-

Posts

2,279 -

Joined

-

Last visited

Everything posted by Adoom

-

Fully glued in. Much easier to weld without the primer in the way. Started the fun time task of grinding down the welds. Got pissed off with the power file cause the 40 grit belts kept catching on the join and coming apart. I went through 5 of them in about 20 minutes. Mental note not to buy the flexovit ones again. I think the problem is that they butt join it with some backing tape. It would be much stronger if there was an overlap, so there is no join to catch. The bosch ones I had were good, but I can only find the 80 grit ones which take ages to grind down the weld. Has anyone used these? Any better than the flexovit ones? https://www.trademe.co.nz/building-renovation/tools/power-tools/sanders/auction-1420958943.htm

-

After much cutting, grinding, trimming, filing, bashing and trial fits, I got the firewall patch to fit acceptably. I also cut off the lower flange and bent up a flange on the top of the tunnel so I get rid of the lip that catches water and shit. I used crc zinc weld through primer on both faces where the panel overlapped. I tried some spots and tacks... Weld though primer is only kinda weld through, my welds looked shit as. So I stopped. Today I got a selection of wire brushes and did my best to clean off the primer through the spot holes. There was success. I'll do some more welding on the weekend. I kept getting blinded when doing those spots along the top because that gutter would block the sensors on my helmet.

-

Hood? You mean a bonnet? Find a similar shape/size bonnet and cut bits off that???

-

I painted the interior of my Starlet racecar with hammerite smooth white. It seemed to take weeks to properly harden. Otherwise it's okay. It's much more forgiving in the prep than POR15.

-

That looks simpler than my idea. I'll have to dig around to find a lump of metal thick enough to put a groove in the right size.

-

Hmmm, it's another thing to try. I think I will just end up unfolding one of the earlier folds when I try do the last one.

-

I lost you... Can you draw a picture?

-

So part of the rain gutter is rusted through and I need to replace a 50-100mm section. But I'm not quite sure how to make the section I have circled.... That little bump is what the trim strip clips onto. This was the idea I came up with.... Haven't tried yet. Maybe there is an easier way?

-

Then I cleaned it with wax and grease remover and warmed it up with the heat gun before putting some zinc weld through primer on. I have done the back of the radiator panel, I just didn't take a photo.

-

Glued in some bits. Came out well. The flat patch will never be seen once I rebuild the box section that goes over it.

-

I bought a thingy. Got a $50 voucher for signing up to MachineryHouse, so it was basically free freight. So much easier than using the vice and bits of angle iron. It does up to 1mmX610mm. The majority of stuff I will be doing is 0.8mm, so it's fine.

-

FYI: I used about 5kg of dry ice to remove the sound deadening in my triumph. If I had to do it again, I'd get a bit more. Near the end, enough of it had disappeared that I didn't have enough to freeze complete sound deadening sheets and had to do them a bit at a time. Much easier at the start when you have enough to just fill up each floor area with dry ice.

-

Looks like a Field Hospital. 'Cause so much white in a white tent.

-

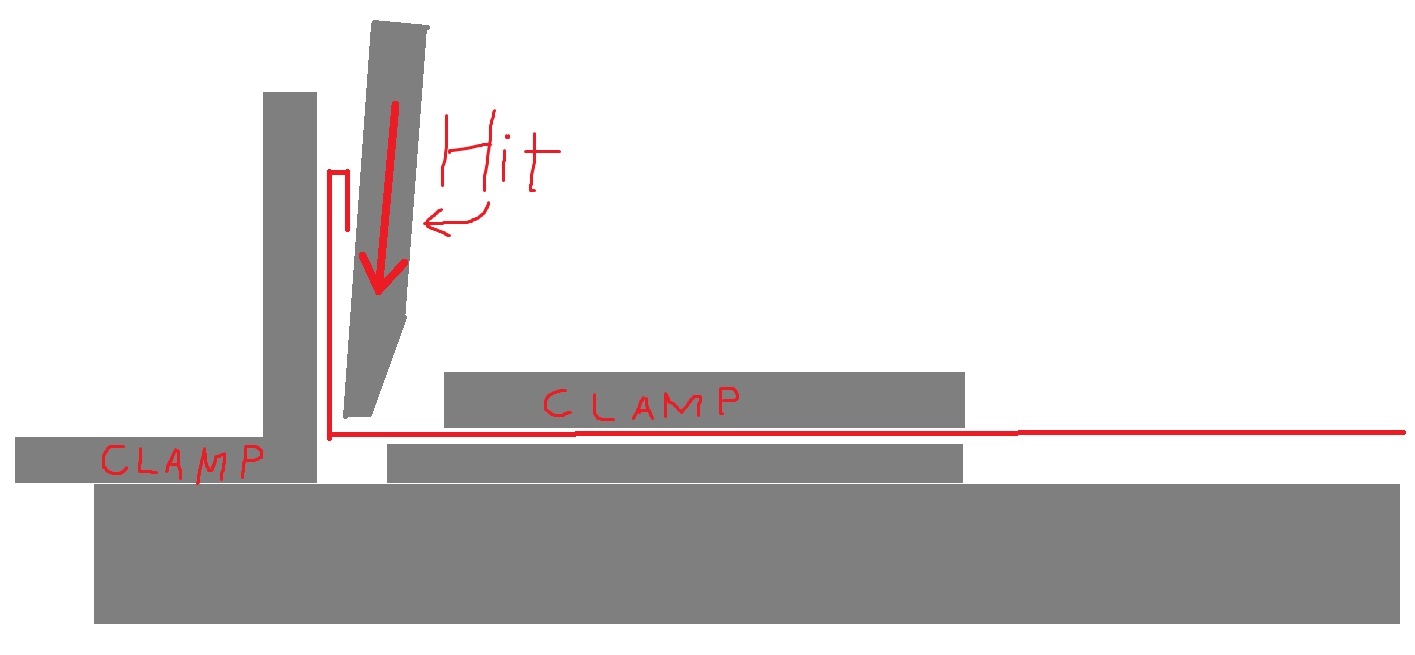

I cut out that rust behind the radiator. And made a patch. This took at least an hour to make and it's the second attempt. The first attempt took longer and was all wrong. Those little bends were hard to do so close together. I also don't have a bender. I ended up clamping two bits of plate that were just the right thickness to the bench, then clamping the patch over the 'groove' that created, then hammering it into the groove. Would be a PITA if I end up needing to cut that bit of panel off because it's in the way of something. I also made this patch where there was some rust pitting that went through. Those round things are magnets.

-

Cracked the uncracked dash I had bought while moving it onto a shelf. sigh. It's a 15mm cracked dent on the top on the dash. The vinyl is so hard and brittle from 40 years of sun.

-

Dang it. Cheers Autos, is 3 minutes up the road from my house. Buuut, it's only open while I am at work.

-

I wanted to be able to get my starlet or bike out of the garage. But I was using the wooden ramps/planks as spacers under the axle stands holding the Triumph up. DOH! So I made a tall 'horse'. It's 900 high. Which is higher than it was with the big axle stands under the front. Easier to work on the sills. This meant I could remove the axle stands from the front. Then jack the back up as high as I could and use the big axle stands at the back, with 2X4 jenga style spacers(nailed together) under them. After removing the small axle stands from the rear, I had my ramps back! I wanted to be able to drop the rear sub frame sometime, so the axle stands are not as far back as I'd like. There seems to be sfa at the rear of the car to support a jack or axle stand. With the subframe, diff, etc in the back and nothing in the front, I reckon there is only 10kg on top of the horse. It's REAL easy to lift the front. I had a got at cleaning up the underseal at the front end of the left sill, so I'd be able to weld there. It didn't come off as easy as the inside stuff. The wax and grease remover didn't soften it much. Might need to get a heat gun to warm it up before using the solvent. Made the mistake of using the flappy sanding disc on the grinder where the underseal is... well, that sanding disc is fucked now.

-

Yoeddynz and Hannah's HB Viva Wagon Discussion

Adoom replied to Willdat?'s topic in Project Discussion

Jack the back up. Start the engine with it in gear. Do a bunch of revs. Push down the clutch pedal, then stab the brakes. Yeh?? -

Could have a terrible accident with the bonnet pins....

-

HAAHHH!!! PUZZLE MASTER!!!!!.. I cut the end off the triumph exhaust to get it in there. Now I have to walk all the way down the other end of the garage through my 'living quarters', the storage piles and the 'workshop area' to get the the other side of the car. Might be faster to just crawl through the doors. Motorbike battery was nearly flat, wouldn't start it, same deal for the STARVIA battery. I put the motorbike battery on charge.

-

So I want to try get the STARVIA into a position where I can get it out of the garage. Maybe I can take it for a WOF so I can drive it!! Unfortunately, the STARVIA is the first thing I put in the garage then I put all the rest of the crap in. The garage is full as because all my house stuff is in here and I am living in it while the house is built. There is no driveway, there is just a ~30cm drop outside the roller door. I want to avoid moving things outside for this exercise, it's wet and muddy and currently dark. I'm standing on a bench to take these photos. I think there is JUST enough room to fit the STARVIA behind the Triumph with its arse pointing out at the door. I somehow need to get all the stuff behind the STARVIA to in front of the STARVIA. Then use the trolley jack to pull the front of the STARVIA around behind the triumph.... Problems: That big box behind it is a fireplace on a pallet... it's fucking heavy. It's too wide to fit down either side of the triumph. There is also a flue kit there, it's not heavy, but it's big. The thing in the bag behind the bike is a lazyboy, it's not heavy, but it's a big and awkward. The bench by the roller door is too heavy to move. The triumph can't move, it's on axle stands with no suspension. I need to lift the drill press onto the bench I was standing on without breaking my back. Feels like one of those sliding puzzles with the one clear space and you have to move the different size shapes around.

-

Sort of on topic. I noticed Cheers Autos in Carterton is for sale. Bayleys ad says "because health". Anyone know if Julian Cheers is still going to be doing certs?

-

Used a bunch of wax and grease remover and a lot of rags and a little wire toothbrush and cleaned the underseal off around where I need to weld the firewall in. I thought I might make a little patch for the floor to make me feel like I'd made some progress. But then I realised that I still needed to remove the underseal from the underside of the floor where I need to weld the patch in.

-

Removed the rear screen. Found some rust. I knew there was something going on under there because where the trailing edge of the parcel tray meets the gutter around the boot, it's just crumbly rust. I thought I'd have to try repair that from underneath... inside the boot. Now I'm just going to cut this whole thing off, repair the parcel tray, then patch these panels and put them back on top.... well that's what I think I can do.... I also removed the roof lining and found a mouse nest! And some more rust. Same place on both sides. Maybe it gets condensation there and it just sits on the panel.... Also removed the front screen. Didn't damage the stainless trim! They used a shitload of mastic. No rust at the front. yay...

-

Woken up at 1am this morning by my shoulders reminding me about how unfit I am and the 3 hours of work I made them do last night. Fuuuuuu. Took like an hour for the ibuprofen to kick in and I could get back to sleep.