-

Posts

3375 -

Joined

-

Last visited

-

Days Won

1

Everything posted by NickJ

-

I would totally be surprised if it didn't. I removed a panel from the Defender that needed touching up, was so much easier having full access to both sides with nothing in the way. Best to point out that i'm not looking for the shortest path to having the Datsun looking good again, i'm looking for the most enjoyable path where I get to learn stuff. If we can hold religious meetings under L4 you're welcome to visit and read me a sermon from the book of hammers @JustHarry

-

So obvious, give that man a cigar! I will have a closer look and see how it is all stitched in...

-

I will quit my job and complete a 5 year panelbeating apprenticeship if it saves me one day of sanding bog, this is the extent of my hatred towards that satanic dust

-

Actually not in the worst shape rust wise, just s small strip at the bottom, the arch is pretty munted, but again, fairly simple geometry to patch up. new panels are available, just at $650usd and the state of shipping right now, i'll give this a few taps before admitting defeat! I have some rimu offcuts, i'll see if any are about right, thanks for the strategy!

-

Who can share some magic? Trying to figure out how to address this panel, has lost all its shape and needs plenty of tapping back, mainly from being beaten back to pack in another tin of bog. While i'm sure I can get it to require far less, how do I go about getting the crease that should be about where the black line is back? My current thought is to address everything else and it should naturally come back, or to I address is specifically somehow then tidy up the edges? Total panel beating noob but keen to learn, worst case i order a replacement panel.

-

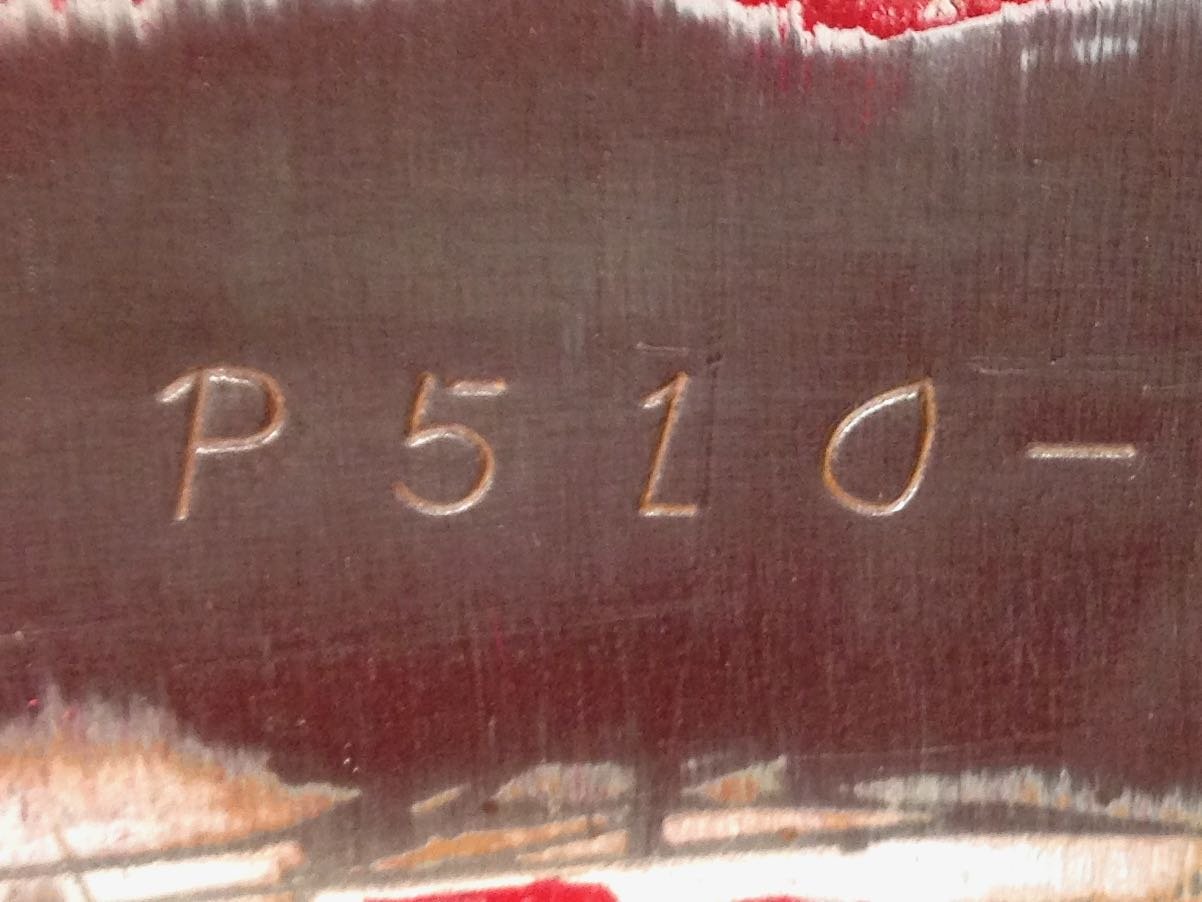

What a day, woke to no wind and blue skies, perfect for getting out and welding up some rust! GC @Bling dropped some panel steel off at my door last week, no excuses/time to rip into it. First on the list was a small innocent patch under the front arch, tore into it with the grinder only to find the reason why it has a similar one on the other side. Factory hole allowing moisture to get behind the layers. Fuuurkkkk, only way to do this right is to take off the rotisserie, peel back the entire skin and treat underlying rust before placing the actual patch. Not to worry, i'll get that at a later date, lets shift attention to something more achievable for the day, the small ripple in the rear guard. Ripping back the paint, what do we find? A text book 90s example of patch&bog.. Whats behind door #1? Hooray, Grot! Open wide... Not really all bad, cleaned out ok, went to grab my tin of weld through primer but nope, not today, just a can of copper gasket spray, dicks, no more patching this weekend. Carried on with paint stripping and seeing if I can better the dodge repairs but thankfully only came up with a pile of composites Figured i'd have a hit at the engine bay, starting with the serial # Back when my father used this body to re-shell a race car he bogged over the serial for obvious reasons, with the car returned to it's original true identity, it was left covered as nothing short of a decent full bay respray would have caused further legitimacy questions. This has been of great entertainment for me at car shows, many Barry has inspected the engine bay, ticking off the obligatory SSS factory parts before crossing arms and proudly stating "hah! no firewall number, its been re-shelled mate, you've been ripped off" before walking away chest puffed and pleased to have rained on someone's parade. Here it is, proudly back in the daylight matching both body tag and rego papers.

- 53 replies

-

- 25

-

-

-

-

Long since forgotten the exact supplier, we used to get them from a heavy diesel type joint for slapping on hydraulic oil tanks.

-

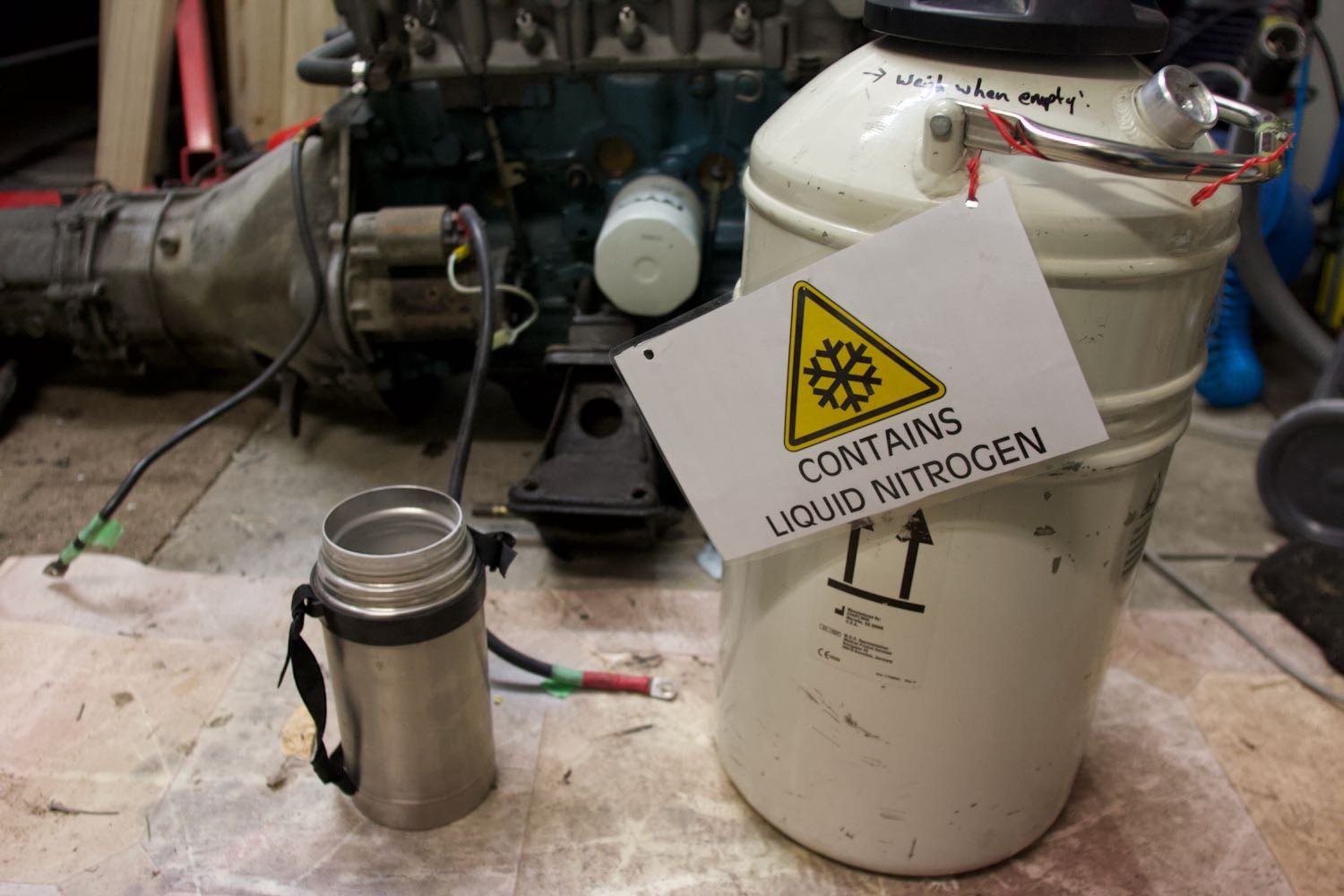

Acetone is likely the better choice, I was nervous the Leidenfrost effect would make LN2 ineffective as it prevents serious liquid cooling of anything at room temp if you can't fully submerse it. The way it worked so well I actually wonder if a bag of frozen peas would have been just as good!

-

Trucking along..... Shell is now 99% stripped and mounted on the rotisserie. Motor and box were dropped out the bottom during the lift, closely followed by the rear cross member, diff and suspension. I've started stripping paint (and bog) from the known trouble spots to start building a picture of the scale of panel beating, so far nothing that make me uncomfortable, more motivational as the patches are (so far) straight forward chop&weld. Work had a few litres of liquid Nitrogen going spare so rather than pay BOC for dry ice I filled up a tank to see how well it can take to sound deadening. Before: Pouring over small sections at a time I was genuinely surprised at how effective it is, large chucks peeling off in seconds. Soon there was a full bucket and job done I wouldn't hesitate to give that another go, so fast and even strips the seam sealer out without breaking a sweat! Having the car on the rotisserie was an added bonus, could position it so that the liquid would pool in useful places.

- 53 replies

-

- 27

-

-

I built this crane from scrap rhs to lift the RTT off the Defender, not quite suitable for your situation but may spur something useable? Park the Niva on the foot and then a spare car battery to run the winch, takes me 20min to take it on or off, including fasteners.

-

So as it was told to me, the cells share a common air path at the top but not electrolyte, having a few dead batteries in the shed I gave it a go, can confirm the battery I pulled the level plug from does not have a common air space, only poured a few ml of acid out, scratch that idea

-

If I ever make time for it, I have an idea in my head for a tailgate spare mount that unfolds to put the spare on the ground, gives bit of lever advantage to lift it back into position too. Something similar that folds the wheel down to window height for yours?

-

First thought was to comment how fucked life is lifting a flat muddy tyre onto the roof, then saw you have the crane, so good!

-

the level indicator can often be wound open to top up electrolyte on stuffed batteries

-

rather than airflow, what static vacuum can you achieve with those fans? I get the feeling you may struggle to generate the vaccuum and subsequent flow required without serious spending

-

Discuss here about Yoeddynz's little Imp project...

NickJ replied to yoeddynz's topic in Project Discussion

The average Hilman Barry would just re-wind the starter to rotate the other way -

Things are moving along at a pace I'm really enjoying. Front suspension is now out, I was concerned the steering linkages would put up a fight but having collected many forms of 4wd ball joint splitters over the years everything came out with ease. For the record, this is the rust spot I was originally set to tackle, and the catalyst for this rebuild Last load of interior and parts shipped away to storage over the weekend, actually quite glad to not have the interior getting in the way or risking overspray/dust. And today after @ProZac's suggestion a while back of cleaning wiring harnesses in ultrasonic cleaners I put one of the door trims through a cycle, very impressed, will trade again!

- 53 replies

-

- 18

-

-

Likely larger capacity though Weirdly the car is registered as an 1800 in the system which is one of the options

-

Currently stripping the Datsun down and can see a cert needed in its future (EFI conversion) Because of its past life as a racecar, it still has the cage mounts, are these likely to cause me any grief come cert time? mostly hidden, but if you know what you're looking at, they could be obvious. It only had a half cage so plate each side behind the front seats and two plates under the rear screen on the parcel shelf. The floor ones make a handy jacking/axle stand point so kinda handy if I don't need to carve them out!

-

Annnnnnd i've got totally off track with cleaning up rust, Went down to machinery house and picked up some castor wheels on the word of @cletus way over what I wanted to spend, but with a few hundred kg rating per wheel, I could hang the whole car on them if needed. Blessed with another calm day I fizzed up a trolley for the rotisserie. Wheels are just poised for the pic, too lazy to drill some mounting plates so will get some profile cut. Pivot point is mad high so I might give it some makita one way action. Last few nights i've snuck out after dinner to slowly pull parts off to assess the rust, rumours that the Japanese assembled cars had better rust protection must have some truth as i've not much more than factory paint everywhere! The rear screen put up a fight (which the rubber lost) pretty stoked to only find more factory paint under here, happily buy new rubbers if it means less rust to fix! With the guards off I found the light surrounds are quite crusty, thankfully the drivers side is much better, will use this as a template to replace. Managed to extract most of the engine bay parts and have found myself quite taken by the cleaner look, good prompt to put some thought into the engine bay wiring when it comes to the time. A while back @Hyperbladehooked me up with a circular connector to use to check fit, bloody glad he did! What wasn't clear when the loom was in is the shape of the inner guard, while I think the socket will fit in the factory hole, it leaves very little space for the connector, hmm, rethink this one or just go all in? Next step is to get the trolley finished, if i'm cunning I should be able to use the rotisserie to lift the body off the motor and box, time will tell..... Whats become quite a blessing is i've bartered sufficient off site storage for all the bits while I complete the build, keeps my workshop far less cluttered!

- 53 replies

-

- 13

-

-

Do you know what happened to that car? There is a surprising number of them still registered, must be even more hiding away, hopefully its still alive? I'm expecting to revisit the urethane cross member bushes when I remove it, no doubt they won't look too healthy! So many options with the heads, did you put the larger valves in or were they standard larger in that head? Still haven't got a clear idea on the engine build, have put it to one side as I focus on the body work..... For future reference, we have discussion threads for builds, this one is here: Keeps a good flow of builds and we can spam the daylights out of each other with plenty of space! (Hopefully a mod can shuffle these over?)

- 53 replies

-

Another warning... Careful with that approach, you still won't have the airflow to do the work. Small compressors often don't have high duty cycles, the instructions state not to use air while running/filling etc. Pumping up a larger tank will give you more work time, but the compressor might get too hot getting there. I recently found a 2.75hp compressor that I was keen on, good flow etc, but it was only rated as low duty cycle, unfortunately had to increase my budget

-

As chief engineer of wheelbarrow alignments, I take my role preserving even tyre wear very seriously!

-

I currently spend a substantial part of my working day reviewing documentation for building quite complex machinery, this is not only for our assembly team but also to satisfy various directives and certification standards from around the world that we are subjected to. Biggest learning is not to do the usual human response and try to control every detail, the art is in conveying the design intent of each particular assembly without constraints, be that tooling, process or parts. For example, if I put down 'torque fastener to 200Nm' I then need to ensure there are torque wrenches available at that station, they are then subject to quality control, periodic inspection and calibration, Additionally, I will need to justify why that torque is specified so that the next engineer understands why that is stated. If the above fastener is not structural and once loaded could fall out with no il-effect, the effort above is quite wasteful. Whenever i've tried to be fancy with describing a process, it has backfired, not in a physical failure, but in restricting movements without rewriting existing documents. I would say it is clear to everyone here that in an effort to define a mudflap (noble intent) this is rearing up to be quite an own goal. While arbitrary rules also hurt, in the case of the mudflap, what is the intent? is there real harm from lack of full coverage? Your pics Cletus seem to shut down the whole discussion quite visibly, unless rally flaps for all?

-

After asking about castor wheels to build a chassis dolly, ol @RUNAMUCK fires me a message "I have a local mate with a 510 rotisserie he might loan you" #projectcreep Quick drive across town with a box of beers and this was in my possession Did I mention custom fabricated for a 1600! Will need modification for wheels to allow moving it in and out of my shed, but all the bones are there and legit, down to ball bearing pivots! All this has as expected pushed any chance of a quick turn around to be a very hopeful proposition, but i'm not giving up just yet, will dive into stripping parts with fingers crossed. First job down, got sidetracked while throwing a some epoxy about on another project and popped the windscreen out, gotta say i'm pretty happy with what was found. The only rust under the seals and it barely qualifies as surface rust (even for a Datsun!) Also shows the three colours the car has been, factory tan, dark blue and the current red. Next move is strip the interior to store away safely and then drop the drivetrain.

- 53 replies

-

- 18

-

.jpeg.4d8083cd0d545fde0dc2963bd650c379.jpeg)

.jpeg.a955098f39cae250a59a3c30263a975e.jpeg)