Rhyscar

Members-

Posts

693 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Rhyscar

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

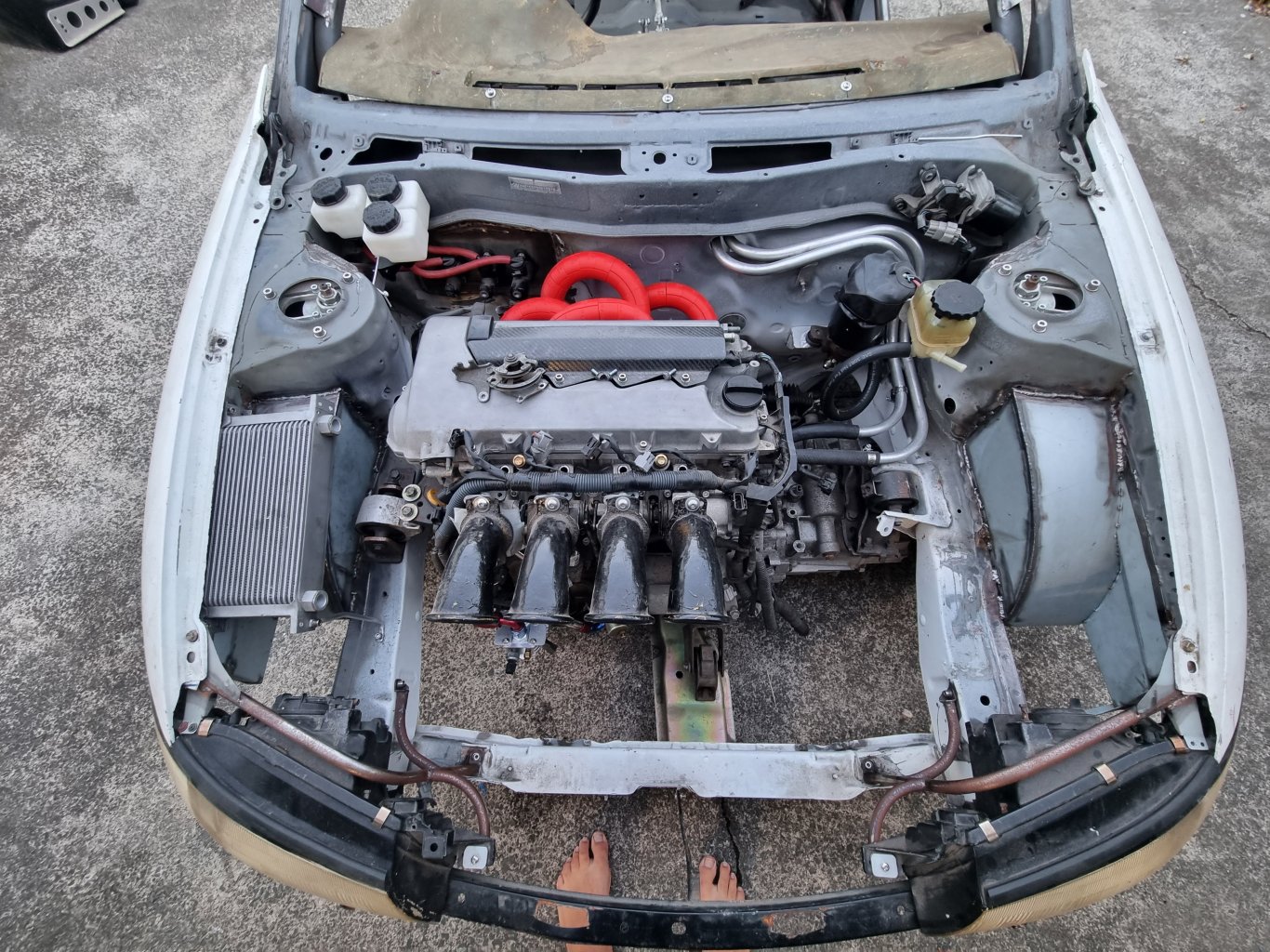

Front bumper ducting for powersteering/oil cooler. Will be vented out the bonnet for low drag/max downforce.- 234 replies

-

- 5

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

- 234 replies

-

- 6

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

- 234 replies

-

- 10

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

- 234 replies

-

- 6

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

- 234 replies

-

- 4

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

- 234 replies

-

- 4

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

New wheels showed up. Went to 17" for max tuck. Car also got painted earlier this year. Went for a replica colour based on Tom's racing colour.- 234 replies

-

- 8

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

Its been a few years since an update. Phew covid sucked. This will be mostly pictures so if you have any questions about stuff I have/haven't done ask away. If you want more updates check out instagram account https://www.instagram.com/garage_rfab/ Nick added to the rollcage. New harness bar and general improvements to increase the safety. New side intrusion, rear brace and strut tower connections- 234 replies

-

- 1

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

Still a bit of a work in progress we haven’t proven our theory fully but here’s what I’m basing it on; scavenging can be done 2 ways. Mass flow/inertia - header lengths, pipe sizes and mass airflow velocities helping scavenge airflow out of other cylinders. The key to this is keeping velocities up and preventing reversion so the pressure differential always wants to empty the cylinder. Acoustic - expansion chamber is to reflect the sonic wave that is generated when the valve opens. The expanding of the wave into the chamber causes a reflected negative wave that if it is tuned to the right length can reach the valve on the next cycle of the cylinder. This is based on 2 stroke theory which is well proven. Every example I’ve seen of one being used the car has made a lot more power than expected so just trying to figure it out for myself. @Roman has some fancy gadgetry to hopefully measure and prove all this at some stage.- 234 replies

-

- 2

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

So finally got off my ass and finished this expansion chamber and my exhaust. I ended up rolling the belly section and rear cone of the expansion chamber. Should have done this for the front half too it was tricky but turned out way nicer! and gave it a polish up finished the tunnel end end of my exhaust off too. It’s a pretty tight gap to fit through hence the pie cuts and stupid amount of mounts heres the whole system complete just waiting to build headers and order a Flexi and I’ll be able to install it for good still trying to to find some 41mm od bends for the headers so might need to find something else to sort in the mean time!- 234 replies

-

- 7

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

I have a bit of a tight spot at the end of my tunnel/fuel tank that required a tight bend. And I was being cheap so I bought some pie cuts from nzpiecuts on Facebook. showed up the next day A+ service! Turned out awesome no purging and bugger all penetration. Oh yeah and I over engineered the shit outa another exhaust mount.. I’ll post a pic of the finished product a bit later in the week! Full disclaimer I’ve got very limited fabrication skills I am a project manager who sits at a desk all day long. But I’ve been super enjoying making cool stuff so I thought I’d give an expansion chamber a go to test a few theories. Patterned it with the help of youtube I don’t have any rollers so just decided to use my small folder. due to there being 12 folds per half each fold is 180/12 = 15deg which is bloody hard at the best of times so I made a gauge so I could check on my progress as I went.. turned out not too bad got a bit of beating to do to get the seams to line up and make it round but not a bad start!- 234 replies

-

- 10

-

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

Yeah it’s interesting that you may never be able to tell what collector style it is from the outside or even looking down the end of the pipe. Need some bends in an assortment of sizes for the next step of header making. Does anybody on here have a trade account with Autobend that I could use for a box of beersies?- 234 replies

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

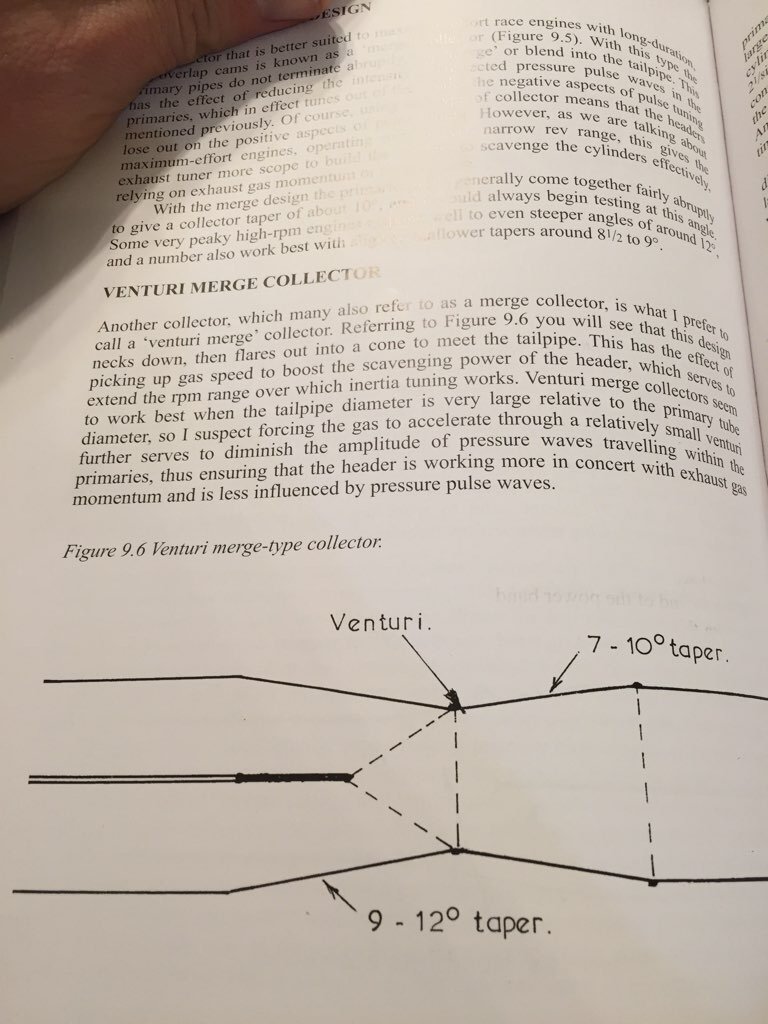

Been chipping away at the exhaust. Been working some big hours recently so took a few days off to reset my mental health and catch-up on some shed work. Finally finished the rear rear section of exhaust thanks to @Truenotch for helping out with another set of hands. Turned out to be a bit of a mission to fit a 3” zorst in a very tight space which required some unique solutions. So so here’s the end product which I’m very happy with. Can’t wait for it to make doorty noises! Bends weren’t quite tight enough so had to cut them up to make them tighter. Luckily the band saw and linisher made this task a dream leaving a nice flat surface to get some mint welds on; In order to get it fitting tight with no movement I over engineered the shit out of the mounting rear mount had double rubber mounts inside the chassis rail for max stealth Rear of muffler had this swanky mount to the subframe and under the subframe i added this rubber to keep it from hitting the subframe mainly as it’s only got 5mm clearance. Been working on building collectors for headers today also. Bit of a head fuck trying to work out how to construct these from the measurements I had but got there in the end. So I’ve decided to go with a Venturi style merge collector and a 4-2-1 header design mainly for packaging reasons. The idea is the gas speed increases momentarily accelerating it through the merge and it also amplifies the any acoustic resonance that we may or may not be able to create with the expansion chamber (standby for @Roman science in near future)... End product just looks like two bits of stainless welded together... Used a bit of card to make a template to get the angles right for the two halves They actually have a small plate/baffle welded in to restrict the area where the two flows merge. Normally (depends on merge angle) the area almost doubles which slows the gas flow and worst case can cause reversion at certain rpms. Welds came out pretty good with no purging only a few small spots of penetration that I’ve mostly been able to get rid of. Smashed through almost a whole d-bottle doing this and the exhaust though! heres the rough plan with my headers; My primaries are 41id stepping up to 44id then this Venturi is 47id before stepping up 56id secondaries and another 51id Venturi and tapering up to the expansion chamber. But that’s about as far as I’ve got sorted at this stage more to come on that next time...- 234 replies

-

- 14

-

-

Looks like the civic needs it’s own project thread in other projects? Loving the carbon work!

-

I muchly suggest adding a turbo to this. Especially with the extra weight it’s going to be SLOW.. we have run a fleet of 3-5 of these things on the farm for the last 20yrs. Had one with non turbo engine + Pajero turbo no intercooler and it went like a cut cat. Was aptly names the drift Ute. would go sideways everywhere easily do powerslides at 100kmh on gravel with muddies. Very fond memories. Keen to to see how your slide one camper goes!

-

I’ve got some 30x30x4 I think and maybe 2.5m of it

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

Yeah the guy who had the 2zz in it stripped it and reshelled all the parts into a ae111 and then sold the shell. I almost bought it a 1-1.5yrs ago when it was sold that first time but we’d just bought a house and the timing wasn’t right. The guy I got it from just never got around to do anything with it. Came without wheels but with a few spare body parts. All the exhaust, swaybars etc are gone.- 234 replies

-

- 1

-

-

How much and what size angle do you need Greg? I’ve got some in my shed I’m probably not going to use this decade..

-

Happy to do weldy things when you come over for beers and zorst chat. Just mark up the location and what you want the mounts to look like and I’m sure we can make them with minimal effort and a few beers. And header mods easy as too just know how far you want the finish point to move.

-

@Roman Dave found this article that claims the effect of variable valve timing when combined with header scavenging waves can be up to 4% https://www.mdpi.com/1996-1073/11/6/1545/htm it discredits the gains as not substantial which I think is incorrect. Another 4% just from correct vvti tuning on 140-150kw is a massive gain! Enjoy

-

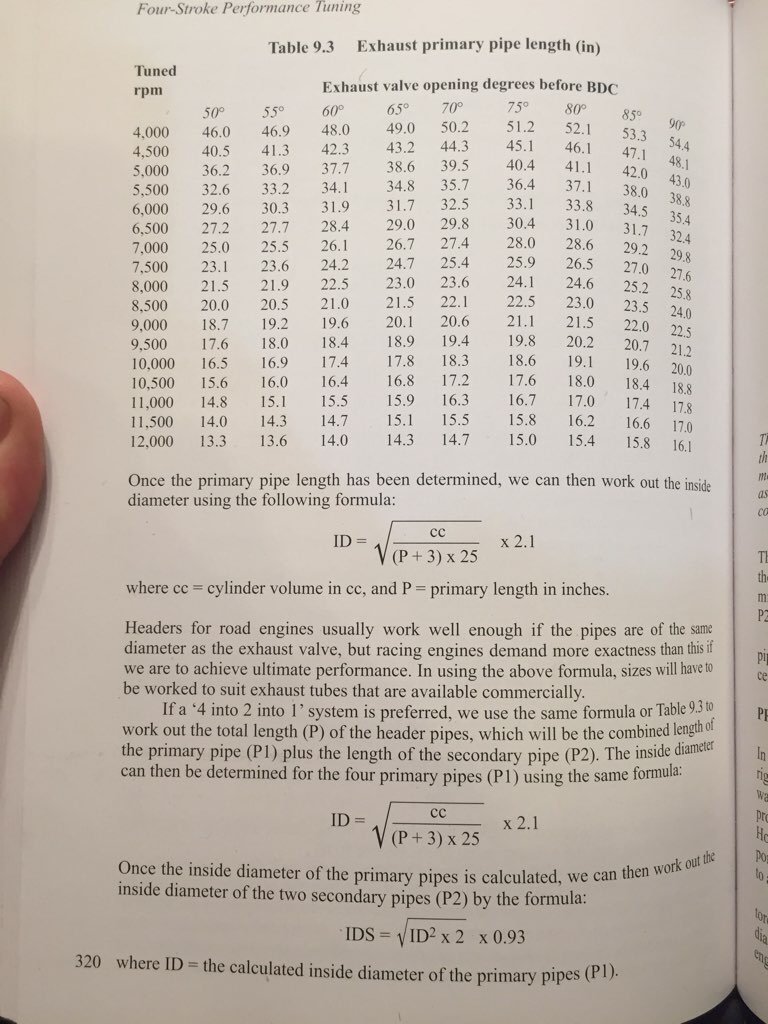

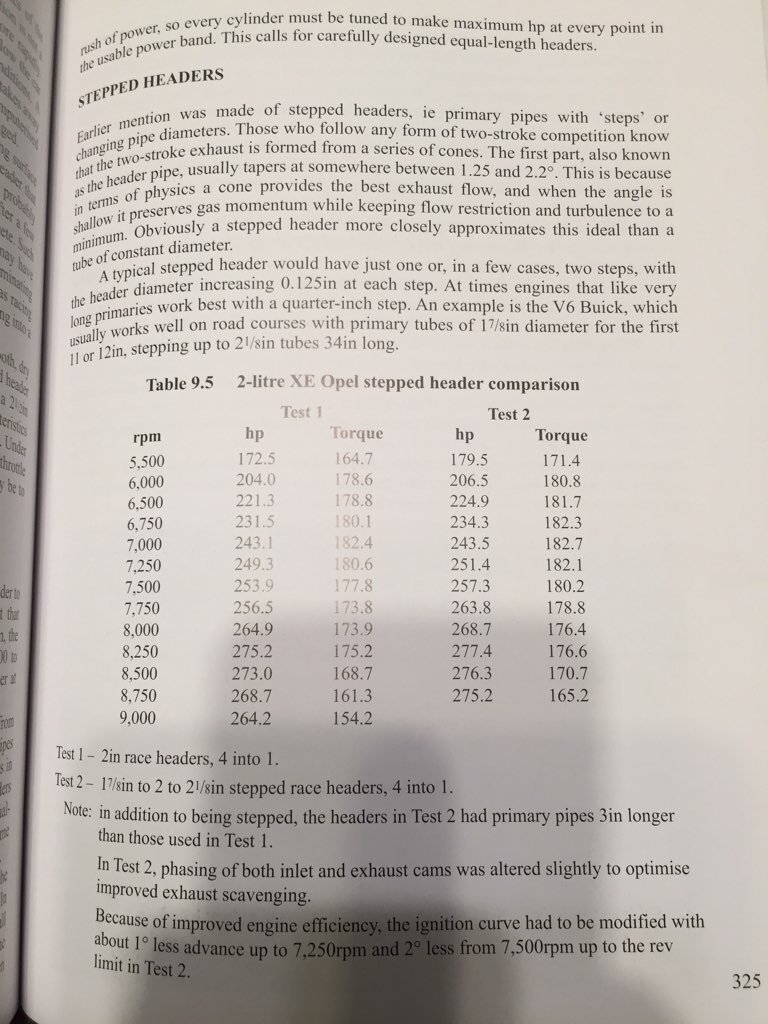

Love the graph Dave! In conclusion; you can spread the peak with vvti by 500rpm stepped headers can spread the peak by 500rpm Venturi collectors also spread the effective tuning range. It’s safe to say the higher the rpm the header is tuned for the bigger the returns you’ll get another interesting point made in the book is that you’ll get maximum gains if you tune the headers for a rpm half way between peak torque and peak hp. If all the above factors are combined into one header design surely a 1500-2000rpm ‘powerband’ could easily be achieved.

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

Ah didn’t think about that.- 234 replies

-

Wow that’s pretty close! Yeah smallport life is much better than 20v and easier to make the same power.

-

Interesting data from this book I’m reading that might help explain the tube diameter change (or lack thereof); engines typically produce peak torque at a mean gas velocity of 250ft/sec. (peak torque rpm is determined by size of pipe diameter) the max hp of the engine is determined by the pipe diameter changing the length of the pipe tends to ‘rock’ the power curve of the engine around the point of maximum torque Here’s some interesting data about primary tube diameter; Stepped headers; and data on venturi collectors; apologies for the spam in your discussion thread! This subject has got my brain ticking over far too fast in the last few days..

-

touge's ae101 racecar - ‘fab it all from scratch’ project

Rhyscar replied to Rhyscar's topic in Other Projects

So the sonic/acoustic pulses move independent of the mass flow of the exhaust and much faster.- 234 replies

-

- 1

-