-

Posts

1615 -

Joined

-

Last visited

-

Days Won

2

Posts posted by Flash

-

-

Interior - Chapter 2

As part of the interior fit out, I'm hoping to add some weight so I can get rid of the concrete pavers that I am currently carting around in the back and at the same time give the van a feeling of substance as it currently feels a bit like driving around in a coke can.

I'm not sure if I've mentioned this before, but the previous owners restored the van to use as a promotional / delivery vehicle for their florist shop.

As they were planning to transport flowers in buckets of water, they wisely had the factory original wooden floor in the rear cargo area professionally waterproofed. It was a good idea, but unfortunately, they gave no thought to any form of insulation or sound deadener.

Much as it breaks my heart to cover up the rhino line, our plan is to start off by laying down a second plywood floor with some acoustic material sandwiched between the two floors. I'll stick the sound deadener to the underside of the new ply so that we leave the rhino liner unmolested.

I can then fix the timber structure for the couch bases to the new floor thus leaving the original floor untouched.

-

7

7

-

-

Interior - Chapter 1

I'm still plugging away at my fibreglass carby hat. It's slow going with just a little bit of glass work each morning followed by long periods whilst I wait for things to cure.

In between that Mrs Flash and I have commenced the planning of the interior.

I've probably mentioned this already, but the plan is to build a double sided couch that will fold down into a queen size bed for overnighting. Something along the lines of the rock 'n roll beds that were popular in the splitty window Kombis back in the day.

The forward facing couch will be located directly behind the front seats and will provide a convenient place for our dog to relax during road trips. The storage compartment under the front couch will contain the engine battery, a second house battery, a voltage sensitive relay and a fuse box with associated wiring for all of the ancillaries that will run off the house battery. With a bit of luck I can squeeze in the jack, wheel brace, jumper leads and an emergency tool roll as well.

The rearward facing couch will provide a convenient seating place when we pull over for a morning cuppa or a lunch break as well as a chilled-out spot to enjoy sundowners at the end of each day's travel. The storage compartment under this couch will contain folding chairs, our little gas cooker, a jerry can of water and place for towels and togs and a few changes of clothes.

As a starting point I've taken some measurements and put together a rough schematic showing a bird's eye view of the layout. Hope the drawing makes sense.

-

4

4

-

-

- Popular Post

- Popular Post

I then removed the passenger side door latch and gave it a bit of a birthday.

The latch is spring loaded but was sticking open which was bloody annoying when trying to close the door again.

Pulled the mechanism apart, gave it a good degrease and a liberal coating of lithium grease. It's not perfect, but it's better than it was.

While I was at it, I took a photo of the interior just to show off the fresh paintwork on my new gear stick surround.

When I first purchased the van, I wasn't a big fan of the upholstery colour scheme, but its slowly growing on me.

-

11

11

-

Ticked off a few more small jobs today.

First up, I wasn't 100% happy with the King Springs currently fitted to the front of the van. Can't really describe the issue, but the ride just didn't feel right. It's almost as if the front felt a bit loose every time I hit a small bump.

So, first thing this morning I took half a coil off the original Mitsi springs and chucked them in. Front now sits slightly higher than with the Kings, but it's still got a bit of a rake going on, so I dig it. Took it for a squirt around my local test track and it feels great.

I was expecting to have to take the springs out for a second round of trimming, so unfortunately didn't take any photos of the trimmed ones, but I did shape the coil end as per the originals and also spritzed a bit of satin black on the bare steel before putting them in.

Sunlight made for a crappy photo, but hopefully you get the idea.

-

6

6

-

-

14 hours ago, Raizer said:

Good to know. Thanks heaps for sharing @Raizer

-

10 minutes ago, Tiger Tamer said:

Sorry, I am not trying to be a pita.

I am enjoying your build and the effort you put into posting up your progress.

Cheers

No need to apologise at all @Tiger Tamer I've got no mechanical background whatsoever and this coupled with the fairly insular existence that I lead means that I rely heavily on my fellow Old Schoolers to bounce ideas off or seek advice from. So, I really appreciate and value your feedback and suggestions. Concerns raised are also greatly appreciated as it makes me question some of the decisions I am making along the way.

-

Maybe a liberal coating of something like this might do the trick @Tiger Tamer

-

1

1

-

-

1 hour ago, Tiger Tamer said:

Me again again again. I do have a worry about fiberglass and a Carby backfire. It seems it is in the firing line if you have a Carby back fire.

If it is, it may pay to see how flammable it is. Of course i could have it all wrong still.

I do appreciate your concern and do share some of your misgivings @Tiger Tamer. But the way that I look at it is that in the case of a backfire I'd be more likely to start a small bonfire if I was running a paper element filter no matter what the filter housing was made of. Back in the early 80s some of the English Fords that ran carbs (Escorts and Cortinas come to mind) were equipped with plastic air filter housings and those plastic housings would have had similar disadvantages. Having said this the resin I've used is particularly flammable so I guess that is something that I should be wary of.

Let me do a bit more homework. There may be some kind of flame retardant that I can coat the inside of the housing with.

-

1

1

-

-

11 minutes ago, yoeddynz said:

A few months ago I fitted the exact same carby setup and kit that you've got onto a 3y powered hiace. The kit came with a Ramflo filter (no less...) and although it works ok it lets through a lot of fumes and is slowly turning into a flammable time bomb.

So the van is back in right now and I'm going to build a steel adaptor to suit the original low profile Toyota carb top hat. I'll report in with progress for ya.

BTW- I had to mill/slot out two of the holes on the adaptor plate because it did not line up perfectly either. I made a manual choke cable using a bicycle cable that runs to a easy pull loop under the drivers seat.

Thanks Alex. Yep, I had to use a reamer to open up a few of the holes in the adapter plate too.

I'm keen to hear how you get on with the carb hat modification.

-

On 14/07/2023 at 18:49, KKtrips said:

Looking fantastic and keep the rake, it looks so cool.

Also as a suggestion for a low key weight increase, a 25mm thick chunk of ply laid on the floor would not look offensive and they weigh the best part of 50kg. Also if you shift the battery right to the back and under the floor should give you most of the weight you need.Thanks for the ply suggestion @KKtrips. Not only would it add weight but if I sandwiched a layer of sound deadening between the floor and the ply, I'm sure it would make the van feel less "tinny". It's a bit like driving around in a Coke can at the moment.

-

-

- Popular Post

- Popular Post

-

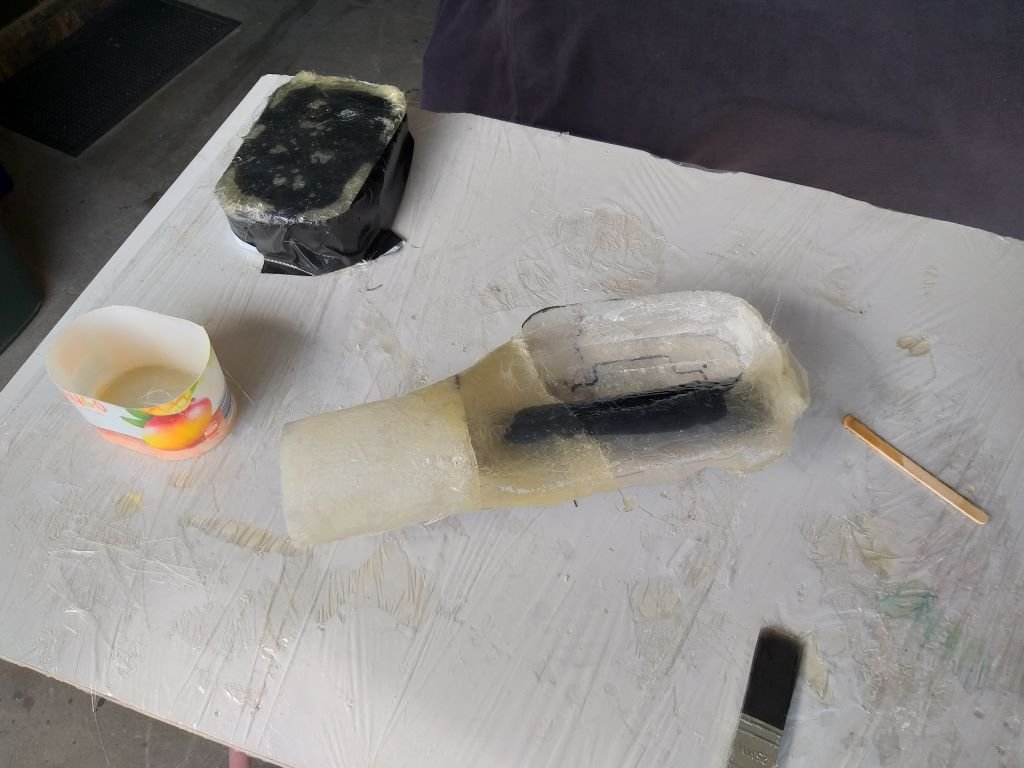

Carby hat - Chapter 4

Checked the status first thing this morning and the fibreglass had gone nice and hard overnight.

Time to break out the bucks.

Pulling out the paper mâché buck that I used on the tubular bit was a piece of piss.

Not so much with the plasterboard sandwich that I used for the main body. That one took a bit of effort.

If I had to do this again, I'd use a modified margarine tub instead of the GYB.

Time for a cuppa and then I'll crack into the next stage.

-

2

2

-

-

Great outcome Simon. You just can't beat that feeling of euphoria after the first start up. Well done mate !

-

Carby Hat - Chapter 3

I've been chipping away at the carby hat in between other jobs.

I wasn't happy with my original buck for the rounded part, so ended up building a mark 2 version out of a block of wood, a bit of electrical conduit and some rattle can lids.

Next step was to cover the new version in paper mâché which took a few days to go off. I was then able to split the paper mâché creation in half and peel it off the wood and plastic bits. Then I used some additional paper mâché to glue the two halves back together. That took another 2 days to air dry.

Final step was to cover the paper mâché and plaster board creations with a layer of gaffer tape and then earlier today I laid down my first layer of fibreglass on both parts.

This is all a bit of an experiment, so it's going to be interesting to see how things turn out.

-

7

7

-

-

- Popular Post

- Popular Post

Another little job ticked off the list today.

Whatever sound deadening the Ford factory put on the inside of the engine box lid is long gone with just a smattering of crusty old adhesive left.

I had a bit of that butyl-based stuff left over from when I did the floor of the Mustang so after a quick clean with my wire wheel, I stuck the stuff down.

Not the easiest job with all of the curves, but it should do the trick.

I've ordered some of that silver heat reflective mat that will go over the top of the butyl stuff just to finish it off.

-

10

10

-

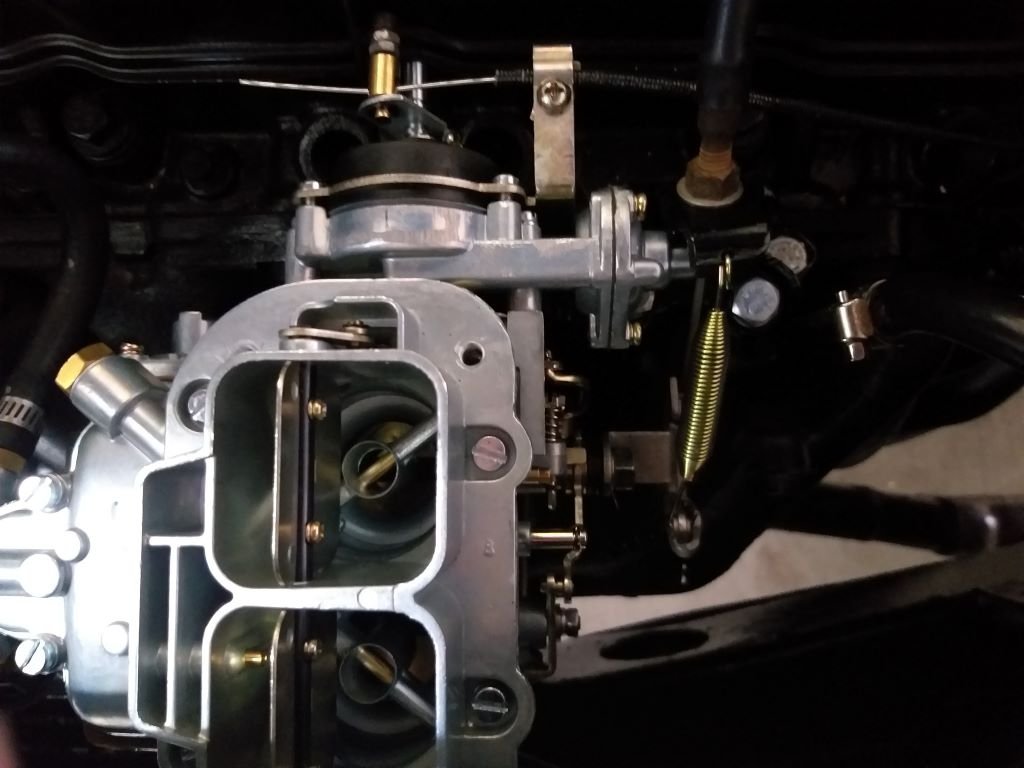

While taking my cement pavers for a scoot around the village, I noticed that my idling was all over the place.

Back at base camp I lifted the engine box lid for a bit of a nosey and noticed that the built in return spring on the carby wasn't always returning the throttle mechanism back to rest.

Checked out the accelerator linkage blister pack that came with the carby conversion and noticed a neat looking little spring included in the pack. That will do the trick, I thought.

Scratched my head a bit working out an option for a holding bracket, then remembered the little auto kick down cable that I cut off the main cable bracket last week. Luckily it was still sitting on my work bench, so a bit of cutty, cutty and drilly, drilly followed by a spritz of satin black and I was able to sandwich it under the locking nut on the accelerator cable.

The result looks just like a bought one.

-

6

6

-

-

Jeez I don't know if it's just my poor old eyes, but the colour of your new carpet looks pretty good to me. Goes nicely with the rest of the interior I reckon.

-

3

3

-

-

Yep, what you are saying makes a lot of sense @Otodat. Now that I think back on the Bedford CF that I built about 10 years back I'd forgotten just how bouncy it was at first. Then I built a fixed bed with storage underneath, chucked in a fridge, spare wheel, tools and a little trolley jack and it was amazing how well she handled with that extra weight.

-

2

2

-

-

- Popular Post

- Popular Post

Following on from yesterday's success with my high-tech concrete paver suspension stabiliser solution, this morning I replaced the Mitsi coil springs with the King Springs lowering coils and the Thames is back to its previous "nose down" stance which in my opinion is the period correct look for an 80s style custom van. I then moved the 5 pavers further forward in the load area to just behind the front seats and took the van for a squirt around my local test track. Suspension still feels good even with the extra weight further forward, so that is good news.

Some of you may be wondering why I'm shying away from doing any remedial work on the rear suspension to resolve the bounce. Well to be honest I suspect that the issue is with the rear lever arm shocks that the Thames is blessed with. They don't leak, they have been filled with fresh hydraulic oil that is the correct grade and when tested the resistance is really good, so there isn't really much more that I can do with them. I have toyed with the idea of converting to modern telescopic shocks but there really isn't a whole heap of headroom under there and with the van having a wooden floor I'd need to fabricate an additional crossmember for the top shock mounts. So, for these reasons I've put an upgrade in the too hard basket for now.

Once I've sorted out the rest of the driving related teething issues, I plan to build a rock n' roll bed with some storage space underneath where I currently have the paver's positioned, so I'm hoping that the additional weight of the new joinery together with an extra house battery and the camping related bits and bobs that will be stored there might just solve the issue. Time will tell, I guess.

Anyway, some photos to brighten up this update as well as a scary photo of one of the lever arm shocks in situ:

-

10

10

-

2 hours ago, Tiger Tamer said:

Convert to a camper.

Funny you should say that @Tiger Tamer as I was discussing the issue with Mrs Flash over lunch and she suggested that I move the pavers further forward in the load area to see if the ride remains improved. Reason being that we plan to build a rock n' roll bed with a storage box underneath directly behind the front seats.

I'm going to move the pavers forward first thing tomorrow and will go for a test drive to see how it handles. If that works it might be the easiest way out.

My original plan was to make the couch/bed out of a timber frame with plywood tops, but maybe the answer is a lead filled metal frame with hardwood timber decking tops.

-

3 hours ago, Nominal said:

Easy answer is to eat a lot of pies

Would be the easiest option for sure @Nominal. Like most English Fords of that era the rear is fitted with what I call grasshopper boxes instead of telescopic shocks. Usually the seals give out and they start to leak fluid. Mine are still leak free and when I had them out I checked fluid levels and they were both full. The fluid looked pretty fresh too, so I suspect that the previous owner had paid them some attention. I'm now wondering if they might have been filled with a thinner viscosity oil, so that might be the first thing I need to check out.

-

- Popular Post

- Popular Post

Big shout out to @Otodat who suggested that I throw a bit of weight in the back of the van to see what that would do.

So first thing this morning I chucked a bit of manky old carpet down to protect the floor and piled in 10 concrete pavers that I had lying around. Total weight was 140kg.

Took the van for a squirt around my local test track and the difference in handling is unbelievable. Really solid feeling with absolutely no bounce.

Spent a while fine tuning the amount of weight required and the sweet spot seems to be at 70kg.

I've left the remaining pavers in the back of the van for now and tomorrow I'll chuck the original King Springs back in the front so that I'm back to the ideal ride height.

In the meantime, I'll give some thought to the longer-term solution.

-

12

12

-

Yep, good point @Tiger Tamer. I had a nosey around the net last night and I can get a set of Gabriel gas shocks for about $30 more than the cost of a standard set of shocks, so I'm thinking of giving them a go. While I'm waiting for them to arrive, I've got some paving slabs and a half dozen or so concrete blocks laying around so I'm going to try @Otodat's suggestion and put some weight in the back to see if that improves things.

-

3

3

-

.jpg.2a077ed92f02d20f1f91266604c39a3b.jpg)

Flash's 1965 Ford Thames

in Projects and Build Ups

Posted

Interior - Chapter 3

So now that we have outlined the general plan layout wise, our focus has turned to aeshetics and the overall theme of the interior.

The previous owners chose an internal colour scheme to go with the British heritage of the Thames, hence the red, white and blue.

As I've mentioned before I wasn't a fan of the colour scheme, but over time its grown on me and the plan is to continue with this theme.

Here is a little sample picture that I stole off the net showing the colour and style of the vinyl coverings for the squabs.