-

Posts

886 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Abarth

-

Sweet cheers

-

Can brake calliper brackets be made from alloy instead of steel and still pass a cert?

-

Jesse's 1981 corona mark ii grande discussion

Abarth replied to Jeffs_Emporium's topic in Project Discussion

That tyre profile is A+ -

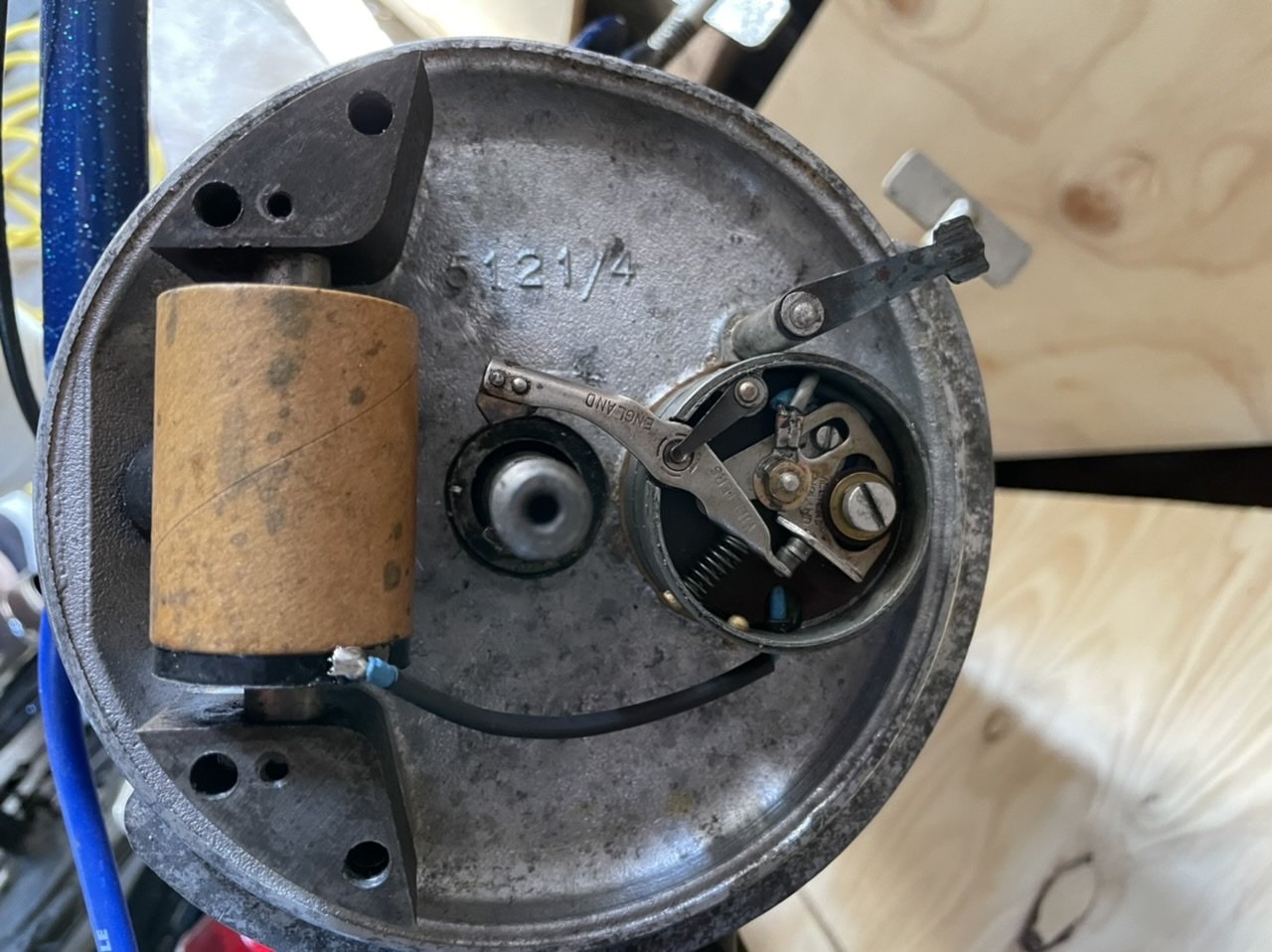

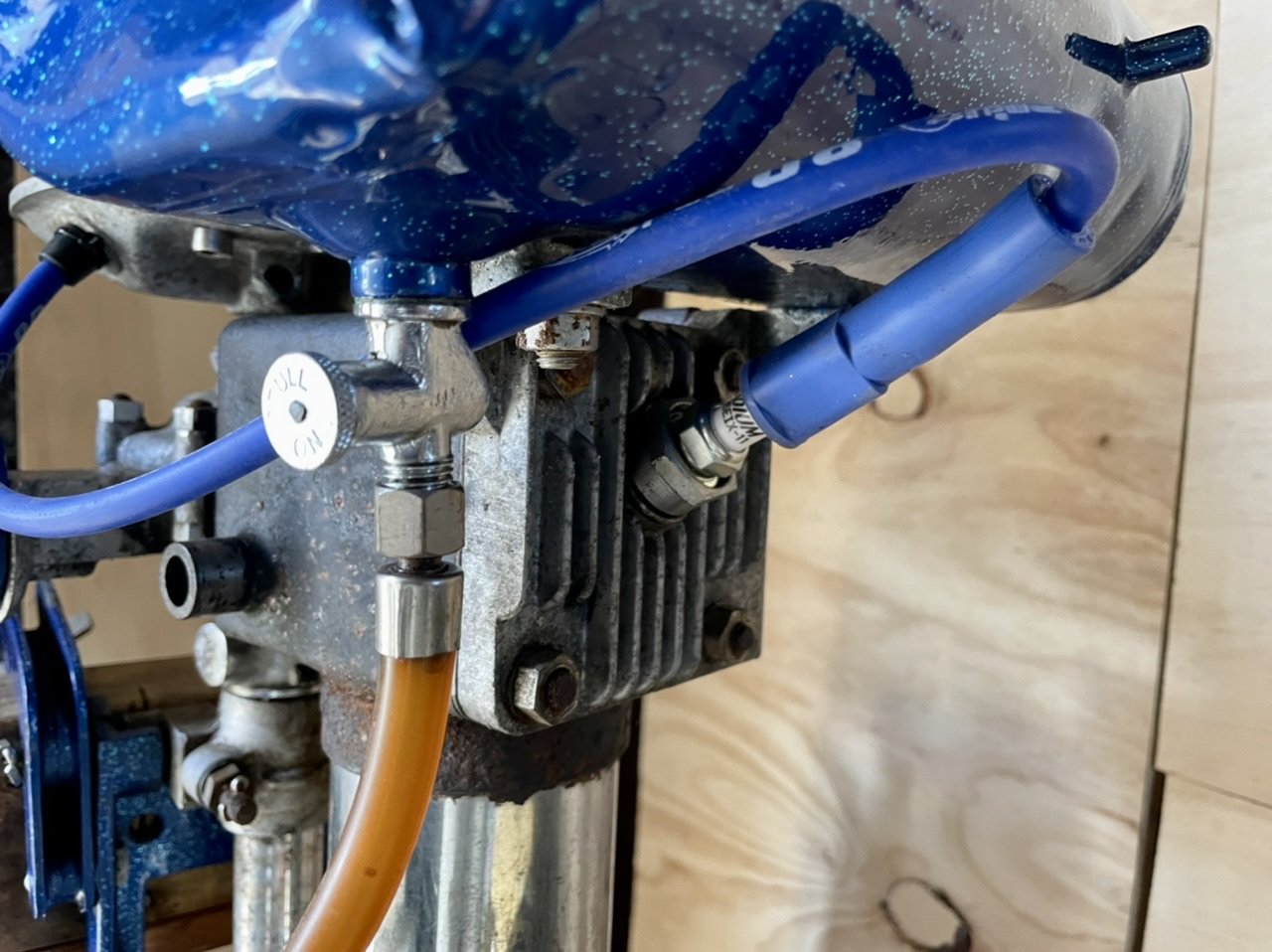

Got a small race this weekend against some other seagulls. Decided to have a look to see what the timing is doing with a timing light. Sparking at 45 degrees before tdc, seems way early but starts easy as. Noticed when I ran it up there was no water. I think I’ve not fitted the cooling pipe correctly. I’ll whip the leg off and check tomorrow.

-

Ok, so after many fails, like the points plate and flywheel was bent. Must have fell off its stand at some point. I stripped the whole thing down this arvo. Cleaned out all the water galleries including the pick up pipe in the exhaust. Had to replace the top part of the crank case as I broke a piece off the casting. Was good to open it up, gave everything a really good clean. Noticed it must have got really hot at one point as the metal around the big end had colouring. Sealed everything up with some gasket maker. Put all the ignition on and turned the motor over with a drill for 5mins to put charge into the condenser. Plugged in the spark plug and it let out a good spark when turning over. This is probably the best condition this thing has ever been in recently. I probably should have done this when I first got it lol. But anyways it’s ocean ready now!

- 19 replies

-

- 12

-

-

Where were we? Currently Sparkles has all new electrics. Got the soldering iron out and banged in a new coil and condenser from the UK. The coil was a bit of a mission as none of the connections or size for that matter match the old one. Soldered the equivalent of the end of a spark plug onto the coil output. Then used an automotive HT lead to send the spark to spark plug. I got a guy down south to send me a spark plug adaptor, taking it from 18mm to 14mm so I can run a modern iridium spark plug. Just have to wait for a new crankcase housing as I broke the old one with holds the points plate in position. Then she’ll be ready for the next adventure!

- 19 replies

-

- 14

-

-

Ok, summer is just round the corner and Sparkles has been neglected all winter. Still had running issues with her at the end of last season, it ran from dead cold for 3mins and then would be gutless or hard to start for ages. All the features you don’t want out at sea. Me being silly and avoiding one of the massive issues I should have fixed early on would’ve probably solved a lot of issues and lead to trouble free motoring. Im talking about the ignition condenser. So I ordered a new one and new coil. The points looked mint so no trouble there. I cracked into it literally breaking the top off the alloy casting trying to undo a rusted bolt. Need to find a blue HT lead as the old lead is just wire with a plastic cap, nothing to keep the water out where it joins the spark plug. Speaking of spark plugs I’ve ordered a 18mm to 14mm thread adaptor so I can run a modern iridium plug so it doesn’t foul from the oily premix. Picture to follow shortly…..

-

Thanks man, just hit buy now.

-

What am I looking for with a auto darkening helmet? I was doing a bit of welding on the weekend and came away with scratchy feeling eyes. My current helmet is a entry level one, even though I jammed a new battery before I started I don’t think it’s as good as it should be, also it looks like it has grinder swarf melted into the lens so I’m 100% sure that isn’t helping. In the market for a new one, recommendations? My eyeballs thank you in advance

-

Yeah it’s expensive right, I was just going to use the aerosol version which is still like $99 bucks. Looks like only Repco supply that version.

-

Sweet as, I’ll spray the wheel arches in two weeks time and report back.

-

Went with Raptor branded bed liner from Repco, only sprayed the primer so far but seems all good.

-

What’s good for painting the underside of wheel arches? I’m doing some panel work so I’ve stripped it right back to bare steel under there. Is it just Primer, paint and use some generic underbody paint, a few I’ve seen are rubberised or bitumen based?

-

While the rust fixing was going on I decided to get rid of this exhaust my 20 year old self made many years ago. To be fair it wasn’t bad, 2.5 mild steel, however the rear muffler sounded terrible. Got some Vibrant mufflers from Speedscience and some stainless steel and started planning out the new 3 inch system. Looks good! Bit of work to do to finish but happy to get it started. Had my chief helper too

- 14 replies

-

- 18

-

-

Where were we, oh yeah rust, ok then…. The Strada has always had this one bit of rust up the the top left rear wheel well. I’d been meaning to get to it for years so today was that day. Whats happened is Fiat spot welded in a panel to reinforce the strut tower how’ve over time the sealant has failed letting moisture in and those inner panels aren’t painted or anything, just bare steel so it rusts that gets worst and worst from the inside out. Ordered a spot weld drill bit which didn’t turn up so I sent it with a regular 10mm drill bit. Got it out reasonably easy.

-

Keen to hear the improvement from the intercooler upgrade, heard good things about the Plazmaman intercoolers

-

Sweet cheers mate

-

Is it true you can’t have a vented oil catch can? Has to be plumbed back in now?

-

Got stuck into the brake situation this weekend. The front brakes have always been a bit scary, being single piston and not even really fully pressing on the surface of the brake pad. Whipped them off to trial fit some Brembos. Got two sets, Peugeot 406 ones and @zep Alfa 166 ones we snagged from pick a part a couple of weeks ago. 406 ones are slightly smaller but are still 4 pots and were the original preference. However on fitting them they are too much of a close fit to work with an adaptor. The Alfa ones however sat perfect with enough room for the adaptor plate to manage any offset issues. Factory Strada disc is 242mm and there is 25mm extra pad space to fill so 242mm + 25mm +25mm = 292mm. So upgrading to 305mm Fiat Turbo Coupe discs seem like the perfect fit. Next I’ll get the discs and start work on a wooden adaptor plate to see how it’ll all come together.

- 14 replies

-

- 12

-

-

-

Fitted a bucket seat to the Punto but the replacement rails don’t have the attachment for the seat belt clasp. Do guys just mount them to the trans tunnel with those FIA plates and attach the OG seat belt clasp to that?

-

I’m about do the same with the Strada’s exhaust. Been looking at Vibrant mufflers. They do resonators and mufflers, all the ones I was looking at appear to be straight through. Speed science sell them. A lot of youtube reviews rate them and seem to have a good rep.

-

To get the rear shocks shortened and a Bilstein insert added was $500 a side. I’ll report back with a quote for the fronts

-

Cheers man. Autolign on the north shore did the rear Bilsteins using the factory housings. I’ll give Iain a call tomorrow about the coil overs