-

Posts

6766 -

Joined

-

Last visited

-

Days Won

32

Everything posted by Roman

-

I cant wait to see how demoralized he gets when the peach cans win again

-

Zac's rotary redux project, because he has too much spare time.

Roman replied to ProZac's topic in Other Projects

I love reading detailed stuff like this, really makes me feel like ive achieved something for the day when I obviously havent. Keep it up please- 50 replies

-

- 10

-

-

-

-

Nissan Micra k11 - Mandy goes to a new happy home.

Roman replied to yoeddynz's topic in Other Projects

So whats the plan, big block motor in with the LSD box, into the best chassis? -

Stu's 4agte 85 EP71 Starlet and 4age 84 AE86 Levin

Roman replied to Stu's topic in Projects and Build Ups

Another cool thing about rampable fans. Instead of instantly on/off and shock loading your closed loop idle. You can gently ramp in the extra alternator load using a timer or whatever and it will help keep engine speed steady without a jolt.- 31 replies

-

- 2

-

-

Currently got shore A 60 filled mounts and its pretty rattly. Could perhaps do the rear one in 70 or 80.

-

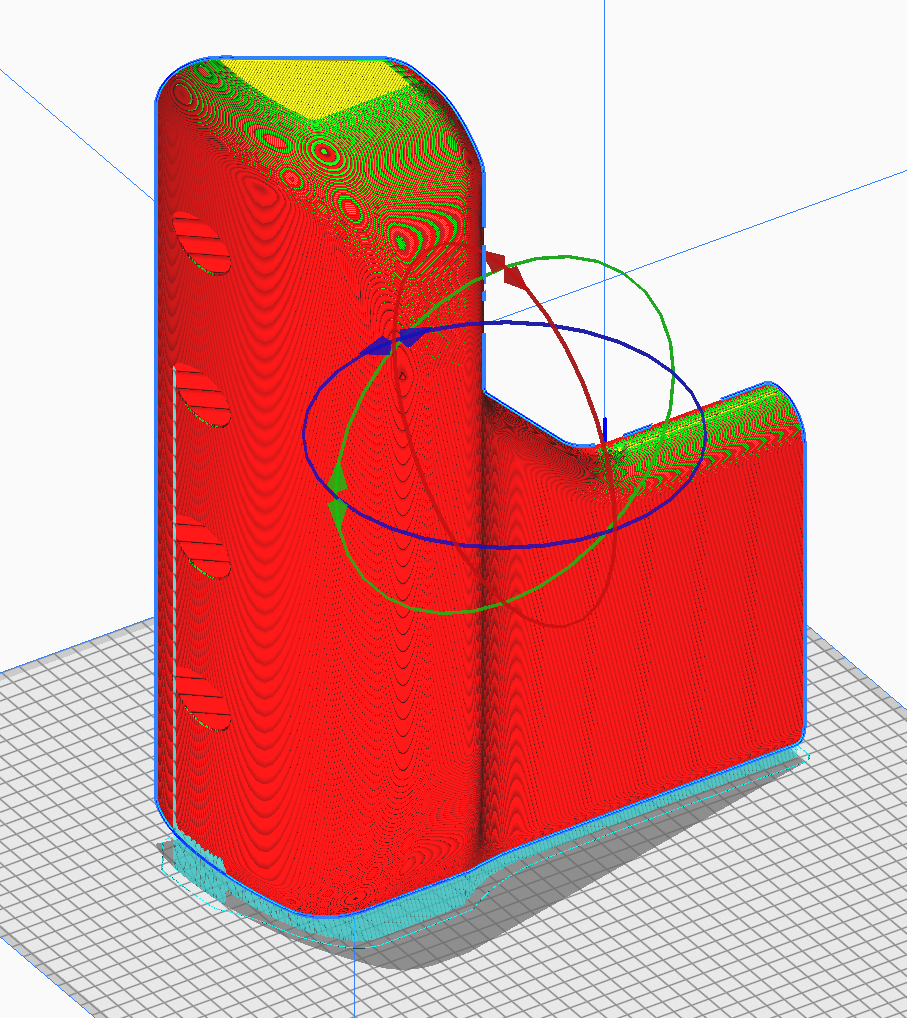

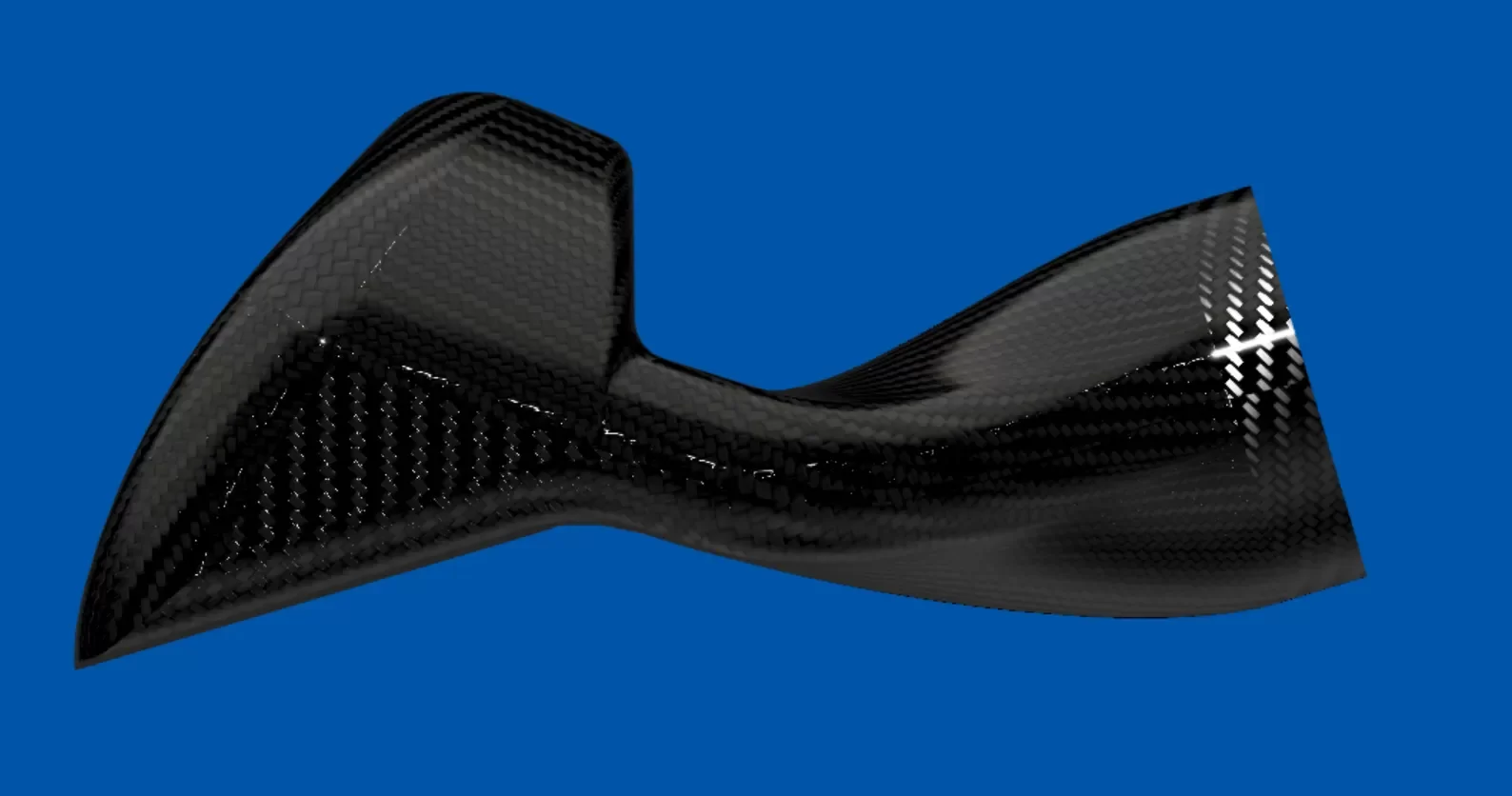

I got a lid printed, clearances are tight. On this one I waxed up the printed part and then popped the carbon part off when it had finished. I might redo it the proper way and make a female mould so everything stays nicely flat on the outside. Because it's a bit bumpy. This needed a lot of sharp bits trimmed off because of my caveman methods. However in the meantime, from a functional perspective - it is, in fact, a lid. Still need to figure out how to seal it on nicely. To be honest it's got a few issues. The primary annoyance is that it hits the bonnet on the curved part near the headlight sometimes on decel. The angle of the pod filter pipe would be nicer if it was back a little further, on a hard decel the filter bonks the bumper sometimes. Which gives you a hell of a fright when you're half expecting a rod to fly out the block every time you're doing 8500rpm This is why I really needed a filter! I'm running on about 30% biofuel I sealed the lid on with some duct tape and it's absolutely incredible how much it's reduced the noise level compared to open trumpets. I'm seeing zero changes to the fuel table (so no indications of being a restriction) However I just cant believe how much it's killed the intake noise. It's still got a 100mm dia opening, and at least that much cross sectional area as the pipe goes up. Obviously it's not great to kill all the cool intake noises. But man I feel a whole lot better about driving it late at night around the place without annoying everyone haha. Now that I know it's definitely not restrictive as-is, I might add a bit more clearance in a few areas. I'll add a boss for the IAT sensor and a pipe fitting for crankcase vent gas. Also, all of my trackdays got cancelled. Hopefully a Meremere test day will still be going ahead in about 2 weeks. bonus content from slightly prior to the noise killing airbox

- 1536 replies

-

- 27

-

-

-

I know you're looking for NZ based stuff, but have you had a scour on YAJ? There's some weird tercel stuff thats a laugh "Unopened Yonezawa Tercel gate Tercel game Men's 5-stage conjugation course for girls You can play for 24 hours!" https://www.jauce.com/auction/s1011126335 https://www.jauce.com/auction/v1008131154

-

Nearly finished this bit, and the lid part is currently printing. Having a 3d printed core is 100% cheat mode for carbon stuff haha. It makes drilling/filing the holes super easy, because I can just work from the other side and shows me exactly how far I need to go (a few of the holes as pictured need a little more work with the dremel) Most of the work is sanding down sharp edges, I dont think I've experienced any splinters more ruthless than from CF. Definitely 100% do not want to get that shit in your eyes/lungs/whatever. Although I've got a setup that can do vacuum bagging and /or resin infusion, or making 2 piece moulds to make a 100% carbon part. Wet layup and retaining a thin printed core provides excellent results that is about 1000 times less effort. It's also nice because you can retain 3d features like upstands for clips or bolts or whatever, rather than being left with a super thin material that you then have to add stuff to. Which is another time consuming step where you could get things put in the wrong place. A++ would cheat again

- 1536 replies

-

- 22

-

-

-

- 1536 replies

-

- 38

-

-

-

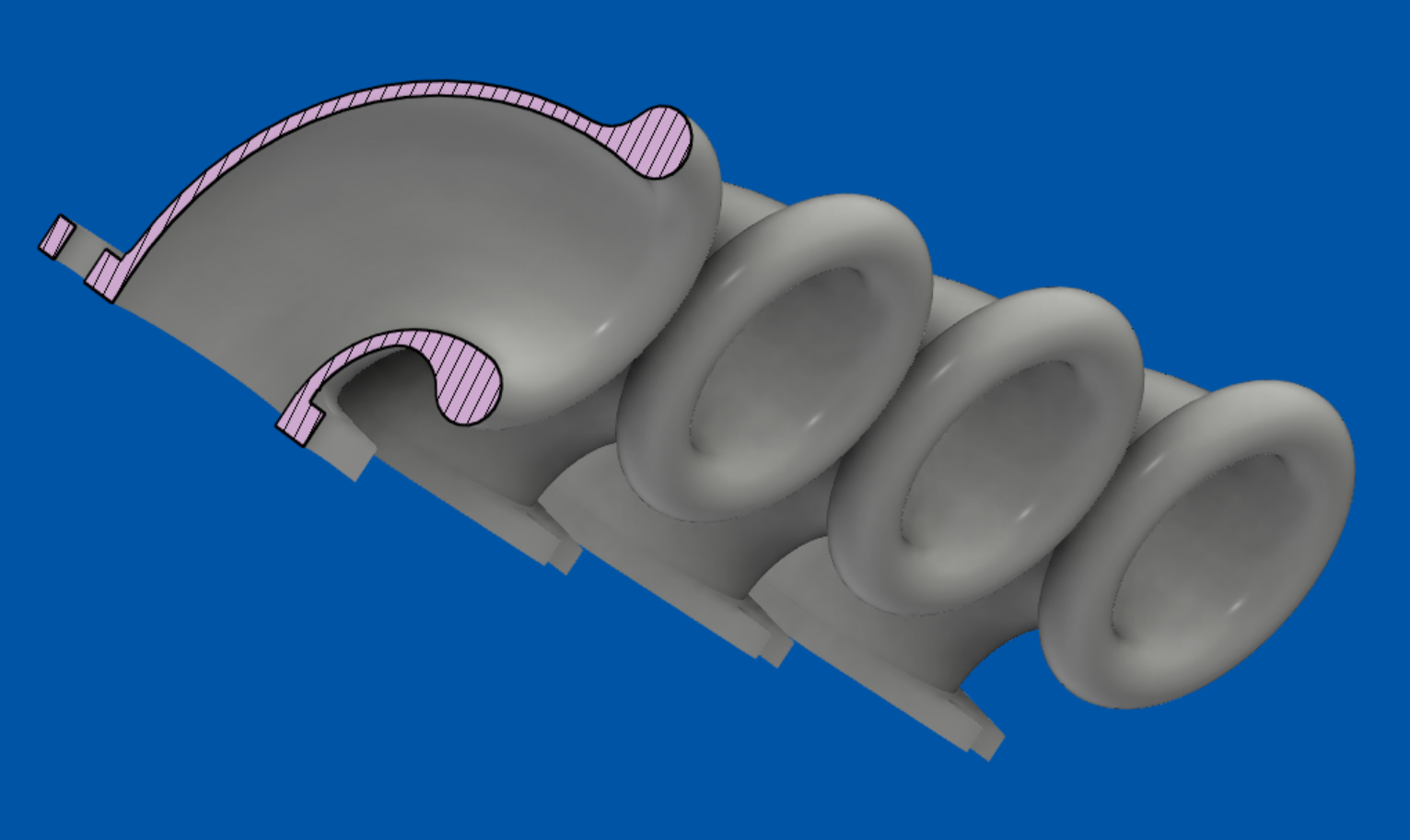

Test fitted ok but need to figure out the filter situation. Pod filter is easiest thing for now So on to version 3.0 to see how this fits And artists impression

- 1536 replies

-

- 18

-

-

-

I love those clips on the super tourer one

-

Time for an airbox to try stop the motor from inhaling 50,000 mozzies per hour. So started with a basic 2D profile. Found it hit where the bonnet rounds off a bit. Bought some play dough and smooshed it around the place to check clearance. Generally better than expected, have got 20-25mm to the closest brace part. So measured up the places I had to cut, then modelled V2.0 which is currently printing Once this is done, if it clears everything and there are no other issues. Then I need to decide how to divide it up into sections so I can still get inside to do up the bolts for the throttles. And then figure out what sort of air filter it's going to have, whether try jam a panel filter on it (probably makes sense given available space by radiator) or just transition to a round to jam a pod filter on there. Still a few iterations left to go until it will be a usable thing, but getting there. EDIT: Will be something like this

- 1536 replies

-

- 28

-

-

Jesse's 1981 corona mark ii grande discussion

Roman replied to Jeffs_Emporium's topic in Project Discussion

looks cool as! Man a passenger could accidentally wreak havoc though with some knob fiddling. Does the glove box lock? Or take good photos of all of the positions haha -

I will have some considerably better options available to test on the day. However I'm still keen to see what it can do on a 185 with a bit of trickery.

-

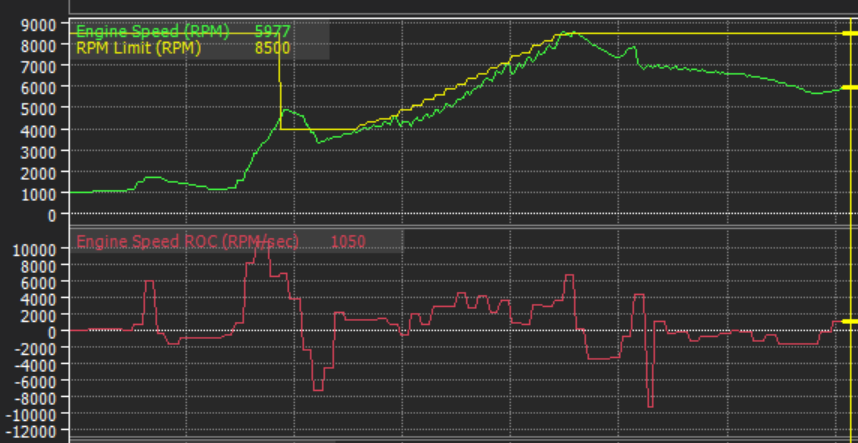

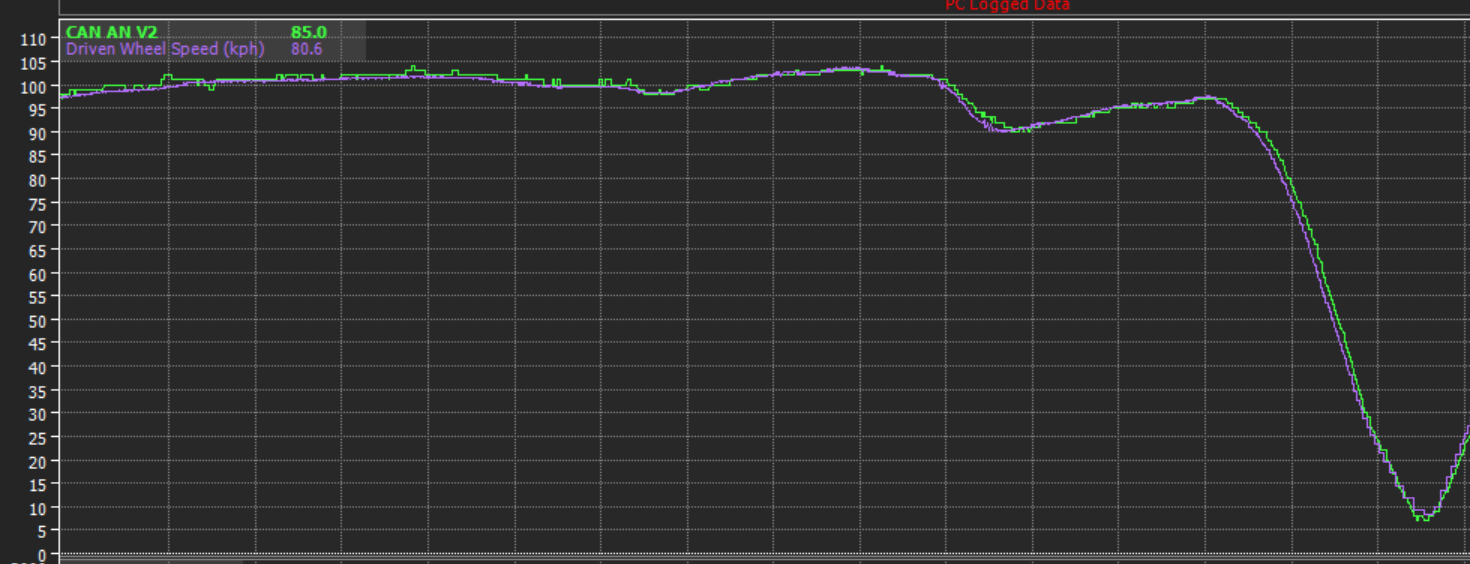

The ECU outputs a value called Engine Speed Rate of Change. But it's not great. This generation ECU (G4+) doesn't have any capabilities for smoothing or averaging, so the results are very jumpy. I checked to see if the rate of change in the first 3 gears would be anything useful, but it's a mess. I think for a max accel ramp to work, you really need an equivalent of a non driven wheel speed signal. in which case you may as well look at slip rate directly. Maybe an accelerometer would do the trick, but untangling yaw/roll/pitch/etc from straight line acceleration is big task. This is what ROC looks like, a bit messy: But for easy adjustment at drags etc, I can setup another axis on the rpm limiter table that is controlled by a potentiometer or canbus input. As ideally it would be nice to have it adjustable in cabin without a laptop hooked up. Speaking of such things though, with some bodgery I managed include my 20hz GPS into the data that my dash outputs back to the ECU. (and use for dash stuff I guess) So this can give a rough equivalent of a non driven wheel speed: (might need to add some smoothing) I'm not sure if this will work well enough to use for traction control off the line though. It has some weird bumps in the values sometimes. But after butting my head against NMEA data for a bit, (thanks, person who wrote a library to decode it) there's some interesting stuff that comes in from GPS. You can get the date and time from a GPS signal too, which is kinda cool. As well as which direction you are travelling in. And Altitude. Also it can plot latitude and longitude, so you can draw a map. Because it's in the same log file as everything else, you can overlay TPS position, or vehicle speed, or whatever else as a colour scale. My fairly bodged together code for this ends up wrapping the values at the moment, if you go too far. Not sure how useful this will be, as I've got no motivation to completely reinvent the wheel of Racechrono etc. Which is already very useful and easy to use.

-

A bolt physically cant come out unless the top bolt comes undone as well. Because it cant unwind far enough to come out of the slotted part. A nut makes me a little more nervous about it coming off and the motor eating it. Although that's probably next to impossible.

-

So a few different things ABS pump / wheel speeds I've not been able to make any progress on the ABS pump swap, because I cant get to an Auckland pick a part site to grab some other wheel speed sensors. Doesnt look like I will be able to any time soon. So for now I've put the regular speedo drive back in, and wired it up. Will just repin to suit standard ABS pump. Track day next Friday! Exciting. Traction control setup Since ABS setup wont work, I have setup a timer based RPM limit instead. If vehicle speed is zero, and you are over 90% throttle. Then the rpm limit changes to 4000rpm. and a timer resets to zero. As soon as it sees that the car has started moving, the timer starts and the rpm limit starts increasing along with the timer up to the normal max. So the idea is that if the rpm goes faster than what is physically possible for the car, it must be because of wheel spin. so a few quick ignition cuts then you're on track again. It's taken a bit of trial and error to setup, but its working good so far. Green line is engine speed and yellow line is the rpm limit. So ideally on a good grippy launch you stay just below the yellow line with no intervention needed. It's not ideal and I'll still pursue getting front and rear wheel speeds. But it's pretty good in the meantime. Rear disc swap It was only $65 at pick a part for an entire disc brake rear end including hand brake cables, ABS sensors etc. So cant complain about that. The only tricky part of swapping it in, is that you need to remove the exhaust in order to remove a heat shield, to swap the hand brake cables. Certainly not the worst swap of this sort I've done. Not sure if I'll get this swapped over in time for track day next Friday. Probably a good idea to get new discs and pads. Trumpet swap So far I've had the best powerband by using some rather long trumpets. They've been through a few iterations fine tuning the angle and lengths so they dont hit the bonnet or the radiator cross member. However the current iteration that I'd settled on still ever so slightly rubs on the bonnet when the motor is under extreme movement. It's only the slightest rub so I'm not actually concerned - and only on one of them. But long term I need an airbox over them and an air filter, so there's simply not enough room. So my only real option was to put a much more aggressive bend in the trumpet and then as a result they are a fair bit shorter. But also more clearance around everything. As a result you cant fit the bolt into the bottom hole anymore, it needs to be slotted So I went for a drive to see how the powerband would change, expecting some slight losses if anything. However so far results are looking better than before, considerably better. Not sure why though. To reach target AFR you can see the closed loop lambda was wanting to add a peak of 22.7% more fuel which is an insane increase. I added the extra fuel then reran, and it stayed on target with minimal trim. So that was interesting. But I'm not quite convinced this is consuming 22% more air with just a trumpet swap. However it's possible that the older trumpets were badly shrouded by the bonnet and the radiator cross member. It's now up to 69.9% duty cycle with the 2ZZ injectors. Previous best was 66%. Although thats only really an indication of what's happening at max rpm. My fuel map is looking increasingly comical. I think I need bigger dia exhaust and/or VVTI to reclaim that mid range. It would be pretty good to get some of that 4000ish rpm region beefed up. On the whole though, have been fixing up some minor issues but I'm as good as ready for track day. Cant wait!

- 1536 replies

-

- 32

-

-

-

Could the distributor be 180 degrees out?

-

Yeah need different pistons for vvti to work. So will do rods at same time. Was going to do exhaust some time after hoist is operational. Thats on hold thanks to covid

-

No progress on anything but while I was doing some work today I came up with this little tune I'm a, fat man in a light weight car, Fat man in a light weight car, Keep going on about power to weight But I'm having second dinner by 20 to eight I'm a, fat man in a light weight car, Fat man in a light weight car, Dreaming of a time when my fast car flies While getting up to speed on a 6 pack of pies I'm a, fat man in a light weight car, Fat man in a light weight car, Thinking in a race that I'm gonna come first But I fit my overalls like a sausage thats burst I'm a, fat man in a light weight car, Fat man in a light weight car, The only racing cup that I'll ever see Is a well supporting bra with a bust size C I'm a, fat man in a light weight car...

- 1536 replies

-

- 22

-

-

-

-

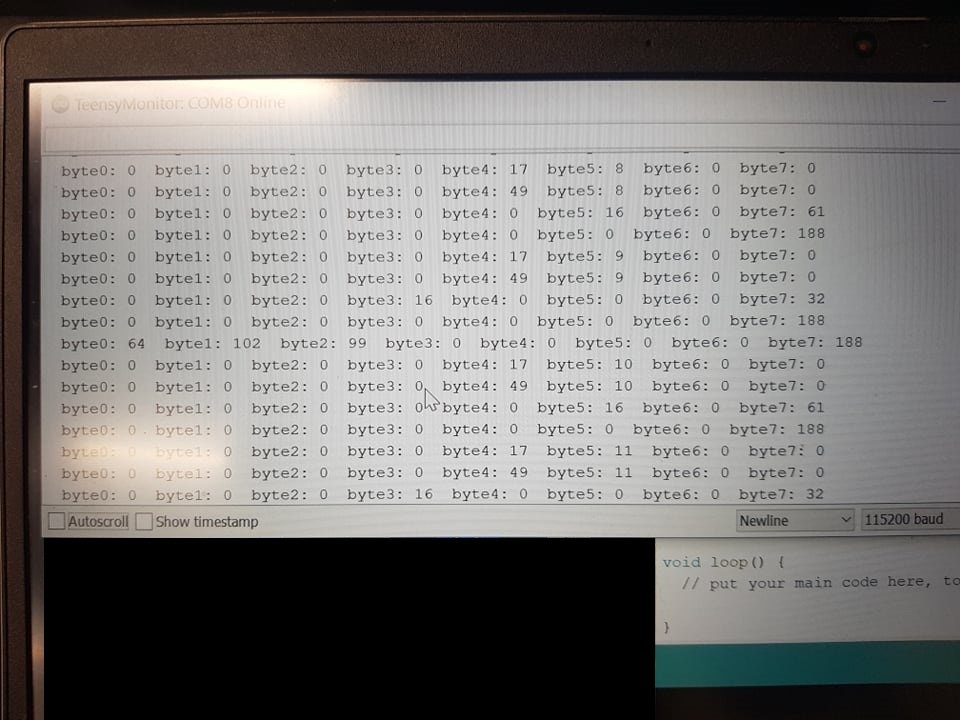

I've been driving this around a bit, still sorting some stuff like minor coolant leaks. But on the whole it's great. I started a bit of a resto on the wheels but ran out of patience and so just painted them fairly half arsedly. 2 meter rule! Havent swapped the tyres over yet. Can confirm that LSD works good, but it's still a fairly narrow window between bogging the motor and over revving and just spinning the front up off the launch. But it's infinitely better than it was. I bought an NCP91 Vitz ABS pump from a wrecker. So hopefully this can output wheel speeds in a digestible manner for my ECU. I found a pinout for this pump, and repinned my plug for it. Except I didnt check the main power and earth wires, for god knows what reason they swapped them back to front. So it blew a 60 amp fuse that I had to drive to Tauranga pick a part to replace. Fixed that and plugged it all in. So after some mucking around I got it sending can frames to try decode. It turns out that Toyota canbus of this era runs at 500kbps and the abs pump regularly sends about 5-6 distinct frames that seem to be largely empty and useless data Two frames have a value that just increments from 0-255 then resets to zero. I managed to isolate the value that changes when you put your foot on the brakes. But that's it! No wheel speeds, yaw, or anything cool or useful. I wrote some code so that instead of getting constantly spammed with all of the messages over and over. It will only show you what's changed since the last time that same message arrived. So if you spin a wheel, if this makes a value change it should show you which frame and byte the data is in. But, im still not seeing anything. After a few hours of mucking around I'm a bit stumped. Possibilites are: -The pump doesnt actually output wheel speeds over canbus (seems unlikely, as these motors dont have a speedo drive in the box anymore, and it communicates with the power steering) -The pump requires some sort of wakeup command from something else on the factory can network to begin transmitting wheel speeds (seems unlikely, as I'm geting brake pedal signal, and it's spamming useless stuff out anyway) -The wheel speed sensors have been revised, and my existing sensors arent compatible with this pump. The last option seems most likely. So next thing to do is source a wheel speed sensor from an NCP90 to test with. Why cant things be easy? They are but I make them complicated

- 1536 replies

-

- 25

-

-

-

Ahhh man, big success today! I got the car together enough to go for a run up the road. There are some big holes in the firewall currently from aircon stuff. So it's open to the engine bay. And when you go full throttle the intake noise in the cabin is so friggen loud that I think I need ear plugs. All of the loom and sensors are working well, new intake manifold with flipped throttles worked out perfect with SCP10 cable. LSD is doing LSD things! No single wheel peels anymore! The new gearbox is a little notchy into 2nd gear but its much much better than the other one. It's all a big relief, gearbox issues are/were main thing I was afraid would go wrong at this stage. Also not a peep out of the alternator! no more squeals. Hallelujah. I took it to the weigh bridge again. 830kg with half a tank of gas. Happy with that! Still on the heavy ROH wheels. So it's looking good to getting somewhere near my 820kg target for drags etc once I've swapped wheels. Swapping drivers seat for a bucket seat would probably be next easy win for some weight savings. Maybe eat a few less pies? Nah. Lots of small jobs to finish off but pretty relieved to have no major issues at this stage.

- 1536 replies

-

- 48

-

-

-

Haha, nah. Just the jaws from the oil filter tool. When I was putting the motor together initially I dropped one of the head bolt washers down an oil gallery... all the way into my freshly sealed on sump. Need to get to a bolt underneath the oil filter thread thing to get it back off. So a brand new filter ends up looking a bit second hand.

.thumb.jpg.0ed5d31c215a53f746a95d351b565bec.jpg)

.jpg.9a6330c546893d5e2069a1038765c028.jpg)

.thumb.png.5655b7eb39eb9a78ecaaa712dc345b85.png)