-

Posts

14,310 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

I wouldn't cert them. Other certifiers might, I dont know. What sort of car have you got? A set of aliexpress shocks seems to average $700 by the time they are here A set of BC retails on average $1700 , but I have heard of them being a bit cheaper A cert is going to cost around $650 regardless of what brand So you might save a grand if you can find someone to certify them, but you are likely going to need another set when they spring a leak in 6 months time, or the lower bushes give out, or the piston falls off the end of the shaft or the car handles like shit or whatever. Then if you get sick of buying replacement maxspeedingrods and put some BC's in it then you have to pay for another cert because they wont match the photos on the cert

-

I dunno, I guess if the certifier missed something and there was an accident due to that then they would be held responsible as well as being injured

-

Yeah that has been a consideration, one of the reasons for setting up my own workshop was to avoid issues around working at other peoples shops, we have to be careful on what we road test as well, if we find a fault that could possibly cause an issue then we cant test drive the vehicle or complete the road testing until its sorted out Stuff like that, and all the small procedural steps all adds time and dramas though, people get annoyed because we might get a car that for some reason cant be driven for a perceived small reason (ie a broken brake light switch) so they repair it and bring it back and then it fails the brake test so they have to bring it back again, meanwhile costs are starting to stack up because the speed limits in Auckland changed and it takes an hour to do a road test so before you know it, a cert that used to cost $400 10 years ago now might be $1000 and "it's just a 308 in a commodore, some came factory like that, why is it so hard " and so on Rant over, haha.

-

Yes there is the technical advisory committee that meets once a month to look at design approvals, people wanting do do different stuff that isn't covered by the rules or is outside of what the rules say, things like that

-

Yes, there are Lvv standards The car construction manual Info sheets Certifier email updates Newsletters Usually training twice a year NZTA sends a reviewer every two years to be present while a vehicle is certified, and the certifier has to show all their paperwork and recording systems to prove they are doing things properly Random jobs are desktop audited when they go through LVVTA for processing as well. So the shit/not shit assessment is like that adjustable spanner in your toolbox, you dont use it often because there are better tools available most of the time As for coverage, we have to have insurance policies for public liability and professional indemnity as part of our operating requirements

-

Depends on the certifier I guess, and their level of experience with japanese parts. I cant speak for other certifiers but you can usually tell just from looking at something whether its shit or not , or at least if you need to investigate further I cant remember ever failing any Japanese brands on quality issues, lots of worn out problems though. Especially when 20+year old imports from japan got popular

-

That link is to a page run by a disgruntled ex certifier who got sued by lvvta for defamation so I wouldn't put too much emphasis on what's on there I wouldn't certify a no name brand coilover, I dunno about other certifiers but in my opinion it's not worth the risk to say some cheap crap is all good when I have no idea what the insides are made like I have seen a set of china coilovers that the piston fell off the end of the shaft and it all flopped around and destroyed itself

-

There is a head restraint standard https://lvvta.org.nz/documents/standards/LVVTA_STD_Head_Restraints.pdf As an example, from memory a d21 datsun ute has bolt on head rests, you may be able to use something like that and make mounts to attach to the roll bar

-

A head rest doesnt have to be part of the seat, it could be attached to something else, it is reasonably common for hot rods to have them attached to things like the roll bar or to the body

-

Have you got long term plans for a different engine?

-

Looks like a pretty solid car!

-

Cpp stuff is usually ok, the main concern with aftermarket spindles is what they are made of and what the spindle pin is made of, the fact that kit uses a bolt on wheel bearing kit gets rid of the spindle pin issue

-

Repair cert= for unregistered vehicles or ones that have been written off If the vehicle is registered, then it wont need a repair cert to pass wof

-

Panhard bar works fine in a car with minimal travel if it's set up correctly Watts link is obviously technically better, but adds complexity You what now?

-

Angles of things is probably why 4wd things end up being able to do this sort of carry on

-

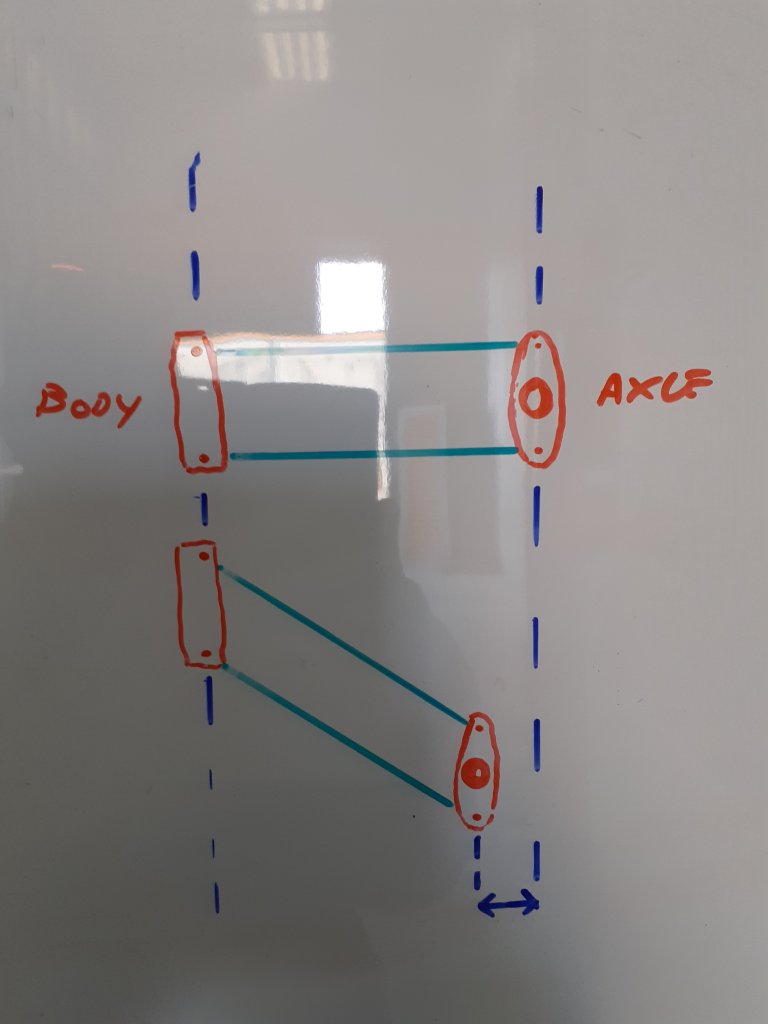

Roll steer is caused by the link arms shortening or lengthening the wheelbase on one side, kind of like how a skateboard works This pic is exaggerated (maybe not if you have a jeep or safari haha)

-

Handling is heeeeeaps better with cross steer setup. With the torque arm deal they still move around under braking as the diff still rotates a bit, if you reposition the arm mounts that can introduce problems if it's not in the right spot as well

-

Pg hydraulics G R engineering Suggest using the clamp style joints not the grub screw type, they always come loose

-

Yeah I reckon it deserves a spot for sure One of the best things about it IMO is you couldnt find a vehicle to do all the things you wanted So you just made one yourself, with some clever recycling and fabrication It's only some fancy paint, hi tech light bars and some 22" wheels away from being a SEMA winner anyway?

- 800 replies

-

- 12

-

-

-

-

https://www.hotrod.com/articles/mopp-0607-mopar-cylinder-head/

-

'302' heads are later model swirl port from memory, are pretty good for a factory head

-

Yeah I dunno, the ports look pretty big and the exhaust manifolds look like 360 ones.... and a 727 behind a 318 seems a bit odd, i dont know enough about what parts should be in a B body though I had a set of 360 heads years ago that had those holes X2 on casting numbers on heads and block, would be interesting to see what's what

-

I think that would be fine, your certifier will probably want some sort of proof that the material you have made them from is suitable, that could be a receipt from the engineer who made them

-

Have done exactly that on my own car, so yeah I think that will be fine Lots of little whacks, take your time and make sure you dont go too far and dent the outside skin

-