Rhyscar

Members-

Posts

920 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Rhyscar

-

Rhyscar's Subaru Type RA of teenage dreams... where less is more

Rhyscar replied to Rhyscar's topic in Other Projects

Wow this muffler is super quiet. Amazing how much it’s changed the sound and volume considering this muffler has only a 2” piece at the front that opens to baffle and the rest is straight through. Got quite a different Subaru growl to it now too. It’s a different car to drive at open road speeds now.- 37 replies

-

- 11

-

-

-

Man, super interesting to see the process/so many different ways of tackling each blemish. Great skills and love that you're pushing yourself to learn new stuff. I've got 4 cars that would benefit from some of this attention... if you're keen for cashies.

-

Rhyscar's Subaru Type RA of teenage dreams... where less is more

Rhyscar replied to Rhyscar's topic in Other Projects

Dude this looks so good. Mounts were perfect already. Just need to find a bit of 3” exhaust bend and I’ll glue the bits together. Keen to hear what it sounds like. Suits the car perfectly. forever grateful!- 37 replies

-

- 22

-

-

-

Sungai's Bush Block & 90's Hand Built (not by him) Log Cabin

Rhyscar replied to Sungai Sungai's topic in Other Projects

Wow this is amazing. What a spot. The driveway looks like it would be perfect to hoon in a AW11 too! Super stoked for you and look forward to seeing you live out your best life. -

This isn't terrible (unlike every other GTO I see). Evo wheels go good.

-

Rhyscar's Subaru Type RA of teenage dreams... where less is more

Rhyscar replied to Rhyscar's topic in Other Projects

That'd be great I'm sure I can make something work with it! As long as it's 2.5-3" it'll be fine. -

Rhyscar's Subaru Type RA of teenage dreams... where less is more

Rhyscar replied to Rhyscar's topic in Other Projects

Done a few summer drives. Speedo cable broke again, replaced the whole thing this time. Clutch is starting to slip a little more, need to give it a bleed (starts slipping after a period of driving so thinking old fluid/leaky cylinders losing their ability to hydraulic things). Clutch is probably near end of life too, but a good condition hydraulic system is the first step... Had a mare with trying some new wheel cleaner. It stripped all the clear off the Speedlines and ruined a centre cap. Supplier was good about it and we'll look to get these repainted soon (they weren't in great condition anyway). So now we're back to factory wheels. Finley loves this car. Every time it gets kicked out on the driveway she has to go and sit in at and tell me all about it. We had a dad-daughter date out to raglan which was an awesome memory to create with the car. Also it's fucking fast on the divvy... Getting sick of dumpy big bore life. Any suggestions on where to purchase a good value 3" chambered muffler? Mild steel will be fine, I'll hide it away and put a 2.5" stainless tip on it to replicate the group A look. Doesn't need to be anything flash, but would like quieter and more refined boxer rumble.- 37 replies

-

- 12

-

-

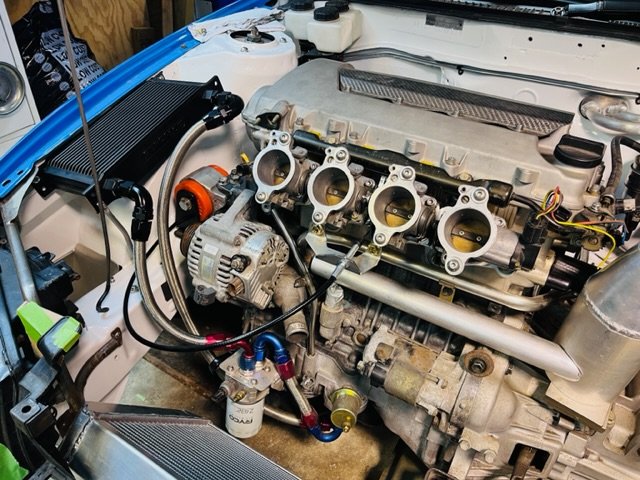

Got radiator side mounts, fans and pipework all sorted over the holidays. These had been holding me up until as their location determines a lot of other engine bay related constraints so was great to get it ticked off. Without a radiator cross-member mounting the top of the radiator was tricky. I ended up welding a boss on each end and finding a shackle bush to mount to the headlight frames. I bloody hope I never bend the front end cause everything will get damaged..... Might need a good crash bar post-cert for bumper-to-bumper racing! Made a shroud for the fans (which are the wrong direction currently due to a brain-fart on my part), mounted 15mm from core so hopefully enough to draw air from whole radiator surface. Have included rivnuts for future addition of bonnet ducting. Now I'm in the process of moving the header tank over to the guard to make the bonnet duct simpler. Should be a great layout when header tank, catch can, rad overflow, bonnet duct and airbox are all finished up. These may take a while to finalise as I'm focusing on jobs that get the car started.. ] This is a HUGE step for me. And super happy with how it worked out. The end is feeling a lot closer and achievable now! Just got to keep moving forward.

- 417 replies

-

- 17

-

-

Truenotch's 1997 Toyota GranV - Francis Jellybean

Rhyscar replied to Truenotch's topic in Other Projects

This is a great investment and the swivel seats are so lush. Will be great for sleeping at the track and general adventures! How good is 1kz towing life? This has IRS correct? -

Awesome thank you!

-

Hey Phil, looking over your ideas for brake upgrade. Where did you find that booster? Is it NOS or from another model? Might be keen to upgrade to boosted brakes in the rally car one day. Thanks

-

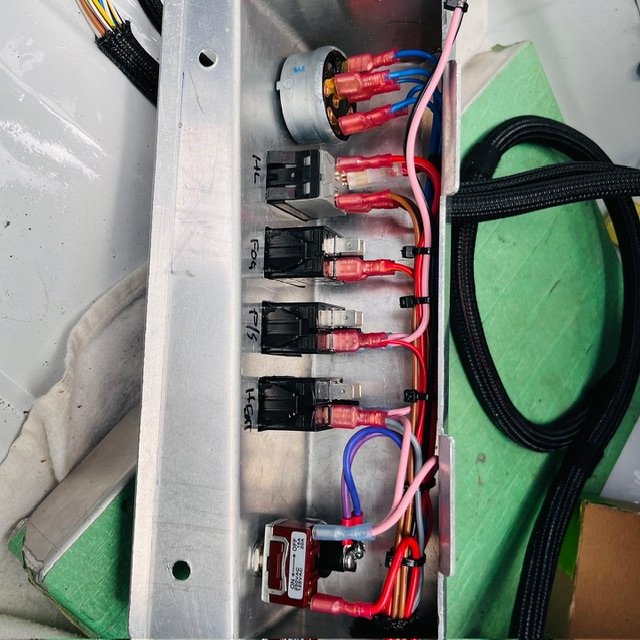

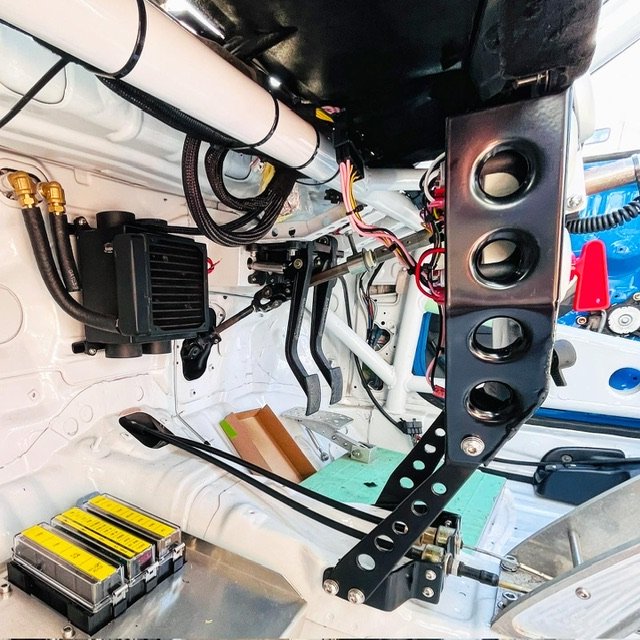

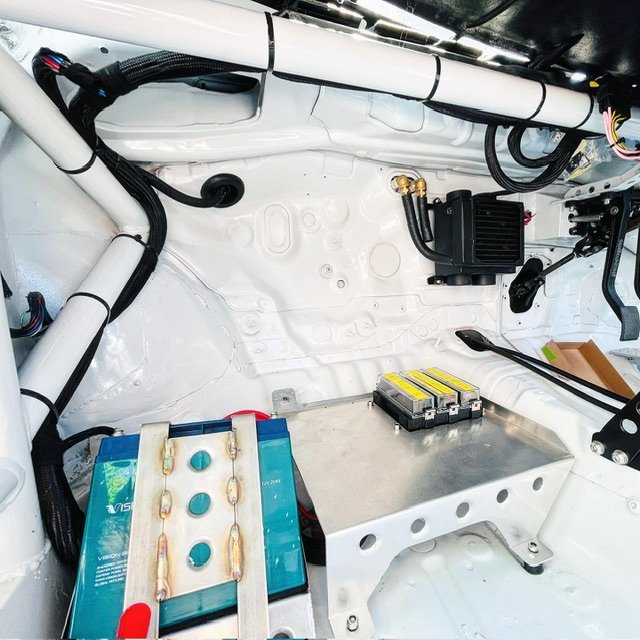

some more detailed shots of the wiring loom front loom is very tucked up against the bottom rad support. Very minimal most of this area will end up getting covered by a catch can so won’t see most of it. Nice and tidy through the firewall. Tight space so stoked I could make this work. Power steering pump still needs wiring from nearby relay. super happy with how it all fits under the dash Gauge lights all working. All the steering wheel buttons and control panel are working mint. Just another plug needed for the rear part of the loom. This makes me happy. So stoked we wired up the yellow fog lights they look great!

- 417 replies

-

- 16

-

-

-

Loving the slam on this car. Can't wait to slay some backroads in this (at a bit higher height) @vk327 cranking into the wiring. Body loom is 98% complete and working. Very exciting to see lights flashing and wiper going. Starting to feel like a real car, not just a collection of parts thats been sitting in my shed for too long...

- 417 replies

-

- 15

-

-

Thanks to @Guypie for machining my intake manifold on a 7deg angle. This netted me 16mm of additional bonnet clearance so I'm happy. This should be enough to design some funky-shaped trumpets to fit under the bonnet. Very interesting seeing @kpr testing results, it seems shape doesn't matter too much, as long as length is correct. IIRC 130-160mm trumpet (330-360mm total) is what I was aiming for. Lots of wiring progress lately. A bit more on that soon, but for now here's some satisfying pictures of general tidyness/not being hory. Made a sweet bracket for the speedo sensor pickup off rear hub. This will drive the Monit (for wof purposes), but also allows ECU to do some launch/traction control things (compare front vs rear wheel speed etc) Sweet bracket for clutch and brake pedal switches. Included clutch to do launch control/flat shift at some stage. Lots of holes because aluminum isn't lightweight enough I guess?

- 417 replies

-

- 9

-

-

Yeah by the looks on silvertops manual to auto driveshaft bracket is different (axles are the same). Unsure if there's enough meat to slot the holes. Toyspeed seems to be down but the answer should be on there. It's been too long since I've done any of these swaps I can't remember anymore. https://www.tapatalk.com/groups/ae111_forum/driveshafts-interchangeability-t6172.html If you don't have any luck finding a manual hanger bracket, I've got a 1-piece driveshaft sitting here for you. Might get you going/rule out

-

Rhyscar's Subaru Type RA of teenage dreams... where less is more

Rhyscar replied to Rhyscar's topic in Other Projects

As summer arrives, have been using this for the odd Sunday drive. Passed a warrant with no issues which was slightly surprising. The more I drive this, the more impressed I am with the performance. It hauls ass for a factory car and has super short gearing. My daughter Finley loves it so that’s the main thing Just a couple of 90s jdm classics out for a cruise gave the engine bay a good clean/detail. Came up pretty good. thanks to @Guypie for machining the centre bores for the speedlines out to Subaru size (the reason they were cheap). Also fitted a set of very used 215s as the 235s they came with were a bit balloney. End result is it looks great on the speedlines. Classic Colin McRae/95 WRC car look Next on the list is replicating the Group A back muffler and looking for some wind up windows and door cards?- 37 replies

-

- 23

-

-

Can’t have carpet that doesn’t match the drapes

-

I don’t do wood things so only have steel-related power tools. Increases the non-desire to do wood things/house Reno’s

-

Bought a cheap dereg shell to steal a windscreen out of it as they don’t make them anymore for these cars. Could of got one custom made but was real spendy. so now I’ve got a windscreen, mirrors, wipers, bonnet pins and all the trim back together, it’s starting to look like a car again! Hoarded heaps of Levin parts from the shell for future Rhys also. this is starting to look great

- 417 replies

-

- 17

-

-

Little bit of progress over the last little while. Got chassis loom back from Drew and got it fitted to the car. Super happy with the fit up and quality.

- 417 replies

-

- 4

-

-

Thanks for the info! Yeah I was planning on sandblasting and strengthening up the frame, maybe even adding a reverse triangulated brace (dunno what these are called) underneath. And yes wider wheels and higher rated tyres are on the agenda. I’ve got a set of 13” work wheels sitting behind the shed that should do the trick. No suspension on this one, axle just bolted straight to the frame. Keeping the fixings lightweight will be a priority I’m thinking I’ll make a lot of stuff in alloy and get it powder-coated. small bit of progress getting this thing onto the back lawn. Required modifying the back steps to be removable to get it past the garage. Win. Now I don’t need to look at it outside my kitchen window every day!

-

I was on a forum break. Detailed most of the build stuff on a instagram page though (might have to scroll back a fair way) - https://www.instagram.com/backyard.advanture/

-

Wow thanks @Stu I know nothing about caravans. Anything to look out for? Unsurprisingly, it is very lightweight and my key concern is repairing the frame so I don't need to run my wooden stripper pole setup long-term. Might beef up the trailer while I'm at it too. I'm guessing these are pretty common issues? Somehow, Hamilton is the capital of caravan manufacturing so I'm sure I'll find an old barry to help with bits and pieces.

-

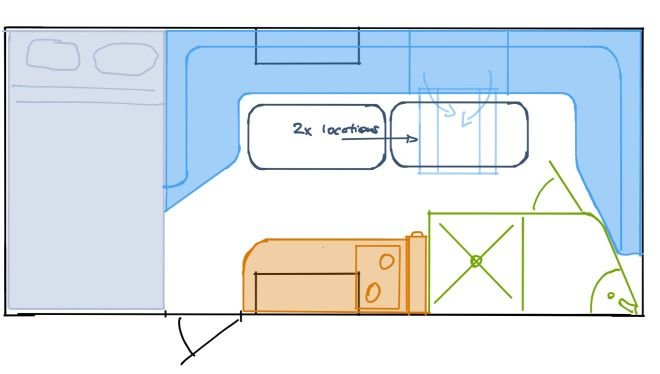

Basic specs we are looking to achieve; - At least 4 berth - Off-grid solar system - 200L water tanks - Hot water/shower and larger bathroom - Gas heater - still towable with the Lexus/mid sized car. Here's one basic concept that might work... will develop a few of these sketches until we land on something we like and then convert to 3D... So the idea behind this project is to apply everything we learned from building a transit campervan during Covid. We travelled the country for 4months fulltime in this and loved it. We sold it, made a stupid amount of money off it so why not rinse and repeat right? Ultimately, the transit was only suitable for 2 people so now with our daughter we want something with a bit more living space.

-

I've enjoyed reading other people's 'other' projects including campervan stuff so will try to post some non-car-related stuff I get up to when I'm not working on the Levin/Corolla/Subaru or Lexus.... So we purchased this sight-unseen at the other end of the north island. Previous owner had stripped it back, had a baby and then realised how much work it is. What could go wrong?!? Last weekend, I towed from Paraparaumu back to palmy with the front of the body flapping around in the wind, roof collapsing etc. 100% dodgy. Wasn't actually attached as welds had broken. It's a 15ft generic 80's caravan. 1930mm inside height currently. Bearings and frame seem to be in OK condition, everything else needs some work. Good thing it was cheap. Aiming for basic use summer 2024 and completion by summer 2025 as finishing the Levin is taking the priority currently. We were looking for a blank canvas to start with so this should be perfect once we address some key issues; - Replace roof skin & frame. Aiming to make it 100mm higher in the centre - Replace front and rear panels (lower) - Relocate a few windows - Repair frame, particularly where it's been cut to run elec wires. Might rebuild parts of it to allow optimal window placement. - sandblast & paint frame. New tow hitch/weld mounting plate - New brake calipers (brackets and discs already there) - maybe replace 12mm floor with new ply Have now propped up the roof and bolted the frame back to the trailer in preparation for towing it back to Hamilton.