V6 I think, so should be about right. Anyway... I think I may well have found a major contributor to the problem. Please see here in photos.... Crikey. That was a lot of shit. In bench testing the lift pump was barely skirting out a dribble. Fuck knows how the main pump was able to even get anything let alone run the engine!!!! Removing the pre-filter and the lift pump went from a dribble to a bloody good flow. Hannah will pick up a new filter today and while this lots out Im going to add another inlet to my tank so I have another return option. I think there may well be some re-mapping coming up.....

-

The lift pump won't run the engine but I think you mean run it through with engine running? I highly doubt the presure pump would or could create this sort of heat though.. especially in a recirculating system. I can disconnect the lift pump and the system will still work.. I discovered this early on one of the first drives over to Blenheim where I'd stopped to just check the setup for leaks and realised I'd not reconnected the leads to the lift pump. I think those commy external pumps can suck enough to work that way. It really needs to bench tested I reckon. Might do that. Wondering if the sound at idle, a high pitched gurgling sound, could be cavitation? Only noticeable at idle but then again once moving it would be hard to note any sounds over road noise. It's annoying as its the loudest aspect of the car. I'll certainly add more rubber mounts than I have to try and quieten things.

-

Cool ! I've not done any arduino yet. Looks like a good place to start. I think..

-

My rails are cast alloy and already have plastic washers fitted ( superior mazda technology...) I think it's heat soak from sitting in the vee and the fact that warm petrol just circulates at low revs. Is your return straight to the tank ?

-

It just seems odd to have to fit a fuel cooler when it should be getting fresh cool fuel from the tank anyway. Plus lack of room, hassle of having extra crap under car. Yeah Nathan, I was wondering about pump controllers. But spendy plus if it was plumbed right it shouldn't need one. I think. Im mean the performance is fine except this hot fuel issue. Oh and the problem with fitting larger return from surge to main tank is the weakest (smallest) link will be the small 6.5mm inlet into the tank. That will always be the restriction. If I bother to make that bigger I'd rather just add a second return inlet into the main tank instead - run one from the surge overflow and one from the rail return. hmmmm

-

I'd have thought Link would have a fairly helpful help section or forum? I don't know Link ECUs at all so I cant help. Ok people of EFI.. I need some advice/help with surge tank plumbing. For ages my current fuel pump arrangement has been like this... But for ages it has always been a bit noisy especially when its hot outside. One time when arriving at my parents place in Blenheim on a stinking hot day and moving the car about on their hot asphalt the engine started idling lean. I felt the surge tank and it was really bloody hot. What I figured back then was that the hot fuel returning from the fuel rails was going back into the surge tank and the engine was not drawing enough at idle to bring in fresh cold fuel from the tank. This is possibly compounded by the fact that the surge tank is filled by a low pressure high volume Carter pump I had been using when the car had the Rotary. So on that day I ended up making the fuel table richer at idle to compensate and that worked fine for when the day was hot as but usually it just means the idle is too rich. I finally had got around to putting the Viva up on the hoist and having a look at things. I decided to add a tee to the return line went from the regulator on the rail to the surge tank. I then ran a line direct to the the return on the main tank and connected the overflow from the surge into the spare input on the tee. This did not work. In fact the pump was way noisier and engine ran lean. So I tried running the return straight back into the main tank and blocked off the overflow. I figured the surge tank would still fill up as any air would get drawn through. But no.. air does not sink... So that didn't work either. I've connected it back the way it was as I was in dire need to go for a strop over the hill to show off the car to my cousin. I took a photo and this what its currently like- you can see the brass tee I'd added when mucking about... After doing more research (that would be looking at stuff on google..) I have noted that almost all surge setups are like mine. So they all have the same potential issue of rising fuel temps within the surge tank. To me it makes more sense to have the return to the main tank.. so long as you have a lift pump that will always keep up with demand and keep the surge tank full. But the surge will still require a overflow to purge air out and that needs to go to the same return pipe on the main tank. Am I right? I don't think I can run the return from the rail into a tee on the overflow line that goes from the surge to the tank because the higher pressure would override the lift pump pressure and prevent it filling the surge. Man that's a tricky one to type..or picture. I figure I could add a second return into the main tank and run the rail return into that? All I know is that I need to stop the hot fuel going back into the surge. I dont really require a huge surge tank as the car does not see any D1 hardcore action. But if the main tank is low its nice to know I wont get any starvation out of a tight set corner heading up Takaka hill etc. Obviously newer cars have in tank pumps with sumps etc so they don't starve nor do the pumps get hot. I'm not keen on having to build a whole new tank nor do I have a heap of room where my current setup is mounted. Not at all keen on a setup in the boot as my boot space gets filled with bikes or camping gear often and I dont want added clutter. Ideas? I might sleep on it... P.s.. Also I am wondering about the effects on fuel pump pressure when the voltage from the alternator goes up and down. If my car bogs down at idle due to my idle not being perfect (due to above hot fuel issues etc) I note that the fuel pump sound changes..like its struggling from the low voltage the alternator is putting out when the engine bogs. Does this voltage change actually make much difference to pressure at the injectors or is there enough leeway from the fuel rail pressure regulator to compensate?

-

Im interested in finding something that works. My speedo reads about 10% fast. It cant be that tricky to make something that slows the pulses down to whatever you need the speedo to see? But I aint a techy geek so its beyond me. Spending $100 on something is beyond me too.. Calling all Neds.. calling all Neds. We need your help....

-

Plus there are a couple hooning about my region that are definitely Bogan spec. But not mighty wagons..

.jpg.a68a3028369a7f3281dcaee1e1f9acc0.jpg)