-

Posts

3,392 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by kpr

-

not sure sorry, they have basic vvt on intake. which advances the cam 30deg when on. usually switching back off between 6-7000rpm. They make best power with 28-30 degrees ign timing up top. haven't come across any weird spots where they need more advance. pretty much like the same ign curve as 16v head

-

Block itself has different sump bolt pattern to 16v, but just use 20v sump. external oil drain not drilled, but otherwise pretty much same. pistons different, the valve cutouts will be in wrong place for 16v head. i dont know if will actually work, but would at lest be limited to little/factory cams. rods same as late 4agze smallport. the 509gram ones. so yeh swap pistons and same thing

-

With the intake and exhaust changes, my 20v junk seems to use less fuel. so good excuse to do that exhaust.

-

pre cooling the intake doesn't do much at all. especially in romans case, since pretty much his whole intake is plastic. which will transfer very little heat. The air going into intake different story NOS goes against the whole NA tuning thing imo. may as well just jam a 150 shot on a stock echo - maybe someone should do this

-

I dont recall those tyres dropping trap speed at low pressure. well not significantly anyway. 10psi and 8k launch should get it moving. need to run less in them than if it were a rwd 13.8 is pretty impressive, but should go at least 13.6 i recon

-

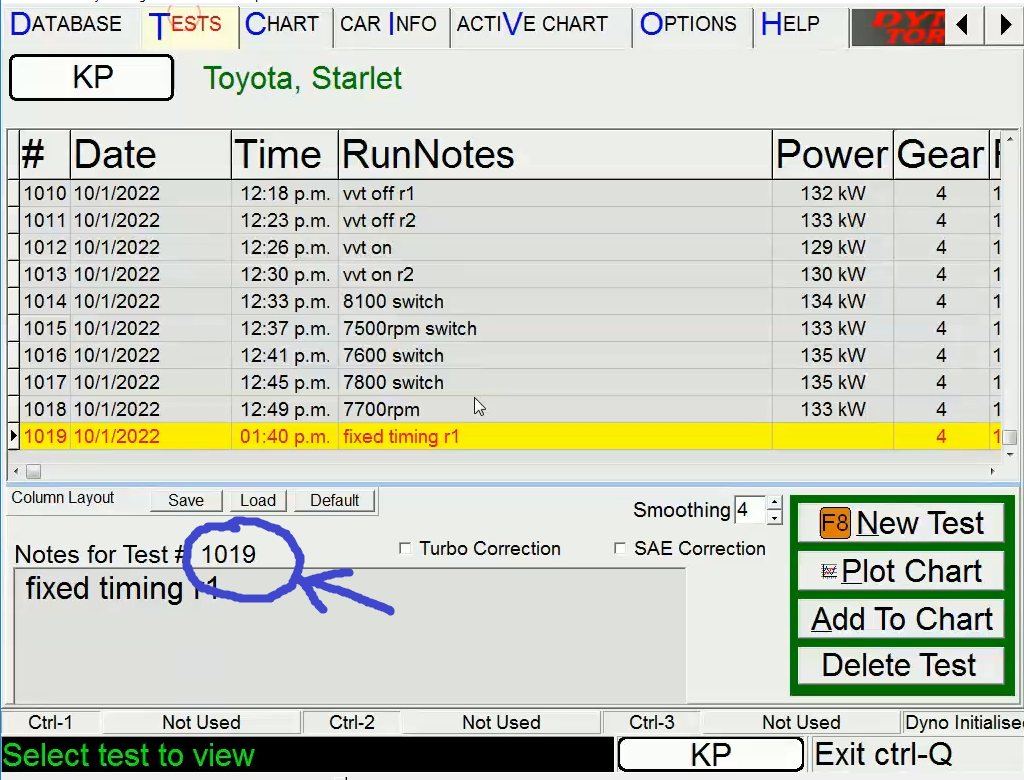

noticed this when editing video. worse than missing the odo roll over. 1019 runs.. And video of the above stuff

- 216 replies

-

- 18

-

-

Done some actual back to backs on this today. First the vvt travel is slightly aggressive for the cams in this engine. 20-25deg probably ideal rather than the 30. but have got the start and end points dialed in for pretty good compromise. i can index the outer pulley to change it. Its running about 10deg more advance than normal when vvt on and 20deg more retard when off. Running the vvt setup first, then switching back to the fixed/adjusble cam gears set at my normal settings Blue: vvt on (advanced) Red: off The pulley takes a little time to travel between advanced and retarded, so the switch point is 7600 rather than the 8100 it looks like it should be. which maybe a little disadvantage in the lower gears when zings through the revs fast. bit it actually helps fill in the dips. poor mans vvti black is vvt switching off at 7600rpm orange is best compromise fixed cam timing

- 216 replies

-

- 19

-

-

-

Further up the runner more cooling. closer to valve will run nicer. but wont be much in it in your case. I'd run the ones in the manifold.

-

radiator size is plenty big for a na 4age

-

The 3576 would be better option in the 35 frame. How much power are you realistically aiming for?

-

Both, but mostly superchargers. you get way more power boost for boost out of a turbo setup. depends on the turbo you use re gate type. a lot of aftermarket stuff doesn't come with internal gate these days. easier just to go external

-

Yeah if you do the math on the bara torque numbers is making 173hp at 3250rpm. which is pretty much peak power for the l67. so can see how the barra would spool turbo way sooner So yeah look at the power rather than engine size if comparing Just looking at the plusar page maybe something like this would be better suited. dont quote me on it haven't looked into it too hard.. https://www.pulsarturbo.com.au/collections/gtx-gen2/products/pulsar-gtx3071r-gen2-turbocharger either way it'l go heaps better and probably more reliable with turbo over supercharger. since more stress on engine to make same power with supercharger

-

Thats a lot of turbo for an L67. a gtx30** would probably be better suited. remember the NA barra makes decent bit more power than an NA L67. Which directly effects how much power it will make turbo and how well will spool the turbo worst bara numbers i found: Power: 182 kW (244 hp) @ 5250 rpm Torque: 380 N⋅m (280 lb⋅ft) @ 3250 rpm moo numbers 177 (hp) Horsepower at 4800 Rpm 320 Nm @ 3200 Rpm | 236.02 lb.-ft. @ 3200 Rpm In a perfect world should make double the power on 1 bar boost ,can usually get close on a good setup. turbo not supercharger, they are horrible bara - 488hp moo - 354hp

-

Long time no update. nothing really has happened to this thing other than being strapped the the dyno with various junk engines. Current one being a long rod 4age, 7a block, 4a crank custom rods, smallport pistons. modified bigport head with 193b cams. so yeh just a polished turd. has all the blot-on's off my good engine and the main reason i actually took the good engine out and put junker in, is this abomination Its something Ive wanted to do since forever ago. actually made some parts way back. but ran into issues and all got to hard basket. about 500 years past and attempted it again with a little help from a machinist friend. Intake cam pulley looks a little weird? Thats because its a vvt pulley off a 20v. They are just a simple on off 2 position deal. with 30 deg travel After some teething issues, managed to do some initial testing today The pink line is what it makes with my normal fixed timing. which is quite aggressively advanced. basically as much as can go, to gain all the midrange with minimal loss at peak. the downside is power drops fast after peak power Red line is with vvt on from start of run, which a touch more advance that what it normally runs. Then switches off a 7300 retarding intake cam 30 degrees little red line is a "stockish" bigport engine. for reference Great success? or did i just build a v8 that idles are 6000rpm

- 216 replies

-

- 28

-

-

-

Pretty close, but bad day for peaches (red) noodle (blue) and cones pretty much the same. maybe the cones by a touch

-

The starlet alone is almost about to crack 1000 runs

- 288 replies

-

- 13

-

-

-

- 288 replies

-

- 13

-

-

-

-

Cheers for offer re tv. will pass though. the crappy little crt fits with my shed tetris at the moment. Not sure about the smoke thing, since engine is consuming something silly like 7000L per min, likely wont see a lot unless have lots of smoke.

-

Not the best example, as length was slightly off. but can see on the skinny blue runners. how they fall over up top, with only minimal gains down low. Pretty much everything ive tired diameter wise, to make a gain in the bottom end, will take a big hit in the top end. Waay more forgiving going oversized. example being something completely silly like the noodles. they hardly loose anything down low.

-

bends dont really have any effect, probably a tiny bit in it if your runner size is borderline already. your average long radius bends are fine. those cast aluminum elbows are a bad day though. somewhere on my youtube i tested them About 1 million people have asked me to test dimpled ones. haven't had any sent my way yet though.

-

I just figured it out, they spin the wrong way for the southern hemisphere. but yeh, been taking to @Roman about it. I might do some butchery, to see if can get them to work any better. I think making the slots bigger would be the first thing to try. cutting a hole in the end would kinda defeat the design

-

Looks like it's hanging on really well!

-

Judging by his fuel map and having vvt. It should at least hang onto peak power for quite a few more rpm.

-

Ive got you covered with that 10k rpm engine prep also. buy some 10 dollar drug dealer scales. weigh engine parts. butcher said parts with preferred item. so everything within .02gram. then proceed to completely ignore anything that spins, because that cost money to get balanced