-

Posts

296 -

Joined

-

Last visited

98cc's Achievements

Advanced Member (3/5)

2k

Reputation

-

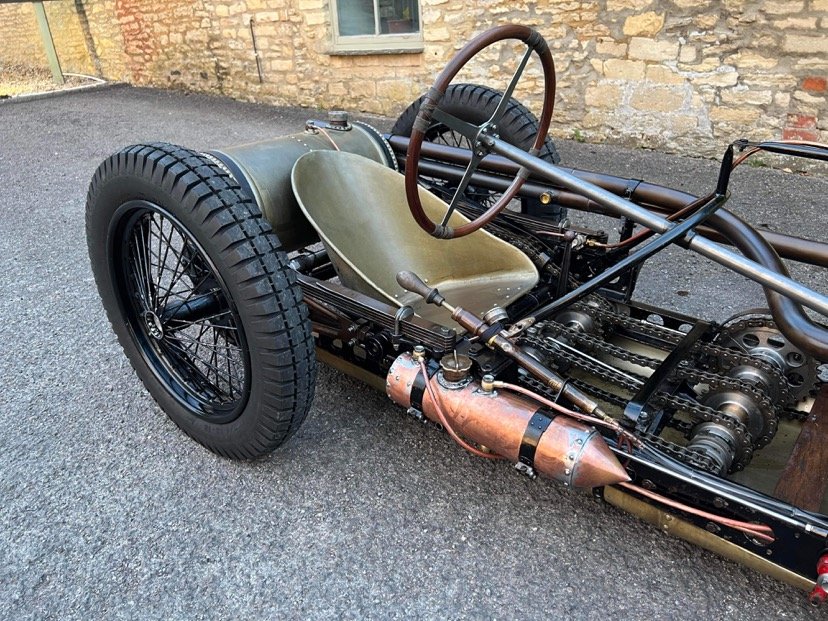

A couple of weeks ago it had its big debut at the the Vintage Revival event at the very historic Monthlery banked circuit in France. A couple of the other GN specials from the U.K. went over, GN Parker, GN thunder bug and the most legendary of them all GN Spider These pics were taken when we had the body off Spider to do some adjustment to the clutch, it shows the standard position of the chains on the axle. Spider was built by a hillclimbing legend called Basil Davenport and held many records in period and would routinely beat far more advanced works cars like the ERAs, Maseratis and Bugatti’s of the time. The engine is a derivative of the lightly tuned 90 degree v twins that the road going GN came out with standard. Constantly developed by Basil turning it into the 1500cc methanol burning chain driven over head camshaft monster that it is now

- 53 replies

-

- 36

-

-

-

Having now been in the U.K. for 3 years my ideas and inspirations have changed slightly from the wooden chassis cyclecar I had originally intended. I’ve been very lucky to get quite involved in the vintage racing scene over here and have made some very good friends because of it. A GN cycle car was always the dream although with none available in NZ to look at and the closest example being in Aus it was quite hard to fathom coming up with one. Since being over here I’ve managed to collect enough GN parts to put together this which is my take on the Hillclimb special concept of the 20s-30s. Going to all the swap meets in the calendar i managed to get hold of all the other groovy bits and pieces that I needed for the build. The defining feature of a GN is its chain drive transmission and solid back axle. 4 different ratios with dog selection. An incredibly simple but extremely effective system with large scope for easily changing ratios. Normally on a GN these chains are on the back axle but on this car I’ve moved them forwards so they are under your legs, this means you can have a low down far back seating position that you can’t get with the chains on the axle. Of course It needed a name to get the poms scratching their heads....

- 53 replies

-

- 31

-

-

-

- 53 replies

-

- 32

-

-

-

Twin thumber started following 98cc

-

Over to the mill to drill through stud holes. Dividing head to do stud clearance cutouts Repeat x 2 Will need a final hone when the time comes otherwise finished

- 53 replies

-

- 34

-

-

First cuts on the casting. This was a serious brown undie moment holding the rough casting on some very narrow jaws boring out a rough casting at the other end. Bored out and head spigot machined. 3.5 inch bore Flipped over and cyl base machined

-

Yep I imagine this will be the case. We did, 3 GP Bugatti’s and was going to do the Mille Miglia the weekend before. Was pretty guttered when that was all cancelled. You just about could of. Chain driven blower might have to be in this cars future. Cyl time. The crowd I got the crankcases of had just done a run of cylinders and heads so I managed to get a set. It was far easier getting them sent a couple of hours down the road instead of to New Zealand that’s for sure. First issue to sort, the only boring bar big enough was a bit large for the toolpost. Couple bits machined up and welded together Should do the trick

-

One year later...... So shortly after my post I packed my bags (including a JAP crankcase) and hopped on a plane to the Uk on the big OE. I’m working in the vintage car world over here and have had some pretty amazing experiences. After spending so many hours looking at pics of cyclecars and the like it’s pretty neat to be at the events where they are running and get a real feel for them. One of the coolest trips I have been on was in Mark Walkers GN Thunderbug. A 4.2 litre Vtwin in a light weight chain drive chassis is definitely a good formula.... Some pics from the last year... Have many more to put up. With so many good vintage car events over here i need to get a car built so have been working flat out on the engine after hours and have made a fair bit of progress Cases bolted together and set up on the rotary table with a mandrel through the drive side bearing boss. Using the boring head to fly cut the decks Drilling and boring the cyl stud and follower holes prior to tapping 3/4“ 20 tpi cycle thread, mmmm lovely..... After all holes drilled and tapped and cyl base spigots bored Next up barrels

- 53 replies

-

- 23

-

-

-

98cc's Resurrection Of The "Smith Spider" 2 stroke race car--Now with SOUND

98cc replied to 98cc's topic in Other Projects

Cheers Mate, yeah was bloody good to meet up. Dennis had an amazing time at Leadfoot, it was the first proper car event he'd been to in over 15 years and he yarned to heaps of people about the Spider which was really neat. He does still drive so it would be awesome to get him back in it, will hopefully be able to sort something out. Really looking forward to getting into this when i get back home, pulling the engine out and replacing the seals should be pretty straight forward and then it will be time to have a third driving session! -

Cheers mate, na I think I will be doing some flicking through the Wiseco piston catalogue when it gets to that stage... Wow awesome, would of been great working at Mcintosh. I think I saw that engine run a few years ago when I was visiting Ken. Were the Hemmings heads original upgrade parts for sidevalve engines? I take it the guy with KTOR on the floor would never part with it? I’ll be making my own flywheels with press fits throughout, will get a 1.5” dia drive mainshaft with the bearings in have. A bit better that the original..... Have got the timing side case machined to the same stage now. Facing the timing cover mating surface as first reference. Flipped over and same stuff done as first half Internal features finished on both half’s. And with a couple of bolts holding it together. Next job get the timing cover bolted on

- 53 replies

-

- 18

-

-

Did you ever see the engine run SOHC? A bit of info on this engine. It’s a 1930 JAP JTOR long stroke racing model of 1000cc. They were used in racing 3 wheel Morgan’s and Brough Superior motorcycles. These v twins are very rare these days and are worth a large amount of money. Lucky a place in the UK has reproduced some accurate castings for anyone mad enough to try make their own. I will be changing a few things with this one to try and get a bit more capacity and power out of it. Made a start on machining the drive side crankcase half. Bearing boss faced off to become the first reference surface Flipped over, mating surface faced and holes drilled. Now clamped down with spacer blocks to machine inner surface and bearing bore Inner features finished Next up timing side

- 53 replies

-

- 26

-

-

Nice cardboard box arrived from the UK. JAP V twin engine kit set, some assembly required..... Should keep me busy for a bit.

- 53 replies

-

- 18

-

-

Good progress on the front axle this weekend. I'm doing a tubular GN style front axle the same as Bloody Mary had. Axle end blanks. 4140 Outer profile milled and kingpin hole bored Ready to go in the axle tube The axle tube. 1 1/2'' 4130 3/16 wall, should be strong enough..... Axle end in. These will get brazed into the tube Complete axle And mock up, made a couple of temporary axle clamps to hang it off the springs. Bloody Marys front axle showing the Austin 7 front stubs and wheels

- 53 replies

-

- 21

-

-

-

Yeah will definitely have to do a couple of early morning runs.... Have been working on getting a front axle put together. I’m using Austin 7 front drums and stubs. These needed a bit of a rebuild Reamed out the kingpin bushes with an adjustable reamer Set up the stubs in the mill, indicated the king pin to get them square. The dividing head was very good for this job The worn bottom surface that needs remachining And after Then needed to make a couple of new kingpins to fit. 4140 bar stock Finished

- 53 replies

-

- 22

-

-

-

98cc's Resurrection Of The "Smith Spider" 2 stroke race car--Now with SOUND

98cc replied to 98cc's topic in Other Projects

Yep all of the tiny weight savings Dennis did seemed to of added up. The body alone only weighs 30kgs. For sure, it did fell like it was a lean issue. Will pull the motor out and chuck a new set in. -

No but a mate has one and wants to chuck it in a Austin 7 chassis. Its a pretty cool rotary hoe when its powered by a v twin! luckily someone has already made JAP casting patterns...... Made a start on the chassis brackets. Did them in two half's so could clamp them to chassis rail and get a nice tight fit before welding. Have also thinned down the rails from 2" to 1 1/2''. Looked a bit bulky and heavy before. Much better now Drilled a hole through it all and mounted the springs. Will need some form of U bolt to hold them down at the front.