-

Posts

412 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Converted

-

Local Area

Wellington

Recent Profile Visitors

1,920 profile views

mk2marty's Achievements

Advanced Member (3/5)

1.6k

Reputation

-

Just a heads-up, the CCM is now up on the website in .pdf form, no login or email needed: https://www.lvvta.org.nz/documents.html#nzccm

-

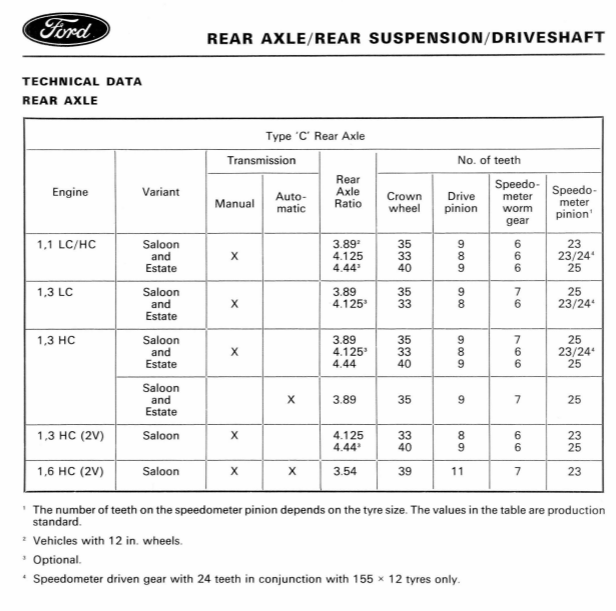

Here's a handy chart to figure out which driver/driven gear you need to get the correct speedo reading for a particular diff ratio: For reference, with the 3.89:1 in my Escort, I found a 22 tooth driven gear in combination with the standard 6 tooth driver in the gearbox gives a dead accurate reading. Took some maths, because according to that chart there's no such thing as a 22 tooth driven... As far as I remember, both the worm drivers and the driven gears in various types are still available on Motomobil.

-

Mk2Marty's 1976 Escort Moredoor Discussion

mk2marty replied to nnzclassiccarnut's topic in Project Discussion

Cheers! I'm pretty chuffed with how it's turned out, but for something that started out as a cheap daily it's ended up a whole lot nicer than I ever intended haha. -

Now, just to throw another spanner in the works, there was a new deadline for the rebuild (or at least a temporary hurdle). A change in jobs (and careers) to a Porirua-based association meant we had an impending move to Wellington coming up, and I am very grateful to Aaron for fitting the car in and laying down such an amazing paint job in such a short amount of time. However, the now-rapidly approaching relocation meant rather than taking the time to piece the car back together slowly, it was a case of stuffing as much back into the car as quickly and temporarily as possible so it could be moved. Already regretting life choices at this point - the weather got colder and wetter the further south we went. Who knew that Waiouru had sleet in February? While the Telstar was fine to tow it over the hill and back, it probably wasn't going to tolerate 10 hours-plus pulling a dead Escort full of parts, so I went with the more sensible option of hiring a Hilux for the big drive down country. Not least because it could then also carry all of the crap in the garage that didn't fit in the moving truck... Once it was tucked up in the new garage, the long and involved process of 'clean, paint, lubricate and refit' could begin. Oh, and a whole lot of this stuff: I figure if it's managed to prevent the Accord from dissolving into a flaky puddle, it must be good (and I really like the smell of it for some reason). Many cans later, and all of the cavities were waxed. Some of it went on the car too, puhuhu As predicted in an earlier post, I've blinged it up a little bit. While it was a pretty un-fucked with original car when I bought it, a base model Escort sort of isn't the greatest place to be. Part of the goal for the restoration was to make modifications to it based on what was available in period, and mostly from the Ford parts bin. Sort of an 'if you worked at a Ford dealer in the '70s and got cheap deals' kind of exercise. It's also an excuse to use some of the parts I've hoarded over the years. So, to that end, it has a full set of factory bronze-tinted glass, remote driver's mirror, centre console, and stainless window trim from a Ghia, 13x5" Rostyle wheels (of the correct earlier offset, either from an early Sport or a Mk2 Capri - this wasn't intentional as I'd have preferred the '79-onward spec wheels with an increased negative offset, but at least I can claim they're correct for an early Mk2/tbh the main factor was just that they were cheap), and a couple of different 2V Weber carburettors. Tried a 32/36 DGAV on it initially, which was simply too big - because it's intended for a Cortina the throat sizes are wrong for anything under a 1600, which means the air speed through the venturis is too low to achieve proper fuel atomisation (so it bogs at low RPM, and generally doesn't have a good time). It has a jetted-down 32DGAV 5E currently (fitted as factory to a 1600 Sport) which has smaller venturi sizes and works better, but the manual choke conversion for a DGAV has never really worked properly, so when I saw a 32DGV 15C (the factory manual choke 1300 Sport/1300GT carb) come up on TM, I jumped on it. Shortly after that, a set of factory extractors popped up, so I grabbed those too. Dad very kindly donated a Sport air filter housing to the cause, and all of these will find their way onto the car once I've built the other engine sitting in the shed. This will end up being based on 1300 Sport specs, with a few extra David Vizard tweaks thrown in (and hopefully the car's original 1100 pistons, for more compression). Managed to score a factory Sport gearbox for it too (which has a closer ratio and allegedly stronger gearset from OE), so that will go in when the engine does. I also built up a 3.89:1 final drive for it, to give it some longer legs on the motorway than the 4.11 it had. Hasn't made a huge difference, but every little helps. Spot the difference. Anyway, circa April '21 it went for its first WOF post-reassembly, and shortly afterward it made the trip up to Auckland for the north harbour all Ford day. This was actually a pretty momentous occasion - the old man brought along his Escort estate (which he's had since the early '80s, and I learnt to drive in), and the two finally went to a show together. It only took like 8 years for it to happen... And that pretty much brings us up to the present day. Still have it, still have plans for it, still have parts in the shed waiting to go on it. However, with a growing fleet and a Fairmont that's taking increasing amounts of time and money, those things are taking longer to happen. Ah well, it's still nice to open the garage door to it. Discussion for additional Escort barrying here:

- 12 replies

-

- 24

-

-

-

Big shout out to Aaron at Full Noise Auto Restorations Ruakaka for laying down a stunning coat of paint: Telstar will tow anything. And yes, it's on the trailer backwards - in fairness, it didn't have an engine over the front axle, and I didn't want to blow the rear window out of it...

- 12 replies

-

- 19

-

-

Thread dredge. I'll try and piece together the rest of the story as best I can remember. We finished the last instalment in Dargaville, just prior to the first wave of Covid. While most of the first lockdown was spent underneath various tractors, the extra few days here and there helped to keep progress going on the Escort. First thing was to cut open the LHS C pillar, where a large hole lurked. Most 4 door Mk2s have this problem - C pillars that rust from the inside out. The reason for this is that the inner vent body doesn't sit level with the bottom of the vent aperture in the outer pillar, so there's always a few millimeters of water sitting in the bottom of the vent. Now, this would be fine if it could just evaporate with the air movement past it as the car drives along, but whatever bitumised sealant Ford used to seal the vent body to the outer pillar skin goes hard eventually, and allows that little puddle to wick its way down and sit between the sealant and outer pillar. This is what causes the characteristic C pillar rust bubbles, and once you can see the rot coming through from outside the car it's too late... This was what lurked under the bubble in the pillar, after I'd cut the hole in the vent body back to reasonable-looking steel. Note the space between the bottom of the hole stamped in the outer pillar, and the bottom of the vent body. Also, offending bitumised sealer visible towards the rear of the hole. Because I like having the famed Ford AeroFlow (TM) ventilation (changes the air in the cabin every 30 seconds, don't you know), I wasn't just going to cover over the vent apertures. Not least because you know that with AeroFlow (TM) you only need to smell farts for 30 seconds until they're driven from the cabin by the incoming fresh air. So that meant I needed to fix the C pillar vents, and find a way of fixing the inbuilt water trap. This ended up being a new channel section with drain and hose (which runs down behind the wheelarch and exits under the boot floor), welded into the vent and sealed against the new piece of steel I welded into the outer pillar. I'm still not entirely happy with how it turned out - it's not the tidiest repair, as access for both death wheel and welding torch is severely limited - however it's functional and non-visible. And hopefully it's solved the problem of water pooling in the bottom of the vent. Didn't take as long as I should have with the welding and grinding and things got a little hot, so I inadvertently managed to warp the panel a bit, which was annoying. Managed to get it fairly straight again with the hammer and dolly though. Rinse and repeat on the other side: Rebuilt the rear of the RHS wheelarch, inner and outer skins: There were a few other places that needed patching - the bottom of the RH A pillar, and the top of the RH A pillar once the screen came out and more holes appeared. After this, I had to make some new guard mounting rebates for the tops of the inner guards, attach the new heater bowl, and attach the front valance and guards permanently. So, it went from looking like this: ...to this: By this point, in addition to the front guards and valance, most of the bolt on panels had been replaced - the bootlid and three out of the four doors were substituted with ones that the tin worm hadn't attacked. It was almost ready for paint. There's enough photos in this update though, so that'll be next time... On a side note, it's bittersweet going through all these old photos again - my little garage buddy passed away earlier this year. Miss her heaps. (Ignore the panel fitment, it gets fixed next update)

- 12 replies

-

- 17

-

-

-

That's the chassis ID plate, which is as much info as you'll get on an NZ-production Ford from this era. If you're lucky, someone at Seaview may have hand-engraved the chassis number (CLBFNx xxxxx) somewhere on the radiator support/inner guards with something akin to a tattoo gun, but this seems to have been a sporadic thing. They didn't start consistently stamping the chassis number into them until the mid '70s AFAIK. My Mk5 has the chassis number stamped into the slam panel next to the body tag, but it's roughly 10 years younger than your car. Because it looks like it may still be attached with at least one of the original rivets, and it's likely the car's only form of ID, lest you incur a world of hurt at entry time best not to drill those rivets out...

-

mk2marty started following DirtyThirty

-

DirtyThirty started following mk2marty

-

K-Trips 1982 Holden Commodore VH Discussion

mk2marty replied to KKtrips's topic in Project Discussion

Totally expecting to see this at work tomorrow btw -

According to my info, the tag decodes as follows: C=Ford UK CKD kit A=Auckland (Wiri) assembly plant A=Escort T=Two door sedan T=1977 production year P=April production month 85878= unique 5-digit identifier Model: A=Escort Drive: 2= right-hand drive Engine: J3= 1300 2V Kent engine Trans: B= 4-speed manual, floor shift Axle: D= 4.125:1 ratio final drive Trim: P = unsure, this code isn't in my chart, but early Sports to my knowledge used cloth seat trim from an Escort GL with vinyl door trims, of either beige or brown. Paint: 7=1977 code L=electrocoat primer 2=Taubmans paint vendor EF= I think this is Olympic Blue, based on research of NZ-assembled Escorts I've seen over the years. We had unique paint codes (because local production), so overseas manuals and colour charts don't translate here. Unfortunately, the guy I knew with the proper list of NZ paint codes just passed away over the weekend, so I can't ask him. 1= again, unsure. A lot of cars didn't have a number here. SVC ST=December 1976 CKD kit generated. So in essence, that tag belongs to a 1977 Escort 1300 Sport, and the powder blue colour is likely pretty close to what it had originally.

-

-

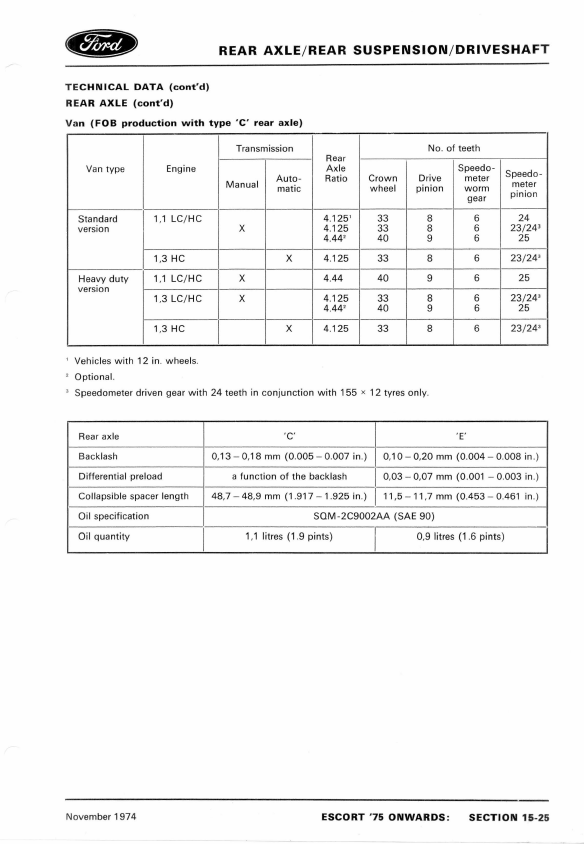

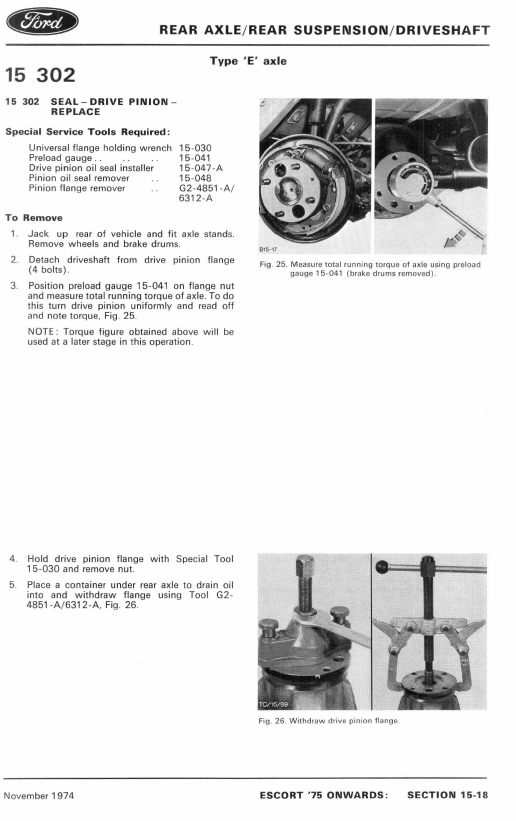

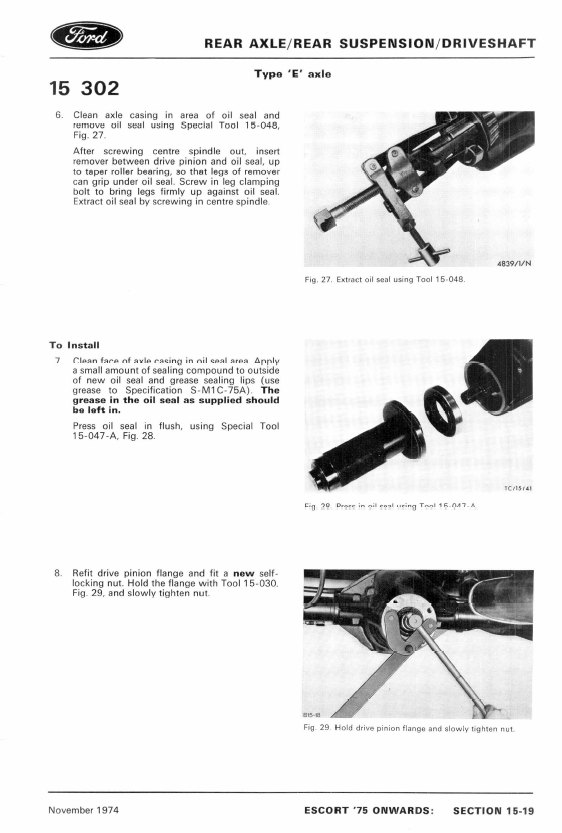

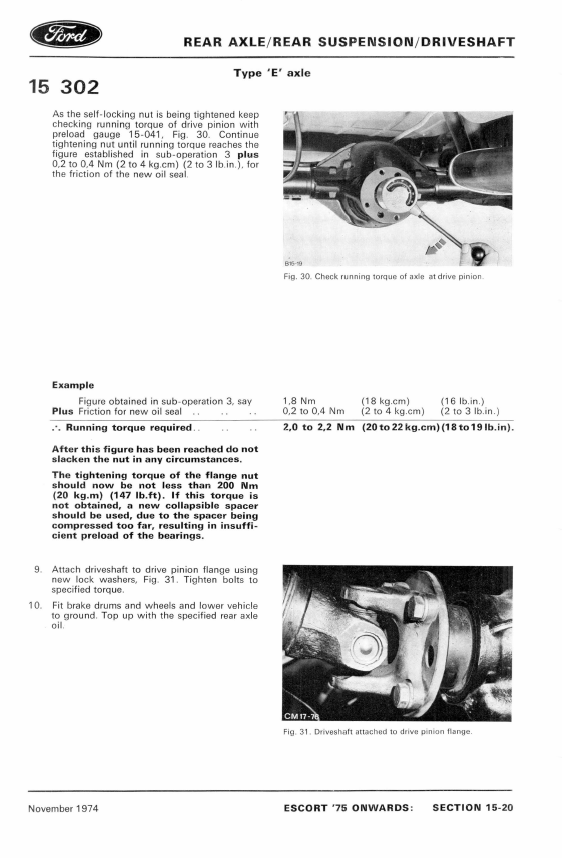

Being a 1600 Sport it should have had 9" rear drums from OE, although yours is a very early production model so it's possible that it didn't get them. Odd. In terms of the oil from the pinion flange, it sounds like it's working its way up the splines on the drive flange, which these are known to do. Replacing the pinion seal won't help this, but a judicious amount of silicon sealer in the splines will stop it. That does mean the flange has to come off and the pinion nut loosened, which unless you're careful and get it back in the right place will upset the pinion bearing preload. Too much and you'll collapse the bearing spacer further, which means pulling the final drive apart to fix. The silicone will probably also mean the drive flange is harder to get off in future, but meh, it's better than an oil leak. As for the backlash, if the axle isn't noisy personally I wouldn't worry about it, a used Timken axle does usually have a bit of backlash. Depends on what you're doing with the car/how deep your pockets are, though. Here are some possibly useful bits from the Ford book (the pictures are of a Salisbury, but the principles are the same):

-

I've got a Uniden R3NZ, which picks up posted speed cameras (via GPS) and speed vans, but you have to mess with the settings a bit to narrow down the detected K band range otherwise it picks up every "your speed" sign/shop doorway sensor etc. It's good for Ka band (mobile radar), it usually picks it up a decent distance away (like several kilometers) unless there's particularly hilly terrain. It also goes off when you're getting lasered, but by the time that happens it's probably too late anyway. Wouldn't drive on the open road without it now, not because massively illegal speeds or anything, more just for the peace of mind on passing lanes or for those random 30km/h signs for non-existent road works. Has the ciggy plug adapter too, so easy to swap with the suction cup mount between cars. Mate had a Valentine that told you which direction the signal was coming from, which was a nifty feature.

-

Cheers for the speedy reply! The car is standard otherwise, so maybe this will be the tipping point for more mods... Or maybe I'll ask the body shop to just weld the guards on. It would probably take a fairly observant WOF inspector to notice the difference, but why risk it tbh.

-

Front guards on a Mk2 Escort are spot welded on from the factory. If I were to bolt them on using rivnuts and M6 bolts every 60mm or so (for ease of panel gap adjustment/removal for future repairs etc) would this get into certification territory? My thinking was that people have run fibreglass guards on Escorts for decades, and given that they predate any kind of frontal impact legislation it might be allowable - the bolts are spaced at roughly the same intervals as the spot welds were, so whatever body stresses the guards carry should be unaltered. However, the bloke painting the car reckons otherwise, and tbh looking at the VIRM it may be classed as a modification to the vehicle structure. Who is right?