-

Posts

3,958 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by NickJ

-

I second vacuum infusion, far better results, getting a solid vacuum and even infusion can be infuriating, but when it works, Between my skin sensitising to the resin and hating dust, i'm not sure why I like working with it.

-

Could you just solder up the holes if they are unwanted?

-

Too rich on start up? I had similar issues at idle for long periods, one grade hotter plugs cured it, although that was on a warm engine

-

We can forgive you for narrow tyres and not bowing to peer pressure on cut springs, but I get the feeling after a full page voting down the distributor you better follow the pack on this one

-

Thats poo, best upgrade i've done is the ceramic heater tap, works without seizing up

-

Heater core looks very similar to a lada one, of which I have a spare

-

//Lame double post

-

Really liking this little project, so rad what can be done

-

I'd be keen to have a poke at troubleshooting it, I assume there are circuit diagrams about?

-

Jeeeeeeeez, all this time we thought you were cheap, wouldn't trimming both the same alighn better with your Barry-ness? put up a swapz post on dirty south for "lowered springs"?

-

If you're having trouble sourcing 6061 get in touch, we have it on the shelf up to 100mm thick

-

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

Just add headskin? -

You're correct, the circuit is simple, but my logic is the hall effect requires no additional gizmos, simpler and initially one less thing to worry about.

-

Only reason is perceived ease, reluctor needs a few more bits to run with the speeduino, but i'm happy to be convinced otherwise.

-

Whats the go to hall effect sensor for cam/crank angle? i've only found threaded rod style industrial ones or vehicle specific options that make mounting tricky, i'm leaning to the industrial style for ease but thats fairly chunky, something small and discrete would be nice, ideas anyone?

-

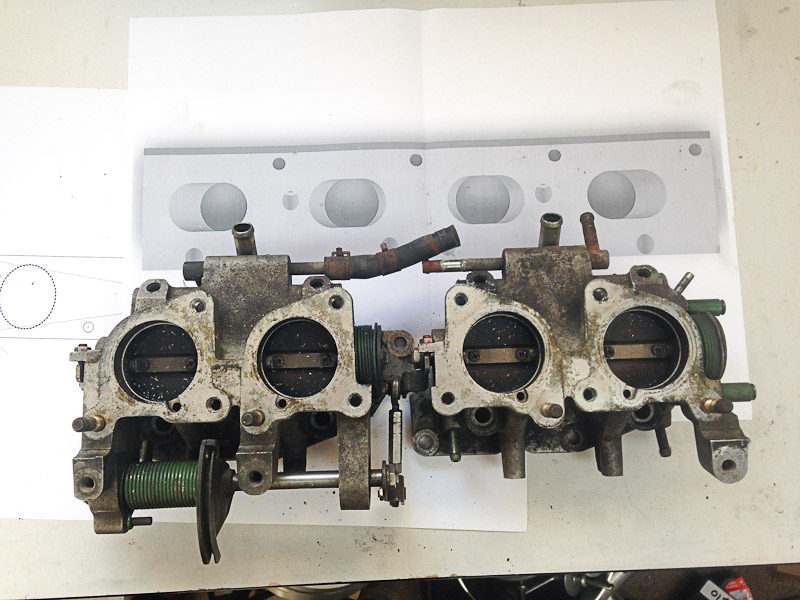

Printed out the profiles for the manifold full size to check I had spacings correct only to find I had the itbs upside down! Few clicks of the mouse later and to good surprise the bolt spacing came out much better, I have a few more gentle tweaks before sending it to the water jet but the design is pretty solid, I'm hoping to have them done by christmas, but she's sneaking up fast!

-

Ouch! but I bet you'd be proud of the fuel economy

-

only brakes on a Lada is breaks

-

flange is the same, but the bearings are different from memory (due to axle diameter)

-

270mm is the diameter i'm working with, going to check out Bart's supply if he can dig them out, but the other options all sound findable

-

On the search for rear callipers to put discs on the Niva, standard conversion is with Fiat 125/132 etc but being they are getting hard to find is there a modern vehicle that offers an easy alternative? Plan to use Niva front discs, so just need a suitable calliper to put on an adapter plate.

-

Plan to locate all the important bits in the cabin if possible, i've given that engine bay a good wash on many occasions, nothing electronic is safe! i'll build an ignitor box for the coils, that is a good candidate for potting, see how it turns out

-

Haha, it already exists and is known as Stycast http://na.henkel-adhesives.com/product-search-1554.htm?nodeid=8802688008193 So yes, yes I could

-

And it would still be a slug!

-

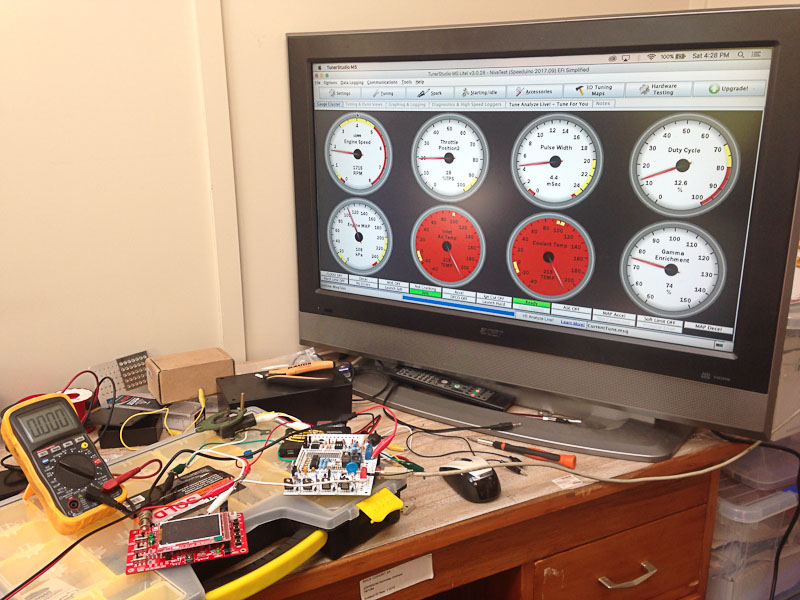

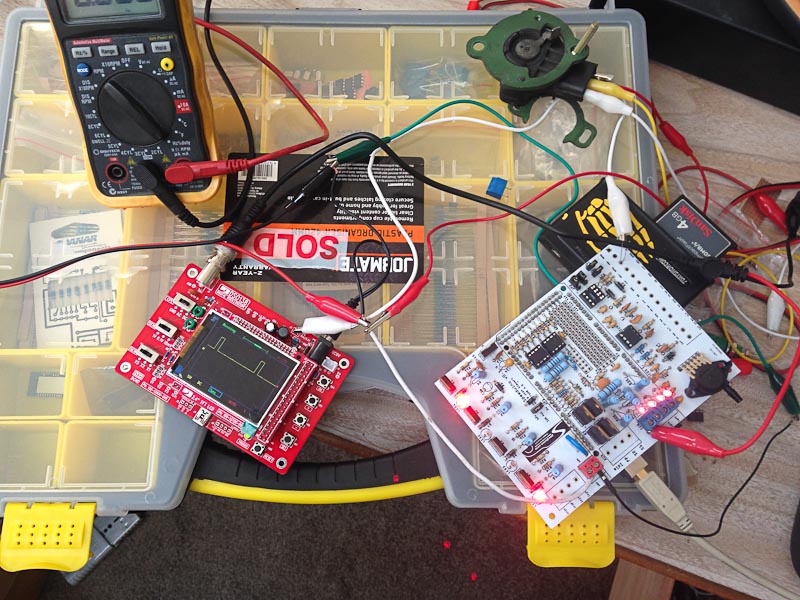

Got the Speeduino running and sat down to give it a bench test, hooked up the tps, fed a simulated crank sensor in and scoped the outputs. Pretty darned stoked to have it this far, found I had installed a few parts wrong during initial assembly which caused some searching, I even contemplated ordering a megasquirt if the fault was too hard to find, but thanks to open source and having all the circuit info available, a reversed capacitor was to blame and all is now working as intended. Drew up a concept for the manifold, while I can't quite make it as I initially though, it will still work with some extra manual labour, the idea being a single piece aluminium adapter plate won't require welding (I just don't have that much time anymore!) bit of manual machining needed and then sitting down with a die grinder for the final match up shouold do the trick. This will also keep the final package tidy in the engine bay, currently the manifold I made to snake around the distributor and dellortos is as large as the head and looks a little out of proportion (say the guy putting all this effort into a Niva) Printed out fullsize for a quick check, good thing as I had the itb sketch upside down! i'll fix that and then look to getting the blank cut out. also need to give them a good clean, a little grimy as well as the token Al swarf from being under a workbench the last few years!