ajg193

Members-

Posts

7,796 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by ajg193

-

Got back from Auckland yesterday and started work on making more plate dies this morning. First set off the press today were for this. I'm too used to the old spacing so these look wrong to me. I will put them through the dishwasher tomorrow evening to age them. Next up is wof prep

- 90 replies

-

- 27

-

-

-

Spent a few days up in Auckland getting this thing sorted for a WoF. Cut out and replaced a bit of the boot seal lip on the body as it had developed some rust holes. Ended up being a bit of a hassle as VTNZ brake rollers were not happy with rear imbalance. After loads of fiddling and adjustments the car stops dead straight now. Took it to Murray Kemp in the end, they checked twice as much stuff as VTNZ and gave it a clean sheet.

- 83 replies

-

- 15

-

-

The car ended up settling down after taking it for a good run. We're on the road now, about 45 mins in the Speedo started playing Anglia simulator, jumping all over the place. Five mins later it settled down again. Car must have some wet wiring somewhere

-

Fucked up and took Anglia to vtnz for wof, multiple rechecks and brake adjustments later they told me to just go somewhere that does a road test instead of rollers. The car stops dead straight with your hands off the steering wheel but every time they test it the back brakes give a different result. Bugger em, booked in for a wof somewhere else now

-

The fault seems related to TPS - engine runs perfectly as soon as TPS is disconnected, apart from gearbox goes funky. However, core plug started pissing now so we had to rip intake off anyway.

-

Will try the old brake cleaner around the manifold gasket trick today. Manual also reckons to try disconnecting the EGR Cleaned the MAF yesterday, didn't make any difference. I can't imagine a Toyota would behave like this

-

Hi all, My nephew got a rubbish old Mazda and we will drive from akl to CHCH this coming week. It has a fault where after it warms up the engine starts cutting out for a few seconds at a time before regaining power. The rev counter still works when it dies. Possible MAF fault? Anyone on here have experience with these?

-

Discuss here about Yoeddynz's little Imp project...

ajg193 replied to yoeddynz's topic in Project Discussion

Where did you get that idle valve from? Is it a PWM type? -

https://www.hampdon.com.au/mig-drive-roller-gear-0.6-0.8mm-v-groove-30mm-x-10 $30AU + $15 shipping to NZ Edit: That's a different part to 7977036

-

If you contact any real welder supply shop (not blackwoods) they will probably sell you one for like $60

-

Also you will probably get away with the 0.8 if you don't bend the hose too tightly. I could try whip something up if you send me dimensions. Will be either hardened or made from something pretty hard like 4340

-

On my welder it is just one set of rollers and you just flip them over to get the 0.6 groove. Took me years to notice.

-

Anyone know if 3y injection system will run a 4y happily out of the box? Brand new 4y long block out of China is $1000

-

Which one of those two cams actually worked better? At what point do the gains from extra area under the curve get outweighed by harsher dynamics on the valvetrain

-

What's your budget? RSP-1000-15 from RS components will do 50A, adjustable between 13.5V and 16.5V https://nz.rs-online.com/web/p/switching-power-supplies/6783868?gb=b Rs is quite good about discounts if you ask, they might chop 80-100 off

-

So why exactly do you need precisely 14V?

-

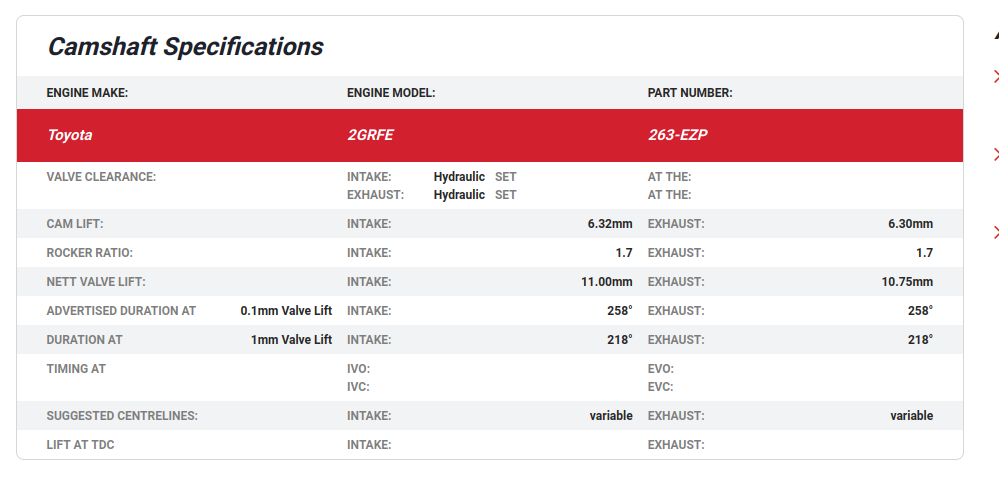

https://kelfordcams.com/product/toyota-2gr-fe-performance-cams-4/ interesting how aftermarket cams get off the ground later but ramp up faster. Shirley those extra ~10 deg would barely be worth the cost? Edit: Looks like the kelford NA option is quite possibly just OEM pattern?

-

You'd hope so, otherwise your big cam would only be like a Stage 1.2 4K 1/8th race cam

-

I wonder what sort of amplifiers Toyota used for their VR sensors back in the day. /rambling Barry incoming My 4K only cranks at 270 rpm, I more than doubled the diameter of the pickup wheel in the distributor and it gets a great signal (apart from some variation in tooth spacing due to questionable machining). I think there would have been little hope of getting a clean cranking signal with factory sized pickups. The distributor is from the VAST era where it would fire automatically if it didn't receive a signal from the ECU. They only had four teeth, no idea how the distributor could possibly predict timing in a reasonable manner. Probably explains why the Hilux is such a turd. I guess Toyota quickly decided the standard four tooth VAST was crap and that's why the Hilux has two VR sensors offset by some angle in the distributor to make the 4 teeth look like 8.

-

Imagine my surprise when I removed the oxygen tank and climbing goggles and scraped the ice off the block to find it wasn't a 2K

-

Yeah, I know. I'm an idiot, one day I will do coil packs.

-

I finally found out why the Starlet has been lacking so much power on the top end, the distributor rotor phasing was nowhere near ideal. For some reason I set it up with the middle of the rotor instead of the trailing edge pointing at the posts at 0 deg. This resulted in the spark having to jump a huge gap at anything more than about 20 degs advance. For some reason it wasn't quite as simple to fix the problem as I would have expected - I tried to just rotate the distributor and change the #1 tooth offset in the ECU but as soon as I got near the correct value of about 90deg (originally was at 76) the engine would lose sync and stall. Nothing I tried worked, until I decided to just pull the distributor out and put it in rotated by one gear tooth. With the offset now being about 102 degrees the whole lot works fine. Looks like the engine wants a whole lot more fuel above 4000 rpm now as it is actually burning what it gets. I've pulled a few degrees of timing out at high revs for now until the fueling is stable, but the car is definitely up on power.

-

I've had issues with trying to get consistent fuelling since day one, mainly due to the fact that the runners are over half a metre long and made of metal so always heating up and cooling down. I don't have a MAF sensor so I was trying to make do with predicting IAT using coolant temperature and flow rates. This works fine at steady state but it takes the engine about 15 minutes to fully stabilise, causing slightly rough running at various times in heavy traffic. I moved my IAT sensor location from the air box to between the injector and cylinder head the other day. After a quick remap the car is a completely different beast, O2 corrections are down to 1-2% from being up to and beyond 15% with old location. It's amazing how fast the temperature responds to throttle inputs. The sensor started out as a closed end GM unit. I wanted to try threading the tip to M8, but the tip immediately broke off. It was full of thermal grease around the thermister. I ended up turning the main thread down and rethreading to M10. I filled the body of the sensor with epoxy to help protect the legs of the thermister. There was a bit of a lug between two runners on the manifold. I mounted it in the mill and made a flat spot then drilled and tapped with tapered M10 thread. The thermister pokes into the air flow about 5-10mm. Hopefully the epoxy doesn't fall apart in the fuel environment. Dodgy injector boots from AliExpress are starting to look a little worse for wear after 60,000 km/6 years. Maybe I'll have to do something about that in the future. To be completely fair I'd be best off changing to ITB with coil on plug ignition

- 90 replies

-

- 10

-

-

-

Rough idle when on brake pedal would indicate a leaking brake booster wouldn't it? Try plugging the vacuum hose and see if it still does it.

-

R&D, newer sensor etc. Just get from the other guys if you don't trust him.