Rhyscar

Members-

Posts

923 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Rhyscar

-

Yeah the guy who had the 2zz in it stripped it and reshelled all the parts into a ae111 and then sold the shell. I almost bought it a 1-1.5yrs ago when it was sold that first time but we’d just bought a house and the timing wasn’t right. The guy I got it from just never got around to do anything with it. Came without wheels but with a few spare body parts. All the exhaust, swaybars etc are gone.

- 418 replies

-

- 1

-

-

How much and what size angle do you need Greg? I’ve got some in my shed I’m probably not going to use this decade..

-

Happy to do weldy things when you come over for beers and zorst chat. Just mark up the location and what you want the mounts to look like and I’m sure we can make them with minimal effort and a few beers. And header mods easy as too just know how far you want the finish point to move.

-

@Roman Dave found this article that claims the effect of variable valve timing when combined with header scavenging waves can be up to 4% https://www.mdpi.com/1996-1073/11/6/1545/htm it discredits the gains as not substantial which I think is incorrect. Another 4% just from correct vvti tuning on 140-150kw is a massive gain! Enjoy

-

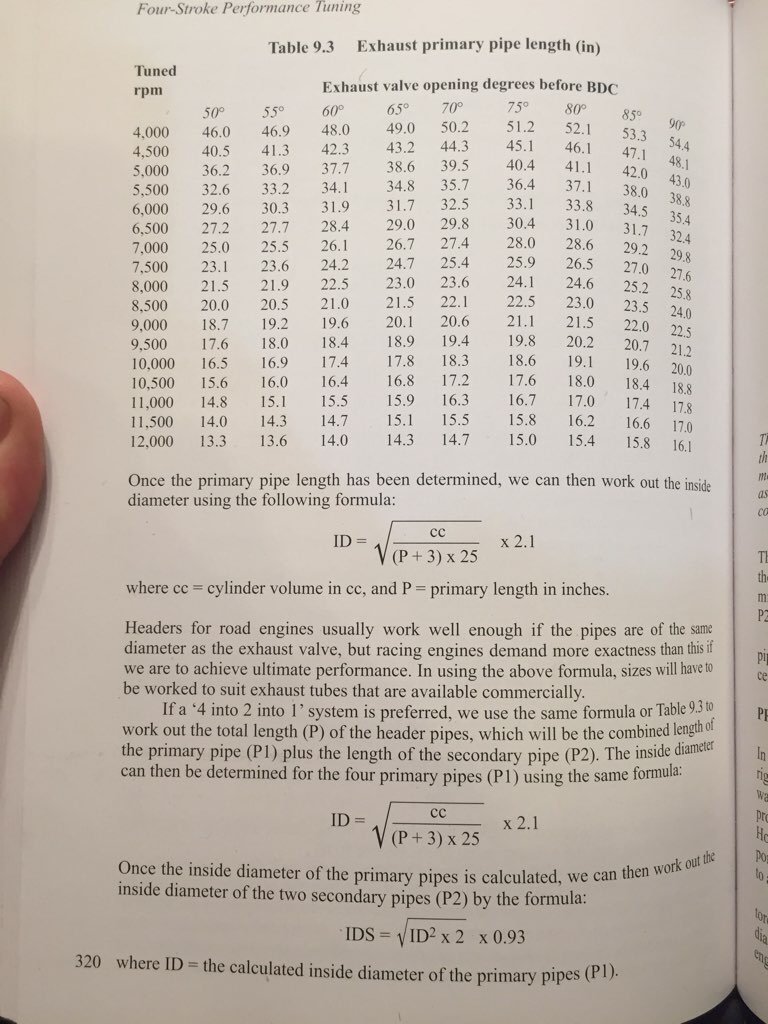

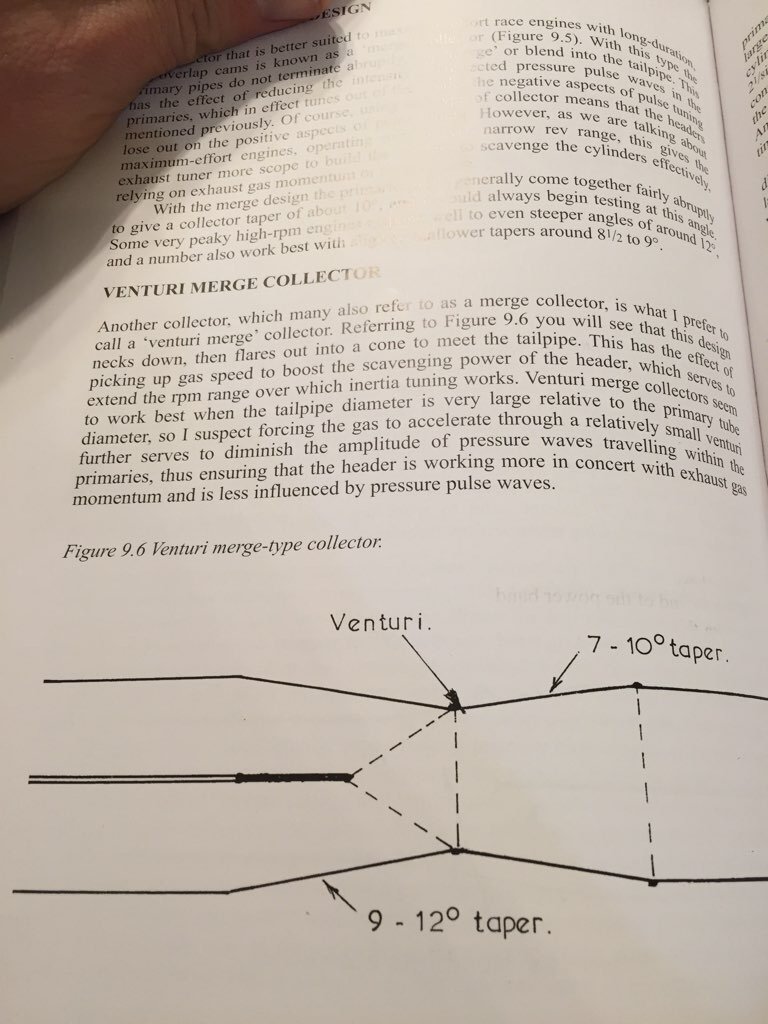

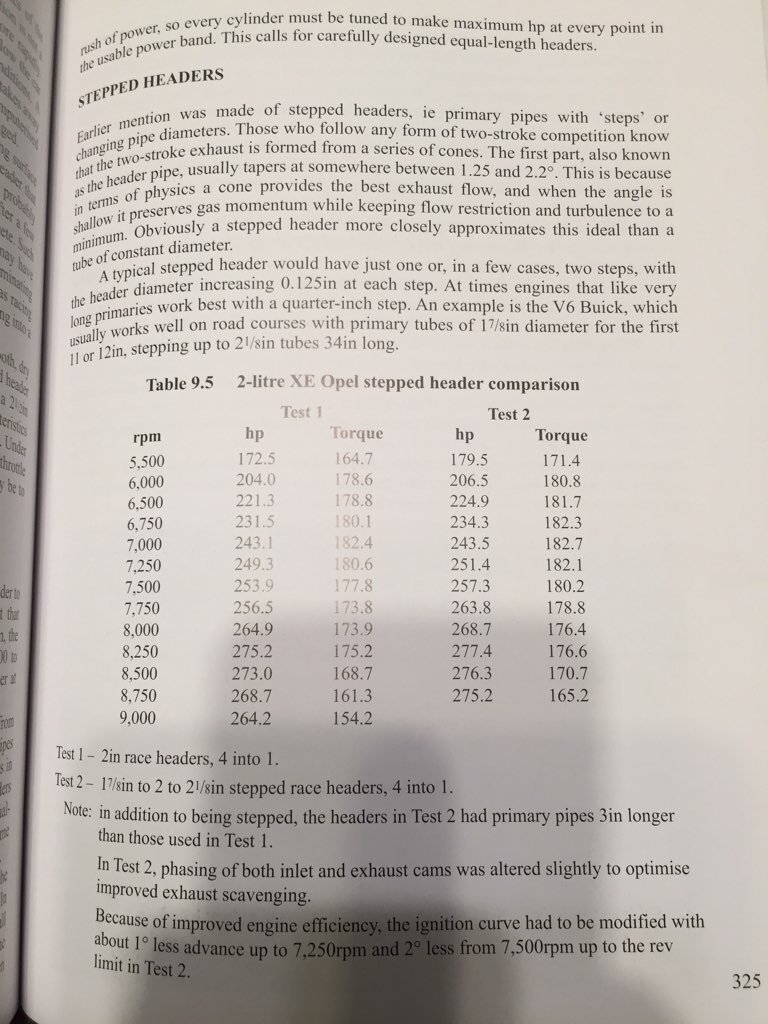

Love the graph Dave! In conclusion; you can spread the peak with vvti by 500rpm stepped headers can spread the peak by 500rpm Venturi collectors also spread the effective tuning range. It’s safe to say the higher the rpm the header is tuned for the bigger the returns you’ll get another interesting point made in the book is that you’ll get maximum gains if you tune the headers for a rpm half way between peak torque and peak hp. If all the above factors are combined into one header design surely a 1500-2000rpm ‘powerband’ could easily be achieved.

-

Ah didn’t think about that.

- 418 replies

-

Wow that’s pretty close! Yeah smallport life is much better than 20v and easier to make the same power.

-

Interesting data from this book I’m reading that might help explain the tube diameter change (or lack thereof); engines typically produce peak torque at a mean gas velocity of 250ft/sec. (peak torque rpm is determined by size of pipe diameter) the max hp of the engine is determined by the pipe diameter changing the length of the pipe tends to ‘rock’ the power curve of the engine around the point of maximum torque Here’s some interesting data about primary tube diameter; Stepped headers; and data on venturi collectors; apologies for the spam in your discussion thread! This subject has got my brain ticking over far too fast in the last few days..

-

So the sonic/acoustic pulses move independent of the mass flow of the exhaust and much faster.

- 418 replies

-

- 1

-

-

That’s interesting. Here is the dyno sheet for the 20v. Is flywheel kw the tuner works on a 16kw drivetrain loss for this car. Hopefully the data is useful. The best engine we had was about 12.5:1. over that it’s diminishing returns over that. Below graph is 13.5:1 but hasn’t really run reliably with that setup. Also found header design for reference

-

Have you seen this? https://thumpertalk.com/forums/topic/1075515-megabomb-header-explanation/

- 418 replies

-

- 1

-

-

4 stroke is the same where you want to have that negative pressure wave reach the valve For the small amount of time where they are both open to draw through more intake charge (scavenging) The trick is to make sure the valve is closed before the vacuum sonic wave stops (length of expansion chamber determines your window) to prevent reversion pushing spent gases back into the chamber. I think we are both on the same wavelength... the 4-stroke application has a lot smaller rewards than 2 stroke but is still worth chasing.

- 418 replies

-

- 1

-

-

Nah not hytechs we got them acoustically designed by Harris pipes in Chch then built them ourselves. This was a about 5 years ago before I had learnt anything about this stuff. Agree that hytechs are the best for Honda’s and so cheap too.

-

This is where reversion (has particles moving) is different to the sonic scavenging wave returning back into the intake chamber during valve overlap. There are gains in the 10-15% range to be had for doing it right from what I can see. In a motorbike situation you don’t need a reverse cone as it is open to atmosphere but in a car where you have an exhaust attached it reflects the high power part of the sonic wave back up the header system essentially isolating it from the following mufflers/exhaust.

- 418 replies

-

- 1

-

-

Yeah it is a black hole indeed. Interesting data about the megaphones. Looks very weighted towards v8 collector sizes though! The book describes them as tail pipes and has similar data around 7-10deg angle and lengths. There isn’t much about the angle of the reverse cone but my understanding is the steeper the angle determines the sonic power reflected and over what rev range. I suspect picking something in the middle of the recommended angles (similar to dads expansion chamber) is the way to go unless you are doing all the calcs and can test 2-3 designs.

- 418 replies

-

- 1

-

-

Yeah the step is the way to go. From what I’ve been reading they broaden your torque range by a good 500rpm. I think it would be worth doing a bit more work on the collector and the restriction straight after Which sets up the scavenging effect. here are the headers on dads car they were good for 140kw but is suspect they are a bit small for the 150 it’s now making. In hindsight we should have gone to 4-1 design as the range it makes power in has so many more variables such as cams and intake than just the header design and you want them to compliment each other slightly offset not all line up in the same spot. Making power is like building momentum (I.e. area under the graph) Keen to see how far this thing can go 150kw is a lot. What compression are you running? I’ll see if I can pull out a dyno graph of the old mans 20v. Edit: @Truenotchafter reading those articles in my build thread I realised my understanding of reversion vs scavenging effect was wrong. I always understood them to be the same thing but they are quite different. the reversion wave (exhuast particles) travels at approx 300ft/s (this may change depending on cylinder/header sizes and compression) and the scavenging wave (sonic) travels at 1540ft/s (this is a number a smart old Barry once told me to use with expansion chamber distance from exhaust valves) I guess the trick is to set up the lengths so you don’t end up with a flat spot caused by reversion but still get the benefits of the scavenging. I wonder if the reversion chambers would effect the scavenging wave too?

-

Yeah that’s it sorry. Maybe they needed to be longer? Agree it will be interesting to see once it’s all together with the new intake. What’s your goal max torque rev range you are aiming for?

-

Going back a few posts here but do you think the 6000rpm flatspot has more to do with the lengths than the diameter of the tubes?

-

Oh thanks I dont so much os browsing these day I’ll take a look.

- 418 replies

-

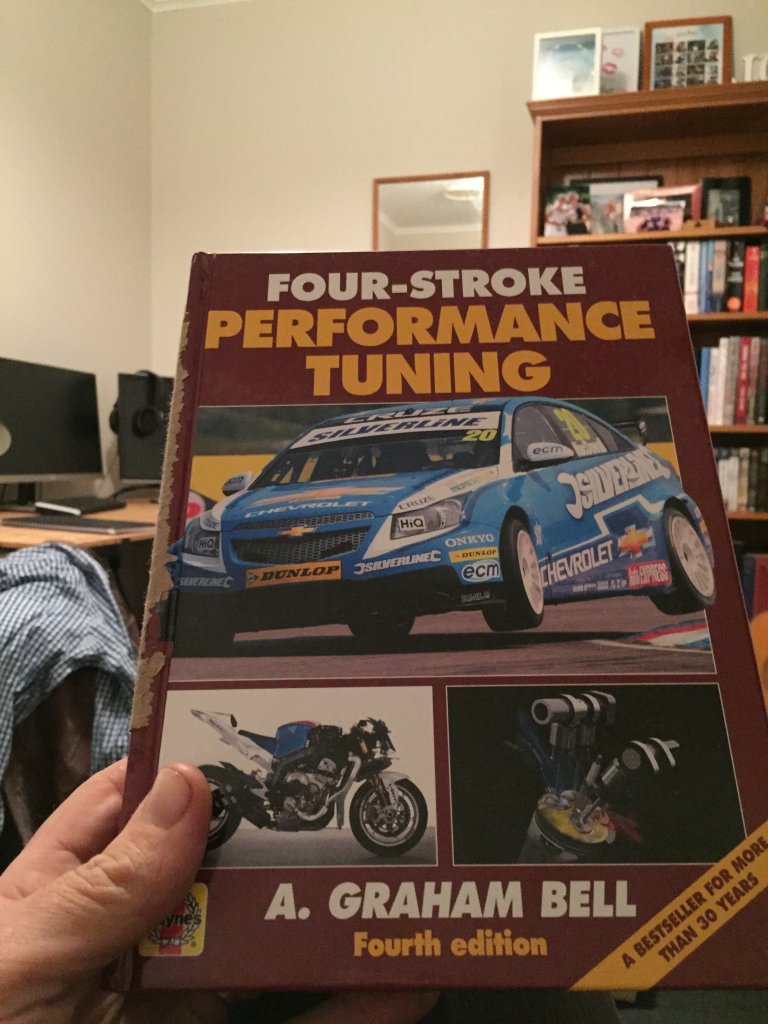

Thanks Markku. Yeah agree it’s the first time I’ve really seen it all together and it blew me away how low it was and how unlike a teenagers-first-car spec it is. Very motivating. In other news I’ve been doing some reading of this book that arrived. Interesting read even though some of the data/engines are old it’s still very relevant. Interestingly after a bit of ready I’m leaning towards a 4-1 stepped header instead of a 4-2-1. Not as much info on expansion chamber design as I’d hoped though. They damaged the book in transit so I’ve got a replacement on the way if you want it?

- 418 replies

-

- 2

-

-

Been chipping away at this even though work has been crazy busy the last few months. Competed the front passenger tub and headlight tubeframe. Have left the inner quarter panel for now due to: a) I didn’t like what I did on the drivers side and need to change it and b) I couldn’t figure out the best solution here so will move on and come back to it when I find more enlightenment. So so much room for activities up front. Airbox is guna be huge!! so I bought my old road car back as a rolling shell that I sold to @Robbo a few years ago. I know it’s a tidy shell and still certed etc. don’t know what I’m guna do with it yet but for now it will sit in a shed at the farm just need an engine so may slap it together for something like 24hrs of lemons or other endurance racing event/get it back on the road and do some doorts or just keep it for when I eventually write off this shell (it will probably happen one day) Had a real lol moment when the strop broke and it rolled off the back of the trailer in the middle of Rotorua! Haha it came with a fibreglass bumper the same as the one I have for the racecar, spare facelift side skirts and most importantly a bumper support so I can mount the racecar one without more fab work woohoo! result is the front end is together for good now. Going to be challenging to drive anywhere on the road at this height (not a bad problem to have) while waiting on more materials for the exhaust I started ironing out my fuel supply pipework. Have used 1/2” stainless tube as an alternative to braided lines as I hate smelly fuel lines inside the car and the ID of 1/2” is the equivalent of -12an or something stupid so will be plenty big enough. Made some fuel line clamps lamps from some Ali I had lying around. Very happy with the result. any recommendations on fuel pump/filter to use? Want something reliable with a no-bleed back feature so I can run two pumps in parallel. Dont need much flow approx 200lph will be ok I think (need to check calcs) I’ve seen too many fuel pump failures at the track or beginning of stages that stop people completing events. Not going to take that risk.

- 418 replies

-

- 15

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Rhyscar replied to h4nd's topic in Other Projects

Those are cool how do you buy one/how much are they? These projects always take way longer than expected. If it wasn’t a good winter project to chip away at I should have just paid the money and bought one in hindsight... thabks kimjon I’ll give it a go! -

Random slightly cool stuff you built but not worth its own thread, thread

Rhyscar replied to h4nd's topic in Other Projects

Solved one of the first world problems we have with our outdoor furniture lately. After browsing mitre 10/Bunnings and not finding any decent quality options that aren’t $500+ made me decide to build one instead. https://photos.app.goo.gl/hY6EvVE2qRRJ448H7 Built a frame then stained some ply and slapped it on the outside. https://photos.app.goo.gl/dYM4WfYmcDWqi9d79 Came up pretty sweet. Now my cushions stay dry when I want to use them https://photos.app.goo.gl/g2e2k7eh5bdaUNUx6 Edit: how do you embed/upload multiple pics? I’ve been struggling along only adding 2 pics to each of my posts to fit under the size limit but surely there’s a better way!?? thanks in advance! -

love these things. Well done to you sir. Continue winning at life.

-

Random slightly cool stuff you built but not worth its own thread, thread

Rhyscar replied to h4nd's topic in Other Projects

Yeah there were a few too many weetbix to bother keeping it. Got plenty of material that needs to go to Tenfive’s for the next bonfire!