-

Posts

14,318 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

Crc 556 works too I think? Years ago I had a mint r32 gtst coupe I went though some concrete splashes that there was no sign for When I washed the car a week later I discovered that it wasn't mud That really ripped my undies That car was a magnet for damage

-

My curiosity was activated at the talk of the marina 6 being a 262 Not the size in cubic inches unfortunately

-

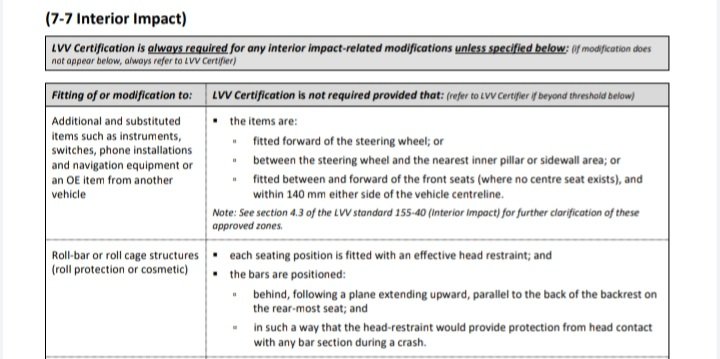

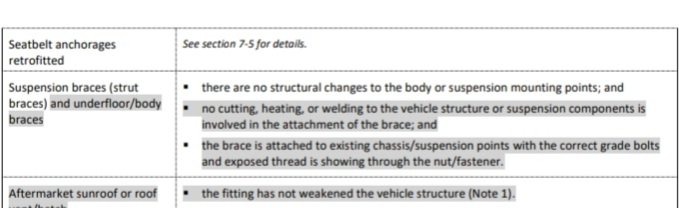

The bits in shaded grey are probably added at the last update of the threshold so that might be why it's a "new" thing Roll bars are allowed, but it doesn't mention mounting

-

-

Just a heads up if anyone is planning on importing a car or has one here that isn't registered yet April 1st is when the govt starts taxing vehicles for their C02 emissions when they are first registered usually these type of rule changes are based on ENTRY date ie if the car is border checked before x date then its exempt This time it's based on when the car is registered, which means it has to have its repair cert /lvv cert/ pass compliance done before 1st April or an extra tax will apply when it is registered This means that LVV certifiers and repair certifiers are possibly going to be even busier than normal because car dealers are well known for leaving things till the last minute and are also adverse to paying more than they have to so will likely be applying max pressure to get things done before 1st April

-

Yeah I wouldn't be driving it every day. I'm too scared to let it go lower than half full , I don't want to know how much it costs to fill from empty

-

Another tip if you are increasing preload on a soft spring- beware of the coils being able to bind. If it's already done it there will be witness marks on the coils Make sure it has less bump stop clearance (including some compression of the bumpstop) than it has coil clearance (ie the combined gaps between the spring coils)

-

Also if you are going to swap springs it might be worthwhile putting new boots on the front shocks Inverted shocks are prone to wearing the top bush and getting crap in there, this can lead to the shafts getting worn and the chrome comes off , then the shaft can't slide smoothly and the shocks 'stick' I had a customer that had ohlins shocks that had play, he tried to get them rebuilt but the Japanese ones have a weird bush size that you can't get so he ended up replacing them

-

Might be worthwhile measuring how much travel the shocks have and set up your heights/bump and droop travel accordingly

-

Did it have lowered springs in factory shocks before? If so maybe it didn't have much travel before bump stop contact, that is very common for factory suspension with lowered springs especially in the front maybe now it has more travel and it can roll now?

-

Looks good all back together. Last thing will be side moldings which you can buy in a roll and cut to length,so I ordered a roll from murica minus the chrome strip Here you can see it in its natural habitat it's an ideal vehicle for trips around town, it fits into car parks that are big enough, and 5.7 litres of engine is enough to haul over a dozen eggs!

- 528 replies

-

- 36

-

-

-

-

Usually clockwise =adjusts firmer, same for inverted shocks, clockwise but from underneath instead

-

Bloody barn find m8 Hasn't had much use lately, I did a friend's wedding last year in it but I think that's the last time it got driven , hasn't had a wof since June last year Might need a bit of panel work in the next few years, the paint faults have not healed themselves. Also needs a windscreen rubber as that leaks a bit

- 62 replies

-

- 35

-

-

If that's what it had originally, that would be OK What sort of car is it?

-

Picked it up Sunday evening, leaving it for a week in the garage for the paint to go hard before I start fitting parts back on it

- 528 replies

-

- 25

-

-

Yessss! I'm looking forward to seeing this running. A plain VR-VS sedan with a turbo ls is high on my 'would like to build' list

-

I haven't noticed it smelling rich, but i have noticed with the stock high pipes that my backpack got a bit of exhaust smell in it and the number plate is slightly stained I have read people's posts on forums saying the same thing , getting stinky fumes especially in traffic Does yours use lots of fuel?

-

Looks better I think. Quite a lot lighter and sounds good, about where I wanted it, not obnoxiously noisy but enough to be able to hear it Start Finish Was pretty straight forward to fit, bolts on apart from the mount brackets, I made 2 aluminium brackets to attach it to the bike and job done Am just waiting on some small indicators to arrive then I can get rid of that ugly bit at the back

- 528 replies

-

- 19

-

-

- 528 replies

-

- 17

-

-

-

Could be something like a blocked exhaust- baffle broken in the muffler, or the pipe is squashed somewhere If you put it in N and give it a rev, what does it do? Does it rev higher than 3000? Is the engine check light on?

-

@RXFORD is a fuckin legend , sorted it out and did a lovely job off to the painter tomorrow Been a busy week, got home and a couple of deliveries had arrived, one of which was the exhaust for the bike so that should keep me occupied for a bit

- 528 replies

-

- 12

-

-

IMO anything faster than 15 seconds needs a proper drag tyre otherwise you are wasting time with any performance mods if you can't use 100% of it to get down the track I've had a few sets of drag specific tyres even on mid-low 14 second cars and if nothing else it makes the car a lot more consistent which is very important if you want to get anywhere in DYO I've raced the VG on street tyres quite a few times, that doesn't have much power and its auto and even then it's a bit of an unknown if it's going to hook or spin

-

Chev is off to get painted next weekend so spent a day removing as many bits as possible while still keeping it legalish to drive to painter 2 side windows and tail lights are 8 screws so I'll do that when it gets there Found some greeblies hiding under a door rubber so it's off to tin tricks @RXFORD this week for him to once again fix my panel related problems, what a top gentleman

- 528 replies

-

- 15

-

-

-

Stoked for you! That is an impressive result! Its amazing how much of a difference some good drag tyres make

-

Looks sweet! What size tyre did you fit?