-

Posts

439 -

Joined

-

Last visited

Everything posted by Hyperblade

-

TRS was good as they had new set each weekend so it forced them to get rid of them early, so sometimes they tyres had only done 1 race. With these guys running the old cars I suspect they will run the tyres into the ground (using in testing etc) since they aren't in the same type of competitive series with the same type of money being thrown at it, but very happy to be proven wrong on that one.

-

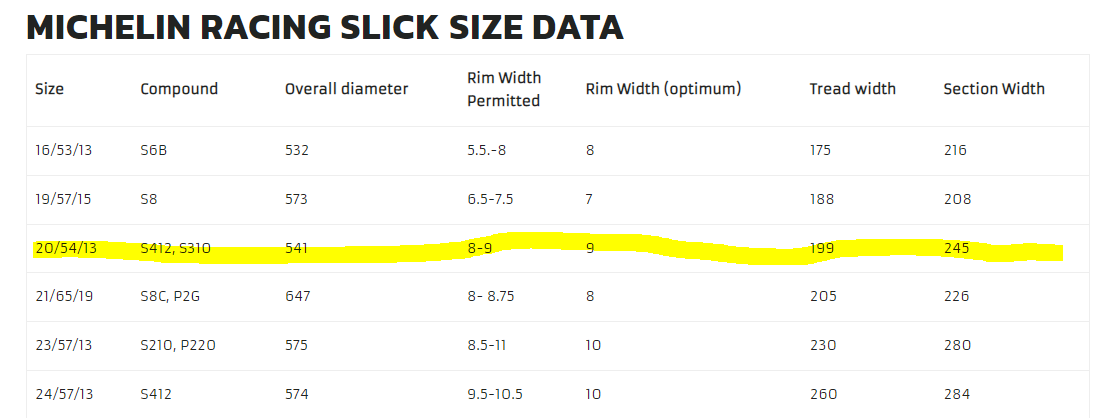

So... The Michelin TRS tyres are/were absolutely awesome (They are a F3/F4 tyre), they work from cold, have amazing amounts of grip and were cheap, hence why I run them. So for track days they would be perfect for you. Unfortunately with the latest TRS Chassis they changed rim and tyre sizes and moved the rears to the front and went bigger again on the rear. So the easy access to these tyres is now gone and everyone who was running them are hoarding them (like me) . The new tyres on the TRS are Hankooks which are nowhere near as good. You can still find the old tyres but they will be at least 2 years old (not really an issue they are still amazing) but it's a lot harder to find a decent set as they are usually pretty worn. Compared to semi slicks there is no comparison, they will have more grip and will last a shit load longer. Just to be aware the tyres were designed for a 9" rim, but most guys run them on 8" rims, this means they bulge out to 220mm but tread is still 200mm they have a diameter of 540mm. The new TRS fronts require a 10" rim and 580mm diameter. The rain versions I've been told are amazing in the wet, the grip is like driving in the dry. A lot of guys use them for hill climbs and sprints where you need "treaded" tyres. If you want new slicks you are looking at around 450+gst a tyre, and I can put you in touch with the person who brings them in, seems like a lot but for you they would probably last many years and still be faster then semi slicks. For pressures run them at 21 psi hot and don't let anyone else tell you otherwise, yes it will be slightly rolly, but get used to it and the grip and life of the tyres is that much better, just be careful on initial warm up as you will be starting at 15-17psi so avoid curbs etc.

-

Are you sure you want to run that clutch plate on a street car? Unsprung clutches are generally not advised for street driving as the start/stop loosens the rivets holding the clutch plate to the hub. And they work the input shaft wearing it. So the manufacturer I talked to only advised using it for drag cars. On the flip side, your right it should help the synchro's due to the weight my mechanic runs unsprung on all their rally cars and has no issues, but they also run sequentials most of the time.

-

Cylinder head bolts: 39Nm (29ft/lbs), 90 degr, 90 degr. (One extra 90 on new bolts.) Main cap bolts: 29Nm (22ft/lbs) and 56 degr. Girlde bolts (M8): 22Nm (16ft/lbs). Rod bolts: 29Nm (22ft/lbs) and 90 degr. Valve adjustemet locknut: 19Nm (14ft/lbs). Valve cover bolts: 12Nm (8.7ft/lbs). Chain tensioner bolts: 12Nm (8.7ft/lbs). Cam holder bolts: M8 22Nm (16ft/lbs), M6 12Nm (8.7ft/lbs). Intake Cam Gear: 112Nm (83ft/lbs). Exhaust Cam Gear: 69Nm (51ft/lbs). Timing chain cover: M6 12Nm (8.7ft/lbs). Crank Pulley: 245Nm (181ft/lbs). Flywheel: 118Nm (87ft/lbs). Spark plugs:16Nm (12ft/lbs)

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Thanks, its been a hard slog, once I can stop worrying about the car I can then focus on my driving so should be some good improvement still to come. It's always easy to forget all the little issues you have with racecars and the improvements you make over the years. And the actual success you're had. As your so focused on the next issue. That's why it's cool sometimes looking back through the old videos and realising how far it's come. Once everything is sorted, I have worked out how I can put a flat floor under whole car including rear axle, so that's the next long term project, but no point doing that until happy with car handling now. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

So this is a hard question to answer, here goes... Before I put the k20 in I was having suspension issues, and it turned out valving of shocks were wrong (to hard), I got that fixed but never had a chance to run on track and check the results. The rear brake pads (that were to aggressive) were also put in before the engine change (I'll explain why this is important later) So along with the 30kg lighter engine and it being set back a long way giving 52/48% weight distribution (previous 57/43%). The new alignment also changed the front camber from 3degrees to 4.25 Along with the new engine we lengthened the wheel base front and rear 50mm each for total of 100mm (same as ae86 now) The rear diff has changed from 4 angled links to 3 link with watts linkage. The rear lsd has new oil and been tightened up. So definitely just a single change like everyone recommends doing... So it makes it harder to pinpoint a single cause for improvement. I can say: The car is more predictable on the limit, it's really controllable when it goes over. This is likely because of the longer wheelbase. The rear grip through the corner and out of it is substantially better, this is likely because of 3 link. But weight distribution can play a part. I feel turn in is better, with the previous setup it really wanted to understeer in and also out of corners. I feel the understeer is a lot better. This would be down to weight distribution but can be affected by the other stuff. However in all of this is the issue I've been having with rear brakes locking so I've had to be gentle on brakes and a lot longer on them, this has meant it's really really hard to consistently hit the apexes as I don't know where I'm actually going to stop so I always leave a lot of contengancy in the braking zone, that means I end up finishing my braking early which then means I'm coasting to corner so don't have the weight over front wheels to help turn in. So I think it's helped but still need to adjust my driving style to suit now. Overall I have a lot more faith in the handling then I did before which allows me to push it more. It feels more complete as a package. So I think it has made a difference. TLDR: yes you should put a 180hp Prius motor in your carina set way back it would handle way better then having that heavy cast iron block hanging over the front end. Or dropping the whole lot in the back might be easier long term. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

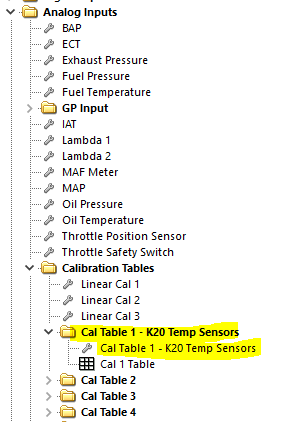

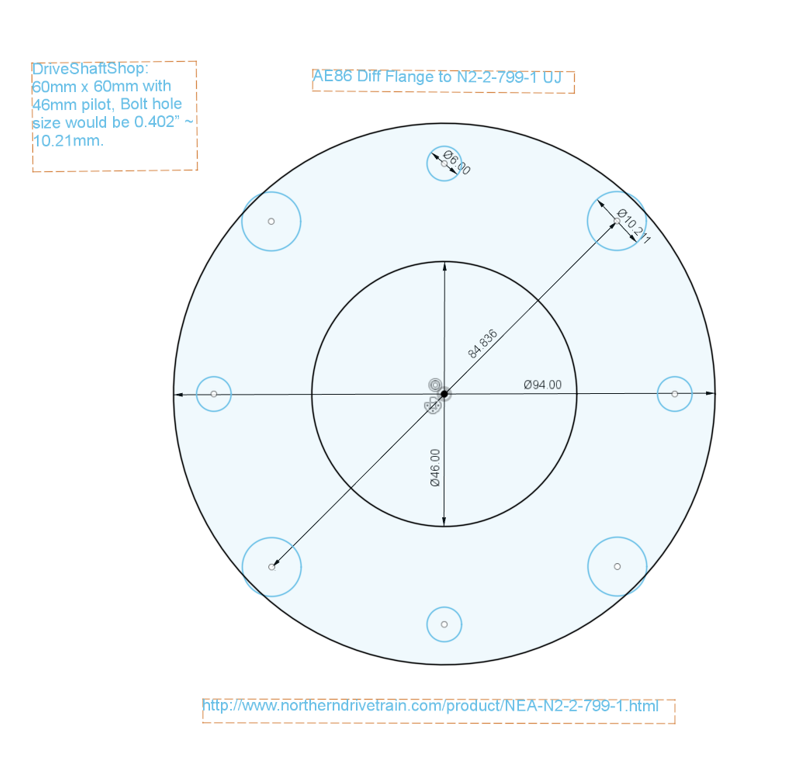

So back out for a shake down with the new thermostat and when the car was allowed to sit in pits for 20 mins it could get up to temp can maintain it out on the track when pushing hard, however as soon as I eased back it dropped to 70c then had trouble getting backup to 80c. I did manage a new PB though of a 1:35.100 which i was pretty stoked with. So getting completely over the whole temperature issue by now and the first race day coming up I decided to put a bypass hose in from the thermostat back to the pipe going into the water pump. Idea being the thermostat only lets in cold water when it needs to. So while testing that on jackstands, I happened to have my dad over who was checking out the temps on the hoses as it warmed up, and he noticed the thermostat appeared to open at 70c, which for an 82c thermostat shouldn't be possible (as thermostats these days are fairly reliable in their operation). Some head scratching and thinking later... In the link firmware I had originally configured the base map off one LinkEcu had done, and they had manually added in K20 temp sensor calibration. Since then LinkEcu have released a plugin ECU for Civics with K20's and they have set up a pre selectable calibration for "Honda K20" temp sensor. Swapping over to that one immediately increased the ECT temp by 9 degrees, meaning it's been running a lot hotter then I was expecting and throwing all the water pump stuff way out. Having seen numbers of 92 degrees in my logs which in reality meant 101 degrees, that's a little bit concerning, we don't think anything's been damaged but it could have been a lot worse... Once that was changed, and with the new bypass the car warmed up within 5 mins, and was a lot more consistent in it's operating temps. Also found my rear brake pads were not the compound we all thought they were (they were more aggressive then the front), so put a new less aggressive set in So going straight into race day and into Qualifying my goal was to make sure Water temps were ok and bedding in the rear brake pads. Qualifying went well with a 1:36.800 which was pretty good considering I was busy doing the above. Water temp was consistently over 80 degrees even when just driving easily around the track. The new brake pads were a big improvement, I had previously been struggling with inconsistent rear lock up, it turns out the old pads would heat up then suddenly aggressively bite which immediately wants to make the car swap ends, to combat that I had been braking lighter and longer which was affecting hitting the apex and general braking distance and also my confidence in passing under brakes. So lined up for Race 1 and got a brilliant start, was doing well holding off a high powered 4wd Subaru, then on lap 2 my clutch pedal went to the floor and wouldn't come back. Looking underneath the car we can see a clutch plate spring coming through the release fork hole in the gearbox... It was an S2000 Exedy HD clutch in a light weight car which hasn't done a lot of work, so pretty pissed off about it all (the same type with the 3SGE lasted over 4 years of hard racing) So currently looking at options for replacement, and hoping there isn't to much damage in the box.- 78 replies

-

- 19

-

-

-

There is free entry to spectators at the first round of Canterbury Club Club Mag & Turbo Race Series this Sunday (14/08) At Ruapuna Raceway https://www.google.com/maps/place/Ruapuna+Raceway/@-43.5381515,172.4851566,14.5z/data=!4m5!3m4!1s0x6d31f5e57000d139:0xdd53fa61bab90227!8m2!3d-43.531912!4d172.486425 Racing starts at 11:30am and goes till 4ish. You can check out some of the cool cars that will be racing at https://www.cscr.nz/driver-profiles Lots of interesting cars will be out there ranging from old classics to modern race cars.

-

- 5

-

-

I use Avidemux (http://avidemux.sourceforge.net/) for basic chopping and combining.

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Yeah it does seem crazy small. However Davies Craig thought it was ok. And it's what I've been recommended by someone who uses it on all the race escorts, mazdas etc. He said it's surprising how much water actually flows through a hole that small. The other thing to keep in mind is that on a circuit car on the warm up lap where your going slow (70 to 100kph) with low rpm but have quite a bit of airflow over the radiator so it's hard to get it up to temp. But at the end of the day I won't know until I get it on track and easy enough to make it bigger, then to make it smaller! I wanted to avoid a bypass pipe as it just clutters up the engine bay and adds more points of failure, so hoping this solution works. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So had the car out to a track day with the new driveshaft and I can finally say the vibration issue is solved. So that's a massive win. Here's some footage (track day so no passing allowed on corners) Car Handling Car handling is taking a bit of getting used to, traditionally when i was mid corner and I put the power down it would want to oversteer. When you get on the power now it actually get's more grip in the rear but also turns in more, which is a very unusual feeling to get used to. But a positive one that I need to adapt to. I ran a 1:36.500 without going crazy on 4 year old tyres and 15 degree day (with only one clear lap), which is down to what I was doing before, so that's nice to finally get back to that. Next target is PB of 1:35.800. Water temperature Water temperature is still an issue however, just hard to get it up to temp quickly. Which won't work for one warm up lap then standing start race. I've been trying to avoid putting in a thermostat as there isn't a lot of room and it's a clean simple setup at the moment (the stock setup is long gone as it weighed 5kg and was in the way of the engine mount) So I finally bit the bullet and after 2 weeks of mucking around with stores in the UK finally managed to convince someone to take my money and ship one out to me. I got the smallest I could find, it takes a classic mini thermostat (82c). I've drilled a 2.5mm hole in the thermostat to keep water circulating through at a reasonable speed. Space is very tight to fit it in and I didn't want to muck around putting it under the intake manifold as it would make it a real pain to service if needed. I only just managed to fit it at the top inlet on the radiator with some gentle persuasion of the oil cooler ducting, not pretty but it works. EWP Setup So my original EWP setup (by the tuner) was a running the water pump at Frequency of 0.6Hz (we will come back to this) and I had been changing the table to try and get it to find a happy medium by itself, so between 80 and 92 degrees letting it scale up as required. This just wasn't working (without thermostat), and I was concerned with the frequency what impact that would have on the pump life as it was basically stopping and starting it 0.6 times a second, which didn't seem like a good idea (but I'm not an expert in this area). So I sent support email to Davies Craig (who make the water pump) for advise on its limits as I was a little concerned by how it had been setup by the tuning shop. Their support staff rung me and spent over 45 mins on the phone to me going through the possible causes and solutions. That's amazing service for just a simple water pump. They said the pump should be fine for my setup (I was thinking it was overkill) and that they hated restrictors and didn't recommend them due to it restricting the max flow of the pump. The best guess was that the radiator was super cooling the water, so when running through the engine it was to cold and so never allowed the engine to get to the right temp, and then when flow increased it dumped a lot of cold water into the engine block, detected it was cold then slowed the pump again. Basically the pump was running too slowly (which seems exactly like what you want when your trying to get the car up to temp). They also confirmed running it at 0.6hz was a bad idea, after some discussion on the pros and cons of higher vs lower frequency (higher = less noise on the circuit) we went with 100hz. And a completely different table. The idea is the thermostat always has steady stream of water flowing over it through the 2.5mm hole so it's bulb will always be reacting fast to the water temp, it allows the whole circuit to heat up and also means the water is flowing through the block faster so means more consistent readings at the ECT sensor and spends less time in the radiator. So up to 82 degrees the thermostat controls that flow, as soon as it goes over that the thermostat starts opening and allowing more flow so so should self manage it, the EWP is then set to max out it's flow as we get closer to 100 degrees, so should eventually settle at a happy medium. Testing on jack stands shows quite a different characteristics in how it gets up to temp and holds it, so I'm cautiously optimistic we might have solved the issue (bar minor tweaking). But on track is vastly different in terms of air flow, so need to get it out for another shakedown. Racing starts 14th August, so need it all sorted by then.- 78 replies

-

- 23

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

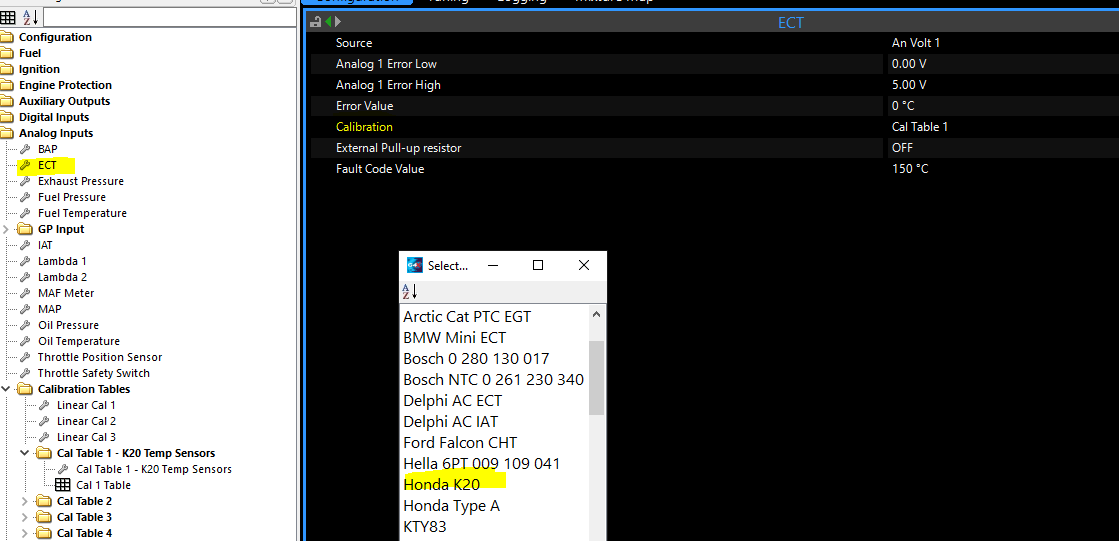

So... Diff flange was all fitted up and the driveshaft was fitted and then checked against the instructions from The Driveshaft Shop, and it was too short... It was extended as far as it could go so could not thrust out if required. To say I was disappointed would be an understatement. I had even double checked the measurements on the quote via email before ordering and asked if it took into account the thrusting and they said yes... When building a driveshaft it's a fundamental measurement, to fuck that up time and time again as I had been pre warned shows that they don't have the process and checks and balances in place to ensure the consistent quality of their products. I contacted the original salesman and he was very responsive, he got me to take measurements with driveshaft in place and quickly had a spacer for the rear diff made and shipped out to me at their cost. (luckily the driveshaft was short, if it was to long that would be an interesting discussion...) Once I had the spacer I made up the heat shielding for the front of the driveshaft, the carbon shaft has warnings on how hot it is allowed to get, and also I want to protect the CV joint from getting exposed to to much heat to prolong it's life. I have a new speed sensor on the way as my one is behaving really weird (cutting off the signal at 5000hz), hoping that solves the problem. Next step is get the car out on track again for a shakedown to see if I've improved the way the cooling works and fingers crossed the driveshaft solves the vibration issues.- 78 replies

-

- 22

-

-

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Flange has been done, and will get fitted this week. I can run the current driveshaft I have or the new one. Just press fits over existing flange. Original flange probably would have been fine with the forces involved and the fact it would have mainly been a clamping force. But I decided it's just not worth running the risk considering the catastrophic consequences that could occur. Come up great. So it turns out 0.5mm aluminum wont withstand 200km+ who would have guessed, I am surprised it actually survived a few laps. I had strengthened the bottom edge, but ran out of material before I could do the rest and got the car on track. Repaired version, with nice rounded edges for the airflow (not that I need any extra, keeping the car in the temperature zone is actually the biggest issue). Painted and it fits in nicely (ignore raw unpainted panel below, at some point will get splitter off and paint that, but not a priority). Sharp eyes will notice the grill is open, once car is fully shaken down and working how i want, then I will blank that off and feed cold air into the intake from the left headlight. Very long term It would be nice to have a fibreglass/carbon piece that replaces the grill, headlights and side lights as one piece, then put a vinyl photo on it to make it look normal. would save a couple of kg and be a lot more aerodynamic.- 78 replies

-

- 17

-

-

As has been pointed out removing the drip tray won't help you as to close to the windscreen, the WRC Yaris are further away, plus they have designed it in wind tunnel. Couple of vents in front of bonnet would work extremely well. Could try and vent engine bay into wheel wells, but then you need to get that air out so would need vents in the front guards. Front splitter just to brute force pressure at front to cancel out the lift. Another option that isn't as drastic might be to add a front bumper lip. My thinking being your trying to reduce the air going under the engine bay, which allows more of the engine bay air to go out under the car, overall dropping the pressure, hence less lift. Bonus is I have a brand new roll here that I never used which you can have, pm me your address and I'll send it up if you want it for this.

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

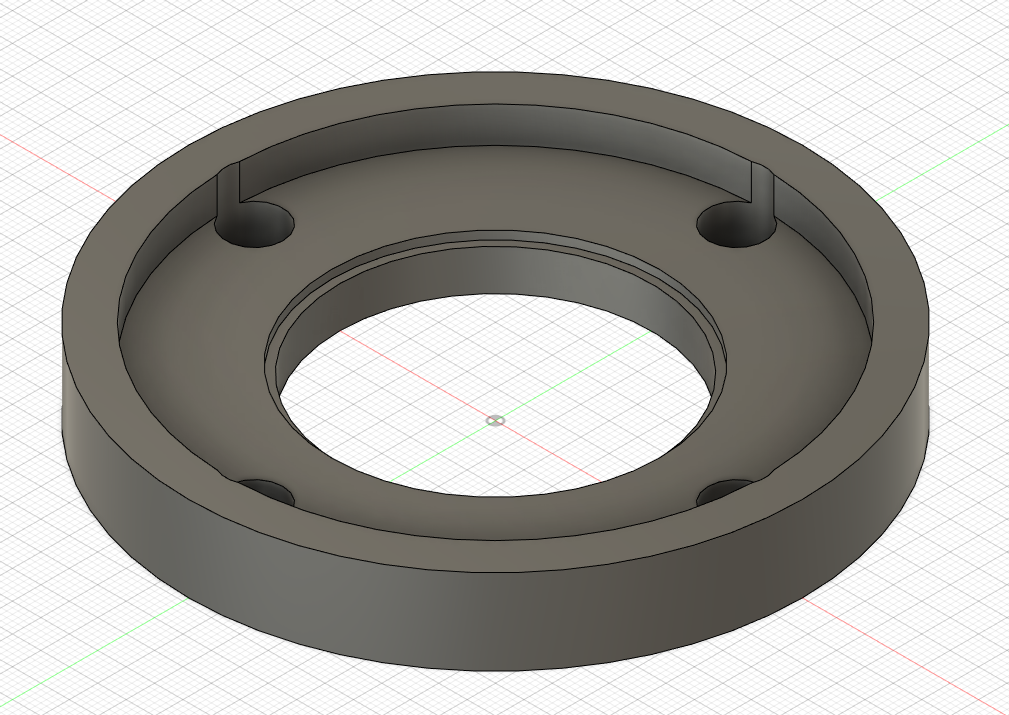

Thanks! I had seen your post and was keeping it mind, only reason I didn't go with you for the flange was I had spent quite a bit of time discussing it with Bert, so don't like to do that to him. The reducer I finally got in the mood to do some work and just wanted to get it out of the way, some better planning from my end and I could have got you to do a much nicer job then I did! I'm sure I'll be in touch at some point in the future We had a look at it but was different sizing. I also need to be very careful with where the diff flange is positioned as the only in and out movement in the driveshaft is the CV joint which is limited to 10 odd mm each way so diff flange can't change position. No big deal, I drew up the AE86 flange in CAD with where the new bolt holes are going Then designed up the adapter flange which will go over the diff flange from the back Should be pretty straight forward on a lathe, and will give the diff flange the extra strength required, not worth taking a chance on just the AE86 diff flange when the driveshaft is spinning at 9500rpm. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Thanks! I alluded to it in my post, but the retarders on the dyno had changed from 110v to 220v, so it's not an apple to apples comparison, i.e if it was on the 110v it may show a bit more on the sheet. Yep all of those apply, the engine has a lot more easy potential then the 3SGE if I want to go down that route. Probably the thing to do next would be a decent set of quad throttles, as I'm sure my intake isn't ideal with the double bend, but that's a lot more money then I want to spend at the moment, need to get the car consistent again first and actually do a full race season. After the last shakedown and being able to stay in the throttle all the way, I can safely say it really pulls hard in the top of the revs i.e from 7000 to 9000 the power just does not drop off like the 3SGE did and the beauty is on gear change it drops to 6700 again right into 200hp again, unlike the 3SGE, so it accelerates really hard. It feels very different in a good way. I'm also hitting max RPM in 6th now which is around 210kph where as before I was only hitting 195kph odd, so it's certainly a fair bit faster. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Some progress has been made. Driveshaft was sent up north to be balanced at a higher speed and the UJ's were tightened. And so had it out for another shakedown at a local sprint day. First race just took it easy checking things over (pretty boring video, best to skip). Second race, gave it full beans off the line against an EG civic with K24 and 300hp at the wheels, he got a bad start... Third race on slicks and it started drizzling, but overtook a Porsche and a Lotus... The driveshaft was a lot better, enough for me to push it a lot harder in those videos. But there was still a vibration there that won't be good for components, best guess is it's the angle of the engine/gearbox in the car, front of engine angled to left to clear headers and for weight distribution which means the UJ's are not in sync. Those videos also have me mucking around a lot with the brake bias as that's been all reset, along with suspension changes affecting rear of the car during braking so still getting it dialed in (sprint day you don't get many laps). Other thoughts, is the S2000 Gearbox throw is as short as the J160 with a short shift kit, if not shorter, it's a great feeling box. Also you may have noticed in my older videos I didn't heel and toe, originally that was because it was impossible to with the stock pedal setup and my seating position, but since I have the new pedal box and seat I really needed to learn, so with the minimal seat time I've been trying to get used to it, still a work in progress as you can see in the videos. So the shake down highlighted a few issues. Driveline Vibration still there What we believe is heat soak of the oil temp sensor as it hit 123 degrees, and there should be no way the oil hits that when it struggled to get over 80 on dyno (with some of my bonnet ducting removed which allowed a breeze over the sensor). Getting car up to temp with the EWP is a pain, it's not quite right at the moment. Was setup on dyno perfectly, but the real world has a lot more airflow over radiator. So before Christmas I shopped around for a driveshaft with a CV on the front, basically came down to only one place who were prepared/could make it to handle 9500rpm. Hence a new Carbon fibre driveshaft arrived last week from the Drive Shaft Shop out of the US, i'll be honest I was very hesitant in ordering from them as I had been forewarned by a couple of people about their quality and after sales support. But I had no other options. I can say their pre sales service was good with prompt communication and fast building of it and shipping. It still needs to be fitted into the car, we are just making up a flange that goes over the existing AE86 Diff flange (from the diff side) to better spread the load from the new driveshafts rear Hilux UJ which has a bigger bolt pattern. Here's the difference between Hilux and AE86 diff flanges. Heat soak of the oil temp sensor should hopefully be solved by some new shield i created. The EWP control is a bit if a pain, the duty cycle is controlled by RPM vs ECT. Which is great but i feel it misses another key input which is the speed of the car which affects the car's ability to get rid of heat. So it feels like half the solution to the problem. You can see the duty cycle all over the place here and the pump is barely breaking a sweat (and that's with half my radiator ducting closed off). For the EWP I made up (by hand, no lathe...) a reducer to drop the coolant pipe size down from 30mm to 18mm to slow the water, it goes into the return feed on the radiator after the water goes through the engine. I'm hoping that means I can use more duty cycle in the pump, so give a wider duty cycle range to play with. I've then tweaked the table handling the ewp to try and get it to be more flexible in it's ramp up/down by letting the ECU interpolate in between the cells more, feel free to let me know if this is a stupid idea... Old: New: So once diff flange is done, will aim to get it back out for another shakedown to see if we have finally solved the vibration and see how we are going with ECT. Discussion here:- 78 replies

-

- 11

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So what everyone has actually being waiting for, the final comparison between Toyota Altezza RS200 3SGE BEAMS and a Honda Accord Euro R K20a engine in the same chassis Still trying to get my hands on a single dyno sheet with the 2 different engines on it. So this will have to do. Modifications/Setup Toyota Altezza RS200 3SGE: 120,000 k's SQ Engineering Quad Throttle adapter plate 4AGE Blacktop throttles 70mm trumpets Combined Piper Cross Filter Stock Injectors SQ Engineering Slim line alternator (smaller Echo alternator) No Power Steering pump or AC Custom header (TRD Copy) to side exit exhaust 2.5" Adrenaline R muffler Link G4+ Storm (Blue) Engine internally stock Lightened flywheel HD Exedy Clutch J160 Gearbox 3" Driveshaft with sliding yoke into gearbox Oil: Castrol 5w40 Rev Limit: 8000rpm Dynoed in 5th gear 1:1. Honda Accord Euro R K20a: 108,000 k's Skunk 2 Ultra Street Intake Manifold 770cc FIC injectors Skunk 2 74mm Throttle Body. 3" intake pipe from pod filter. Custom header to side exit exhaust 2.5" Adrenaline R muffler Stock water pump replaced with EWP Alternator replaced with smaller Honda D15 one. No Power Steering pump or AC Stock Oil Pump and Balance Shafts replaced with ported Type S oil pump. New Timing chain Lightened flywheel HD Exedy Clutch Link G4X XtremeX Honda S2000 AP1 Gearbox 3" Driveshaft with sliding yoke built into shaft as gearbox has flange VTEC 4500rpm Oil: Castrol 5w40 Rev Limit: 9000rpm Dynoed in 5th Gear 1: 0.94076 Same: Tires 54cm Michelin Slicks at 21 PSI, on same Rims Same AE86 Diff (Brakes were changed from stock to AP with knock back) 4.5555 Crown wheel and Pinion. Same Dyno Different: Dyno retarders have changed from 110v to 220v. Results 3SGE : 201hp @7250rpm 173.6 lbft @5150rpm K20a: 206HP @8250rpm 167.9lbft @5300rpm Thoughts I'm a little bit disappointed in final figure, but I think my expectations were to high. You have to take all the HP figures that everyone posts with a grain of salt. Especially anything from the UK who like to give made up flywheel figures when they dyno there cars on a rolling road... Changing from a front wheel drive to rear wheel drive setup definitely has more drivetrain loss, from what I've read a factory stock S2000 AP1 with 240/250hp at the flywheel dynos 200hp at the wheels. Also a lot of people show "stock internals" figures which include changing cams etc. So the power figure is in the right ballpark really for the modifications (stock K20a has 220ps at flywheel) as rear wheel drive. Looking at some of the NZ figures I have seen, the engine would probably get quite a gain (20 to 30hp) from a set of drop in cams (no other valve train changes) But if you ignore the single figure and look at the dyno sheet it pretty much makes 200hp from 6700 rpm all the way to 8700 rpm which is a very significant power band. So overall, it's a good improvement. Shakedown So I then got it out to the track and managed 4 laps before the gearbox lost most of it's oil when a bolt came loose. Luckily I was going fairly slowly so no internal damage done hopefully. However a bigger issue is a massive driveline vibration. Plan A: Driveshaft is getting balanced at 5000 rpm (it does 9500 rpm in 6th) Plan B: CV Front joint on the same shaft, or a replacement driveshaft. Driveshaft is to short to go 2 piece and we think the angle of the engine and gearbox is impacting the universal joints. However aftermarket CV joints for these are supposedly not very good. So currently looking at options. Car definitely felt like it was pulling really hard, but with so few laps, and me just making sure everything was working, not a good indication of final result. Videos: First 2 Laps: Second 2 Laps (where it dropped the oil): Flyby (Potato Cam):- 78 replies

-

- 15

-

-

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

No. But adding a driver in doesn't change the bias much at all. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Last bits of major fabrication done (front swaybar, driveshaft hoop) and finally had it on the scales for corner weighting. Before on left, current on right: All fluids and 30+ liters of fuel on board. Little bit off my goal, but shows how hard it is to take weight out of something. Could probably get another 15kg by going to fiberglass hatch and doors, but that's just $$$ I don't need to spend at the moment. Very happy that 35kg has come straight off the front!- 78 replies

-

- 14

-

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So managed to get it going finally after a bit of faffing around, Honda decided to helpfully change the crank sensor from EP3/DC5 K20a's to the CL7 K20a, that took a while to work out. First successful start. Starting it highlighted a weakness in the breather baffling I had done which meant oil was being pushed out. Here's Honda's original design: Here's version 1: New Version 2: Very tight fit and designed to force the air back on itself. Work has been done on the ducting into and out of the radiator and oil cooler. Radiator Exit: The oil cooler exit was a lot trickier, I needed space for the intake pipe, withour comprimising the ducting site. Pretty happy with how that's come out. Bonnet exits, still to be tided up. Big thing outstanding is the air intake, so been mocking up options. In the end I will go up with a straight simpler solution, plasitc pipe will be replaced with ali for smoothness. However I want to make sure it's got a cold air feed/box, so a bit of fabrication is going to be required around getting cold air from the head light. Here's a walk around of the whole car at the moment.- 78 replies

-

- 18

-

-

-

Congrats! I'm a little bit further down the conversion track then you which means you might find some useful information in my build thread for what your about to go through. Otherwise post up questions, and I can also try and help answer them as I've got my head around these engines now. Yours looks like a CL7 version, so a couple of things to note. They come with balance shafts which you will have to replace if you are moving the pickup to the rear, the only place I've seen offer that rear sump was Kmiata (Kpower now). https://kpower.industries/collections/kmiata-swap-parts/products/k-series-miata-oiling-solution That also needs a replacement oil pump, so it probably worth doing the timing chain/tensioner at the same time as you have to remove it to do the oil pump chain. I didn't but then realised my chain had stretched (motor had done 106,000k) by a couple of mm so ended up replacing it in the end, but i'm going for every bit of performance. I've been buying all my genuine replacement parts from Amayama as they come in a lot cheaper then anywhere else you can source them from, you just have to work out the part numbers etc. The other thing to note is the CL7 version is more like the USA K24 then a EP3/DC5 in some of it's items like water outlets etc. And the FD2 engine was based on the CL7 as well. In terms of water outlets etc I would say give aliexpress a go first, I brought genuine Ktuned stuff, and the quality was pretty poor, which means you could potentially save a few $$ by just going for the Chinese knock offs. Good luck!

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So I've been slowly chipping away at everything, with life getting in the way at times. Finally managed to get the extra baffle i needed for the sump, it's a Clockwise Motion FD2 baffle, meant to be one of the best and should be handle the gforces on the slicks i run. Of course even though the FD2 engine was initially based on the CL7 one, Honda decided to change the sump ever so slightly between versions, so had to modify the baffle to fit. Engine back out to fit it, clutch and flywheel all installed and rear main seal done while it was out as it saves possibly doing it later. Gearbox has new bearings throughout as the original ones at 140,000 k's had had a hard life. Engine and gearbox back together and all back in and shifter finally fitted. New fuel rail arrived, and could finally fit the FIC 775cc injectors (smallest with datasheet i could get for the cheapest price) and FPR to the mainfold and fitit all for the final time. Next was cooling, so I got some ali pipes bent up to a template I made, keeps it really nice and simple (and light) and the only joins are at the engine, radiator and water pump. The standard breather is on what is now the back of the engine, which is pointing at the firewall and would just be pain to route to. Also when racing best to have a good breather system so 2 10AN female fittings were added to a valve cover i stripped and then painted. Next up was the cabin wiring, a pretty significant job, and the final piece of the puzzle was the console. Actually quite challenging to make as it needs to be within reach when i'm strapped in and also handle the main cutoff switch which takes up a lot of room. And to get it looking half decent takes some planning. So first step mocking up position of switches to make sure I can reach them. I want to be able to easily maintain and diagnoses any issues with the wiring, so I then made a grame for everything to attach to. Worked out where to put the cutoff switch. Then wired it all up. I'm running some nice Deutch connectors at the rear so I can easily unplug them and check what the pins are doing with a multimeter. Final version all painted up But finally all fitted up Heres the engine bay at the moment Exhaust has been fitted for final time and I'm getting down to sorting out the last of the stuff in the engine bay (ducting, intake piping, catchcan etc)- 78 replies

-

- 41

-

-

-

I'm using the Deutsch HD30 bulkhead connectors and found them great. You can get a cheaper version HD20 which is composite instead of aluminum and they come in various mixtures of pin sizes max being 47. https://www.msel.co.nz/epages/motorsportelectronics.sf/sec69a2cb9283/?ObjectPath=/Shops/motorsportelectronics/Products/CONHDP242447SK https://www.msel.co.nz/epages/motorsportelectronics.sf/sec69a2cb9283/?ObjectPath=/Shops/motorsportelectronics/Products/CONHDP262447PK Total from msel would be $160incl But you will need the crimpers for the pins (but might be able to borrow some from someone) and personally I would recommend a mounting plate to stop them spinning. If you want to see an HD30 fitted in person just send me a pm.

-

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

Just saw your video Please go and check your seat mounting, your seat is moving around way to much for my liking Here's a recent example where a seat mounting broke, note that it was a low speed crash in the scheme of things and the belts could probably have been a little tighter... You can see the seat moving around prior, but a lot less then yours... https://www.facebook.com/sambushellmotorsport/posts/1987233984751634 Ended up with damaged ribs.