-

Posts

3,390 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

Nice, what are you going to use for the rollers and controller? there is a diy dyno page on facebook, with a few dudes who seem to know what they are on about if you're not on there already Mines an old vane bed like the one your originally bid on. but a 6000, not sure if its a cc130 or cc160 retarder. previous owner had the rollers knurled seems to grip fine when car is tied down right. think the retarder is getting a little tired tho

-

full vid of the outboard test:

-

really need a good turbo setup on them, to get the extra weight moving. especially on a bigport engine

-

Had a little accident before first test run. they were a bit close to the ground . so yeh fail. think they would have done ok, if made it into the paddock and not hit bit of concrete on side of driveway haha enter v2 these were front strut inserts. so bigger shafts. sealed gas shocks, you know the ones that say dont open or heat. i did neither of course. they are twin tube, so the outside bit just holds oil and nitrogen pressure. they have a pretty basic shimstack that bolts to end of shaft. i drilled out the rebound bleed holes and modified the shim to bypass more oil on rebound. done this so they return faster. plus the other butchery can plainly see in pic. the only real pain in the ass was the seal at the top. it just pushes up against the outer housing. so i had to preload the housing when welding them back together. put 90psi compressed air in them. one had slight leak with air in it alone. but seemed to fix itself once put oil in them. So.. they actually act like real hydro bumps. as the shaft goes in it compresses the air more and acts like a spring. along with the compression valving. the dumbed down rebound valving lets them pop out fast but not too fast, so shouldn't push the car back up. should be able to mess with oil level and air pressure to make them harder of softer if dont explode first. they have 50mm travel

- 20 replies

-

- 18

-

-

Had a little play with the injector timing. didn't seem to do anything. but didn't change it a huge amount. unsure how much if any effect it would have if not having stand off issues. My end game is probably a lot different to guys in the racecar world as well. Ive messed around a lot getting the lower end of the power curve to work. which isn't really a priority on a 10,000rpm race engine. Doing this is pretty much fixing the reversion issues, which will cause stand off. Dunno maybe i just got lucky and my injectors were big enough to get all the fuel in, in the window of injector timing i tried Intake is pretty well insulated from the heat. if look at pic at top of the page, that black bit between head and throttles is acetal plastic. there is a thermal insulator gasket between that and head as well. Then on the trumpet side of throttles is obviously insulated again with silicone joiner.

-

Mine idled just fine, no different to normal. even though it looked like it shouldn't guessing the closed throttle plate was kinda acting like a carb. Didn't seem to have any standoff issues. in the first part of the below vid, it kinda looks like it does. In the 2nd part with camera looking down, can see it firing some fuel back out on the rev limiter. injectors are 980cc Bosch ev14 . have a pretty nice spray pattern once have a bit of duty cycle. only running stock fuel reg. non referenced which i assume is 43psi. intake never gets warm on normal setup. with the outboards the ali section before the throttles had condensation on it whole time it was running dyno runs where done within 30 mins of each other dont share this vid anywhere.

-

well no major gains. I can say its horrible at part throttle. didn't even attempt to tune part throttle, after seeing all the fuel hanging about. At wide open it seems fine once it sucks up the fuel puddle and gets a few revs. It gains a little power and seems to smooth out the power curve a bit. assume this is from the fuel mixing better once it has some airspeed. also had to pull some fuel out up top. possibly better burn with less o2 left over? for the same reason. So yep need that staged sequential injection. im too poor to spend that much for a few kw, so back to normal now. also I had to shorten intake over normal setup. hence why looks bit janky inside

-

This is the same shit, just minus a cylinder. 50% more power on 8psi boost, with a wind on the pump. no intercooler, stock airbox. just adapter r to stock manifold and some pipes. 1hz looks to be the same deal

-

I wanted to make some getto bypass shocks for the rear. but the shocks i had hanging around wern't long enough. soo getto hydro bumps instead yep thats a hilux front shock with 4age valve springs to return the shock. 50mm travel, take off the factory bumpstop and should have another 30mm or so up travel as well some more butchery required but will go here somewhere

- 20 replies

-

- 22

-

-

-

-

So then old mate @Dudley with one too many clutch kicks snaps an axle. then winter comes along, so been parked up for many months. fast forward to now'ish. the paddock drying out and the gc begging for some upgrades first up the front shocks. still had the og toyota shocks in the stuts. which means can be pulled apart and modified cut the internal stop off and welded it back on 40mm lower down done some janky mods to the valving in the shocks so has more compression valving. plus ae85 springs = 40mm more travel. 9inch in total got em in there just full droop, should be enough to pass a cert on the ground, pretty much textbook offroad spec 50/50 droop compression

- 20 replies

-

- 17

-

-

-

-

@ajg193 got nothing on whats to come... Setting the scene still; After some paddock basing, it went something like. quote @Dudley "its over heating gonna go in" nek minute see the GC heading towards jump i built for the hilux, then proceeding to jump said jump.

-

Not even my car @Dudley , but is amazing. Ke20 with big block 4k beyond repair. but instead of getting parted or scraped, it lives on

- 20 replies

-

- 27

-

-

-

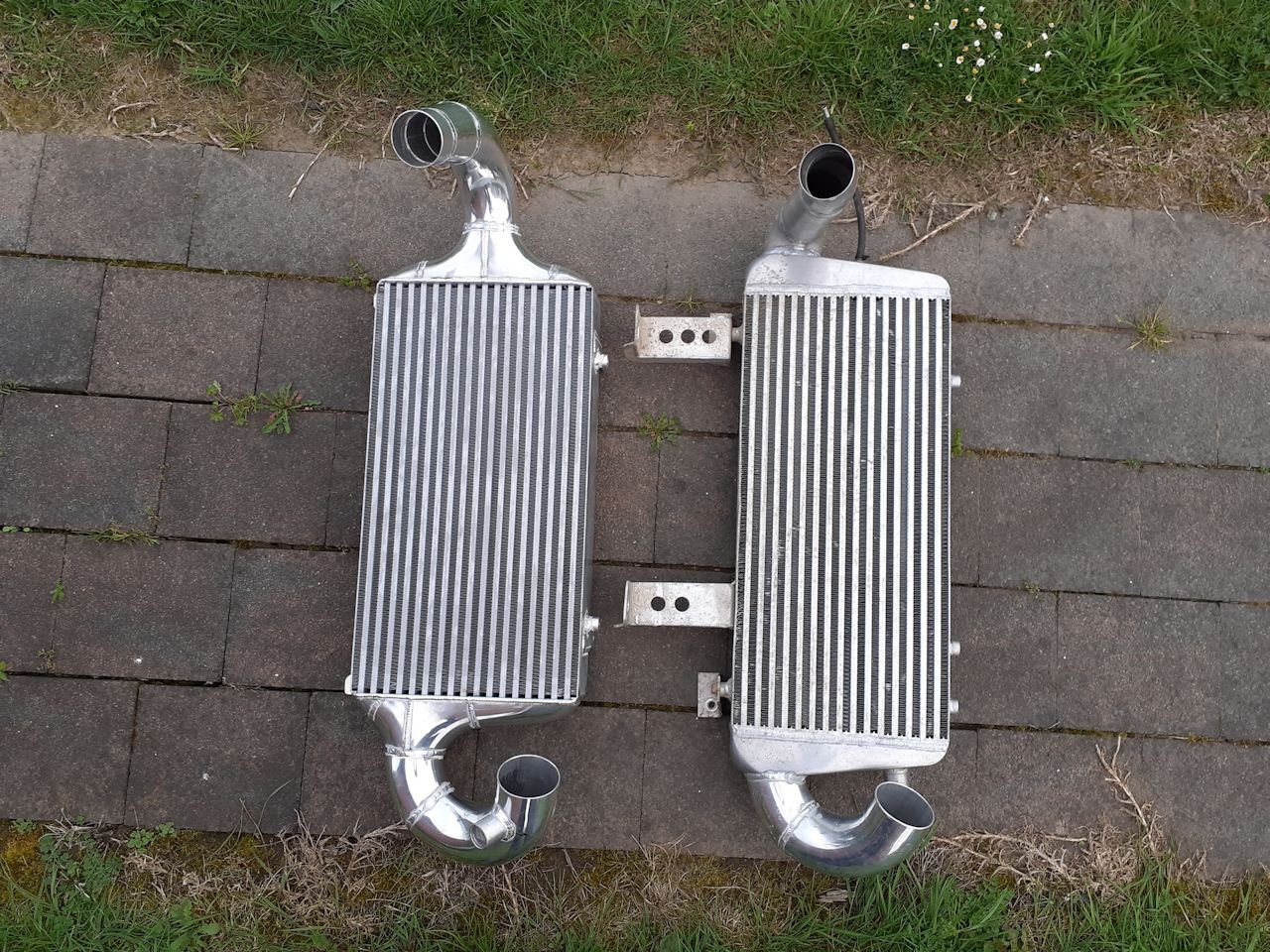

If you have a spare 17mins of your life to waste. this is how i made the end tanks with a claw hammer and angle grinder

- 171 replies

-

- 14

-

-

-

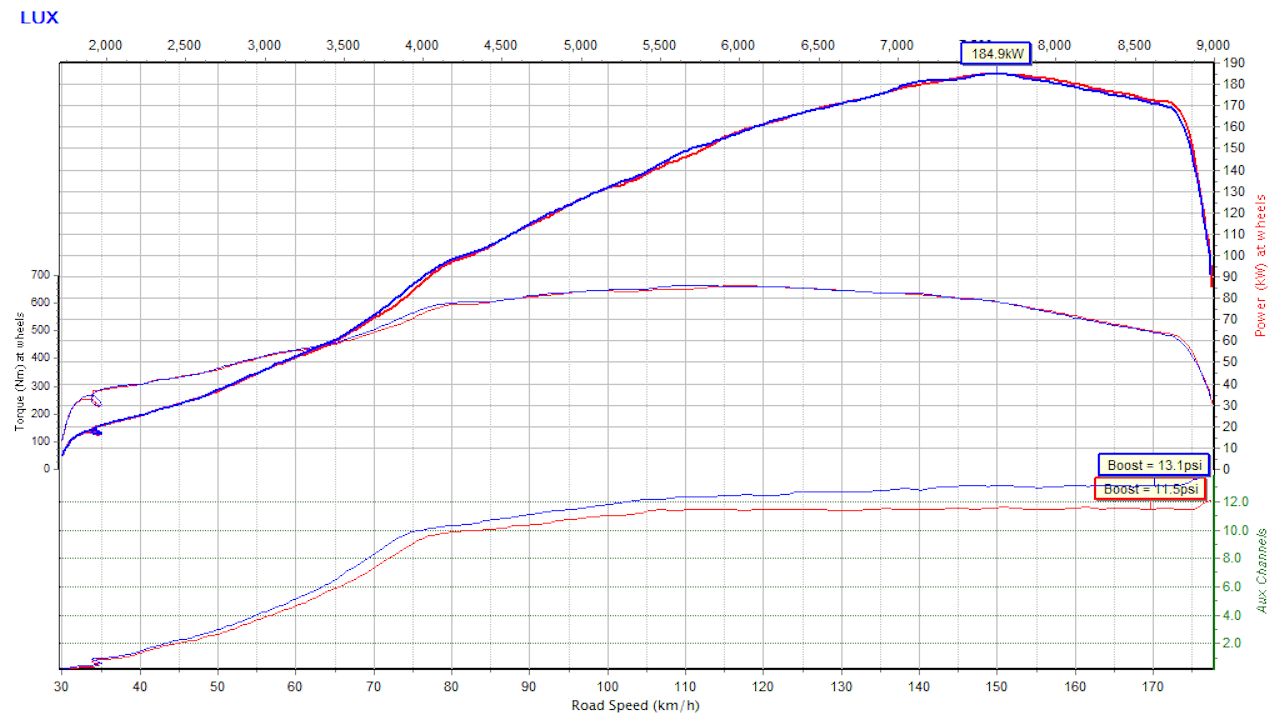

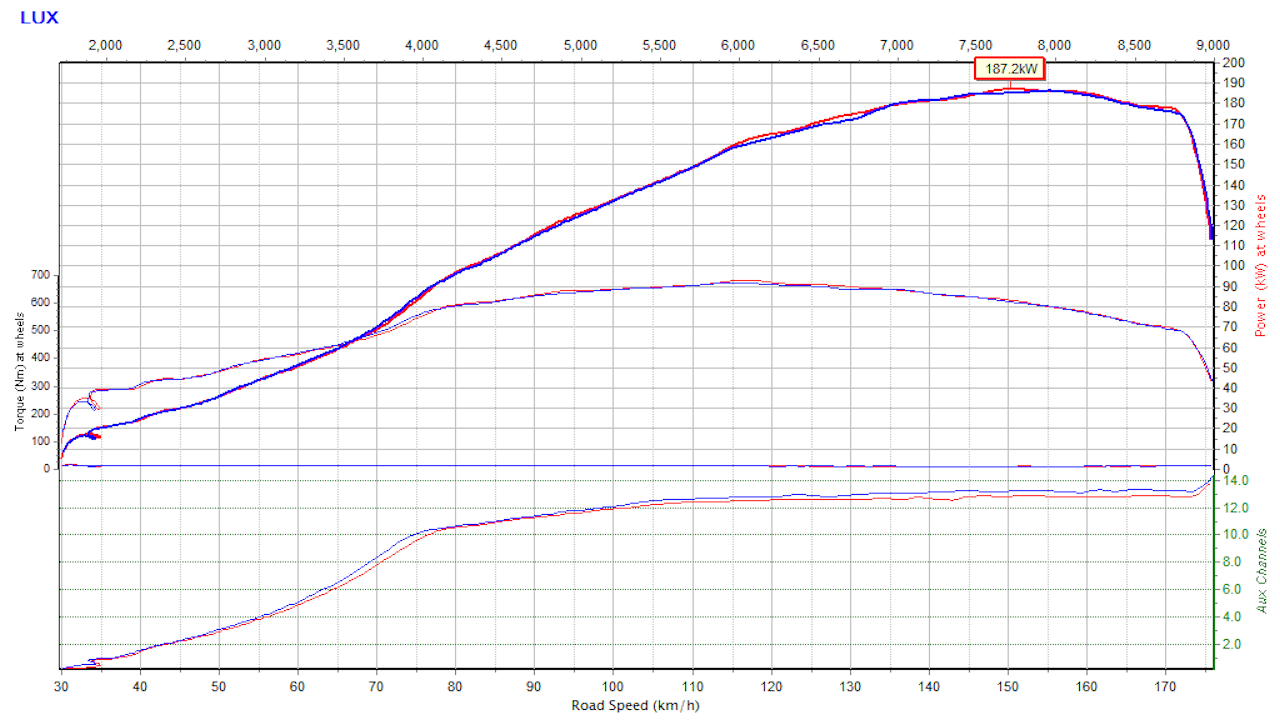

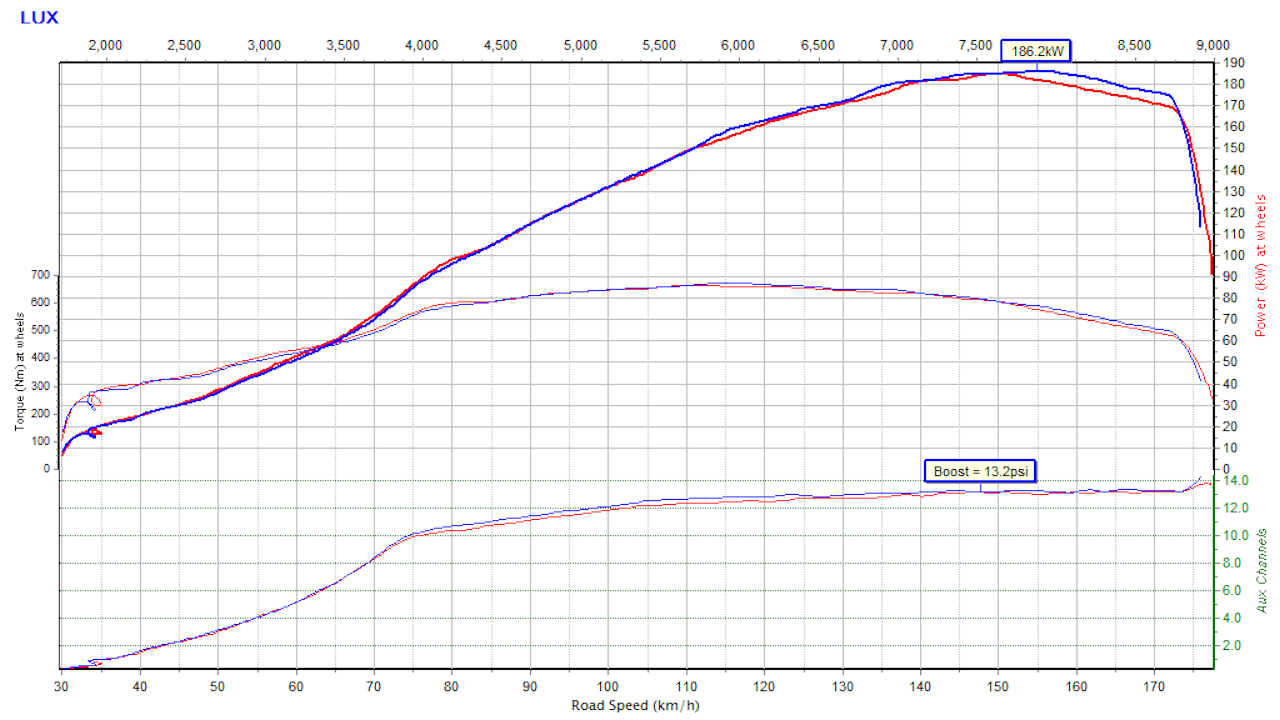

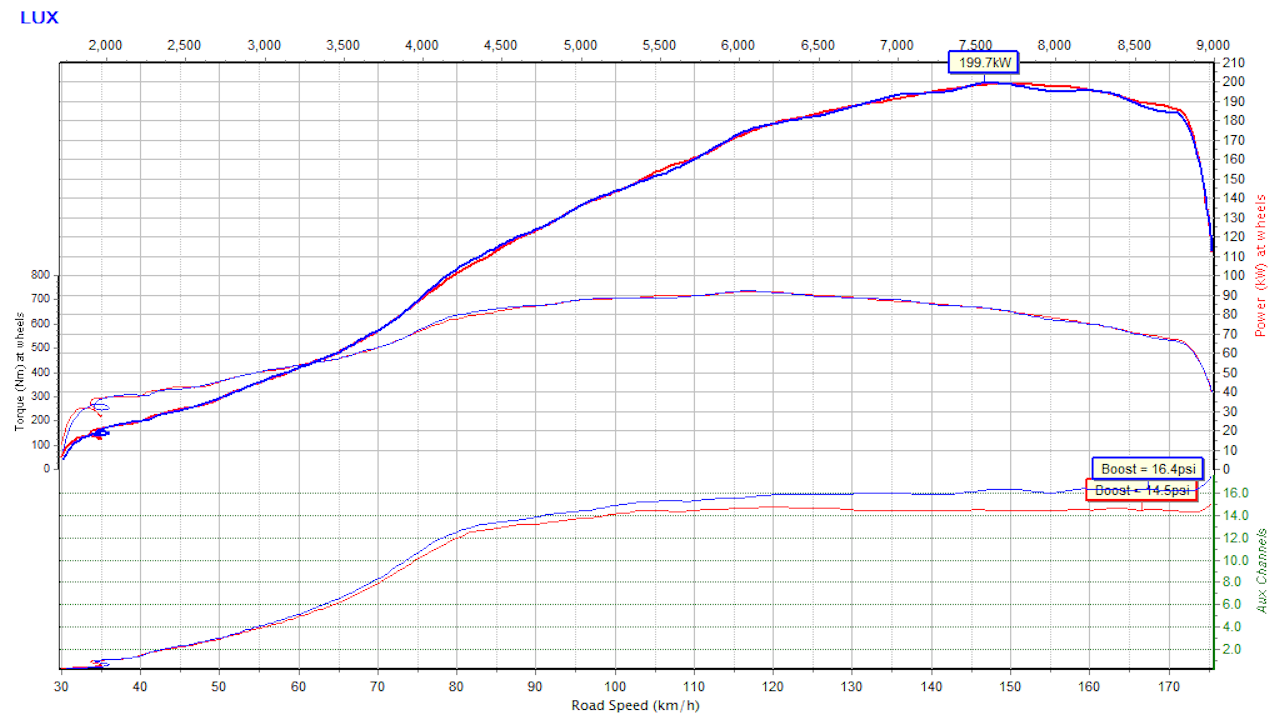

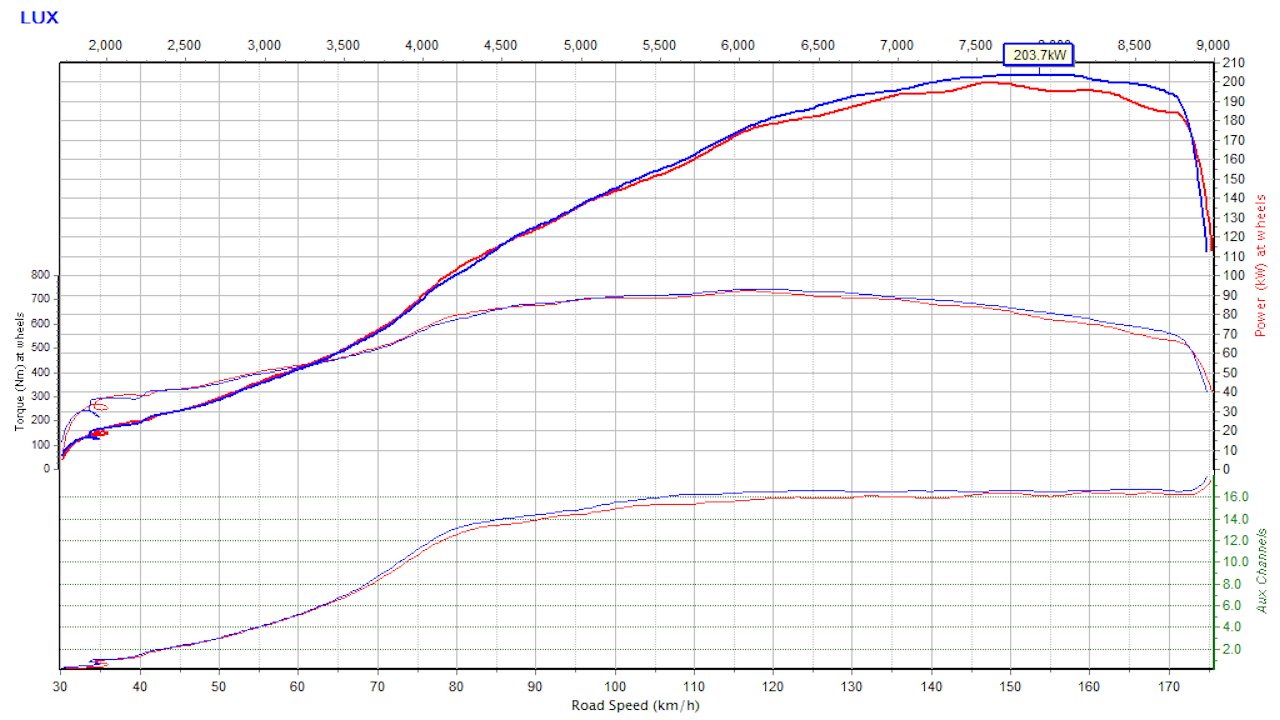

graphs.. this one is the old intercooler red boost line is measured post cooler blue boost line pre cooler 1.6psi pressure drop new cooler red boost line post cooler blue boost line pre cooler 0.4psi pressure drop red old cooler blue new cooler boost mesured pre cooler on both, being bang on the same up top. but more air makes it to the other side = more power with more boost wold cooler gets worse. 1.9psi pressure drop new cooler still only 0.5psi drop gap in power getting bigger at higher boost. and hanging on longer. So yeh no massive gains. but cooler was definitely a bottleneck as suspected.

- 171 replies

-

- 15

-

-

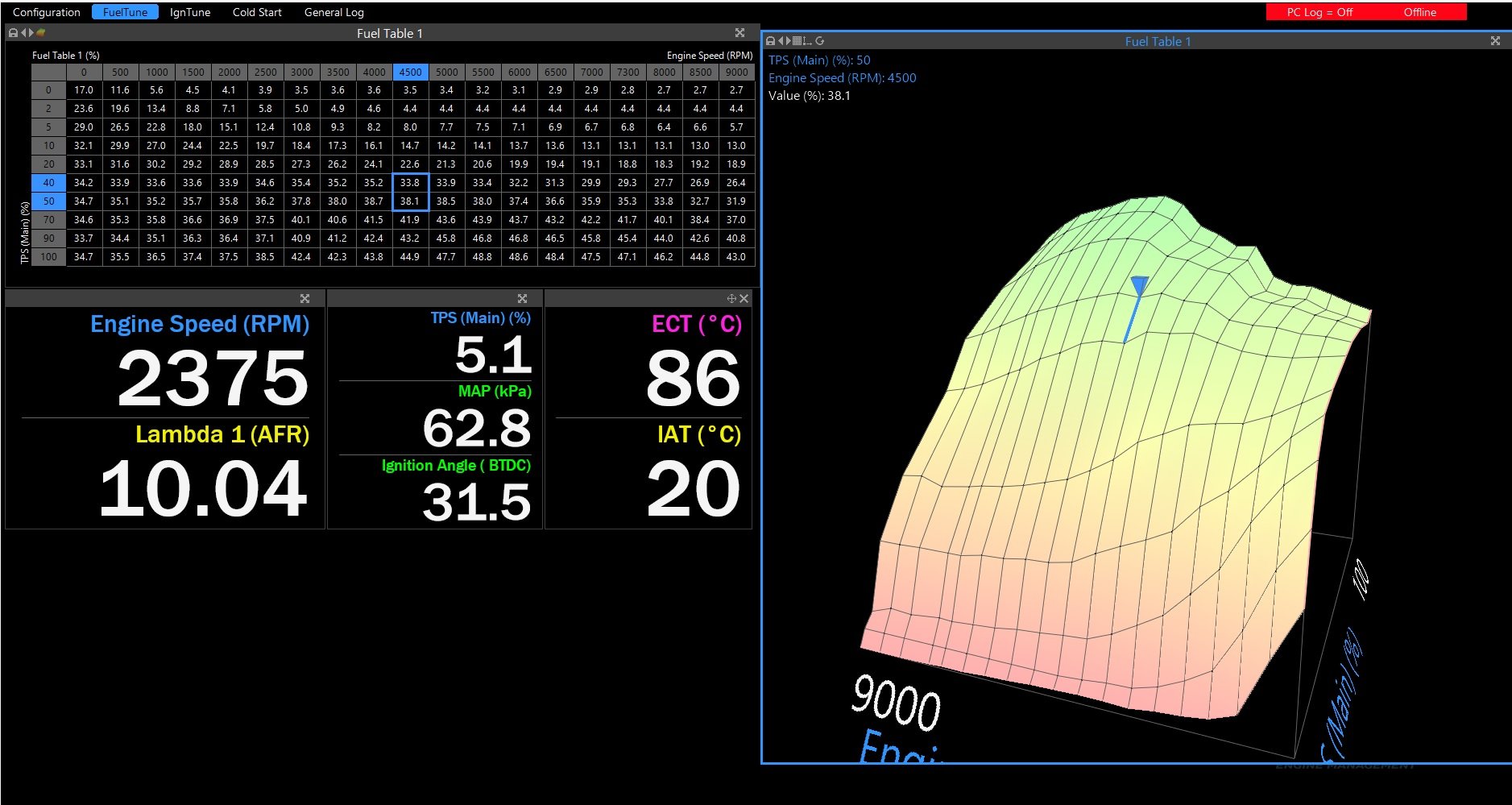

i find this works good for alpha n. this ones off my 20v turd. need quite a bit of resolution at low throttle openings but can space things out quite a bit in the higher openings.

-

looks like you need a few thousand more rpm judging by that graph

-

- 171 replies

-

- 25

-

-

my 20v junk has the same thing with the brake lights wired to ecu. the late model stuff doesn't let you brake an accelerate at the same time. so no line locks in ya new hilux. I assume that wasn't the reason in the 20v tho, since the brakes would overpower the 20v with ease

-

Bit off topic but maybe of interest, every goose was having a moan asking if i tune the car between my tests. So this shows how much the power changes with fuel ratio. also what i keep and eye on when doing the tests. cbf'd watching = 13.5 - 11.5 - pretty much same power. into the 10's power starts to dive. Yeh ok, I just wanted to show off my mangy horse / unicorn photoshop,..

-

@Dudley Gonna be jealous of my panel beating skills. Only using a builders claw hammer with some duct tape over the end, and a 6 by 2 One down 2nd one in progress. outlet needs to be towards the bottom so bit different to the inlet side. looking decent so far

- 171 replies

-

- 33

-

-

-

- 171 replies

-

- 29

-

-

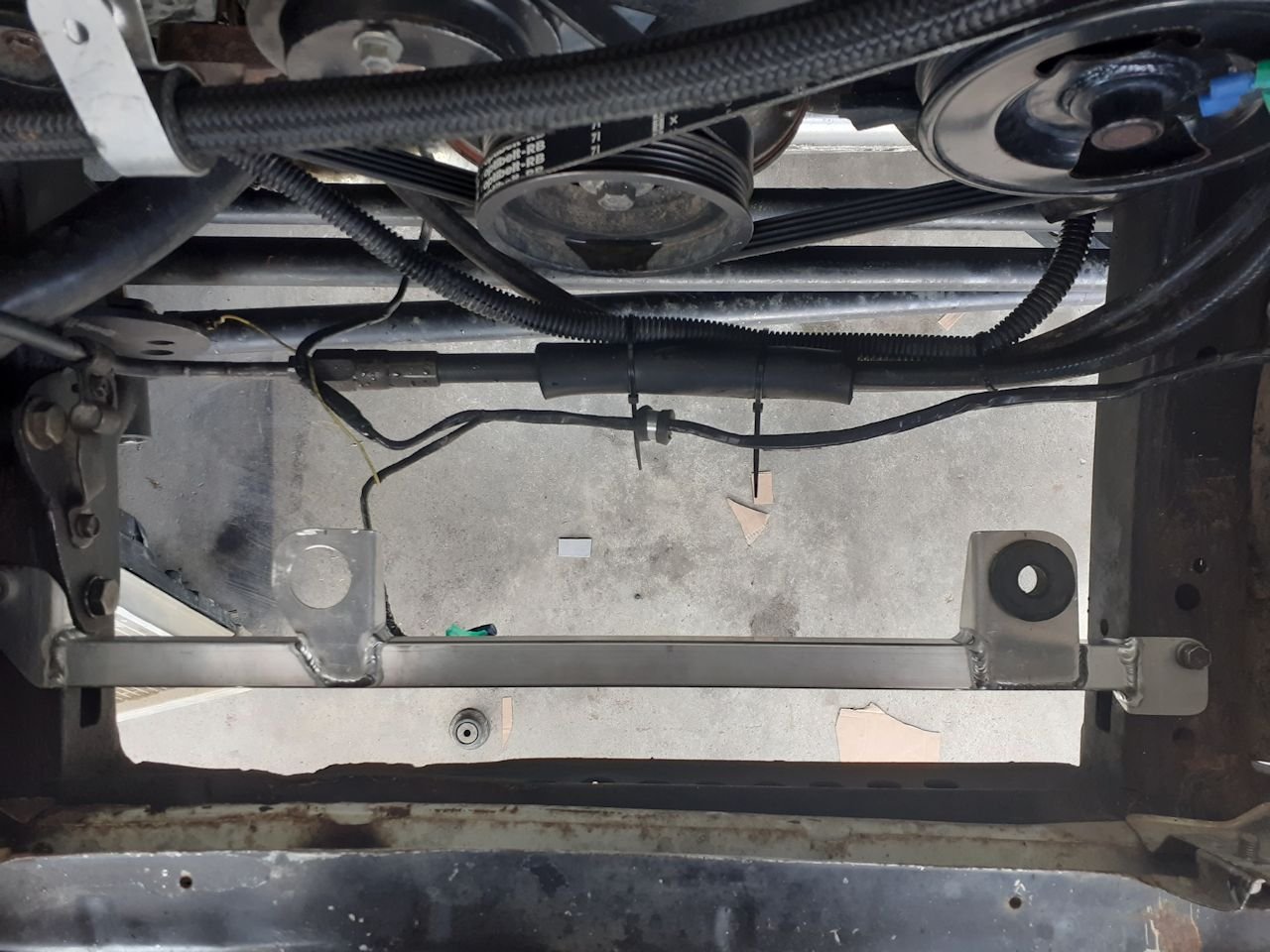

made lower bracket thing for radiator to sit on main cross bit is made from thin stuff and brackets 3mm. weighs pretty much nothing goes here managed to bend and beat bend into shape. bit more hectic than planned. looks to be working all good, just gotta manage to make 3 more

- 171 replies

-

- 15

-

-

-

bald supercats are amazing on the back of my paddock car, lush ride and little grass damage. would trade again

-

wrong thread yo. but close enough. only got post iat sensor. The temps were never really an issue, china intercooler cooled good. just doesn't flow enough