-

Posts

295 -

Joined

-

Last visited

Everything posted by 98cc

-

- 58 replies

-

- 7

-

-

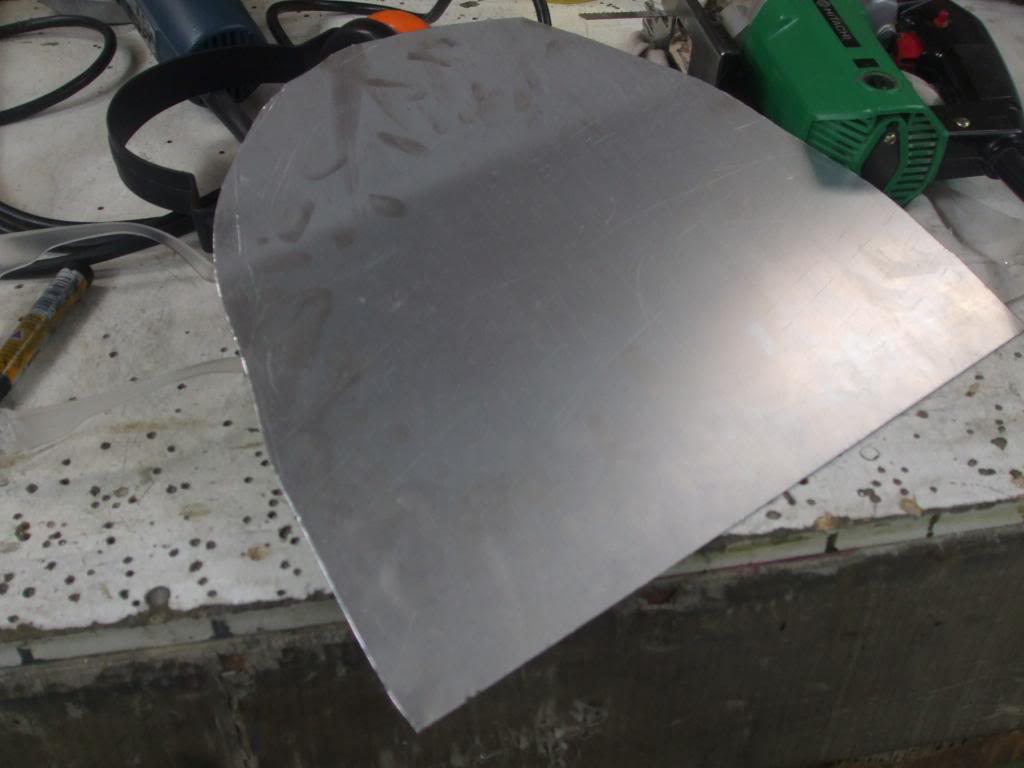

I cut out some holes for the go fast knee scallops, these large openings were quite handy as after i ground out the large amount of filler i could get in there with a dolly and get rid of all the dents, the tank is now real smooth and fair also made up a little fill in patch for the front of the seat to blend into after a good sanding to remove the surface rust

- 58 replies

-

- 9

-

-

That brings us to a couple of months ago where i saw that the bike was starting to rust and corrode from sitting around so i got back into it. first off was getting the seat finished cut out and fitted welded and filed up

- 58 replies

-

- 14

-

-

Here's the pics from making the seat 1/16 ally blocking the sheet to shape lots more hitting and shrinking around the edges A few passes through the wheel and its starting to look like something After final wheeling and trimming The base was made out of slightly thicker material, no blocking required though just a few passes through the wheel Mock up This is how the bike looked sometime in 2014, after this pic was taken progress pretty much stopped while i was working on other things

- 58 replies

-

- 16

-

-

This is a project i have had on the go for quite a while now, it always seems to get put aside when other projects come up but i am determined to have it finished this year, Famous last words haha. I wanted something a bit different from the standard bantam and seeing as the project was a basket case i didn't feel bad about making something different out of it, so racer it was! Anyway here is a pic as it stands today I got given a basket case bantam project in 2013, i did a fair bit of work to the bike 2013-14 and most of the pictures following are from that period The project.... Frame with reassembled forks and rear suspension I got the engine cleaned up and back together with new seals, bearings, clutch pates, sprockets and gaskets I had the engine running at this point but i have since fitted a big fin 125cc barrel and head which i had bored to fit a new piston. BSA only made the big fin 125 for 1 year before going to the 150cc motor so i was quite lucky to get it, pic below is the small fin barrel Next job was making up some clip on bars Tacked on found some levers at a swapmeet as the original bantam ones are part of the handlebars At this point i decided on a colour, Ceramco blue so got some bits painted up And Tom Morris made me some stainless spokes for the rear Rear wheel laced up

- 58 replies

-

- 18

-

-

Steam and Vintage Country Festival 2017

98cc replied to tortron's topic in Upper North Island Region

Yep me to -

Much excite, heading over tomorrow after work. How many other people are staying in the hahei campground?

- 92 replies

-

- 1

-

-

- Rods place

- bit of a climb

-

(and 1 more)

Tagged with:

-

Very cool project, where did you get the rims from?

-

Yeah sounds like a plan!

-

Awesome, I'm looking forward to seeing it

-

Thanks man, im looking foward to getting that norman off you!

-

N3k, yes the main requirement to go on the tour was that you had to be dressed in a period costume for the whole event. Most of the penny farthing events overseas and especially in Australia everybody on a penny farthing seems to be wearing lycra which isn't a very good look so the Oamaru club has made it mandatory to wear period gear in the events. I don't know about the Thomas Stevenson outfit Tortron but the ride has been going on for nearly 20 years now so i imagine it has been done. Plans for the next project, i have a few on the go at the moment. My BSA bantam racer is leaning against the wall looking very sad after over a year of not being worked on now so i might get back into that, I am also doing a rebuild on a small home built plane with a friend of mine and restoring a vintage Vincent water scooter so i have a fair bit of stuff to keep me busy. Have you heard of David Wilson? he rode the length of NZ a couple of years ago on a penny, i think it took him a couple of months, obviously not much of a challenge compared to what you have done! Yeah it sure was awesome Steelies, it might be an event for next year as well

-

Yeah it was very cool to meet up with some of you OS guys st the swap meet! From what I heard Friday was the day to be there, lots of veteran and vintage motorcycle stuff that was all sold by Saturday. The ride details were: Day 1 was Arundel to Mt Somers, 25km. Day 2 was Erewhon to Mt Somers, 25km, We had an awesome tail wind and we probably had to only pedal 3km of that distance! Day 3 was Mt Somers to Rakaia 50km and the last day was Leeston to little river via a cycle trail around lake Ellesmere 50km. It was such an awesome event i can highly recommend it for anyone who is into old bicycles. Here are a few pics from the ride The 2 trailers with all the bikes loaded up Here are 2 of the 3 really nice Dursley Pedersen replicas that were on the ride Canturbury plains Re tyring a rear wheel on the side of the road after the tension wire through the center broke At the start of the cycle trail at Motukarara Chris having a go at swapmeet A shot with one of the sweet traction engines at swapmeet Rakaia Tavern Stack line up There are a heap more photos on the Oamaru ordinary cycle club FB page if anyone is interested too Time to get onto some of the other projects......

- 97 replies

-

- 14

-

-

Thanks for all the awesome comments guys! The place that we are staying at tonight in Rakaia has internet access so i can catch up on a few things. The ride is going extremely well so far and i am very pleased with how the bike is going, no problems yet and i think we have done a bit over 100km now. We went out to Erewhon station yesterday and had a good tour around which was cool. Tomorrow is the big day with a bit over 80km to do so i am looking foward to that. I have managed to master a few tricks now like no hands riding, peddle dismounts, coasting down a hill with legs over the bars and I am getting the hang of balancing on the thing stationary. Oh yes the newspaper article, The lies!!! its amazing what these reporters seem to be able to pull out of thin air haha although he did get most of the things i told him right. DIRTY6 yes that pic is of one of the 6 other penny farthing riders on the tour, there are also about 16 vintage safety bicycle aswell. Anyway thats my internet just about up, I will put some pics up of the ride next week when i get home.

- 97 replies

-

- 15

-

-

Well I think i can call this project finished and I will report if its been successful after the ride haha. Both of the bikes are done, I had a big assembly day last Sunday and I have ridden them around the block a couple of times now and they both go really well. I haven't got any pictures of them both together yet but i just took a few of my bike so here's a big pic dump of it all finished. Tonight's job is to wrap it all up ready for its trip down to chch in the plane with me tomorrow night. The ride that i'm doing starts in Arundel at 11pm Tuesday. The ride ends at Akaora on Friday after about 180km of riding. Im doing the chch swapmeet on saturday as well which should be a pretty good event.

- 97 replies

-

- 23

-

-

Thanks Ned! Its all done now just about to do a big update

-

Well the bikes are nearly finished now which is good because im flying down to chch next Monday to start the ride! The top coat color has also been sprayed on all the parts. One of the last jobs that had to be done was to make the handlebars. I originally thought i was going to have to find someone with a tube bender and mandrels suitable for the job but i managed to find some 2.5mm wall hydraulic tube and this bent very easily without wanting to collapse at all. The handle bars are bent with a hump in them to clear your legs at the top of the peddle stroke. There is a piece of threaded rod welded into one end for the bars to screw into the head assembly Starting the bend With a little bit of heat on the outside of the bend the tube just pulled around And bending the other side to match (the hard part!) I got the bars and all the fasteners nickel plated, i did all the polishing myself to save time and cost at the platers. I can highly recommend Electroless Coating Systems Glenfield for any nickle plating you want done, top service and they do a very good job. I also did the grips, for those i raided my dads file draw, i was lucky i found 2 with exactly the same wooden handles After trimming a bit of each end a putting a 5/8 hole up the middle and giving them a good sand they looked like this And stuck onto the bars, they are still wet with the first coat of sealer, there are a couple coats of varnish to go on yet. All going to plan final assembly of both bikes should be tomorrow night

- 97 replies

-

- 11

-

-

Awesome bike! Are you going to do a full restore or just fix it up? Do you know why they were plated and then painted?

-

Cool might see you there then. Supposedly back around 1870 they had only invented 3 colors. They were Black, dark blue and burgundy. As i am trying to make this one look like an original Its going to be a dark burgundy as lots of pennys are black and blue. I got the first coat of epoxy primer on the bikes and i got them all sanded up last night I will hopefully get another coat of primer on tonight and then give the bits a good wet sand and then topcoat sometime this weekend!

-

Thanks for all the comments everyone! I suppose everything i do i try to do to the best of my abilities so i can have pride in the finished product. Thats what i couldn't understand at school engineering classes, most of the guys didint give a toss what their work turned out like and even if they finished it at all. There are so many awesome and inspiring projects on OS so its good if someone can get something out of what I'm doing. Steelies, i think lead should be encouraged for sure! BL, you should defiantly head to Oamaru if you are keen, the full ride that I'm doing is 4 days long, i can send you the details if you are keen. Also chuck a pic of that BSA up! FB, about the braking, these things generally dont have them. The main form of braking is by putting back pressure on the peddles. Some pennys have a spoon brake on the front tyre but they are pretty ineffective. Are you doing the full ride Valiant? Thanks rusti, its good that i dont need to go to my dad every time i need something welded now

-

I have basically finished off every thing that needed making on my bike now, all that's left is handlebars and paint which i will hopefully start this week. As i said before i was hoping to make my forks more like the originals, they are all done now and i am extremely pleased with how they have turned out. Pics.... I started with this head casting. I got it from the guy in Oamaru, it's a steel casting that was taken off an original bike. I cut of the handle bar spigot as it was to small for the 5/8" handle bar tube that i wanted to use. I got it in the 4 jaw running as true as i could get it and then machined the 2 degree taper down the length of it. I then drilled and reamed the hole for the adjusting bolt to 1/2" for the next step. I found a 1/2" center drill with a broken of end so i could modify it with out feeling bad, i welded it to a 1/2" rod and then ended up with a long center drill. With the long drill running really nicely in the reamed hole i cut the bottom bearing surface, the long center drill worked well and didn't wander at all when i started drilling. After that was done i bored it out some more and tapped it to 5/8" UNF. That finished off the head and i started on the fork tubes. For those i used the squashed round tube i got from Oamaru. The problem was that i didn't like the look of the long straight tubes when all the other parts on the bike were tapered so all i did was cut a big long triangle section out of them and welded them back up. Tacked back together And all welded up. These long welds were good practice for my tig welding, im slowly getting better at it. I get to do a tig course next year through my apprenticeship so im really looking forward to some proper instruction. For the fork end detail i just cut out some blocks and welded them on. Cut to shape and roughly filed up. And after final shaping and sanding with the bearing carriers fitted. Once all that was done i welded the 2 fork tubes to the machined head. I did a few plug welds aswell to make sure its as strong as it can be. Once that was done i gave it a good file up to fair it all in. The other problem with these fork tubes is that when the round was squashed flat i don't think they had a proper former in it so it was hollow in the middle. This didn't look to good either. Ever since seeing Manu's pics of leading his Ariel tank i wanted to give that a go, these fork tubes were the perfect thing to do so. I asked a good panel beater friend of mine if he would give me a hand and show how it was done so i got some pics of the process. First thing was getting the surface perfectly clean and getting some flux on it. Then tin the whole surface with the body solder Next was getting the lead on. It was a fairly big stick and you heat the end up with the torch until a lump falls of onto the bit of steel you just preheated. You work your way along until there are lumps of lead stuck to the length of the part. The key to the whole thing seemed to get all the lead on in one go so you don't have to put more on later over the top of it. He told me that it is much easier to file of excess lead than put more on. After that was done you go round and using a wooden shaper heat up each lump of lead at push it around until it is roughly the shape you want. After all the lead was on i gave it a real good scrub in water to get rid of all the flux and this is what the forks looked like Now for the fun? part, I dug out my dads body file and got into it. After the basic shaping it looked like this. It happened pretty quick because the lead is very easy to file as you can imagine. And what they looked like after finial filling and sanding. I have also machined up a new handle bar spigot and welded it on, its also tapped 5/8 UNF for the bars to screw into I also finished of and painted the rear saddle mount and spring. The leather saddle is riveted on with big copper rivets. The front seat mounts ready to be cut out All fitted up with the front mounts bent to shape. I also set up the adjusting screw in the rotary table and milled a 1/2" hex on it for your spanner to go on. And how the bike looks at the moment. I am wrapped with how the forks have turned out and they now look like they were in 1870. If i had handlebars i could ride the thing, i am going to strip it down and hopefully get primer on both the bikes this week. The ride that im doing on it is less then a month away now so hopefully the painting process will go smoothly and then i might even be able to get a bit of practice in!

- 97 replies

-

- 23

-

-

Thanks 7VEN, yup its all coming together now. Did you see many of these things over in England while you were there?

-

Very cool! Is the villiers bike a thing of the past now?

-

Thanks Tortron, no i dont think i will do any lug detail, the ride is only a month away now and i still need to get both of the bikes painted and do all the final details. A good replica penny will generally sell for between $2-3000 even up to $4000 and originals are well into the 7-15k range. I got my bike welded up on the weekend so i will do a big update sometime this week.

-

I have made up the first set of forks now, i just need to make the handle bar mount and weld it on. These forks are for my mates bike This is the steering and neck assembly, very simple but effective. The thread at the top is 5/8 UNF. It will have a lock nut to hold it in the right position when it is all set up. I got my dad to weld the pin on as it's the highest stressed part on the bike and I'm not really keen on it breaking of when I'm up on top of the thing haha Fork ends i made earlier welded into the tubes with the bearing carriers fitted Getting it all set up ready to weld in the steering assembly And all welded up with the fork rake and wheelbase set I have made up most of the bits to put my forks together now, they are going to be different to this set and much more like they were in 1870 with a cast head arrangement and taped fork tubes and a few other different details. This should make them much nicer looking than the standard forks for these replicas

- 97 replies

-

- 13

-