-

Posts

14,271 -

Joined

-

Last visited

-

Days Won

87

Everything posted by cletus

-

Can do pie cut if it's tig welded, NDT, and has a fish plate over the cut Other options - find a ball joint that is flat/not angled the wrong way for your application Or a pair of tapered spacers to angle the balljoint. Have had a couple of people do this to correct balljoint angle

-

Tomble's adorable go cart / distraction / Alto Works

cletus replied to tomble's topic in Other Projects

Is a complete new long block available from suzuki? You would think a small 3 cyl engine from a current? model would be cost effective to buy but probably not -

I had a escort with a modified 1600 a long time ago, that had a 2" pipe and a couple of resonator type mufflers, it was quite raspy I then put that motor in a mark 2 cortina and 2.5" exhaust with a single triple pass muffler before the diff, it was a deeper sound but from memory it sounded quite good

-

This one had a legit (from memory) label but the top loop was less than 3mm thick , so I'm picking in an accident it would probably cut the belt

-

They could be acceptable if nzta recognizes CCC as an acceptable standard for seat belts There are many belts made in China which have standard markings on them which are acceptable HOWEVER china is notorious for just putting a label with a safety standard on whatever the fuck they feel like. Sometimes the standard is not even relevant to the part, ie they will put an 'e' number relating to lights on a seat belt. There's a note in the virm about one particular brand which has the label but the top loop will fail in an accident , they are not allowed. But if its like anything else made in China, bur Chuang Zhang seat belt is no longer allowed so they just change the name to super lucky golden horse seat belt safety co and away they go again I wouldn't trust them Can you take a pic of the top loop?

-

SUGGESTIONS/RECOMMENDATIONS FOR VIVA CONVERSION

cletus replied to La Viva 71's topic in Project Discussion

Technically, requires cert due to capacity increase, regardless of power increase -

SUGGESTIONS/RECOMMENDATIONS FOR VIVA CONVERSION

cletus replied to La Viva 71's topic in Project Discussion

As others have mentioned First thing is to figure out 1. how much you can spend 2. How much can you do yourself 3. how fast you want it to go and what do you want to achieve Most worthwhile swaps are going to need a gearbox/brakes/suspension/diff upgrade which is where the $$ required starts stacking up If you can't do much yourself that also will get very expensive quickly This may dictate what you end up doing If he's just starting out and learning how to work on cars then it's probably better to start with an easier bolt in swap, as mentioned a 1256 with some mods to liven it up a bit, that doesn't need gearbox/brake/diff upgrades -

Runamucks - VG Valiant Sedan of Lawn Ornament & Rust

cletus replied to CUL8R's topic in Project Discussion

A RUNAMUCK build thread update? Is rain falling upwards? Have pigs taken to the sky? I'm actually abit fizzed to see progress on this -

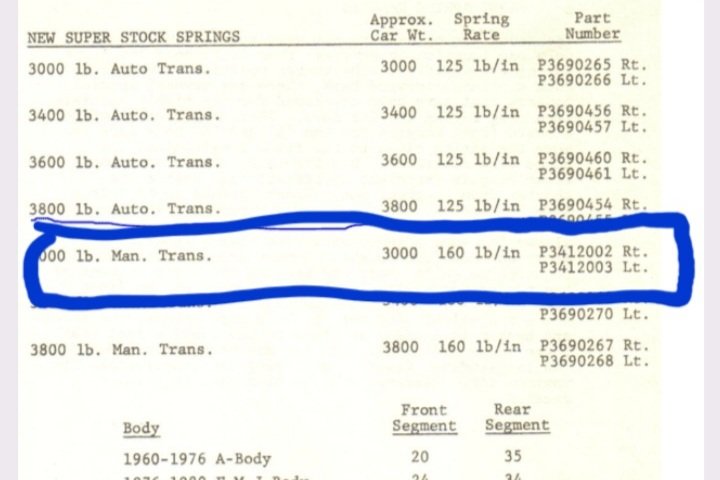

Ages ago someone gave me some mopar super stock springs which are meant to be pretty good for these things, I never really thought much about using them though because they are a bit wierd, they are different side to side with different shape and length leaves in the pack, apparently to counter the torque effect I thought I'd try them so put them in The leaves are considerably thicker (7.5mm vs 6mm originally)and the front eye bolt is bigger, plus they have a bigger arch so I knew it would raise it a bit, so I put them in and took it around the block. It is definitely stiffer, but not unpleasant, the height is now within 5mm per side, but looks dumb so I pulled them back out to get reset 50mm lower

- 134 replies

-

- 35

-

-

Springs So after a couple of drag meets I'd noticed the right side was sagging a little bit, it was about 15mm lower. I'd always known the rear suspension would need a bit of help and I think the spring has had a bit of a tweak from being shaped like Steven hawkings spine The pinion snubber has been working hard as well, it's actually deformed the body side, and the witness marks show the pinion snubber bump stop has been squashed to the point the bracket has hit the floor. I think this was probably at Hampton downs as where I was doing skids there was a bump that you can hit which unloads the tyres to get it spinning At os drags I'd put a camera under its bum to see what's happening and it was quite interesting The spring gets quite twisted and the left rear tyre gets squashed a lot more than the right side due to the diff wanting to rotate The car always feels quite flat though . The VG used to do the opposite, it would squat considerably on the drivers side Perhaps it's because the fatty driving it is in the right place for ballast haha

- 134 replies

-

- 12

-

-

This is one of the things that makes a club great

-

I can't see a problem with doing that, but you would want to discuss it with your certifier. In my opinion a good way to do it would be to do a design approval, that way if it's approved , you can give the approval to your certifier and they should be able to pass it if it's done correctly The only reason I suggest that is what you propose is not in the manual and it could be classed as a custom chassis rail , which then has to meet CCM reqs/ be 75x50x3, but that would make no sense in your application There's not much in the CCM relating to monocoque vehicles and chassis mods

-

New springs that are a bit stiffer to cope with less travel, some good shocks and maybe some clever trimming of the bumpstop might get it to a point where it looks the same but drives much better Is it 2wd or 4wd?

-

Usually just checked with them fitted. Belltech usually are ok but I've never seen any on a later model one like yours, which has a bolt in bearing unit I think? I'd be making sure you really want spindles, as they are quite pricey, plus cert, plus bump steer check, plus they can open up a can of worms as far as tyre clearance etc I have had customers fit drop spindles because they wanted a 50mm drop but it ends up with a whole new set of problems, like the tyres can now go 50mm further up so rub on big bumps, or the spindles change the track slightly so the tyres stick out, need geometry correction to pass bump steer check, rims rub on suspension arms , bla bla bla Some of the earlier trucks are actually better off with just a spring drop if you don't want it slammed as it gets the geometry better ie the control arms are flatter

-

Yes. even pre approved complete front ends (heidts, rods by Reid etc) all have to have a bumpsteer check done you'd be surprised how many fail

-

None of them are pre approved , all have to have a bump steer check done

-

Every time recently that I've asked LVVTA if a vehicle can have its GVM reduced even a small amount , the answer was no. One was a Ram TRX that the gvm was 3560kg which made it a heavy vehicle Another was a ute where if the gvm was lower they could have used a better size tyre It's something to do with NZTA rules, not lvvta

-

I think if the caliper doesn't have any recesses in the bore on the piston side, where that extra bit is on the back side, then you could machine it neatly for the hose to locate into. You would want to make sure the hose is going to be in the right orientation Otherwise if you think you might need to adjust hose position, probably better to get a hose end fitting that's rounded

-

Looking at your lifter situation If they don't work or cause problems, I wonder if it would be easy to make some adjustable solid ones that just plop in the holes with an adjuster/pivot/jam nut at the top

-

- 528 replies

-

- 30

-

-

sheepers MS51 of hyperbolic enlightenment and anomalies

cletus replied to QCADTA's topic in Project Discussion

Copy paste from a tech article on V8 lifters, I assume a OHC engine would work on similar principles Hydraulic lifters eliminate the clatter and the need for periodic adjustments by maintaining zero clearance when the engine is running. They do this by using oil pressure against a spring-loaded plunger inside the lifter body. Oil fills the cavity under the plunger when the valve is closed. This pushes the plunger up to take the slack out of the valvetrain and hold it tight. A one-way check valve inside the lifter holds the pressure inside the lifter as the valve opens. Since oil is incompressible, the oil trapped under the plunger prevents the plunger from compressing and the lifter act like a solid lifter to push the valve open. Hydraulic lifters are also kinder on valvetrain components than solid lifters because zero valve lash reduces the hammering effect that occurs when the valves slam shut at higher engine speeds. There’s no air gap to fill so the valve simply follows the cam lobe as it closes for a more gentle landing. This also reduces noise and helps extend the life of the valvetrain components. Under normal driving conditions, there’s no danger of the valves being pushed off their seats or not fully closing when they seat because the valve springs exert more pressure on the valvetrain than oil pressure inside the lifters. But at high engine speeds (say over 6,000 to 6,500 RPM), hydraulic lifters experience some limitations. At high speed, hydraulic lifters may “pump up” and hold the valves open causing the valves to float. This can happen if the valve springs are not strong enough to maintain normal valve control, and the lifters try to take up the slack that really isn’t there. This overextends the plunger and prevents the valve from closing all the way. The same thing can happen if the oil inside the lifter does not bleed down quickly enough between cycles to maintain normal valve lash. Hydraulic lifters can also “pump down” or collapse” at high RPM if they are leaking too much oil pressure internally due to sloppy assembly tolerances. This creates too much lash in the valvetrain, which results in noise and loss of power. Hydraulic lifters are precision fit assemblies. The plunger is closely matched to the housing to provide minimal clearance so the leakdown rate is not too great or too small. That’s why you should never intermix the internal parts when you are cleaning and rebuilding a set of hydraulic lifters. Do each lifter individually so the original assembly tolerances are maintained. One of the key differences between stock production hydraulic lifters and aftermarket performance lifters is that the latter usually have tighter internal tolerances for better oil control. Many performance hydraulic lifters also have better valving that allows them to handle more RPMs than their stock counterparts. A good set of aftermarket performance hydraulic lifters will typically allow an engine to rev 1,000 RPM higher than with stock hydraulic lifters. Some can handle even more RPMs. Even so, most hydraulic lifters can’t match the performance and reliability of solid lifters over 8,000 RPM. That’s why high revving engines in NASCAR, drag cars and circle track cars still use solid lifters. Hydraulic Adjustments Hydraulic lifters still need to be adjusted when they are initially installed so the plunger will operate in its mid-range of travel. If the plunger bottoms out, it may prevent the valve from closing causing a rough running engine and possible valve-to-piston contact. A plunger that is over extended and near its upper range of travel may not be able to maintain zero lash as engine temperature changes. This can increase engine noise, and it may even cause the plunger to hammer against the snap ring causing it to fail. A hydraulic lifter plunger may also become over extended if an engine has sticking valves or excessive wear in the valvetrain. It can only take up so much slack before it runs out of adjustment. -

sheepers MS51 of hyperbolic enlightenment and anomalies

cletus replied to QCADTA's topic in Project Discussion

hydraulic lifters- i would think that opening up the feed holes could possibly be a negative thing anyway as they use oil to take up the "slack", if you increase flow, the oil could potentially leak back out of the lifters easier? on old turd pushrod things, at high rpm the lifters can pump up, and hold the valves open. my white car has this problem sometimes. this info may or may not be relevant, but might explain why theres not much oil flow, and not a whole lot of pressure in the oem setup -

Yup that's ideal if you can line those holes up

-

They have to be secured to the hub with a single countersunk bolt, wheels have to locate on the center spigot, wheel bolts screw in 7.5 turns , can be certified

-

First trip done. VG tows it better on the open road than pootling around town, no mirrors or power steering or power brakes is a little bit challenging for maneuvering though. Got a bit of a list of things that could be improved/finished

- 528 replies

-

- 56

-

-