-

Posts

17444 -

Joined

-

Last visited

-

Days Won

134

Everything posted by yoeddynz

-

I never got a chance to go look today so it's a Saturday job now. But thanks for the suggestions so far.

-

But thanks. Its definitely sounds like mechanical banging sort of thing but I can try the injector plugs. I dont have a 'proper' scan tool but matey boy down in the village does so I could try that.

-

Fella came by our yard yesterday with a 1gr-fe powered prado making a terrible valve train clacking sound on the drivers side bank. I didnt really know anything about these engines (until I did some research last night that is) so at the time I suggested it could have a collapsed follower/lifter. That's what it sounds like. He took it home and had pulled the cam cover off but can't find anything amiss. I've found one video online that has the same sound.. I'll try to get out to have a look at it for him later. Anything else I could check other then turning it over and checking the valves are at least all there and operating. I figure I should be OK to pop the cops back on and start it up for a few seconds without the cover - see if I can locate the noise. It will be messy I know. Toymotor experts please chime in with sage advice @AllTorque etc etc

-

It is a lovely colour I must agree

-

I'm just going to put this here...

-

It's Italian isn't it. Yes - I can certainly point you in a direction away from me... If you do happen to get it, not saying you will, but if you do I'll pop over for a look/laugh.

-

Yes @downtime I believe we all at oldschool want to see @ThePog get his car back

-

Yeah that's a no go on imps unless one was to change the outer joints from hooke joints to cvs - which would be quite a ballache. The imp driveshafts failing point is the small diameter along the length and they twist. A problem that was solved with the larger 1" diameter imp sport shafts. They are hard to find at sensible prices though. I'll be joining my scooby shafts into the imp shaft as close to the uni joint as I can and run a sleeve on top as well, so increasing the diameter. I don't think either Damian or I will have issues with failure given the fairly modest power we are expecting * *and then he goes fitting a supercharger (a Bart-charger)

-

I'll be interested to see what he says because I'm planning on doing similar between my scooby and imp shafts.

-

Good boy.

-

-

Not sure. He posted it up on the nz impers facebook group ages back. I don't know if he's got any further than sitting it on a bit of wood and taking a photo. But yeah- lots of room. Looks like some sort of quad bike diff in front? How do leafs go in reverse- I presume the motor just runs in reverse? Set that up and then just stash 386 of these in any available space about the Imp you can... ETC ETC...

-

Nissan leaf engine in an NZ imp...

-

Since the last update there has been some progress. Its good when I get stuck in on a particular part but often I end up doing a little bit here on one thing and then a bit on something else and find I often finish up without feeling like there's been any real progress. But I think this is just the nature of this sort of build. The hardest parts are done and while I feel like I'm nearing the end of the 'project tunnel' there is still a load of small bits to do. I think I'll do the white board thing. Write down all the jobs remaining and start sussing out a plan of attack. Or put the kettle on and watch cat videos on instagram instead. But hey- progress is progress no matter how small. Plus Hannah is going to leave me alone for 3 weeks while she takes off to the UK to see her family. So apart from having to feed our cat child I'll pretty much be a free man and can spend as much time as I want working on the engine. Or watching more cat vids and riding my bikes. Anyway. Oil filler. I drilled holes, tapped holes and mounted the base part in place.. I cut a 45 degree angle on two bits of tube, welded them and created the horizontal part.. Then drilled and tapped the flanges for the upright. I have left the final height decision for now. It'll be better to decide on that when the engine is sitting in place. My gut feeling is that I'll have the cap set a lot lower because there's plenty of room to get a oil bottle/funnel in there for filling. I have marked a line on the upright so you can get an idea of where the oil height sits... I have a couple of nifty/silly ideas for the filler tube upright and checking the oil level. I'll play around with those ideas later on when the engine is in place and I've completed more of the harder jobs - like driveshafts and gear shift rod etc. It'll be a treat. Next thing is to finish the top two water pipes that leave the heads. I had already made the front one some time ago and was about to start the rear one yesterday when I spotted an error I had made. The front pipe I had cobbled together and bolted in place.. Which pushes into the head as such... But I discovered when I looked into the hole that the land within the bore only goes in 10mm before it opens right out. I thought it was a longer land and as it is now the position of my pipe sits when bolted in place has the O-ring sitting right on the very edge - not in the middle. You can see where the factory pipes placed the O-ring in the middle with a visible mark evident here... I could easily move the bracket or weld up and re-drill the hole. Its only out by 3mm. But I'm not very happy with the look of the pipe - which I had made up out of bits of the thin old steel pipes. It's quite visible right there on display on the top of the engine even when the inlet and alternator are plonked in place.. Potential corrosion points too. I was going to paint them black but I think I'll make new stainless ones - easy now I have some proper stainless bends. Another thing I had done to the engine a while back was to cut a load of the castings down, including removal of most the original engine mounts. It really cleaned the look of the engine up. Last night I realised I could removed some more ugly. The little tube fittings left over from the exhaust air injection emissions system. You can see them here next to the inlet ports.. They pull out, sealed by o-rings. The holes left go down through the end of the heads and feed into passage ways that feed into the exhaust ports. None of this system is needed and its just extra mess. I have a couple of ideas on how I could seal up the holes neatly. One idea involves tapping out the holes with a suitable tap and screwing in some bungs and this meant opening up the magical workshop portal... into the world of stuff that I really don't like to have out cluttering up the workshop.. I have this old barry spec set of little drawers that my uncle gave me filled with all sorts of specialist taps... This one, a BSB (British standard brass) looks ideal. But before I start making more mess with taps and machining up plugs I have another idea that will probably turn out neater. Speaking of trying to make things neater. The original paint on the engine is pretty shot. I was thinking of getting it vapour blasted but I reckon the bare alloy finish left will just end up flashing off with corrosion in time - especially in the Imp where the low pressure zone tends to pull dust and moisture in over the rear mounted engine. Plus I'm a bit wary about the idea of anyone going near the engine with blasting equipment, leaving sand everywhere. I think painting the block might be a better idea. A light grey similar to the original colour. More to think about anyway.

- 98 replies

-

- 46

-

-

-

DABUZZ'Z 1971 MAZDA CAPELLA RE + New 74 RX4

yoeddynz replied to dabuzz's topic in Project Discussion

This is exactly why I made sure I laid down a shit paint job on my Imp - so I don't become too precious about it, can't park it anywhere and end up having to sell it for 100k plus -

Good point!

-

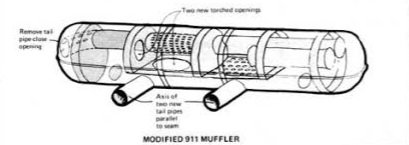

Sadly that won't be the case. The two outlets will go into a porsche style width ways mounted silencer assembly. Something sort of like this.. I think there will be too much chance of residual exhaust gases within the casing mucking up the reading. My plan is to have the sensor positioned somewhere on one of the secondaries just before it goes into silencer.

-

@NickJ Two sensors and a switch that can swap the controller between them

-

Just planning ahead for the fuel injection o2 sensor stuff on my flat six. This time I'm going to use a 14 point 7 controller. Probably a sparten 2. Looks good and from all accounts it shits on innovate products (which I had a fair few issues with on my V6) I'm undecided as to whether I fit just one sensor (and associated controller) to one bank. Did this with the V6 and it seemed fine. I figure if I make sure my injectors are all matched and my cylinders heads/valves I know are in good condition then there really shouldn't be a difference between the banks on a system that's fed air equally by a single central mounted plenum. Or stump up double the costs and run two sensors... the megasquirt 3 will handle two (or more if using canbus) but I don't think I'll gain much, if any, extra efficiency. Just info. Plus I'd have to run two 52mm gauges if I want that info on the dash. Speaking of gauges.. I'm wondering if any wideband afr gauge will work with spartan. I'll ask them but does anyone here know. I presume those gauges just take a 0-5 volt signal? Also, whilst looking on Ali I found this. It's a 'ration' gauge...

-

Random slightly cool stuff you built but not worth its own thread, thread

yoeddynz replied to h4nd's topic in Other Projects

Given the air pollution in Oxford City when I lived there, which seemed way worse when I last visited, I'm not surprised. I think you were only allowed to burn smokeless fuel there (not wood). Is that the same in most cities there? -

Random slightly cool stuff you built but not worth its own thread, thread

yoeddynz replied to h4nd's topic in Other Projects

Cheers for the offer - but enjoying burning lots of wood right now. I'd have to suss out a separate spot for one in the future though! Then collect more oil/service more of the locals cars. -

Random slightly cool stuff you built but not worth its own thread, thread

yoeddynz replied to h4nd's topic in Other Projects

What sort of flow rate/mils per hour do these things use? -

Random slightly cool stuff you built but not worth its own thread, thread

yoeddynz replied to h4nd's topic in Other Projects

That looks similar to the one that iirc @avengertiger was going to build - using some big discs off a truck (or drums..i cant remember) Yeah- damn they can go hard! What's the smoke output like? Fairly clean once up to speed? Our current woodfire likes to leave little spots of creosote over the yellow car if its burning sappy pine/wind is blowing the wrong way. -

It's just sitting there in the field with another. I'm going to pop in sometime and have a yarn with the resident Barry there.