-

Posts

13257 -

Joined

-

Last visited

-

Days Won

79

Everything posted by cletus

-

If you want to make them look neater - I remove the plastic insulation bit, crimp them, then put heat shrink on instead to insulate it

-

Yes, with conditions Brake lines have to be able to be inspected at wofs so you would need to have no carpet or make a flap in the carpet for inspections. Unless the brake pipe is inside the car factory then that doesn't apply Fuel lines can be in cabin , can't have any joins inside cabin though

-

50% increase over oe There's usually somewhere they can go, up against the sill etc

-

See edited quote In the whole time I've been doing certs I've only done a couple of cars where the owner has fitted a rear loop , it's easier and much better in my opinion to move the pipes, if a car has enough extra power to fit into that requirement then it usually has a fuel system upgrade anyway so needs extra clamps and a new pipe made A rear loop is also difficult to get right as it has to allow for full suspension travel and pinion angle change so it has to be a big oval shape. Often on a lowered car driveshaft clearance to the tunnel is borderline especially with a bigger than stock shaft so adding a loop that will stop the shaft hitting the pipes can make clearance challenging And it won't help if the shaft fails in any other way than u joint failure. If it lets go in the middle then it will still take out the lines. At least if the lines are moved away that's one less thing to get damaged

-

Both total length and spring platform height adjustments are important. The height that the bump stop limits the travel is something that many people overlook or ignore I've always found it a bit odd that MCA is so anal about not adjusting the base height, when the setting required can be so different depending on what wheel and tyre combo, suspension design/type. I'm guessing it's them trying to stop people who have no idea what they are doing from fucking things up I've had a couple of cars set up as per their instructions come in for cert that had basically no travel because the owner had adjusted the spring seat down , it didn't rub sure, but it also had about 10 mm of bump travel. One was hard work because the owner didn't want to change anything "because mca had set it up and they are experts and know everything" A lot of common aftermarket adjustable shocks don't have enough travel to be messing around with spring platform heights much at all

-

https://flowkoolerwaterpumps.com/blogs/cooling-resources/doesnt-coolant-need-more-time-in-the-radiator-to-cool I've recently been through all the same stuff as you, tried several different thermostats and none at all, and have tried both ends of the spectrum as far as restricted flow and max flow. I thought the above article was interesting For what it's worth, in my situation, the best combo was the maximum flow option, but id be the first to admit it's not ideal and the cooling system is borderline at best

-

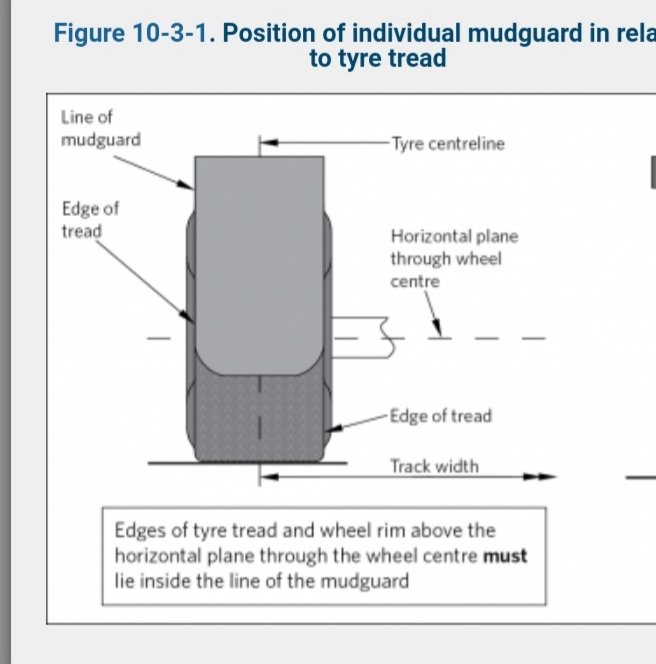

According to the wof manual The tyre TREAD must be covered to at least the middle of the wheel height ie the centerline of the hub However in real life this often does not happen and nobody enforces it There are literally thousands of cars around that don't meet this rule Cert rules are slightly different

-

-

If it's registered in nz prior to 2010, no cat required If it's post 2010 it gets complicated

-

Front shocks out again to swap to a 14kg spring instead of 10. I wasn't happy with how much coil clearance it had

- 128 replies

-

- 24

-

-

Yes, but thickness usually needs to be greater

-

Congrats on new shed too, looks like a good size

-

A big angle on a driveshaft u joint and a grease nipple binding up?

-

Sweet! Is there much difference between SA spec Fairmonts and the NZ/AU ones? Did they get regular falcons there? I know a guy who imported a GT from SA, he said it was basically the same but was called a Fairmont GT instead of a Falcon

-

If you put it in neutral and let the clutch out, anything happen?

-

I wouldn't know Bart, I'm a grown up and would never do anything like that

-

Next thing to sort out was tuning. I wanted to get this and the cooling sorted before I get it certed, because I didn't want to have to redo cert if the carb was going to be too hard to get right and I end up swapping to efi I rebuilt the carb when I swapped the motor in. When I had the whole setup in my VG I had a guy in Australia modify the carb to work better . From memory it was pretty good apart from a little flat spot at one point It's taken me a while to re learn about carbs and turbos again as there's a bit of mucking around getting them to work right I had some issues with lean backfires where it would pop back thru the carb at light throttle which was a lot worse than it was before . I swapped the old adjustable blow off valve back onto it as the one I put on it this time was a bit weak and would blow off early, with a carb turbo it's quite easy to have boost above the carb and vacuum below it, so the valve would open and leak boost which I think was doing wierd stuff to the carb So that made it a lot better Also put bowl vent extensions back on And had a fiddle with the boost referenced power valve. This seems to be where the solution is if I can adjust this a bit more finely

- 128 replies

-

- 25

-

-

Alrighty then I think it's good enough for now. I'll see what it's like when summer comes but at the moment I can drive it all day and it hangs around 170-195 depending on what I'm doing So final stuff done= Flowkooler pump (I'd forgotten but it already had a high flow pump but I think the flowkooler one is better) Wrapped the crossover pipe in itchywrap No thermostat (barry) Bypass restricted to 6mm Two 11" spal fans on a shroud- originally I sealed it around the whole radiator and put holes in the bottom and made rubber flaps like an oem type shroud, I put a gopro in the engine bay to see what the flaps did at motorway speed and they only opened a little bit. So I put a seal just under the fans and removed the rubber flap, so the fans cover the top 2/3rds and cool that bit Also made a lip spoiler thing to direct air up to the bottom 1/3rd of the radiator which in my theory helps cooling at speed. This is a tester and I'll probably try to make a better looking one

- 128 replies

-

- 31

-

-

Sweet! My grandad has had one for a long time, I think he's in that book. He used to tow it with a Porsche 924 It's looking a bit sad these days, it's been sitting for a few years now I remember a yarn pop told me about the Lilliput being quite short, so that it would fit in the shed they were built in?

-

Looks real good now!

-

Probably OK but would need to be certified

-

If its a single skin, thru the rad support or the panels forward of the strut mounts then probably OK for cert What car?

-

Neat. I like the kind of rugged look. Height and wheels are good too

-

I have a video somewhere of one of those kits It didn't work very well, but also the cotton reel shaped spacers that attach the caliper are too long and they flex

-

Have seen someone use an oem rear caliper off some sort of car with handbrake mechanism built in as a handbrake caliper They just sealed up the brake hose port and filled it with brake fluid and used the mechanical handbrake part