-

Posts

14,318 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

Oh thanks! Stoked to see it from the outside haha

-

That pic on the side of the road is mint. So refreshing to see a vk that's not formula blue, or a Brock replica Looks great!

-

spoke to him this morning, he has the part in stock, its on its way he said the trans has to come out to get the pin out to replace the lever, internet says it can be done in place, so ill have a crack and see if i can do it in place first. theres a plug in the bellhousing behind the converter that has to be removed to slide the pin out which looks difficult to get to he said hes heard of it happening a few times, can be caused by band adjustment being a bit loose, the lever gets a bit more of a hard time with a manual valve body and full line pressure all the time

-

727, built by WAER, but they use mostly stuff from A+A I think?

-

Went to chrome at Hampton downs for the weekend, gave it all the beans, took heaps of randoms for a ride , did a lot of skids, used quite a lot of fuel It was good fun and I was pleased with how it handled a beating , until it decided to do a power glide conversion on itself and delete second gear. Came out of a corner and floored it, and it went nowhere Still had first and third gear and wasn't making any puddles or noises so drove home , pulled the pan off and it's broken the second gear band apply lever, which is an upgraded aftermarket one I think I can replace it without pulling the box out There's a bit of sparkly stuff in the pan and on the filter but I dunno if it's anything to worry about, I changed the fluid a year ago but this is the first time i have taken the pan off since it was built I'll have a chat with the guy that built it and see what the best plan is

- 134 replies

-

- 32

-

-

-

-

Rear spring bushes done Now I could have just bashed a new set in and been done in an hour or so but, just because I couldn't bring myself to put new bushes into spring shackles with surface rust, it turned into a whole day job to sandblast, paint the brackets and shackles and all the fasteners , and nobody will ever see it apart from you, and the wof guy I've now owned this thing for 15 years

- 62 replies

-

- 30

-

-

Daves new school holden shambles. Oops Rod knock deluxe today.

cletus replied to Muncie's topic in Other Projects

unga bunga me tune with screw driver- 756 replies

-

- 6

-

-

-

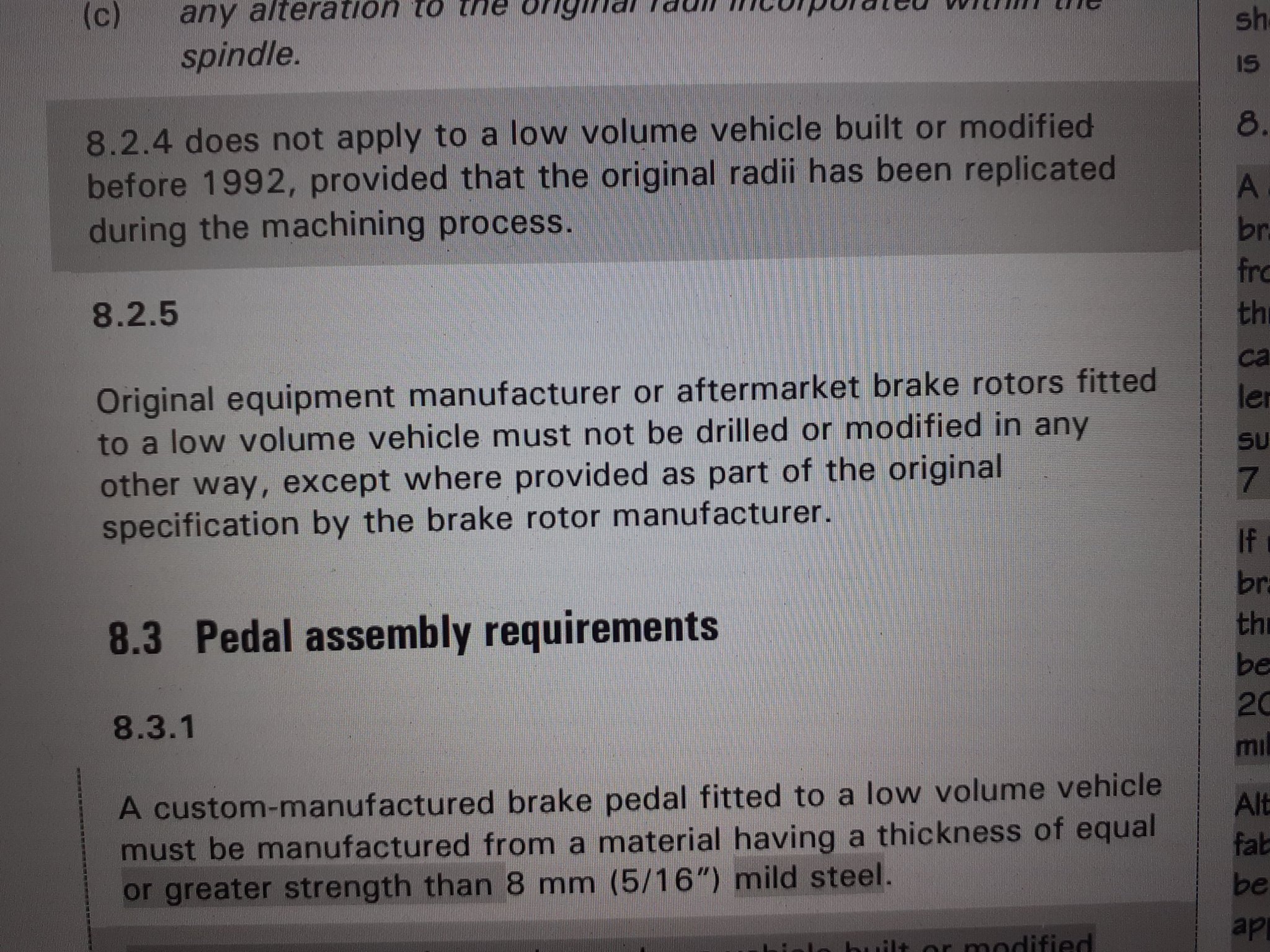

Correct Reputable arm manufacturer can be mig Custom made arm tig and ndt only Oe arm modified where the weld is critical ie if the weld fails- the arm breaks- tig and ndt If it's a non critical weld on a factory arm, ie welding on a bag mount or steering stop, or strengthening plates, mig is OK

-

Yep that's fine

-

from info sheet 04-2020 to find this info you must play the game of read every document ever and try to remember where it is written Spherical bearing rod ends with threaded sections should not be used in a situation where a vehicle’s corner weight and suspension loads will travel directly through the threaded section of the joint ‘in bending’. In some cases, a spherical bearing rod end can be used as an inner joint on a loaded arm where the loads are significantly lower; however, the suitability is dependent on the position of the spring on the arm (the further inboard the spring, the greater the load on the inner joint), and such a situation may require engineering analysis to validate the loads, or may require individual approval from the Technical Advisory Committee (TAC).

-

lvvta would likely not allow that design due to threaded rod ends loaded that way

-

I wanted some dog dish type hub caps, did some research, it's quite difficult to find a 10-1/8 cap that has the right shape, the wheels are a reproduction of 60s chev or Ford wheels so the caps you can get have ford or chev emblems on them. Mopar caps are smaller and don't fit this style of wheel I took a punt on some chrome dome type caps but I don't think I like it, there's too much of a dome shape to them, reminds me of a vw wheel

- 134 replies

-

- 16

-

-

-

-

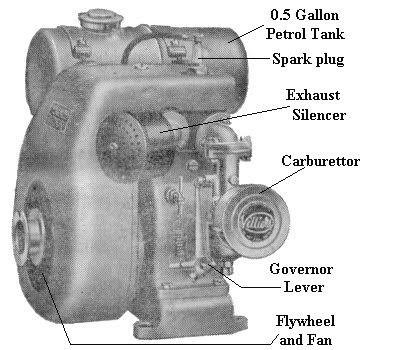

Ah sweet , thanks! No silly Whitworth bolts to deal with then haha I have got a shroud for it fortunately

-

This one I've had running , I've got to make a muffler as it's the loudest thing in the world ever And this one to have a go at next, I don't know what this one is, maybe a generator or washing machine engine?

- 528 replies

-

- 14

-

-

There is an arrow on the alloy flywheel backing plate, I didn't check if it had one on the flywheel though. Can't remember if it had a keyway sorry, I just filed the points through the hole in the flywheel

-

Barry activities Cleaning out my grandads garage, I have found a million small engines, many have been sent to scrap but a few have been kind of interesting to mess around with This is one . Villiers mark 10. forgot to take any before pics but it was at the bottom of the pile, been sitting for many years, no compression. Pulled the head off, exhaust valve was rusted open, disassembled, cleaned it all up, got compression back, filed the points, cleaned out the carb, made a muffler. Starts first pull and runs sweet, the governor works I was going to strip the covers and paint etc but I dunno if I can be bothered, I don't have any plans of actually using it on anything useful. Maybe I can be one of those old blokes who has a collection of engines that pump water into a drum for no purpose Apparently they are 98cc and about 1hp.

- 528 replies

-

- 22

-

-

Can redrill stud pattern and machine surface of discs but nothing else according to the book. CCM brake chapter is due to be updated shortly but I'm not sure if anything is changing regarding disc machining

-

Discuss here about Yoeddynz's little Imp project...

cletus replied to yoeddynz's topic in Project Discussion

This 100% I intensely dislike new vehicles, especially when they have cameras and sensors that bingbong when I do something it deems as wrong I had a day at work where I had to road test 2 cars , one was a tesla, the other was a really rough holden 1 ton with a grumpy LS and shitty old T10 4 speed Tesla was nice to drive but the holden was fun, to the point of if I had to choose one as a daily, it would be the holden -

If it has methanol in it , it has to meet all requirements for a fuel system So every one I have certed has 'water only' on a sticker on the tank, passes cert and nobody ever puts methanol in it ever at all because that would be illegal

-

It's impossible to give a minimum thickness as offset, design, type of caliper mounting all influences how thick it needs to be. Basically it shouldn't flex. You can weld it to the diff housing but not to the bearing housing if it's cast or forged , and has to be tig/ndt, so it's often not a practical option

-

Yea, because of that guy and the incidents he caused, NZTA came down on all certifiers and vehicle inspectors like a bag of sledgehammers lvv certifiers had it pretty easy as we have had a robust system in place for a long time but repair and heavy was a bit of a free for all and every certifier was basically on their own with no checking what they were doing Since then it has got a lot tighter, wof included

-

There is a cert system for heavy vehicles, there's probably a different threshold for things like turbo swaps than for light vehicles LT400 is the name for heavy vehicle certification

-

over 3500gvm- sorry cant help you, i know nothing of the world of heavy vehicles apart from knowing that getting a gvm lowered is not possible, you might be able to body swap a old body onto a truck chassis, im pretty sure thats been done before under 3500- what you are talking about doing is doable. i have done a couple of mini kenworth truck bodies on chev silverado chassis where it might get tricky is doing an old body on a new truck chassis but if the chassis was from a truck with a higher gvm than 3500- if the weights all work, you might be able to do it but i dont know if lvvta would allow that if you used the chassis from a 3500gvm truck like a dyna or something then that would be ok, no different from using a hq ute chassis or l200 etc

-

300mm

-

Like a calf feeder but with innies instead of outies

- 414 replies

-

- 10

-