-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Everything posted by flyingbrick

-

yeah have been looking at one very similar on trademe, comes with bottle etc. both orange anyway... if that matters.

-

You'd think so?!!!!!! I have just been searching on trademe, not much worth buying (comparatively huge money for steaming piles of shit, although i do have my eye on a few there that could be worthwhile depending on how bidding pans out. take a look at what is available, maybe I'm just a cabbage at searching trademe (as well as everything else)

-

yeap!!! I cannot believe the pricing. I think im going to end up buying from australia as even with shipping I'll be saving 30%

-

Hi all. Right so its been 6 years now since I actually worked professionally with welders. I am now wanting to buy myself an AC/DC Tig but cant believe the prices now being asked - unless my memory is way way out, it seems to be that prices have doubled?! or perhaps the cheaper options are just no longer available. What budget options exist? I have to prioritize spending pretty heavily so I'm definitely not looking for trade quality. edit. seems fucked. I can EASILY find an ACDC tig welder in australia for 700NZD and they dont look like the worst things you could own. Here in NZ you are looking at double that?!

-

why dont you try raise compression?

-

I would like to see the centre of the bonnet cut out. Six trumpets poking out would be awesome!

-

Could you turn each row of throttles 180 so that the servo hangs off the other side- then stand them up more vertical so that the air doesn't have to do such a sharp turn after the throttle? Or, could you do a one piece lower manifold that manages the cross over, then mount the throttles basically flat as soon as they have finished crossing over? edit: You appear to be moving too quickly on this, so i'd like to add more complexity. Thanks.

-

I watch a lot of boat building videos on youtube. no idea why. Anyway, they often drill through fibreglass and foam to mount things to the deck- and they need to protect the raw edge within this hole from water. To do this, they drill the hole oversize, fill with epoxy resin, then drill their final hole down the centre. Basically, there is a "crush tube" of resin formed. As resin has a relatively high compressive strength- maybe this could work and be easier than a crush tube

-

Sad that I have been beaten to it, but yeah. The bolts provide a clamping force regardless of if slotted. The spigot in the center needs to remain a circle though (lol) and yes, no to welding as the HAZ could be more detrimental to structure than any slotting.

-

3 generations of Muncies impulse bought the same GN125.....

flyingbrick replied to Muncie's topic in Two Wheels

yeah but you are a sicko -

Finally got the bike totally buttoned up and out for a test ride. HUGE difference to how willing it is to change direction- really impressive how a tiny alteration (I thought 7mm down up front was strangely specific) can change so much. Also gave it a wash, clay bar (It pays not to get confused) and wax.

-

3 generations of Muncies impulse bought the same GN125.....

flyingbrick replied to Muncie's topic in Two Wheels

Hi Zach. Cool Bike. The bike is a pretty well sorted package right now- reliable, on its way to being legal and its brakes and suspension will match the engines performance. Keep enjoying it and get something faster when you are ready - a GSXR250 doesn't cost that much in the scheme of things and comes complete with better components in a well sorted package that the GN will never match (even after tons of mods) -

Also. Thankyou for including the area of the valve stem in your calculations @Roman, your attention to detail is much appreciated.

-

this is exactly what I do. That or a photo with a ruler. I also utilize works printer for getting scaling etc right. Most printers seem to be extremely accurate when printing things 1:1 scale, and they can do it in a few seconds, so with this sump flange I'd just have printed it out and put on top of the sump to check. @Roman since we are going to be neighbors soon- more than happy to use works printer and bring you home stuff if needed, we even have a3 paper.

-

Hi David. RIP blueballs. I'm excited to see what happens with the carina now! Please get that X member cast. Lets build our own little foundry!!!

-

Those are all pretty good points.

-

I am curious (because i have limited materials knowledge) as to how they choose aramid fibre over carbon fibre when manufacturing this duct work. There has to be more to their thinking than simply wanting to add some color contrast to the otherwise black and blue engine bay.

-

The very obvious path forward is solid mounting of the engine. 3d print some mount stuffers.

-

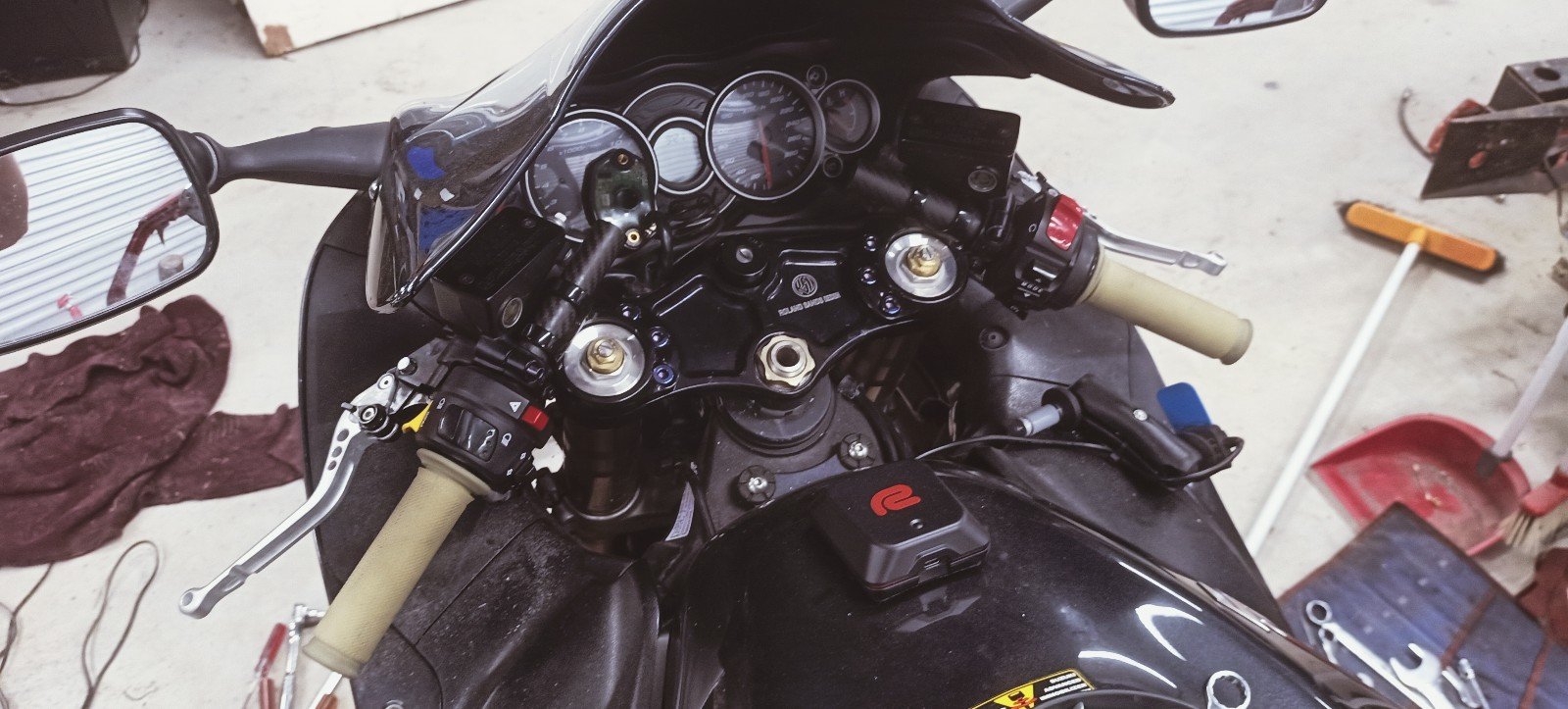

She ain't no custom bobber, but I still get a bit of satisfaction out of this. Another KG saved off the front end. The factory top yoke is a two piece unit with a bottom plate that ties the forks together and then a top plate that holds the handlebars. The two items are bolted together with big bolts and isolation bushes (I don't seem to have pics of the bottom plate) So that's now been replaced with the new billet aluminium item which is one piece so saves just over 1kg and looks cool too. That's well over 2kg saved off the front when you include the CF bars. The new top yoke also has another benefit. The factory setup does not allow any lowering of the bike by sliding the tubes upwards. The new yoke has relocated bar mounts and holes right through, so to increase steering response I have lowered the front of the bike 7mm. This moves weight to the front and steepens the fork angle. Some guys lift the rear 1 or 2 inches to do the same thing, but I'd hate to increase the seat height and make it harder to handle with legs down. Also fitted a hydraulic brake switch banjo bolt on the rear as I had no switch since doing the rearsets.

-

Yeah I don't think you are waxing quite enough, and pva is a huge safety net. It's biggest pro is that it dissolves in water so I'd your wax ain't good enough and your parts still stuck- you just soak the whole lot in water till it pops free.

-

that looks so good dude.

-

I'm no electrical engineer, take this with a grain of salt, I'd have thought the vehicles battery would do a very good job of smoothing voltage across the entire vehicle? or @Roman do you think even the increase to 14.5v during charge is likely too much of a fluctuation? If you need more smoothing just throw in a small bank of capacitors to take out higher frequency oscillations

-

thats a great idea, my first thought was "nah the factory ECU wont be able to send a compatible signal......WAIT A MINUTE"

-

Thats my fault. The story lacked depth so I said it was not aerodynamic LOL