-

Posts

2,878 -

Joined

-

Last visited

-

Days Won

4

Content Type

Forums

Downloads

Events

Gallery

Everything posted by azzurro

-

Now we know it runs, next step is to make it worth driving The interior was pretty good condition but there was a lot of evidence of rats eating and storing snail shells in the engine bay and mice droppings in the interior, but no evidence they lived there long, and the shed it was in wasnt water tight so it was all a bit smelly and musty Anyway, all needed to come out for a clean & deodorised the seats, throw away the original horsehair underlay and to make it easier to do a few other jobs, like... Improve the shifter opening, replaced the galv flashing and countersinks that didn't really cover the hole, replaced with some alloy sheet (from the Sign of the year!) Metal from that trailer is in 5/5 classic cars we own now. Removed interior: Easiest approach is just remove everything to get eyes into all the corners of the floors and etc, and much easier give everything a good cleanup. Floor condition is most excellent, no rust at all! 'New' Underlay (free second hand stuff) to replace the original horsehair stuff that was a bit smelly and flat. I think the front carpet might be ex-torana too, it doesn't quite meet up with what im pretty sure is the original HQ rear carpet. Both carpets are in nice nick, and we will cover the gap (which under the seats) with some cheap nylon outdoor carpet from m10 that we will also use for the parcel tray that is also unmolested by axe holes for 6x9s etc. Rear came up nice as well, car has a tan interior with dark brown headlining - class! Removed the steering wheel and cleaned it, spayed the steering column black (was grey and still has the column change mech in it) and tidied the dash (omg its so janky!) up a touch, and also the wiring behind it mainly by removing anything that has added in as it either twisted, sometimes taped, chock blocks or vampire taps. And then remove the dead weight out of the boot to make room for bodies and crates of DB Its easily 80kgs, empty Things will likley slow down a bit now, as from here its time to start spending money on parts, most likley starting with brakes which i have not even had a wheel off yet to even check what they are apart from being discs up front and drums out back) I suspect the weird too easy/dead stop half way pedal/no brake function issue is the piston is jammed halfway down the master cylinder, as there is no leaks from any soft lines, and lots of fluid in the MC.

- 29 replies

-

- 37

-

-

Ma te wa to Bill and whanau, then we headed home, with our van loaded up with other treasure from the shed(s) Forgot to mention i got jealous of her getting new car, so I got me one the same colour as hers on the way up. Given i had to drive this, Kirsty was driving the van the whole way home, she was none too pleased about it (But, yes it is better than my current 2005 Forester X its replacing in every way, thanks for asking - 2002 XT, totally stock, sub 200k and after a few wee issues (MAF sensor, oily connectors, new spark plugs) it really kicks when the whirly boi winds up!) Good Day in Welly before overnight sailing Breaky fry up in Kaikoura a quick stop to rise the north island off And about 3 days after we got home, this turned up. Used Classic Towing - worked out fine, but lucky both Bill and myself are home most of the time because the communication around changes of plan was a bit lacking tbh. The man can sure back a trailer tho. Its a fricken whale compared to my 'big' Fiat, an easy foot wider. Time to poke the bear First thing, remove the CNG stuff from the engine bay. Not only is it unfillable, the electrics are one of the layers of fuckery (the least bad to be fair, but also totally redundant), the tees that loop into the factory heater coolant lines to stop the regulator freezing up were corroded apart, and the carb hat gas injector thing made the air cleaner butterfly nut rub on the underside of the hood. 'New' heater hoses (from the old CNG line) and a bit of a wiring tidy up Fuel pump clean (no go in Feilding, leaks like a sieve now, still no pumping action), now bypassed with a clicketyclack, needs a rebuild kit (diaphram and gaskets) Carb cleanup, was pretty clean inside the bowls etc, works ok now, needs a kit too (tore a gasket) Dirty ol' single barrel Stromberg BXV-2 is clean, now sitting on the still very oily 173 Bosch dizzy removed, cleaned and oiled, gap reset, but all the points, cap, rotor, leads and sparkplugs all look relatively low miles, so perfectly fine for now. Changed the oil and filter (oil was black and smelled like petrol but no chunks), re-crimped a new loose connections, taped some twisted wires, removed some vampire taps and chock blocks as well Put it back in starting from first principles (ignoring the marks, get cylinder 1 on compression stroke at as close to tdc-ish you can with a long thing in the spark plug hole, rotor pointing to lead 1) and it was about 90 degrees off where it was before - dizzy couldnt be turned enough to get the right timing, so i wonder if it had been tutued with before and the hassle of it not running well was why it got parked. Bill did say it had several minor issues needed sorting out and they got a newer, better car and he just stopped driving it. Anyway, buttoned up and after some further fine tuning it starts on one pump of the pedal and idles smooth. Not smoky (any more) Still no coolant or brakes.

- 29 replies

-

- 42

-

-

Then of course it was time to have a good look while cleaning it a bit, and taking stock So, its a 1974 Holden HQ Belmont Sedan in Orchid Red. Last wof/reg in 2001, so was on the road into Kpies early 20's around the same time i met her. Seems it also got the Torana front seats, maybe the centre console? Interior looks pretty good under the dust. Overall looks pretty straight and complete. Some rusty bits of course but not too bad at all for one of these 8s out back and 7s up front, massive CNG tank in the book gives it a rake. This car was a NZ new factory 202 manual 3 on the tree car. Bill bought it cheap from a guy who bought it to put the v8 that was in it into something else, or something - bought with no engine in it anyway The engine and box now in it is a 173 (2.8l) with a manual 4 on floor from the aforementioned rolled Torana, which had recently had a fair bit spent on the engine (??) It has a single barrel Stromberg and also has CNG. Only $4.20 to Whanganui! Took the plugs out and oiled the cylinders, cleaned the sparkplugs and filed the points and hooked up a battery. Neighbours come to assist. Many opinions were shared We managed to get it to fire off on squirting gas down the yap, but it just wouldn't keep running. The consensus is that the timing and/or the electrics are weird Brake pedal does nothing till halfway then hard stops, no braking action. Handbrake kinda works. Engine isnt stuck and clutch is free and gearbox goes into all gears. Bill is stoked it fired up, Kirsty is happy, and that it rolls at all is good enough for the transporter man. We push it back in the shed to wait for the transporter

- 29 replies

-

- 38

-

-

Organized time off and ferrys etc and a cool 10 days hanging in Fielding. Real barn find! Her names on it so this must be it. We pumped up the tyres and had a general look around one day Then cleared all the stuff out over the next few days, did a lot of gardening too, Hooked it up to the van and pulled it into the light

- 29 replies

-

- 47

-

-

-

This is not my car. Im just the low rate mechanic. What i knew about this car was: My Father in Law, Bill, has 'The Holden' in a lean to shed. Kirsty learned to drive in it, and shes always wanted it and Bill said she could have it one day. It has the engine and gearbox (exact details unclear) from the Torana her older brother rolled when he was 16 'dodging a rabbit' on a gravel road. Its been in the shed pretty much since they moved into the 'new house'. He used to bring it out sometimes to wash it but hasnt for a long while. She put her name on it a few years ago and sent me a pic. My first and only view of it till now. Then a couple months ago, he said 'come and get the Holden' So, we did.

- 29 replies

-

- 26

-

-

Sounds great! Well done

-

Yeah, thats not 3D scanned nor did they take more than cursory look at the pattern you gave them to "copy". Id take it all back and ask them to not have the work experience kid play with the pipe bender this time. Close isnt good enough with that kind of part (as well they know as exhaust people), and thats not even close.

-

Nice! Good work on driving onto the trailer The older xx00 series Fiat stuff is noticably more solid and made with quality materials than the 12x stuff i reckon. Been impressed by the pushrod engines too!

-

azzurro's 1966 FIAT Duamilatrecento Familiare (2300 Wagon)

azzurro replied to azzurro's topic in Projects and Build Ups

As mentioned in the show us your mancave thread, ive recently been trying to make a bit more room to shoe horn more stuff into my 'deep store' I have some freshly levelled and inspected pallets just begging for some worthless junk to be piled upon them The stuff in question is what remains in my storage unit in Helensville, which is mostly junk, including a 2300 wagon parts car. Getting cleared out is loooong overdue (we moved to Dunedin nearly 4 years ago!) and the monthly is much more expensive now post covid than it was. Im not going to do the math on how much ive spent to store this shite vs what it would have cost me to buy now off ebay with shipping from the most expensive seller if i ever needed it. Nor will i consider the time cost of the carry on described in this post retrieving said stuff. Anyway, plan hatched to drive my van up, surf in Kaikoura, visit the FIL in Fielding, hang with the cuzzys in Rotorua and Maketu, pick up @vivaspeed trailer in Tauranga, drive to Auckland, and over a week of also working in person in the City and visiting family and Muriwai friends, sort out and pack up the storage unit, and drag the wagon back to Dunhole, cut it up and drop the trailer back to Geoff in Oamaru. Whole think too 16 days and took me a week to get over. Trip up SI was nice, Dud to Kaikoura in one hit, then wake up to this day of fun uncrowded waves at Mungamaunu before the 2am ferry Then early morning pick up some OS freight in Welly, Fielding for a cuppa with the FIL then to Rotorua to stay with my cuz. Maketu the next day to hang with my other cuz on the beach, then to Tauranga to pick up Geoffs trailer, made it as far as Bowentown for the night. Next day thought Auckland to Helensville to drop off the trailer and have a peek into the void. Sigh. The next week was work in the city and visting. Also picked up some vege crates to stack everything into. 3 loads to the dump (the move to Dunedin happened very quickly and a lot of stuff just got thown in there, on top of the excess of rusty car parts) Finally on the last day it looks like this Van looks like this Wee hidey hole int eh back - i could still sleep in there, like a frankfurter in a hotdog bun First leg fully loaded was a bit sketchy. Tail wagging the dog, despite the van having the heavy stuff (incl 2 gearboxes and 3 engines) The main issue was the heavy end of the wagon is the wrong way round on the trailer (no engine + a load of (light) stuff in the rear), and the trailer and van tyres were underinflated as well swapped ends at westgate and it was much better and even better after pumping all the tyres up, and when I moved the wagon back a bit in Mercer and it was even better. No dramas after that.... I pulled over just out of Mangaweka cause the spare on the trailer looked wobbly - i thought the wheel nuts ight have come loose, but they were tight - it was the carrier was wiggling itself off. Strapped it up and when i got to the FILs in Fielding, ol' mate Colin from next door dug out his old stick welder (made a few hotrods with it back in the day) and blasted it back together with his safety stubbies and jandals on 7am ferry back to Picton meant on the road by 4.30am, but a cabin for a snooze on the trip over. Home in Dunedin by 10.30pm, strait to bed! Van went well, averaged 10.5l/100km on the way up more or less empty, 12.5l/100km on the way back, fully stacked. Next few days spent sorting though the stuff i collected and chopping up the wagon Crates of stuff, 3 sets of seats, set of rims, spare 2300 interior bits, 2300 parts, 3 engines, two gearboxes... a set of 14x6 'MOD VIP' in 4by98 stud pattern that look sort of like a rare factory option on 131 that i might try out on the ute. Cant find out much about them but they are light and straight and 4x98, soo... And a shitty old car to cut up Doors off, glass out, starting to fill the car back up with stuff i wont be keeping Might look ok, but shes pretty crusty up close. Unfortunately i didnt get as many rust cuts as i thought, but i did get the main bit i needed which is the front valance which will come in handy soon 125 and 2300 panels all of which came down in this run. Thanks to @nzstato for the borrow of the plasma cutter, much quicker and quieter the the grinder! Crates stacked And all put away. There is a bit of a system now, but more sorting to be done too. Next job, fixing up Geoffs trailer (the stick welding didnt hold and i ripped the spare mount off again in Rolleston). I think it was a combination of being a fair bit heavier and front heavy than the race Vivas it usually carries, the effects of rust, and some less than perfect welding 40 years ago, but I wasnt going to give back a borrowed trailer in a worse state than i borrowed it! Front half much more solid now! One last job for the trailer, taking $27.50 worth of 'car bodies, stripped' to the recyclers Thanks FE 6269. last Wof was a clean sheet in 1995 at 75,765km Anyway, thank fuck thats all done, looking forwards to not moving stuff for a good while- 108 replies

-

- 31

-

-

-

- unicorn poop

- rust

- (and 8 more)

-

yours is a later model than mine i think so colours may vary but basically your hooking the two pairs that go to/from the external regulator together (the two fat wires whcih are the main feed to the car fuse box, and the two skinny ones which deal with the lamp). there may also be a lamp relay under the hood which might complicate matters. pretty sure you need to bench test the alternator with a load and a light/12v as per the setup you would have on the car or it wont output anything (the lamp is an 'exciter'). Mine is a 'single wire' which means there is only one control wire (and one main feed which isnt counted) - i think you said yours is a two wire (which i take to mean two control wires + main feed) If its a two wire you are outside of my experience, but maybe a pic of the back of it or the labels for the pins could help figure out what what they do and how to hook it up?

-

I had a look at my 125's set up and consulted the wiring diagrams to confirm what ive done the thin signal wires from the alternator to regulator (giallo) and regulator to IGN light (azzurro) wires are joined together - direct line from the later model (Lancia Delta ie i think? ) internally regulated alternators signal output direct to the dash light. the thicker main supply wires from the alternator output post to regulator (grigo) and then regulator to fuse box (rosa) are* also connected together. *i have strung a new main cable to a relay to take the load off the ignition and light switches, but yeah, basically its straight bypass of the old regulator

-

I have already clearly explained precisely what to do, in my earlier post, which I refer you to below, for your convenience I said good day, Sir

-

azzurro's 1966 FIAT Duamilatrecento Familiare (2300 Wagon)

azzurro replied to azzurro's topic in Projects and Build Ups

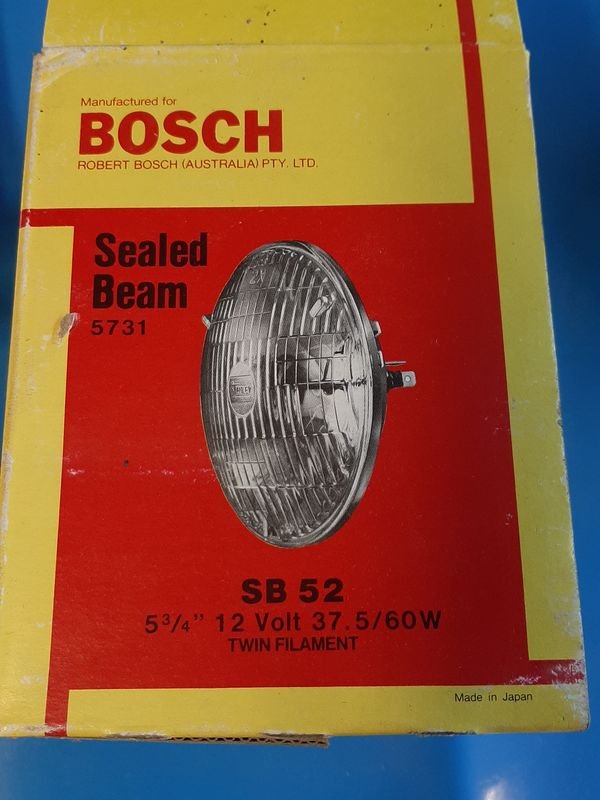

Crossing more things off the list Headlights the outer (lo and hi) headlamps had started to tarnish. They are noname/Repco ones i think. The inner high beams are Cibie and still in good shape and are very good The retaining rings are pretty shot tho, these ones are chromed steel, my 125p ute from 1989 in contrast has stainless ones - they are standard 5 3/4 retainers but stragly seem pretty hard to get hold of (read expensive or 'out of stock'!) , so if anyone has a good source let me know. Would like 4 but at least 2 would be good. I had jumped on a wodge of 12v car electrical stuff on marketplace a while ago, mainly for the NOS Bosch bulbs, which i was holding onto for just such an occasion Turns out they are reboxed Stanley's made in Japan, not bothered at all Stanley stuff is top notch, just pretty interesting. Pic on the box even has Stanley in the centre I took all the other lights off and cleaned everything up a bit including all their connections, and swapped out the silver grille back to the black one tidied up and resprayed and the best bits from both. Looking good sparkly eyes Crank Pulley and Radiator hoses Took the radiator out to access the crankshaft pulley Old one had this chunk missing on the rear side that I only noticed just before leaving for Nats. New one read to install along with a cleaned up and repainted balancer pulley and the centrifugal oil filter cover. Removing the radiator also meant i could swap in the new factory lower radiator hose i got in, and swap out this nonsense. Im now comfortable with trusting the factory temperature gauge, so i dont need this mechanical one any more either, but ill use this one in the van rather than the china electric sender one in there. Used some phosphoric acid to clean the top of radiator while it was out and a respray as well Lower hose in , much tidier, and the routing past the alternator is much better too, no rubbing on anything, and with the hoses sized to the different inlets and outlets its much tidier all round Clutch Pedal feel on the clutch pedal had always been a bit funny (seemed to 'stick' at the top) and when the gearbox was out checking out the clutch was out there wasnt anything obvious mechanically wrong. Pulled the master, which apart from some typical crusties in the pushrod end, seemed fine And the slave, again nothing scary, but worth tidying up and re rubber greasing everything Ended up being the pushrod on the pedal, i thought it was not adjustable but it was just stuck ! , so now thats freed up and antiseazed up and adjusted a bit and it seemed to have sorted it. Swapped out the lever arm sping on the gearbox for a lighter one too, will see how that goes. Clutch feel is like a modern car! Im sure ill have to adjust it a bit to set the bite point to the right spot once i get it off the jackstands but theres no feeling of sticking or jamming at the top of its travel now. Electrical This car has two horns from factory, there's a switch under the dash to switch between them - a Town which an electric piezo tooter that lives under the front wheel well, and a Country which is supposed to be two chromed air horns run off a chromed compressor that is supposed to live in the engine bay and point out that grille. This car didnt come with the air horns, and ive found some horns, but not stumbled on a compressor yet (i have an eye out for a cheap chinesium one but no luch as yet) Anyway the snail style horn i had was a bit weak and strangled sounding and i picked up a dual snail style horn that had a mounting bracket from some Audi at PickaPart when i was in Auckland last. Fits great! No pics but ended up chasing a bunch of electrical gremlins (turned out the old horn itself was fine, the wire at the connector end had gone green/patinad, and was letting though anywhere from 8-10V meaning it sounded sick), and tidying a bunch of wiring, including pulling the fuse box and cleaning that up too. Everything is much brighter now TOOT TOOOOT! Also pulled the plugs, cleaned and gapped them (0.40mm); pulled the distributor out, filed the points flat, degreased and cleaned, and reset the gap (0.45mm), Turns out the Vacuum advance diaphragm is blown Only makes a small difference and only at very low rpm, but ehhh. Will probably need to send that off somewhere to get fixed, as ive not seen them for sale previously. I also have 5 spare ones that all have leaks too. Also cleaned out the carb including blowing out the jets and the crud in the bottom of the bowls - quite a layer of fine silt, probably rust from the tank making it past the filter . Reset the timing (12deg), tuned the carb, timing, carb, etc dialing in on the sweetspot and now starts and runs really nice. Only a couple of things to do and it will be off the stands and as good as its ever been .If anyone knows of a place that does diaphram preplacement let me know- 108 replies

-

- 30

-

-

- unicorn poop

- rust

- (and 8 more)

-

well done untangling the magneti spaghetti. I didnt see why you set off on this maniacal task tho? IME the wire and connector quality itself is pretty good, but the layout and logic is messed up. Is there a reason you replaced all the wires too? I mean im all for it, just wasnt sure why?

-

azzurro's 1966 FIAT Duamilatrecento Familiare (2300 Wagon)

azzurro replied to azzurro's topic in Projects and Build Ups

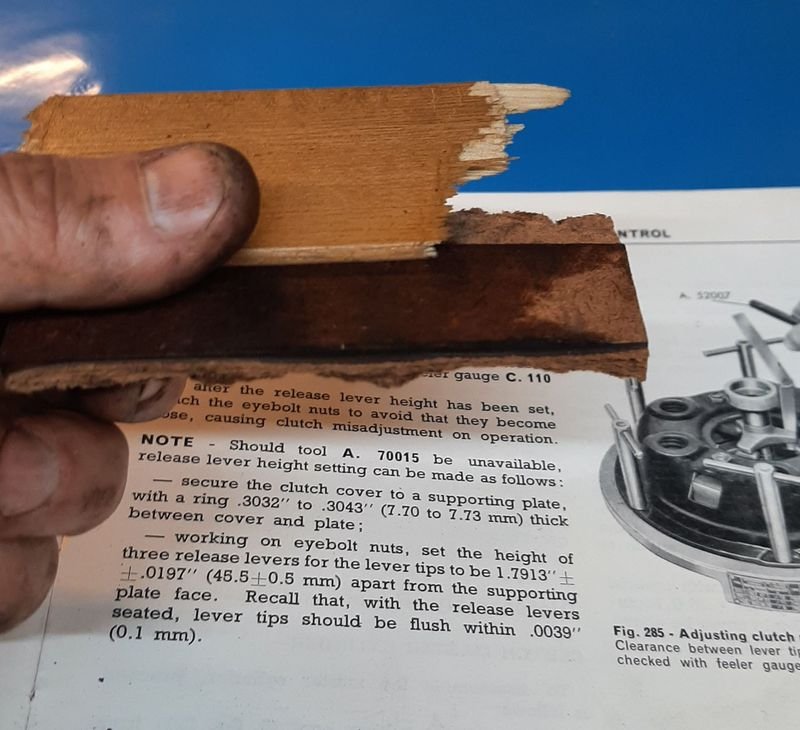

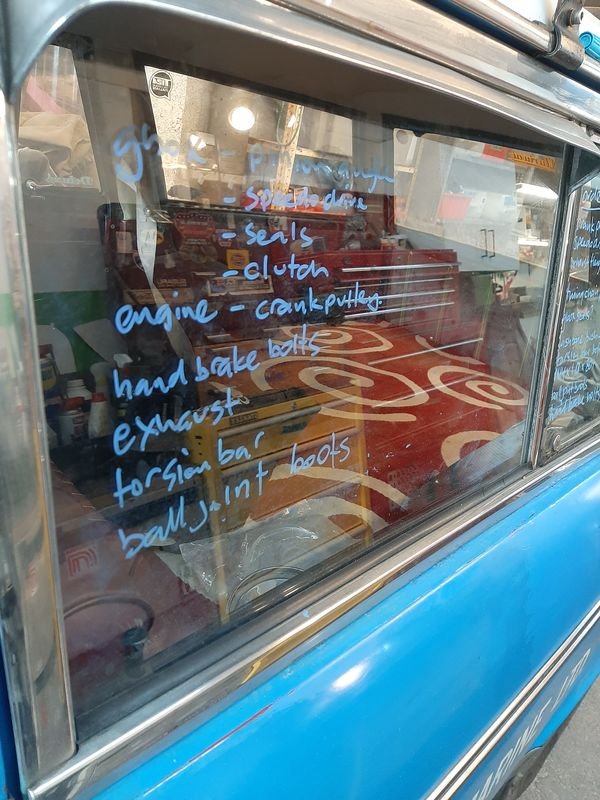

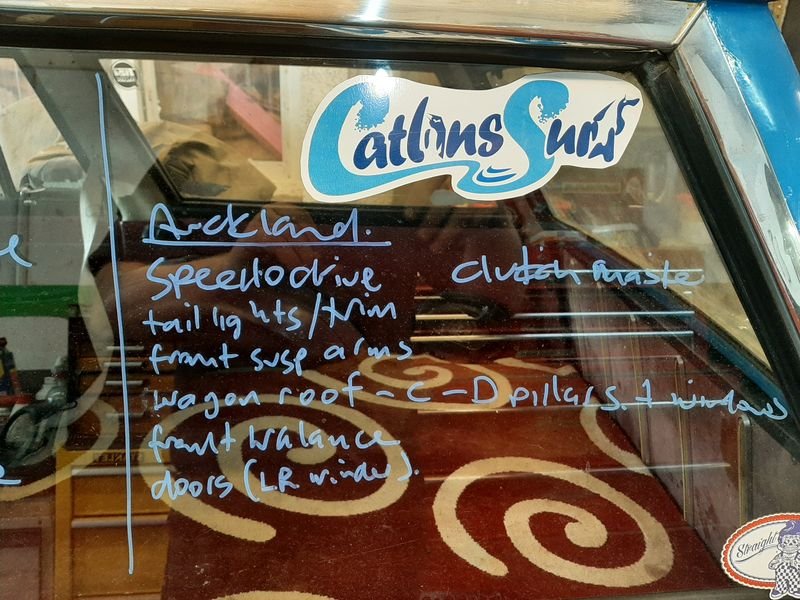

Had to go to Auckland for werk, and came back with a LOT of excess baggage My buddy sent me up with a coffin bag to get 'a couple of boards' ended up being 3 Surfboards (collected from GHS in Muriwai as a favour for my other Muriwai pal who lives down here too - a new 5'0" custom for his daughter and a couple of stockers for him), plus a new 9'2" Mal turned up for me in the post And some gluten free fake meat from Blissful Foods on Mt Albert Rd - nomnom And managed to get out to the lockup to dig though the treasure and filled my luggage with about 20kg of Car parts, including a box of 2300 treasure that id left behind last time such as a spare diff head, some starter parts and a speedo drive I also made an online order, including a starter pinion, pedal rubbers, a special 2300 only crank pulley, speedo cable and an oil pressure valve (for teh 1100T Van) Next job on the list was really a bunch of 'while im in there' tasks all requiring the gearbox to come out - gearbox leak(s) - gear linkages had got noticeably worse over nats trip, to the extent i was having trouble getting into first - get speedo going (speedodrive in gbox is busted) - clutch is a bit shuddery - centre bearing on driveshaft seemed loose So, gearbox out, first, woodwork. Bit easier than bench pressing it, and less likley to drop this cast iron deadweight right on its aluminium pan Lump out Gear box seals in stock The front and rear seals were not leaking but the linkage seals sure were, 24x14x7 btw Rear main nice and clean too, suspect a drip on the rear pan gasket tho. Flywheel clutch and pressure plate all good. One of the clutch fingers was a bit higher than the other two so i adjusted that back down to match the majority. Hopefully that's the slightly juddery clutch bite issue. More woodwork - these wood scraps ended up being ~7.5mm which was good enough to make the alternative to Special Tool A.70015, which was unfortunately unavailable. Pulled starter apart to replace the pinion drive which was running on - an issue since i originally got this going All nice and clean with new paint, new bearing and new pinion Centre bearing. Was new ~5 years ago. The bearing is still fine, and the manual suggests the rubber is supposed to be a fairly loose fit. Nevertheless it got the Sika Flex treatment whcih will hopefully protect the rubber and stiffen it up as well Bits and pieces get 2k black with a brush. Should last better than any single stage or spraycans all of which which ive used before and decided all are a total waste of time under a car imo. All ready for reinstallation, cant see but the centre bearing hanger is all sika'd up, and there is some 4mm rubber strips under the small void that is supposed to be between the gbox mount and the xmember - mount was was soft from the gbox oil leak, should lift it a few mm back to 'as new' Hight and support/stiffen the mount back up and stop it from rubbing on the crossmember. And then installation is reverse of removal as they say. upper bell housing bolt special tool with all the extensions Spent the weekend getting it all back in and adjusting stuff, including replacing a few linkage bushes and clips to tighten that up as well, and got it started up just before, and ran it though the gears on the stand. Speedo works for the first time ever! Linkage is much better! Clutch works! Starter sounds great! Exhaust doesn't leak or rattle! feels good man!- 108 replies

-

- 33

-

-

- unicorn poop

- rust

- (and 8 more)

-

azzurro's 1966 FIAT Duamilatrecento Familiare (2300 Wagon)

azzurro replied to azzurro's topic in Projects and Build Ups

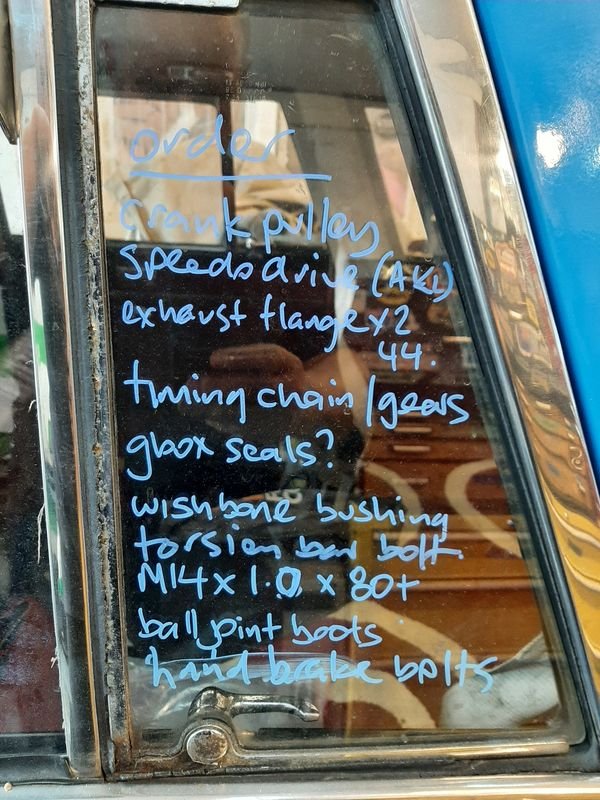

Post nats i made some lists of fixing and getting . First job, swapping the other front wheel bearing that i didnt swap before nats that surprise! had started grumbling pretty bad on the homeward leg - wasnt getting hot just noisier, i had it on board, but CBF changing it on the side of the road if i didnt have too Another original factory fitted RIV bearing and seal on this side, swapped out. Thatll do it! Probably started with small rust pits from when it was sitting all those years, and after about 5000km on a kerosene clean and a regrease finally punched though Then i put GIB on the front half of the garage ceiling/kitchen floor and some new lights. Way better! Exhaust - way too low, also, to loud (what?) The old girl sits pretty low, and we had pretty bad exhaust scraping issues around Maharau and anywhere with judder bars really. The constant battering made it bend mounts and droop, and leak and fume out the interior and i had to fix it a couple times at Nats. LOW LIFE This before shot shows why - when i first built this i put the flange at the easiest spot to do up, but its also at the lowest point, right between the wheels. It sounded pretty good , with long 1 1/2" secondary's to 2 1/4" just before the diff, into just one straight though muffler but was also pretty droney, esp @ 2k and 4k rpm, and so the drones was nearing peak about highway speed (100 is ~3.5k rpm in 4th) . Ill move the flanges and flexis in front of the torsion bar mount/x member so all that can be both flatter against the floor and loose the 10-15mm extra diameter forward to a less scrapey location Looking towards the diff - will put the muffler somewhere between the merge and the diff Also Ms Azzurro was getting headaches, and declared she wouldn't ride in it again untill it was sorted out. So thats that then. Basically need to tuck it up a bit more though the middle, by moving the flanges towards the engine, and stick in another muffler Had these bits in the stash, some left over 2 1/4 and 1 3/4 pipe and a 2 1/4 muffler ex my 125 After much faffing this is the new rear section, new muffler before the diff, and flanges moved about 500mm forward and staggered Shiny and chrome Still lower than the aluminum finned gearbox bottom plate with a dangly drain plug, but thats good. Would like to build a sump guard/skid plate one day, but for now it remains to the exhaust to protect it Loooong secondaries, but a few 100mm shorter, so be interesting to hear what that does to the harmonics - definitely had a noise peak at 2k and 4k before Nice and tucked up and flat though here, the old exhaust had lots of scraping here so hopefully that small skid plate will stop the lower edge of the muffler getting hooked on a curb and ripping the whole lot off Gained at least 10s of mms! Thats good! Fired it up once the RTV set, exhaust sounds smoooothh, much lower volume, but has lost its race car bark. Sounds like a modern car quiet. thats good to, i guess? (I must be getting old)- 108 replies

-

- 21

-

-

- unicorn poop

- rust

- (and 8 more)

-

Have used both of these before no dramas https://www.dellorto.co.uk/ Or https://www.carbparts.eu/?lang=en The second one is the feels slightly dodgy one i think you are thinking of. Ive used aliexpress for scooter carb jets, but not weber/dell stuff When i lived in auckland I called in to weber specs a couple of times, they had what i wanted in stock, but was very spendy. murray knows his shit but both times made it pretty hard to enjoy giving him my money, so ive not since, but, ymmv

-

Ill have a look at mine, i have an internally regulated alternator on my 125 - from memory it was as simple as unplug the voltage regulator and plug a couple of those wires together, but exactly which i cant recall. Im probably explaining it wrong, but in my mind, the alternator light on the dash works on the basis of who is winning the Battle of the Volts (path of least resistance?) between the alternator and the battery, if the alternator is pushing out more pressure (volts) than the battery, the pixies can then take the path that avoids the lamp (which is also a resistor - that why you cant use a LED there), but if the battery is winning, the path though the bulb is taken instead (cant push though the regulator??) and so it lights up. How that relates to the wiring idk, but now my brain is mush, and you are now stupider for reading this, ill go take a look and report soon

-

I did not. "Count to 10 please" "Tahi, rua,... iwa, tekau" "Ok, thats a pass" "thanks, have a good night, bye!"

-

Good run around with some good peeps. Noone has any road legal os whips, and i didnt take many photos Sweet line up! 125p pickup, Aristo, VR6, Pulsator Loristo navigating the dips Hotttt photo shoots Then back to NZStatos sweet shed to share hot meat and do lawn equipment revivals. Many lols

-

So long time no update on this. After my last post I fitted up the refreshed door frame Looks really good especially compared to the other side, which ive still to do, because it would be easier with the van turned around facing the road Which is cool, because the van now has a running engine, selectable gears, brakes and all the electrics work... I could drive it out the driveway, maybe an accidental quick bimble around the crescent and then back it in to its spot. Foreshadowed above tho is needing a new oil pressure switch causing the oil light to not go out. I had ordered a cheap set of aliexpress gauges (volts, water temp, oil pressure) and wired them in too - i like being able to see whats going on in more detail than the very basic dash lets on - swapped the oil pressure one out for an old mechanical one i had, because i trust them more than the cheap electronic sender/gauge and i had some adaptors that fit the block. Anyway, hooked the gauge up, and cracked the line to let the oil fill the line and push the air out, and fired up the engine (which runs great), but oil didnt fill the line So I did the right thing and took the fitting off and gave the jandal for a bit (nothing i hadnt done before) and some sort of dribbled out. Took the sump off and pulled the oil pump out, cleaned and checked it including running it witht eh drill in the drained oil - seems fine given how much oil it splurted over the driveway. Ill probably order a new pressure relief valve to be sure even tho the other one seems fine - the spring is stiff and it seals. Tried a couple other things to see if i could trace how far from teh pump the oil was getting to but its pretty hard to tell without being an oil molecule. The oil pressure sensor is near teh end of the line in terms of oil supply, but seems it is getting to the centrifugal filter (which just upstream of the pump) so it will be at least partially in the crankshaft bearings, but it isnt really pushing up to the tappets/head at all (which still have moly grease on them from assembly) So i assume i either put a bearing shell in wrong way round at some point or the crankshaft is full of crud. Either way the engine will have to come back out to be torn down again to find out what the fuck. So yeah, its been sitting untouched for about exactly a year. And then the other day it was just sitting there looking kinda cool, so I might start the process of pulling everything out of the engine bay, again, in preparation to drop the engine out, again

- 64 replies

-

- 30

-

-

-

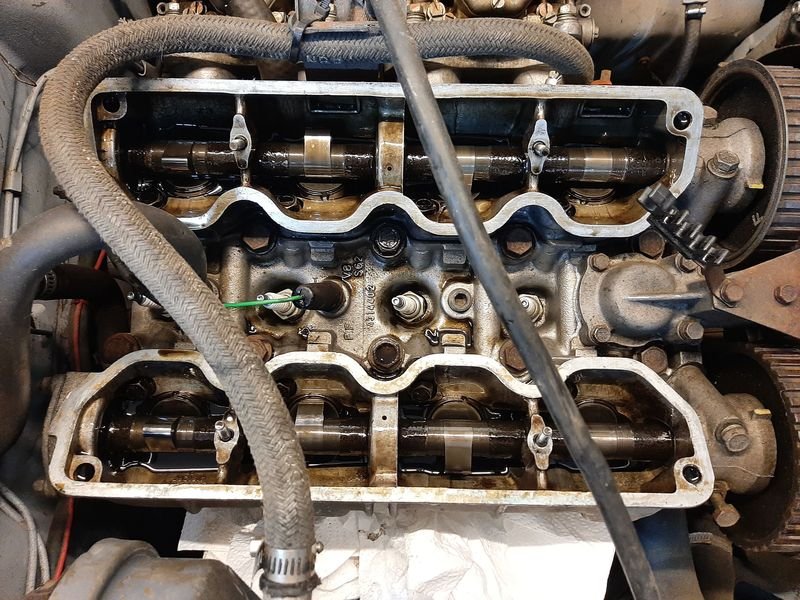

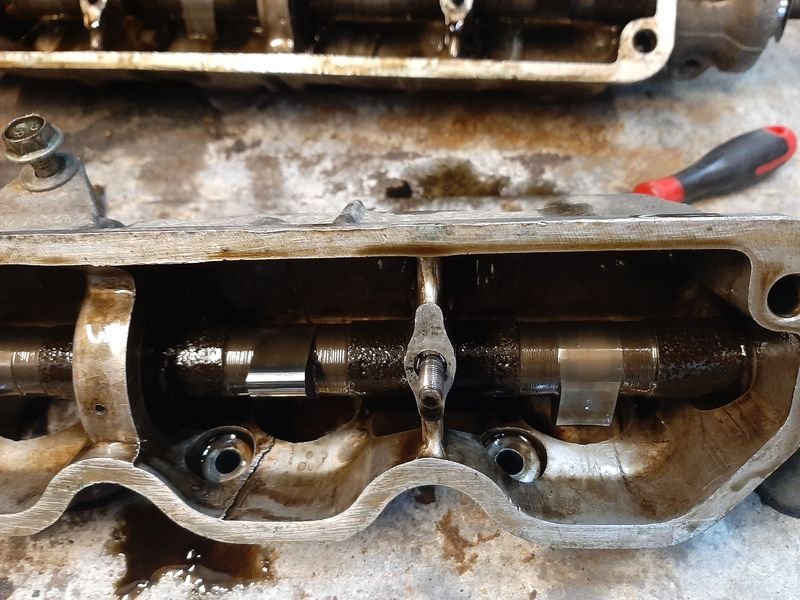

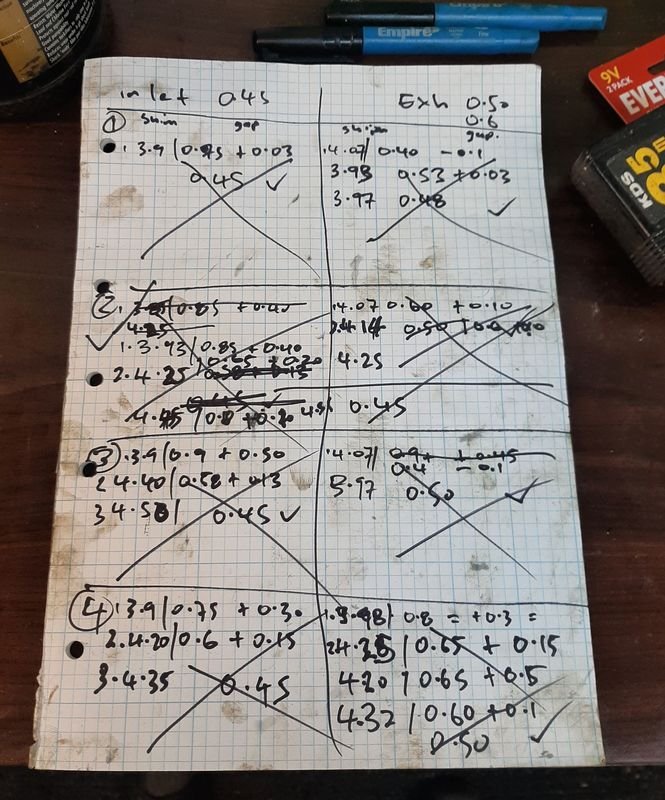

Drove this on some errands the other day and then my 125 and was reminded how different they are in terms of drivability despite being pretty similar set ups The 125 sedan has a 2 litre twin cam with twin 40 deloorrtos, and its smooth around town and has torque like an electric car, This wee truck on the other hand has a 1598cc twin cam with twin weber 40 dcoes, but it's never run quite right on any carb set up ive tried especially flakey at low speed, off idle etc, and no amount of carb fiddling would get a smooth idle, and not as much torque i would expect (accepting the 2l vs 1.6 makes a big difference) and an annoying tappet noise i could never shim out. So kicked Little Blue out onto the driveway with the van (update coming soon) and drove the ute into the cave for some engine work. --- When i tidied up the engine in the truck a few years back - and put a new 'big valve' head on along with the cams that came in it as per this post ... I should have swapped out the cams then for any number of good standard ones i had (still have) , but i didnt, i guess thinking it might be a hot cam or some such, hoping it was not just a crappy regrind So anyway, finally dug out my box of cams and cam boxes - most factory cams are pretty similar profile - but there is a nice set of late model 132 2l cams in a pair of boxed id cleaned, greased and regasketed when i got them ages ago in anticipation of eventually getting round tuit Time to dive in - cam covers off, can see the shims and buckets Cam boxes and buckets off, showing the valves ' Reground cam boxes on the bench - can see how the regrind reduced the base circle, and these are early 'narrow lobe' cams too, i measured ~8mm lift There is no obvious damage or wear (probably only driven a few 1000km since new), and while i didnt really measure anything (nor do i have the tools or patience to do it properly) i think just from feel the ramp is a lot flatter to me seems like they would 'slap' like a rolling triangle rather than smoothly roll like the eggier shape of the factory ones (which would explain the noisy tappets) and could be imagining it but i suspect the lobe points not all exactly 90 deg from the others making one cylinder (or more) not quite perfectly in time with the ignition and cylinder which would also explain the choppy idle and poor running generally - crappy warranty regrinds... Looking back up through the cam bucket guide at later 'wide lobe' cams (note how the cams just clear the buckets), probably ex a 2 litre 132, with ~9.5mm lift relative to base circle - what looks like rust is my copper rtv finger prints in the storage lanolin grease the shims for setting valve clearance (inlet 0.45, ex 0.5) are on the top of buckets, need a special tool to hold the buckets down, a pick and a magnet and sometimes the air gun to pop them out, as well as a bunch of shims Tiem to dig out the shim box! including special bucket holding down tool, specially bent and ground down screwdriver/pick for poking the shims out of the bucket, and handy dandy magnet. as you can tell from my collection, most standard scenarios are in the 4.00 to 4.20 range, the ground cam i took out were in the larger end Set all the clearances - following my 'foolproof' system... As above its a bit of a faff to adjust the valve clearance, not so much the actual swapping different thickness shims on the cam bucket, but mostly the admin of rotating the cam shafts and fiddling with a bunch of quite different tools - verniers and 19mm spanners at the same time. A bit easier with teh cam belt off and pistons at half mast, but still a faff. rotate camshaft so lobe is pointing away from shim surface Measure the gap with feeler gauges, largest able to fit without forcing (say 0.65mm), write it down calculate required shim size target on these cams is 0.45 inlet and 0.5 exhaust, so if our gap is 0.65 the gap is 0.20 too big for the inlet cam, measured gap MINUS target gap = the difference from the current shim you need, positive = thicker to close the gap, or negative value means you need a thinner shim to open up the gap. required shim that is the current shim (4.05) PLUS the difference (+0.20) = 4.25 in shim collection (if we needed a thinner shim, 4.05 plus -0.20 = 3.85) Rotate cam shaft so cam is pushing bucket/valve down, insert special tool, rotate a bit more so tool holds the bucket down, dig out the old shim shim with a pick, and a magnet, a blast of shop air will pop most of them if they are vacuumed in install new shim, write down size in book rotate camshaft to release cam tool see step 1 Proof of how simple it is, i think i did each valve at least twice, one up to 5 times Next day, tuning Fired up first time and a lot quieter, and even idled from cold. Thats better than its ever done (it had always needed some throttle feathering before) After adjusting the ignition timing and good 2 hr fiddle with the Manometer, ir thermometer on the exhaust and teh wideband i even as i've ever got them. Dropped the idle jets down to 50s (from 55s) before, should be on 45s for an engine of this capacity Managed to drop the idle to (a stated) 900 at 13-14AFR, previously wouldn't run smooth under 1200, at about 11.5-12AFR but also have a mean lean spot off idle (plugs were pretty dark before) Seems to run a lot better now, need to give it a run on my 'test track' to see if it actually is, but i decided probably not ideal weather for fiddling with carbs on the side of the road today

- 81 replies

-

- 28

-

-

-

- gottacatchemall

- fiat 125

-

(and 4 more)

Tagged with:

-

Sleeektoy's 1965 Daihatsu Compagno. Discussion

azzurro replied to sleeektoy's topic in Project Discussion

This is coming along great, looks like its not even very rusty? I have bought the same side lamps for my 1100T van, I knew you would have some at least some joy in the older fiat parts bin Could you say where you got the tank done, and if you dont mind, how much? -

Actually probably 1 drivable - lil utey might get a blast

-

Keen as a bean, the King George Drive is a good one in not so thin on OS rides with 3 that are drivable, but all are no reg no wof ... no worries?