-

Posts

2,733 -

Joined

-

Last visited

-

Days Won

7

Content Type

Forums

Downloads

Events

Gallery

Everything posted by gibbon

-

OK some new developments; i pulled the coolant temp sensor and checked it, it seems to be functioning, 2k ohm at ambient down to about 700 at boiling temp. I tested the internal resistance of the inlet temp sensor and there's something there at least, no idea what the nominal figure is. i have three airflow meters and they all gave the same result. i also blew back through the fuel return line, there was a bit of resistance there but i could hear it bubbling back in the tank so don't think it's a problem however i did notice something - the meters seem to have some kind of calibrated bypass tube? and some have a single, and some have a double. the one that was previously installed was the single unit. i have no idea if it's the correct one. but if the ECU is anticipating a load of additional unmetered air from a second tube that isn't there... that could well be why its running rich as buggery

-

That's what I meant sorry. So there's nothing sensitive in the line back to the tank?

-

OK the good news is that i seemed to have fixed the major problem - i pulled the secondary injector, it was all clean, reinstalled it, pressurized the rail and put some power to the injector and it sprayed like a champ. put a test light across the wires at the back side of the final plug and suddenly it's lighting up and the car is revving out.. so i'd say either a shitty connection somewhere which i've made right with vigorous plugging/unplugging, or maybe the injector was seized up and i've freed it up when i tap-tap-taparoo'd it into place because it didnt quite want to go in she's still running rich as shit at idle, @bigfoot i checked the return line from the regulator, it was full of fuel so it's at least the valve itself is opening. i agree the rail pressure does seem high though, the return might be full of fuel but maybe it's fuel that isn't going anywhere thanks to a blockage further down... is it safe to disconnect the line and just blow it back with compressed air? when i pressurised the rail i could see that there were no leaks from the injectors or their little housing doodad @kws i wouldn't have a clue what it's nominal figures are supposed to be for the temp sensor... i guess i could pull it and bench test it with a heat gun to see if it at least changes values.. i've never found a service manual for this particular engine and don't really want to take figures from the closest other manual as there does seem to be quite a few differences. what air fuel ratios would you expect from an auto choke function? is there a chance it's rich as shit just because it's still trying to warm up?

-

The fuel pump is an unknown quantity but there was good pressure at the tb and the return line from the regulator was wet so I think it's getting fuel OK The engine cuts out at any rpm with enough throttle input, or at 3500rpm if I build revs slowly at low throttle

-

Airflow meter I think I've just confirmed that the secondary injector isn't getting a signal to fire which would explain the cutting out.. going to try measuring again straight off the ecu whether there's an actual issue with the ecu or if not firing the second injector is part of limp mode, I'm not too sure. Perhaps it's upset about something else

-

I've never had this car running really so not too sure what the deal is. it's rich, it's lean, it cuts out on anything more than half throttle... the issue is explained in the YT blurb but here it is again car starts and idles easily, the AFR gauge shows it getting progressively richer, but i suspect it's rich from the get go and is just getting more accurate as the probe heats up? i've changed the fuel filter and checked the pickup sock, I don't have a pressure gauge but I tapped a sender into the throttle body and it's showing in the realm of 50psi which is probably in the ballpark but which highlights another issue entirely, this is the 12v starion engine that nobody knows anything about or has any manuals for anyway so it runs pretty rich and doesn't seem to lean out as RPM increases unloaded. on backing off it leans out quite a bit momentarily. really stabbing the throttle causes it to abruptly cut out, on recovery it runs off the gauge lean, but a blip on the throttle returns it to running reasonably rich. at the end of the video i floor the accelerator, you can see it cuts out before it makes any boost it seems to be more load related than RPM related, the TPS seems to be functioning normally. the car has a knock sensor, optical dizzy with no vacuum advance. won't rev, wont build boost, running very rich, these are probably hallmarks of limp mode but i have no idea if this car even has it. read a few fault codes but they make no sense whatsoever, they don't correlate to any of the codes in manuals for the other engine models. i have swapped out an airflow meter and ecu but nothing has changed. what should i look at next? got a speeduino here but it'll kill me inside to rip back into the wiring

-

with smoke pouring off the oft-handled greasy exhaust, turbo and manifold, the starion fired into life and settled into a polite idle with very little actual hassle apart from having to rewire the fuel pump. I vaguely recall my workmate saying *something* had to be done in order to start the car but I couldn't remember what, he couldn't remember what, and the seller's contact details were about three phones ago, and I bet he can't remember what either. All I know is that the black & white wire that feeds the fuel pump wasn't anywhere in the main body loom so I'm guessing it's somewhere else with a killswitch attached to it. Anyhoo check out the glare from that CRISP AS FUCK WHITE. the car would be more complete except I absolutely refuse to pay retail for bulbs and so am currently waiting on about twenty various shaped and sized globes to limp over from chinaland. Obviously I've skipped a bunch of stuff but it's been mainly fiddling around putting bits of trim on, wiring back together, and faffing with the turbo plumbing aside from it being pretty much time to fire up, the other reason for getting the cars out was to swap them over, relegating the GT6 to the Naughty Corner next problem I have, the car revs up fine, but if I try and stab the throttle to make some boost, it runs EXTREMELY lean (like, off the gauge lean) and cuts out. Could be the fact that it's running on five year old 91 drained out of the triumph? not too sure. I remember some wisdom of old "don't buy a starion with electrical problems, it will NEVER RUN AGAIN"

-

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

Pretty hungry now tbh -

I did wonder if it might be too hard, even a "hard" sanding block has a little bit of flex both in it and the paper over the top I thought 1000 would be about right to knock off runs and orange peel?

-

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

I guess so Can't wait to force a burger through a mask -

Speaking of 2k basecoat, my car needs to be knocked back after painting, I have a dumb question... Has anyone tried knocking back paint on large flat sections with a whetstone? Say 1000 grit or so, it's dead flat, larger than a standard sanding block, no need to buy sandpaper, no messy old bits of paper hanging around, no wasting time changing paper etc

-

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

Given we'll get the obligatory level 3, 2, 1 wind down on top of that, I blimmin hope not -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

gibbon replied to tomble's topic in Project Discussion

You could just about read the geological epochs in all those layers of bog on the front panel lol.. is there actually anything wrong with it, or just layers on layers? I have a couple of spares if you need one It's fantastic to go back to bare metal, often time you'll strip back a pretty good looking panel only to find snakies of rust lurking underneath I'm not a professional painter (HA HA HA LIKE, AT ALL) but I'd imagine they'd prefer to have the car in bits than all together. It just makes for a more complete looking job. I don't think they'd be particularly interested in needing all the trim etc either -

Aw sweet something new to buy on aliexpress. See you in an unknown amount of working weeks you good thing

-

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

that's the end of that, then -

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

I can state with certainty that I'll have nothing better to do. Burgerfuel again is it? -

Just has chassis number and vehicle weights on it... I can just make out a manufacturers part number on the bottom. So buy blank, fill it out, gotcha ....best way to fill them out nicely? It looks to be very lightly etched, not stamped

-

My dataplate is missing, how can I go about getting another one? Car has no VIN number, chassis code is visible on the firewall, car has live plates and is on hold, the dataplate was removed for rust repair on firewall by PO and subsequently lost

-

Yeah mate I reckon that'll work, can I have the rod to go with it? Tried to PM you but it wouldn't go through @kyteler

-

this is the beast here. obviously it's supposed to be in one piece, seemed a shame to just chuck the whole thing shoot me a PM if it looks like what you've got, thanks!

-

hahah no shit, i was about to add "really just hoping that someone has one with a busted jaw" lol. I'll get a pic of the rooted bit

-

has anyone ever repaired or gotten parts for these cheap vices? turns out this baby is a holdin' vice not a crushin' vice, i stripped the main nut on it. the nut is a barrel and plug thing cast together, I see this type of vice for sale all the time so presumably someone's dealt with this shit before in the meantime yo dawg i heard you like vices, heres some vice grips to grip yo vice while yo vice grips... (seemed to do the trick at least)

-

What the shit, I've never owned a car younger than twenty years old and suspect I'm nowhere near the only one

-

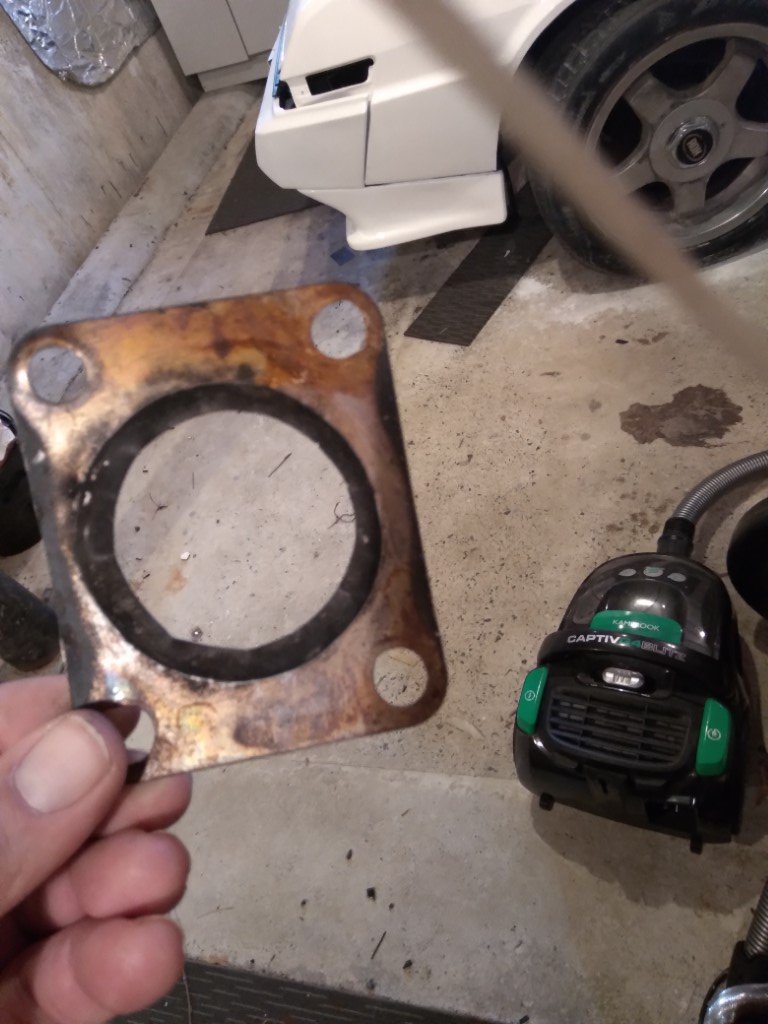

things have occured. most are bad painted the rear bumper and kit, chucked them on. the lights still need to come out and have the surrounds done. where it promptly ran into some fitment issues. not too sure what's going on here, its almost like the bumper needs to be pulled back a good half inch, which would leave an ugly gap between it at the body proper. hmm. the kit can't go forward as it fits nicely in the wheel arch already. I'm almost tempted to just go without it if it keeps giving trouble, the car already has a pretty bulky back end JUST LIKE YO MAMA the dump pipe mk 1 had some fitment issues (and got its own thread) and thus dump pipe mk 2 was born which clears everything and allows the heat shields back in with a little adjustment. its made out of a stupid amount of segments as i didn't have nearly enough bends to create what is essentially a stupid corkscrew shape. it's ugliness has since been somewhat assuaged with a liberal coating of hi-temp shit weld hider. still better than what came out though! i swear! anyway while all of this was going on i suddenly became aware of a burning smell and smoke from under the battery compartment area so apparently the low light sender for the headlight washer reservoir just shorted out, whilst sitting in an empty and highly flammable plastic container. it would appear this thing isn't fused? I'm a bit surprised as I had only just reconnected the battery to put the windows down, but i have had it connected before with no issues, and I haven't really touched any of the wiring (although it is a mess). so potentially this thing was just waiting to burn up at some random point, fortunately I didn't leave it hooked up and wander off. The car doesn't have light washers anymore anyway so I might as well biff it. bit scary really JUST LIKE YO MAMA some adjusties turned up, probably will never fit them because I loathe suspension work had a chuckle at this too, it came off one of my spare turbos. "i dunno man, i fitted the bigger turbo but it just doesn't have the top end i'd expect". looks like it was slowly blasting its way through, he'd get that power eventually so yeah, shit stuff, scary stuff, cool stuff, funny stuff. no actual progress.

-

Whangarei Monthly Meet. Wednesday 18th dec. Burgerfuel 7pm

gibbon replied to bigfoot's topic in Upper North Island Region

Holy ass its busy. Saw an ex Lancer in the carpark