-

Posts

14248 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Raizer

-

She even gave me my own chopping board just for engines haha

-

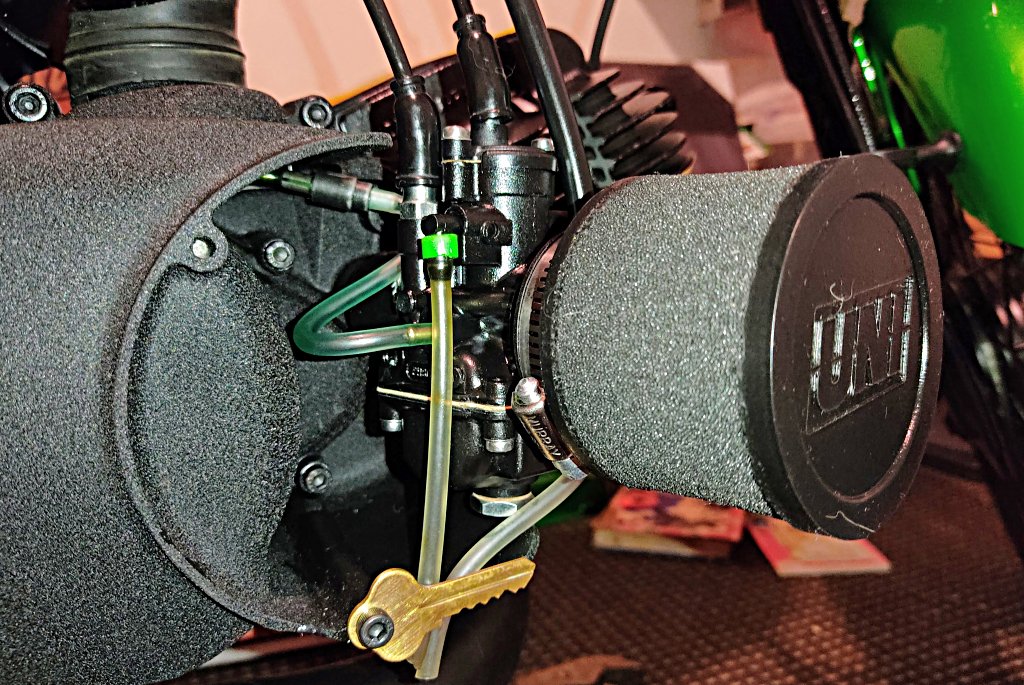

New carb got completely stripped, squirted with CRC's finest satin black with more enthusiasm than @MopedNZ playing with a bum gun after a night of S.E.A's dodgiest street food and cheap beer. It also went for a bit of a spin in the lathe so it'll actually fit in it's spigot. Reassembled and refitted with fresh mounting o-rings Along with the digital clock with bonus tachometer function I also treated myself to a rather nice RK X-ring chain finished in jet black with gold accents So now it's ready to add gearbox oil and attempt yet another "first" start. If the noises are gone then I should really finally machine the new flywheel for it then it'll be ready for summer pesting!!* A summer later than planned but hey Ha If it's still tapping I'll likely cry/push it outside and forget it exists. *Keep an eye out for an Auckland City 2T pest and succulent Chinese meal fest event in the upper north island events section*

- 191 replies

-

- 15

-

-

Te Urewera Undertaking, 2020 Nov 27th, 28th, 29th.

Raizer replied to johnnyfive's topic in Upper North Island Region

Did you happen to be following @Shakotom at the time? -

Couple idle heat cycles, retourqe head, send it. /I easy for a bit if I've got a new clutch to bed in.

-

Yeah you have to do that, it's the only way to get enough oil flow to wash out the large amount of swarf they come packed with for shipping.

-

Te Urewera Undertaking, 2020 Nov 27th, 28th, 29th.

Raizer replied to johnnyfive's topic in Upper North Island Region

Covid shipping has fucked a lot of things. -

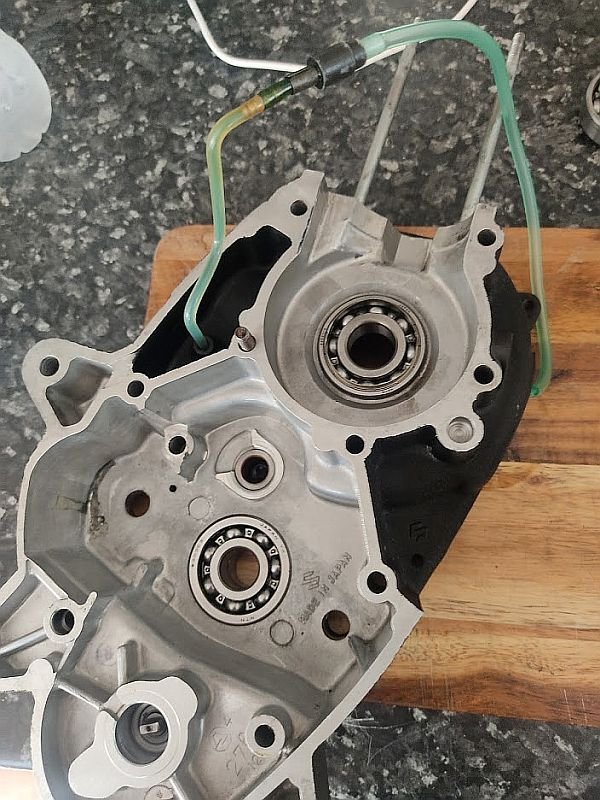

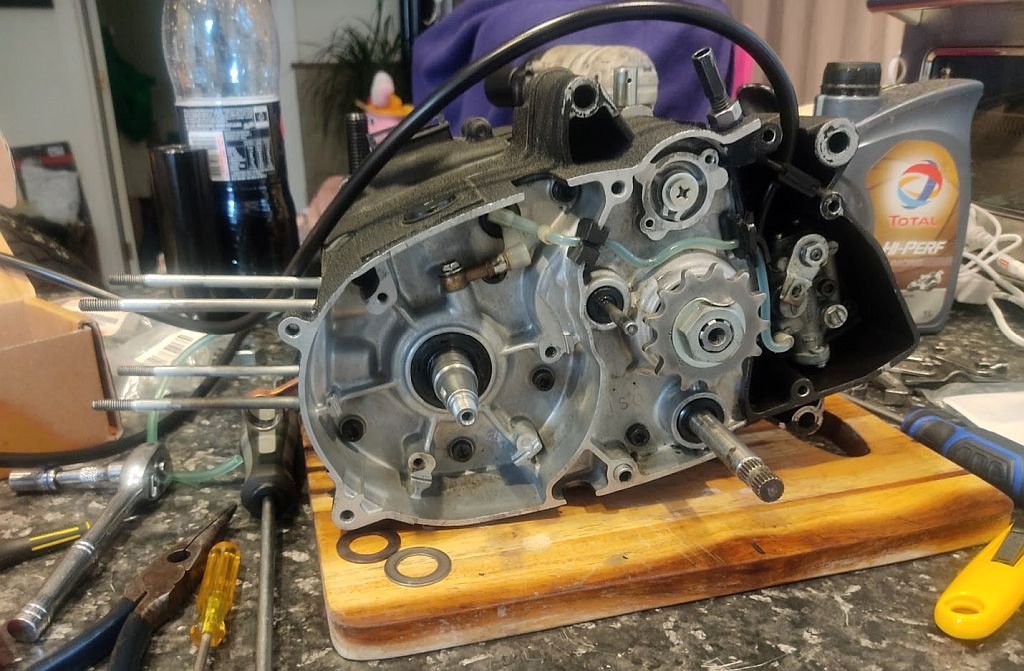

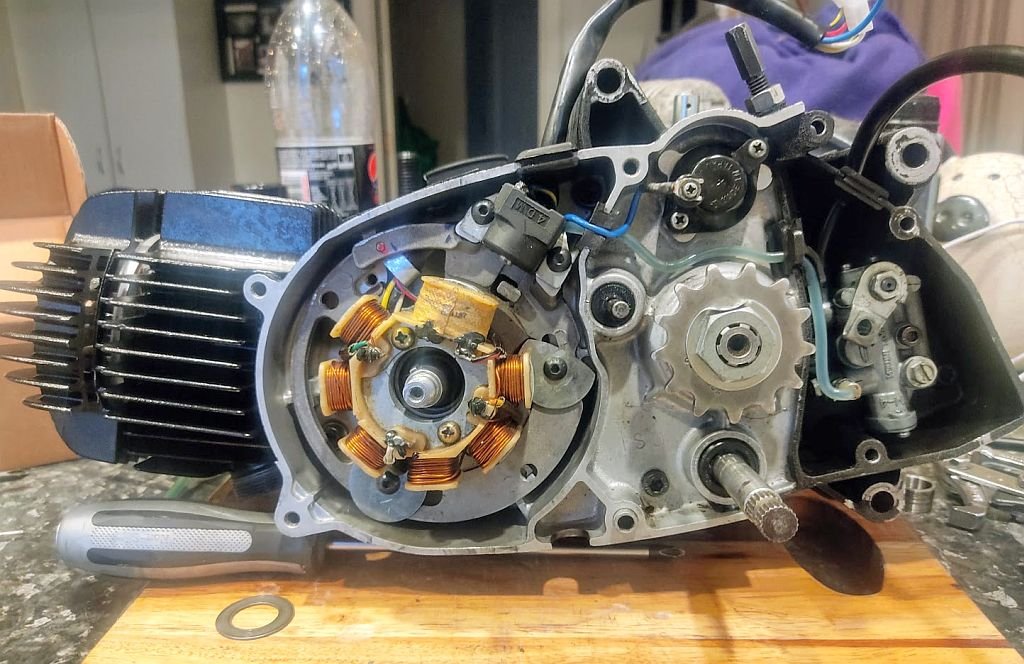

Whacked in a new bearing and a longer piece of 2t oil line. Test fitted gasket, have to trim a bit where the boost port has been opened up. New crank puller makes life soo much easier!! Was about here I realized that in my fever induced brain fog I'd neglected to fit the oil guide plate to the left side of the crank as well as the spacer that I had not long rubbed on the oil stone to get the crank clearance TMM specified. FUCK! Got to try out my case splitter tool, while it does make things easier you still need to tap the output shaft free of it's bearing as you go. And just my luck the bearing stayed on the crank, and since they are ex-Japan, it was brand new and I CBF waiting for Japan post again I shot down to SCA Gingerly pulled the bearing, the left bearing has a skirt to guide the 2t oil, so I was only able to pull from the outer race. But I'm pretty sure I got lucky and the bearing still turns smooth, so reused it. Turns out Jonny must have taken .75mm off the OD of the old carb spigot, this new one doesn't fit in the gap, good thing I have a lathe now ha! Will be able to spin this one down to match once I get it set up and figured out. And yeah, that's about as far as I have the energy to get it right now.

- 191 replies

-

- 11

-

-

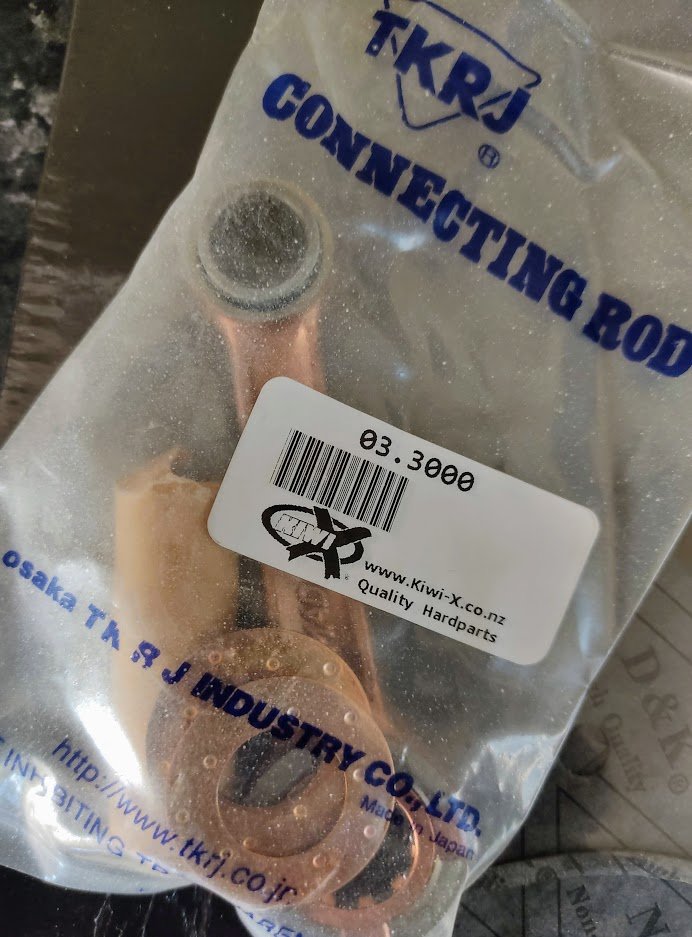

Some more SGP goodness arrived on the 4:30 autogyro from the Orient And got the crank back from Tauranga Motor Machining with the fresh new rod kit installed and balanced better than factory! The oil seal and bits in the white bags are to replace the one bushing I reused, it's the spacer for the sprocket and the original was worn enough to leak a little oil. Inside the big end of the old rod: And a few of the rollers aren't too flash either Looks like it was actually using the cage as a bearing surface!! Would have loved to have seen the old pin! The old boy at TMM explained how to measure the side clearance to the main bearings, apparently .03mm clearance is needed, most mass produced 2t engines come a tiny bit of preload as it's faster to just whack them all together close enough than actually take the time to make shims for every engine.

-

Twin cylinder called for twin post?

-

What model Rotax is it? Some have both cylinders firing a the same time so single port would be no issue at all.

-

-

At the moment I'm just choosing the best shipping deals, the wholesaler I normally use isn't shipping outside the EU currently thanks to covid. Carb came from Treatland, carb parts from Pedpower UK and the tools from a shop in Hamilton. Get a lot from WeBike too

-

Will dig out the Naraku kit I've got kicking about and get them up to you

-

Always slightly nerve-racking taking grinders and drills etc to brand new parts, but needs must! 2.5mm through, then 5mm to open up the press fit area Good slather of loctite retaining compound Result!

-

Fuck a 145 main would have been absolutely drowning a 70! I've got a range of 5mm Dell jets around 100 I could chuck you to try.

-

Sent the crank off this morning, should have it back at the end of the week, also couriers finally delivered a few bits I ordered mid last month from the US and UK + some tools I ordered Friday A genuine Dellorto PHBG 19 BD. I was already running a PHBG 19mm, but with all 4t parts, this one came loaded with all the good 2t bits + "race" float bowl with the cap to change jets fast and the adjustment screws on the opposite side to normal which should be good for the A50. And since it didn't have the 2t oil feed from factory I ordered a fitting from the UK, somehow ended up ordering the 2t atomizer, bushing, slide and other bits at the same time so can convert my old carb

-

Unless there's another Aubrey with an interesting old scooter collection in Palmy that recently sold an AF24 engine it will be your one old lol I messaged you on FB when you first put it up on MopedNZ and claimed dibs for @chris r knowing he'd been looking for one and was out of phone reception.

-

Was @Aubs selling it too, just to complete the tag fest lol

-

After a fucking mega struggle pulling the carb off/out of it's oring retained hole, I dropped the engine again, then stripped the engine again. One thing that had been bugging me since I first built it was the crank web blocking 3-4mm of the intake port Figure while it's apart yet again I might as well take the opportunity to do something about it! Doesn't really look like much was taken off, but hey it should breath better and more power is always a good thing right? Now to package up the crank and send it off to get built. Also I found a replacement for the massive Uni filter

-

Fucking GC!! Was pretty much set on doing the rod change myself, have access to a big press, lathe and dial indicators etc and know how to do it, just don't really have the confidence that I'll be able to get the run out down to 0.05mm! @MopedNZ highly recommend Tauranga Motor Machining so I gave them a call and with the quote I got, there is no point in me making press plates and everything else I'd have needed to make to attempt it, so if time/motivation allows I'll pull the engine out and get the crank up to them in the near future. Not really much of an update, more of a thanks Callum!!

-

Top of this page, I tried a .9 alloy gasket and measured .8mm squish clearance with the engine hot. Edit: I'm back to being highly suspicious of it being the big end bearing, been watching a pile of videos on YouTube of dirt bikes etc with fucked big end bearings and yeah sounds very familiar. Rod side play measures up fine, but it's easily possible that the needles in the bearing are pitted or flat spotted, also since it tried to seize a couple more times yet there's no signs of that on the piston I'm thinking the bearing has been trying to lock up solid at high RPM. Guessing it's the bad clutch sound Sparkle warned me about lol! Hopefully @MopedNZ can track down a rod kit in NZ, otherwise I'm looking at either a genuine rod and crank pin from Japan + thrust washers from the UK. Or a full Long brand after market kit from the UK. Really can't be fucked rebuilding this thing yet again (or afford to tbh), but hopefully can get it all done and actually get to ride the fucking thing this summer!!

-

Checked the timing, was about 23°, played with it between 22° to 28° BTDC, no change to the noise at all. Have left it set to 24°, should back it off to 26° or so as I confirmed the CDI does in fact have an advance curve built in (a LOT of cheaper ones don't). I'm impressed by the ToolPRO timing light so far, 99% sure they are a re-badged Innova 5568 *Halve the RPM numbers, it doesn't go below 2 cylinder in 2t mode* So now I'm back at square one with the noise, screwdriver stethoscope says it is in the top end but I'm running out of ideas!

-

B.J Moss sheet metal here in Gisborne. https://www.bjmoss.co.nz/ The stuff I got was .7*mm, was just something they had in the offcuts pile.

-

See if @Aubs can run a tape measure over it?

-

Was worth a shot! haha