-

Posts

1005 -

Joined

-

Last visited

Everything posted by Kiwibirdman

-

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

Got a couple of hours in the garage this afternoon. Alternator back on, battery tray and battery in, some more wiring finished off. Still got some wiring under the dash to finish off, small stuff like connecting the lights from the auxiliary gauges up to the dash lights, plugging the fan for the heater in to the fuse box, connecting the brake light switch........ -

Nice car. LS1, auto and power steer would make for a perfect daily driver.

-

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

Picked the alternator up from the Auto Sparkie this afternoon. All the smoke has been reinstalled, new diode pack and bearings and shiny outside. Tomorrow morning install. -

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

One side of the exhaust is all together, will get some black paint before final fitting Front Pipe Tail pipe in mid build Finished tail pipe L Lots of time spent putting all the bits together. The second side should be much faster as there is more space around the tank and because we have an idea where the pipe will go. I haven't decided if I'm going to run a cross over pipe, probably see how loud it is, also if it sounds funny. All the other Holden V8's I have had were dual exhaust with a balance pipe. The other thing I finished was the Steering wheel and adapting the ring off the LC Torana steering wheel to the EJ Wheel. Both wheels have the same spline and depth so that was a good start. I had to grind off part of the center of the wheel to get the plastic ring to fit. Then made up a spacer to hold the ring off the bottom of the wheel. I didn't take photos because grinding with a power file looked like a hungry rat had been busy. The self cancelling worked perfectly, but no circuit through to the horn. After dicking around, pulling stuff apart I found the wires under the dashboard hadn't been connected. A couple of connectors and all tests out OK. Still have to buy a horn to make noise. The guy with the Hillman Imp van is booked to do the Windscreen and rear window next week. I'm going to chase Robinson's Instruments for my fuel sender and the auto sparkie for teh alternator tomorrow. Also going to order the drive box for the speedo, the Dakota Digital one has a lot of good reviews. Just weighting for the Visa card to roll to get the bill in to next month. Here's a photo of the steering wheel- 129 replies

-

- 11

-

-

Changed the exhaust on my Silverado recently. It has a dual 2.5 system with reasonably large straight though type mufflers. The tail pipes went out the back, one on each side, so the passengers tail pipe crosses over as both mufflers are on the drivers side. The passengers side tail pipe rusted out on the back of a couple of tight bends so needed replacing. Wanting to have a change I decided to have a side exit just in front of the rear wheel. I also thought that having tail pipes that were 600mm long would be a bit louder. The old ones were 1.5 and 2.5 long. Interestingly the exhaust is no louder and potentially a bit quieter. I am wondering that now the tips are side by side, does this has an effect on the sound, they used to be about 1.5m apart. The other thing is the pipes take a hard 120 degree turn straight out of the mufflers then another turn back to exit out the side. Could this have a muffling effect? Any ideas?

-

Looks very much like the Black and Decker that I have. Very useful to have.

-

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

Got most of the stuff for the exhaust from Autobend today. Not feeling like going down into the cold tonight. Will get into it tomorrow. Maybe the Wu Flu is coming for me............ -

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

Alternator got dropped off Friday to the Auto sparkie to get the smoke put back in. Spent a few hours working on the exhaust. I have to get the front pipes stretched to fit over the head pipes, no space to put flanges on the join and I want to be able to get the headers out so no welded joints. I will also put flanges on the tail pipes just after the mufflers. Plan to get the exhaust finished this week, should heave the fuel pump/sender unit back next week then get it started. -

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

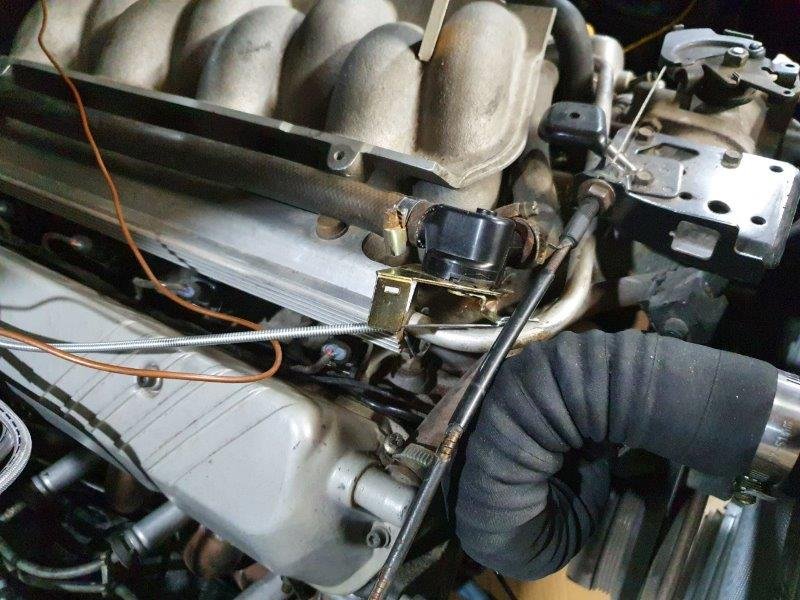

Got off my lazy arse and went down to pull the alternator out. Here it is and smells of burnt. Start of front pipes from this afternoon And a couple of photos of wiring and battery.- 129 replies

-

- 10

-

-

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

My mate who has been doing a lot of work with me on the car came round with his Mig welder to start on the exhaust. While the car was still on teh ground I decided that this was as good a time as any to connect up the battery and spin over the engine. No fuel pump so it was never going to start. After a couple of false starts, not having the main fuse in make the electrics go badly, the engine spun over OK. DId it a second time and heard a funny noise. Next thing smoke started to come out of the general area of the alternator. I whipped the battery cable off and the smoke stopped escaping. Pulled all the power leads off the alternator and every thing looks OK. Suspect the alternator has a short, Trying to build up the motivation to start pulling it apart. I'm hoping that I don't have to pull the radiator to get the bolts out. Normally this is a 10 minute job on a Holden motor, not so much in this car. On the plus side we have a plan for the exhaust and have started chopping bends and welding pipes. -

For the cam timing, the method of both valves open the same amount on TDC is the tried and true way of doing cams of unknown origin. It should be close enough to get you running, you can always play round with the cam timing once it is going. Pretty easy to do on a Pinto and no chance of bouncing valves off pistons.

-

J.e.d.'s Walkinshaw Rep friendly discussion thread

Kiwibirdman replied to j.e.d.'s topic in Project Discussion

Cool Car. Manual or auto? -

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

After thinking about the rear brakes and asking some questions I decided that drums are going to be just fine, mainly because the wheel cylinders are about $45 each and by the time I did the rear disc conversion I figure I was going to be another $500 - $700 into it. The money insanity has to stop somewhere. BnT had the wheel cylinders in stock so 2 hours on Thursday night saw them swapped over and brakes bled up again, all good so far. No doubt there will be some adjustments once the car is driving.Have to touch up the paint on the diff as brake fluid managed to go all over the place, lucky its only aerosol can black. I also picked up the new battery and re-terminated battery leads Tuesday. Put all that in today and finished off more of the wiring. I stand back and look at it and think that it could be much tidier, and them I remind myself this is not a show car and it is all practical. The instrument cluster and fuel pump/sender unit went to Robinson's on Thursday. They use a crowd in Auzzie to supply modified resistor cars for the sender. Hopefully they have one on the shelf and it will be here in a week or so. Once I have that back the fuel tank can be painted and go in. I'm not keen on painting until the pump is in, bound to scratch it otherwise.. The list is getting much shorter.- 129 replies

-

- 11

-

-

There are 2 more mounts on the other side of the trans tunnel, basically mirror image of these 2. Due to the shape of the floor the centre one went on to the tunnel. I hope that is going to be OK for cert. The outboard ones are on the wheel tub.Sorry about the photo. This is looking at the seat base/seat back. You have to have the back of the seat out of the car, the base folds out of the way OK. The belt come round the seat and sits nicely. Here are the 3 belts I hope this all makes sense.

-

This is the passenger side of the car. The left hand belt is for the position beside the door, the other half of the belt is on the wheel tub. The right hand belt is for the centre seat so these cross over to give the correct spacing. Happy for you to come round and have a look at the car if it helps.

-

Spot 1 is where I put the center belt on the EJ Wagon. The Seat belts cross over to get the proper spacing. I haven't put the car through certification yet, this was how @cletus advised me to do it. Position 2 will put the belt under the seat base. I can take photos if you need.

-

Flat mate of mine years ago had an XB Falcon van with disc brake diff. Apparently the diff came out of an LTD. Park brake, foot operated, was rubbish.

-

The Holdens use a drum in the middle of the disc for the park brake. My Silverado has the same deal and it works really well.

-

True. The more I think about it, spending $80 and having it all done in a couple of hours is looking much better than pulling the diff, replacing bearings and seals, changing the handbrake cable and lots of fucking around.

-

Already have a VZ commodore master cylinder so that isn't a problem. I was worried that there might have been issues with not having a RPV.

-

Thanks.

-

I have been led to believe that commodore rear disc assemblies, caliper, disc, backing plate etc will bolt onto an HQ to HZ Salisbury diff. Does anyone know for sure?

-

Kiwibirdmans 1962 EJ Holden Wagon

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

At the start of lock down hell I wrote a list of things to get done, which is further up the page. I have been knocking them off bit by bit, or at least getting to the point that I need to buy stuff. Old fuel pump removed from the tank and new on e fitted. Turns out the connectors inside the tank were corroded when I started checking before putting everything back together. I had anther tank off an earlier car (VR commodore from memory) and this had a better set for the wiring. New pump swapped over to the VR pickup and all checks out with a muliti meter. Thought I would check out the fuel gauge and make sure the sender would work before it all got put back in the car. Turns out that the original fuel gauge works ok but is totally incompatible with the commodore sender. All Holdens up to 1971 use 30 ohms full, 0 ohms empty. Commodores use 30 ohms full and 300 ohms empty. The first call after lock down will be to Robinsons instruments to see if they have an easy fix. If not it will be to get the original sender out of the old tank and see if its usable. Next job was to fit the heater controls and make them work. I have found a heater, they were an option and my car never had one, and spent a fortune getting a new core installed. I had bought a HZ Holden heater tap at Kumeu a few years ago from a guy selling new Holden parts. I had also bought an Aliexpress choke cable to use as a push pull. Here is the heater tap in the engine bay. The tap didnt come with the clip for the cable, they are available And the heater controls Tonight's job was to finish bleeding the brakes. I had started and run out of fluid. I was talking to a mate about it and he gave me some not very old stuff he had sitting in his garage. The fronts bled up and gave a nice firm pedal. Went to do the back ones which appeared to be good. Got my son who was helping to stand on the pedal and no stopping on the back wheels. I pulled the shoes off one side and pulled the dust caps of the wheel cylinder, lots of rust. That explains the no brakes. Might be a good time to do a rear disc conversion. I understand that commodore rear discs will go on a Salisbury diff with out too much fabrication. -

Lucky bugger!!! I would have killed for something like that when I was his age.

-

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

Kiwibirdman replied to Roman's topic in Tech Talk

I have the same one. Was perfect for hydraulic control banks that had to be 20 ft/lb and no more, because you could see it getting close. The guys using the expensive click type ones always went way over and then the control spools would bind up.