-

Posts

7,218 -

Joined

-

Last visited

-

Days Won

39

Everything posted by Roman

-

Thread bump for good option found. Has a 5 pin plug that is + - DC motor and a 3 pin TPS. Has been successfully used for ITB ethrottle. ( not by me) Looking at the list of compatible vehicles there's probably a bunch of these at pickapart and similar on diesel Audi / VW / etc. https://www.aliexpress.com/item/1005007187820465.html

-

If you had an incompressible fluid like water then this is true. It cant expand so it has no choice but to slow down. But exhaust gas is springy so can vary its density as well. Which is probably the real benefit. Expanding and dropping pressure.

-

Balance tubes are built into my manifolds. Each side tees together at the back of the motor. But even so, would see one bank or the other go rich or lean depending on how i adjust the cable. Again its not the end of the world if they dont 100% match up, I can set closed loop wideband to work per bank. In some ways im just being fussy. But then also if I have to remove the intake later on. I dont want to have to go through some stupidly fiddly process each time to get it back where it was.

-

Current setup is probably absolutely fine above 50% throttle (or whatever) so can still drive the car as-is when other stuff is finished. Speaking of which, I now have the exhaust shape finished and hung. Added a bunch of heat shielding to things near the exhaust manifolds as well. Just need to finish welding up the over-diff part then assemble. Then the car can finally can come down off the stands! Excellent Agree that push/pull rod is a good way to go. But the problem is unless I get the center rotation point exactly between the banks. I've likely got the same extent of imbalance going on. Ultimately though I want this car to have cruise control and the throttle blip. So keen to see how it pans out. Once exhaust is all bolted back in, main thing left to diagnose is the engine (or ECU) voltage dropping off. Have got a decent plan to isolate the issue but need the motor running to test. Getting there.

-

@Dudley Not sure if you knew this, but back in the day Toyota engineers were told they need to develop a pure racing engine. Which is how the 3K-B came about. To this day it's the only street motor ever known to be able to run a 4 quarter race cam.

-

Aahh sweet so instead of the 3 quarter race cam used in starlets, this motor only needs the 2 quarter race cam

-

Trying to keep pushing the pedal, this cant be full throttle can it?

-

Yeah thats what the actuators look like, that operate these throttles on the factory motor. But the actuators are $1000+ each which is nuts. A few aftermarket options like that but all cost heaps. E36 units were about $25 each so worth a punt.

-

Fizz levels are high but as always I've got problems. Haha. My throttle pull cable system isnt working well enough to synchronize the banks. It will do weird shit like... Both throttles start at 10%. Blip it up to 30% throttle, one will land at 10% and the other at 12%. One will land at 0% and one will land at 2%. Then blip it again, and both at 0% (or whatever) Then the imbalance ends up different depending on things like how quickly you push the pedal, and whether throttle angle is increasing or decreasing. weird. So its not like I can just make a compensation table for it. After a bit of head scratching I think it is because of the springyness of the cable itself. I'm trying to wrap a springy cable around 2x tight radius pulleys by varying amounts. The more wrapped around it is, the more it wants to try unwind itself back out straight. So this does chaotic sort of things to the TPS position of the second bank. In terms of full throttle tuning/power, none of this stuff is really too much of an issue as I could simply set end stops that both sides bang into. But it causes an unacceptable level of problems below that. I dont want to spend a massive amount of time chasing my tail on this when it comes to tuning time. Especially if I'm trying to make my 2025 deadline to take it to @kpr I could switch to using dyneema rope for the linkage cable, so that there is zero springyness and zero backlash. This would likely all work fine. BUT Cable throttle was all just meant to be an interim measure to quickly get the car going, before changing to ethrottle later on. Now that I'm balls deep in pondering the many complexities of cable based bullshit. I am looking back in the direction of ethrottle again. Ethrottle will just keep moving each side until its exactly on target (or very close anyway) So just for a refresher for what I've unsuccessfully tried already: -Dual Triumph 1200 throttle banks. Would have worked nice, but port spacing wasnt good. -half arsed attempt at pushrod setup -Bulldozer ethrottle. Too huge, lacked some safety features, cables way too long, whole thing way too big -Holden cruise control unit. Looked good, but had a stepper motor inside and complicated electronics. -cable based bullshit I've now found a new set of magic beans ethrottle option that I am hoping will work well to pull the throttles open. Which is the cable based traction/cruise system from an E36 BMW. Which looks like this: The reason I think this one might work where the others havent. The motor has a 2 wire plug, so I suspect that it is a straight DC motor. No brains in it, no TPS, no speed signal, no stepper motor. The motor is totally divorced and just has 1 job which is to pull a cable. which is exactly what I need. I ordered a pair of these from ebay so they're a few weeks away unfortunately. But will be cool if it works. My current cable based setup needs both pulleys on the same plane, which meant they had to go way out front of the motor. But these could instead mount these down the back, or offset from each other if needed. So it's all out of the way. So then the path is more clear out the front for my future airbox scheme. I'll carry on workin on the exhaust and trying to figure out the voltage drop issue until these arrive. If anyone locally has one I could borrow to test with until these others arrive. Would be appreciated!

- 130 replies

-

- 24

-

-

Haha geez, its like you had to weld half the car back in. Good job on saving it! A lesser man would have thrown the towel in

-

Coincidence? He recently tuned a 1NZ. Now he is obviously unleashing it's technological secrets onto the 4AGE. apart from oil filter location

-

New head setup is looking freaken sweet! Be interesting to see how it goes with the revised port angle.

-

Love love love how this is all going! That strut brace looks amazing. Cant wait to see final result for the airbox.

- 417 replies

-

- 1

-

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Yeah I wasnt sure if you meant you "filled it" by adding another wall or something haha. -

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Does your muffler have any sort of packing in it, or is it a box with chambers? Maybe you need a section of perforated pipe, that is then packed with steel wool or whatever -

More just concerned and hypervigilant at the moment, listening out for creaks bangs and so on. and trying to dial fuel in and so on. It's enjoyable to watch the video though haha. One thing I learned yesterday. If you are revving up your car in the garage. Try not to hit an ignition only rev limiter, if you want to avoid spraying fuel everywhere

-

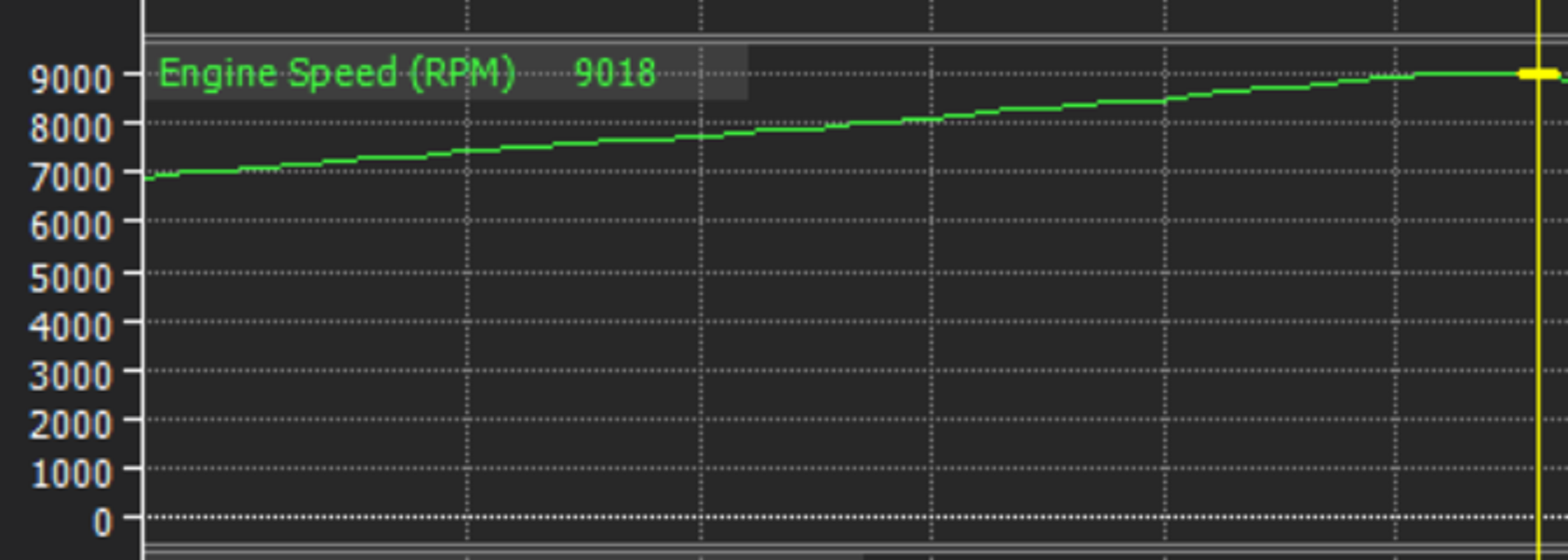

I bought a 3" Adrenaline R muffler, and I've been hoping that just 1x muffler will be sufficient. So welded a flange on and bolted it up to the end of the 2-1 section to test it out before committing. I'd say its probably still a weeee bit too loud (Still need earmuffs on when it revs out) So I'll have to try stuff something else in there too. This one was filmed with the camera bit further back, and the audio recording level turned down so it wasnt clipping. In person it's still ear splittingly loud. Currently the ignition timing is all very conservative, as I'm not sure what the motor is going to like with port injection and the 12:1 compression. Overly delayed ignition timing means more exhaust energy (noise) comes out the back. So it will quiet down a bit as the timing gets dialled in. Currently there's no VVT advance happening, everything is just at home positions. So from experience the intake starts getting a LOT LOT louder when you start introducing some overlap. As much as I do love some incredibly obnoxious intake noise. If it's so loud that it's melting my brain. Will need to make an airbox to calm it down a bit. Ha. I am still chasing an issue (by which I mean I havent investigated it yet) where the reported voltage to the ECU drops off, when the rpm goes up. I am suspecting this relates to a bottleneck at my fuse/relay box. So will do some troubleshooting. I have officially run it to the 9k mark now, and valvetrain has survived. Haha. So hopefully a bit more left in it yet. It feels tantalizingly close to being drivable! I need to make some heat shields in quite a few places. As there is a huge % of the engine bay that is line of sight to the radiant heat emitting from the exhaust manifolds. This video is probably a fairly good representation of how the car will sound when it's finished and driving.

- 130 replies

-

- 52

-

-

-

That Morrinsville event was great, cheers for the heads up about it. I was amazed at how many of each type of car were there, I wouldnt have thought there were that many left in total. Yet heaps very nicely presented, so probably at least 10x more still lurking in garages etc. Love that you're putting some mileage on the car and out enjoying it!

-

I am more than happy for people to pay me to build 1NZ motors haha. Next project is repowering my partner's mini. They actually do make some kits to bolt a 1NZ and C56 box in. Might be a nice option but see how I go. Engine bay is insanely tiny.

-

Well, someone else is carrying on and waving the 1NZ flag which is great. Marino from Whangarei took his vitz to the Garage1NZ workshop for some dyno tuning today. It's an iterative improvement on some things that I did. So its an earlier 1NZFXE, with the mechanical waterpump. The innermotive 264 deg cams and valve springs from Thailand. (about half the price of JUN/BC stuff) 20v throttles, 4-1 manifold and a 3" exhaust I think. Sneak peak at @kpr's new youtube channel logo: Made a delicious ~160whp at 8500rpm And deserves honorary oldschool.co.nz membership for adding some 13" wheels and slam. Good shit Marino! Love it.

-

Having just finished making a 2-1 merge thing myself, I applaud you on managing to do it without any flexis. I put three in, for "cant be fucked" reasons when it didnt fit nice.

-

The new motor is back in the hole, and so far so good. Last time I got as far as running the car through the gears up on stands to make sure everything was working. So this time more of the same, but since the motor hasnt crapped itself. I've been dialling in some of the low load areas just by running the car up in 5th gear. With a blip to 8900rpm for good measure. EDIT: not 89,000rpm, haha. Yes, I need to tidy my garage up. But was full of fizz to just get this running haha. Anyway, some observations so far. 1. When the fuel is a bit more dialled in, the throttle response is SNAPPY! As in, mega snappy. It's gonna be awesome I reckon. Feels a lot more snappy than 1NZ did. Hopefully it's not too touchy on first blip of the gas. 2. I got the hot idle sorted and stable, idling at a nice 750rpm no problem. Then have run it through a few iterations of trimming the warmup enrichment. Now it starts nicely off the key, with no foot on the gas even when cold. Excellent. 3. I've been having a weird issue where after cranking, one of the widebands stops responding on canbus. But if I unplug/replug in then it works again. I've got a spare relay in my fusebox, so I'll hook them up to that. So I can just have them come on shortly after the engine starts. Which is probably the better way to do things anyway. 4. Currently at idle there is around a 10% imbalance bank to bank, in wideband readings. Which is interesting given that there are the air tubes linking two banks together. However it might need a little more fiddling with the throttle stops and so on to get it to match. Otherwise perhaps I've got a small air leak somewhere, ahead of the wideband on one bank. Or maybe a poorly performing injector. Will narrow it down and figure it out. It will be interesting to see if the problem goes away once the throttle % goes up. As that indicates a different sort of issue either way. I can make a compensation table in the ECU to get the air fuel ratios fixed up anyway, if long term they are slightly problematic at full throttle conditions. 5. The way my fuel rails are, the injectors can rotate underneath them 90 degrees either way from their normal position. So, when the injectors are in their normal orientation. The widebands will show something like 14.6:1 air fuel ratio. If I rotate the injectors 90 degrees, it now shows around 16.4:1 on the wideband. Then this is very repeatable. Interesting! The injectors must have a dual spray pattern left and right, which changes to top/bottom when you turn the injector. It's crazy to see that it affects combustion quality and the reported air fuel ratio so much. That's all for now, I need to finish mounting the battery properly and finish the exhaust. Then it's about ready for a bash around the paddock or maybe a trip to the dyno. Cant wait to hear it under some load at full chat! It feels like I'm getting to the fun part of the project, and where it's fun testing and setting things up. Exciting.

- 130 replies

-

- 48

-

-

-

Looks like good progress! Gonna be awesome to hear it fire up.

-

I think they just run on a zillion volts and are peak and hold. Every aftermarket ECU that can control DI decently, needs to interface with the OEM injector power module thing, or use a 3rd party one. This motor from factory has a little computer thing that bolts to the front of the engine. It accepts normal-ish injector inputs into that, and I think fuel pressure and some other stuff. Then magics the output of the injector to give the desired amount of fuel I think. Unless you want to run stratified charge mode, I dont think the benefits are hugely pronounced over port injection for this kind of thing. But, yeah. Either way, the DI pump gets cut off so the engine can fit, and the big cams wont work with it anyway. Making some press fit dowels or something is still the best solution, as it leaves more room in the Vee for my clusterfuck of wiring haha.

-

Yes that can happen but I'm skeptical that temperature is the actual issue. I think there are two possibilities. Temperature related, it all overheats. But it's all stainless? The injector is completely enclosed in the aluminium head which is a great heat sink. Aluminium will start melting before stainless does. There is a teflon ring on the injector but it's well into the head and isnt exposed to combustion temps or close to it. Or: The lack of fuel pressure is the problem The fuel pressure stops the combustion pressure from pushing the injector pintle open. Apparently direct injection runs somewhere between 100-300 bar, which is why it needs the mechanical pump. Then peak combustion pressure is somewhere around 35-70 bar. So when you have the fuel pressure, you have 230 bar pressure differential, working in the direction of holding the injector closed. Without the fuel pressure, you have 70 bar (~1000psi) working in the opposite direction. Trying to push the injector open and nothing to stop it except for the small spring inside the injector that pushes the pintle to the home position. The only instance that I've heard of the injectors blowing their guts out, was with a BMW/Supra engine where they were aiming for ~1000hp and were stuffing a zillion pounds of boost in it. So my thoughts are that if I just mechanically lock the injector in its closed position & give the pintle return spring an infinite rate (fill injector with high temp epoxy) then it's going to be fine with an NA motor where combustion pressure isnt going to be mega. I filled the injectors yesterday. Had to pull the filter baskets out, fill with a small syringe, and use the heat gun on the injector body to thin the epoxy to help get the air bubbles out. Now this might not work and it may indeed be that high temps make the injectors blow their guts out. But will see how it goes.