-

Posts

787 -

Joined

-

Last visited

Everything posted by Benno

-

Finished removing the underseal. What a shit job, lying under the car scraping with a chisel. Only a bit of surface rust, cleaned up no worries with a strip disc and wire brush. Gave it a coat of Brunox, scuffed up with scotchbrite and brush painted with epoxy primer. Not mint, but good enough for the underside. Just need to move the stands and do the same for the jacking points now. Getting the fuel tank dipped and lined, rear brake cylinders sleeved at the moment. Next, I will tidy up and paint the diff and fuel tank.

- 34 replies

-

- 30

-

-

Fuel tank cleaning/restoring recommendations Christchurch

Benno replied to 4dori's topic in South Island Region

I've got mine getting dipped, cleaned and lined at Hornby Radiator shop at the moment. Should get it back next week, will report how it went when I get it back. -

Argoshield, the gas n go bottles are labelled as MIG GAS at bunnings

-

Slowly but surely getting on top of the rust. Got the boot floor patches all welded in and painted with epoxy. Been working on getting the outer edge sorted. Wasn't keen to section the whole length to get the curve right. Got myself a shrinker/stretcher which made things much easier. My first attempt was to make a jig which had the right curve, bend a right angle then hammer to form a profile. Results weren't great, so back to square one. Cut, bent and welded some box tubing to get a curve the same as the boot. Welded and clamped on the bent and stretched angle, hammered flat. I butt and plug welded it on. Now just working through smoothing out the welds with a flap disc and power file.

- 34 replies

-

- 28

-

-

-

If you want a quick and easy, but effective rust kill/coating Brunox is king. Can get a brush-on or spray on coating type. Grind off the CRC shit, Brunox over the rust, hit with 2K epoxy primer and live happily ever afterwards.

-

All sorted, found someone with one. Thanks anyway

-

Thanks mate, wee bit far to justify though I reckon. Cheers

-

The check engine light has come on on the daily (2007 ford mondeo), has anyone got an OBD scan tool I could borrow? The one at supercheap didn't work for some reason. Cheers, Ben

-

Got the boot floor repair patch sorted, made a wooden template and hammered the side to suit. Cleaned off as much rust as I could in the boot strengthening crossmember, treated with Brunox. I will paint the areas I can with some epoxy primer, will get some cavity wax down to the areas I can't before I weld the floor path in. Started making a patch for the boot edge. Started off with my high quality sheet metal brake Clamped and welded to some SHS, hammered to get the right profile Fairly happy with the end result, will still need some minor shaping before I weld it in

- 34 replies

-

- 20

-

-

Where in NZ sells butt welding panel clamps? I ordered some of these a couple of months back, still haven't shown. Ideally would prefer to pay less than $50 for four from machinery house or restospares. https://a.aliexpress.com/_mt49Yeh

-

Got the spare tyre well sorted. Working on making up a patch for the boot floor. Made a template out of some rebar and plywood, used my hydraulic press to form the steel. Came up fairly well. Next step was to bend up the edge, I used two bits of EA welded together to make the basic shape, then hammered using a bit of flat bar.

- 34 replies

-

- 28

-

-

Kept going until I had chopped out most of the rust, got a few holes now. Also slowly been working through scraping off the underseal. Slow, shitty job but starting to make some good progress. A multi-tool with a scraper attachment makes the flat bits a lot faster and easier.

- 34 replies

-

- 14

-

-

No, got a prototype working but ended up using the Arduino for something else and never got around to getting it finished off

-

Got the fuel tank, rear suspension and diff out. Did a bit of digging around the fuel tank filler and found a bit of a nasty surprise. A rust hole under the filler had been filled up with silicon. There was a bit of sheet metal tacked into place and rust holes along the seam had been bogged up. Haven't quite figured out how I'm going to fix the holes along the outer side yet. It will be mostly hidden by the bumper, but will be incredibly difficult to grind any repairs smooth.

-

Got the engine bay and front grille into colour I've reassembled the front suspension, car kinda rolls now. No steering components yet. Next plan is to pull the diff and exhaust and start to tidy up under the car.

- 34 replies

-

- 20

-

-

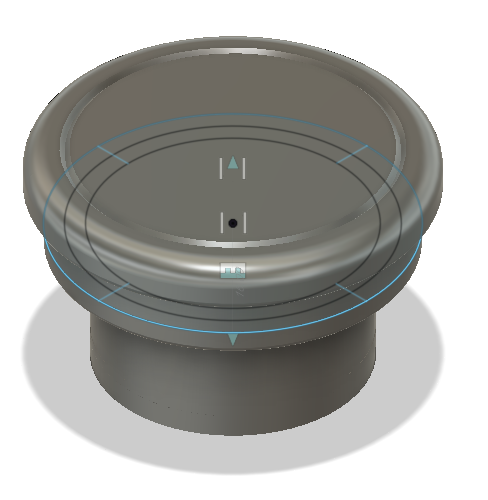

Got the engine bay into high build primer, first round of sanding under way. Also been working on a horn button for it. It's got an aftermarket steering wheel with no horn button. Quite like the steering wheel, so I'm going to 3D print one

-

Since my last update, I've got a bit done. I've finished cleaning up the roof, treated the minor surface rust with some Brunox, brush painted the interior with some satin black. I've painted the suspension components with epoxy primer and 2K gloss black. I've also done the inner guards with 2K gloss black, will do the underside and boot when I get around to them. Next step will be to get the engine bay into high build primer ready for top coat.

- 34 replies

-

- 14

-

-

I know nothing about 1Gs, but are you sure your battery is charged? The radio is not wired to turn off when you use the starter, the voltage drop from the starter motor load causes the voltage to 'brown out', dropping so low the radio will switch off. Sounds a bit like the when you go to crank there is not enough charge in the battery to provide enough current for the starter to crank, but the voltage will drop enough to turn the radio off. Check the battery voltage, perhaps stick it onto the charger.

-

Hey mate. Can't remember how I managed to get it off sorry, been a while. I managed to find a section of a manual, nothing comprehensive though sorry https://drive.google.com/file/d/10-gfz1VmBIo6W_7HzypVFA3Cf78guO8X/view?usp=sharing Interesting project, you should put up a post on it!

-

Haven't forgotten about this. I got the shocks converted to gas strut, pretty hapy with them so far. Been bare metalling all the other front suspension bits, will paint with epoxy primer and 2K black once it gets a bit warner. Also removed all the sound deadening from the roof. Wee bit of surface rust, nothing too serious. Will clean off and paint with brunox.

- 34 replies

-

- 15

-

-

I have heard good reviews for kilmat, purchased from amazon. I haven't used it myself yet, but plan to at this stage

-

From my research, it seems capri rotors are similar. The height of the rotors is off by 2mm and the centre bore is a bit too small, but could probably be machined to fit. Unsure about the PCD, but the Zephyr discs are also 4 stud so could be redrilled if necessary. I think I'll get the existing rotors skimmed and see how bad they are, should be good enough to get me through revin at least. https://www.nzautomotive.co.nz/products/disc-rotors-ft-ford-capri-cortina-escort-mk1-245mm

-

My Zephyr brake rotors have some fairly deep rust pitting. I have tried to find new rotors, without any luck. I have spoken to someone who could machine some for me from billet steel. Would these be legal, for re-vin and WOFs? Apart from accelerating wear to the discs, would there be any issues from remaining pitting if I got my existing rotors machined to at or near the minimum manufacturers tolerance?

-

I've got an Accuspark in the escort. No problems with it, so much smoother and less maintenance than the points were

.thumb.jpg.89e9027588c21c739d107223b250cfc8.jpg)