drftnmaz

Members-

Posts

1124 -

Joined

-

Last visited

Everything posted by drftnmaz

-

Yea the SU's are interesting to get your head around but once you do they are great! things like different oil or springs in the pot etc are great for fine tuning, but hard when rough tuning to know if they are close, also the turbo SU have a needle that was different to all the rest I came across, very thin at lower section and constant taper the whole way, lots of fuel when you need it! Here's some pics, hopefully they help you in noticing the differences... The 2 things I found that usually limit carb setups are proper spark control and correct fuel pressure.

-

Well that wasn't so hard... So due to the lack of paying work atm i'll move onto my own turbos (silver linings aye!) first up is a turbo for my B6t BD mazda which I'm trying to get back on the road, factory they come with a VJ6 or VJ13 turbo, but these are mostly dead by now so everyone replaces them with a common VF10 from a subaru, these have the same awesome 9 blade turbine but a bigger inducer(7.5mm) on the compressor, I've run these before they are well suited, but then there's a size bigger again called a VF8, this changes to a 10blade turbine and another 5mm on the comp. Vj6 = Turbine 43/52-9 Comp 32/52mm VF10 =Turbine 43/52-9 Comp 39.5/52mm VF8 =Turbine 46.5/52-10 Comp 44.5/56mm So many years ago I got someone else to machine my b6t turbine housing to fit the VF8 turbine, in hindsight I think I'd rather build a hybrid of the vf8 comp on a vf10 turbine wheel, but let's just concentrate on moving forwards not changing the plan! So i decided to tidy up the housings, first up the intake to the turbo, I forgot to take pics, got caught up with the mission at hand, but the internet can supply this pic to show the factory intake (50mm) I made a 10mm bolt on plate (would have gone 8mm but couldn't find any in the workshop) then clocked her up on the lathe and made a 15degree taper from plate to wheel, bringing it to ~62mm then did a bunch of angles to make a bell-mouth of sorts, I will weld a 3" pipe to it that will goto the afm/filter, but won't do this until I can mock up in the car because I think I may have to angle that pipe... Next up I put the turbine housing in the lathe and tapered the exit from 48mm to 52mm(about the limit while still having a decent amount of flange to clamp) only ~5degrees of taper so hard to see in a pic, then I cut up my old dump pipe to get the flange, bolted it to the housing still in the lathe and bored out the flange to match(was 48mm), I also moved the washers between the flange and housing to space them apart so i could oversize this hole as the flange has some movement and I didn't want a lip if installed crooked by accident, also used a taper here to help the gasses to keep expanding and promote turbulent flow Next up the turbine housing had a meeting with Emily, the wastegate hole was machined from 15mm to 22mm and offset upwards a couple mm, then flapper from the scrap td04hl housing was fitted (31mm replacing the 25mm) the arm was then welded to extend it so the flapper could fit, then re-drilled on it's new center, the flapper was put in the lathe and pin height adjusted to suit then welded into the housing, housing also needed a touch of clearance on side, but I don't have a die grinder atm so had to do it on the mill with not much room to do nicely... (you can see in this pic the first taper I did on the turbine exit, I went back and redid this to go almost all the way to the tips) Now that wasn't so hard... up next I wanted a challenge, something I didn't know if it was possible... I have a few hx40's kicking around so wanted to put one of those into a small housing, but of course can't spend any money so have to find something in the collection

-

Those of you that know me in person will probably know that I love turbo's, and have a little collection, about 5 years ago I had a friend with a balancer at home I would commission to build turbos that i'd sell off for extra money for drifting, but one day he sold all his equipment and I stopped, but kept collecting some while trying to downsize the common ones. Then recently my buddy @Atex blew the turbo on his van, so after abit of research I found they ran a early Tdo4 turbo, so i found a really cheap Tdo4HL from a airtrek and offered it to him, a week later he asked me to machine the turbine housing out for him, I hadn't done this before but after seeing some pics I decided to give it a hoon and ordered some new cutting tips for the big boring bar I was yet to use. 3 days later I had the pieces in front of me, but the cutting tips were lost in the mail, but I was keen so pulled out the mini boring bar and devised a plan to make it work, I put the turbo in the lathe being held at the V-band/turbo end and then bored out the exit to 52mm so i could then flip the turbo around and hold from that end, then I could clock it up and machine the important end, boring it from a 39/47 wheel to 46/52mm, tbh this was pushing the limits of the material in the housing but I like a challenge! Got it to fit, learnt a few lessons, wasn't my best work but hey it's only a l300, sent it on the courier the next day and he fitted it the day after, then I explained how to adjust fueling, later that night I got a video of it pulling 18psi, and a excited atex enjoying the boggie. and some afterwards pics Compressor went from 10T 35.5/49 upto a 15T 45.6/52mm so she moves alot more air now! The 4d56? turbine housing is 4cm, and the old airtrek one was 5cm

-

So now I guess your wondering what I use these machines for... well the mill I do make a couple products that pay it's way, the lathe however I generally only use for fun or mates projects, seeing as i'm learning I don't like to think i'm any good at it. So onto some of the toys... Decided I needed some 2stroke in my life so started small with a Goped for the kids, tried to keep it simple as possible, friction drive, no clutch, push start etc The kids have to pass their license test on this before they are allowed to drive the gokart... When the oldest nephew was young I promised him we'd build a gokart for his 10th birthday so after years of collecting parts and learning about the triangle of speed (fast, reliable, cheap, you can only pick 2) we had a free 100cc honda motor from a waterblaster, a bunch of steel from old school tables, a free seat (think it was a poolseat???) and we slowly came up with a design and started building it every school hoidays, but then his birthday got close so i finished it off, I donated some gokart wheels I had, spun up some spindles to suit the fronts, ended up having to buy a accelerator cable, a chain link, a clutch with 10t sproket, the rest was all scraps and things i'd build to suit. And this is what we built, a 3 wheeled kart that teaches you lots about driving haha, Can see young josh lifting a wheel in the 2nd pic! Next post up is Lockdown turbos, what i've been spinning up while work has dried up thanks to china.

-

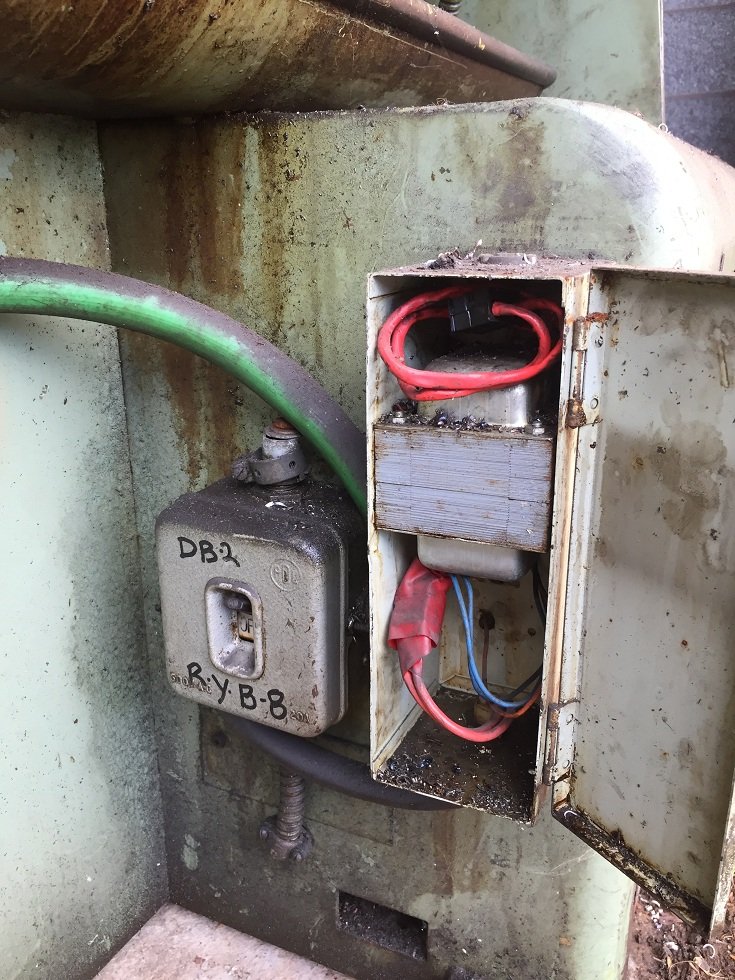

Next up I powered the motor up to half speed and slowly engaged the clutch lever and she started to spin! so I tried all the gears and found only one to be noisey, I guess this is the speed it spent most of it's life at... it's got 8 gears and it was number 7 (700rpm) so if I need to do alot of work at that speed i'll pick another gear and add more frequency to the motor, although I haven't tried over 70hz yet, would prefer to get the motor balanced if I was going to run it at 100hz or similar. Then I twiddled the levers and spun the handles, clocked up a piece of steel and had a go at cutting, this wasn't pretty, not only did I not know what I was doing (all I had done is read a couple old lathe books) but everything had lots of wear so it wasn't long before it went wrong and I wound it into a area with lots of lash and it dug in... ok time to step back and assess... I pulled apart everywhere i could find wear and shimmed the best i could with what i could find in the workshop and with a bunch of trail and error got her to a usable state, and i was finally in the world of making round stuff Here's the shed from outside, pretty boring but keeps my tools mostly dry And the old Wiring and step down transformer for the missing light (would love to find a factory light but not easy in nz) This is all bypassed atm. And found a old pic of Emily in my messy workshop, (it's not always this bad!) can also sorta see the oil burner heater behind the bonnet, and the start of a bbq next to it.

-

Sweet, blowthrough is much better! I found with the blowthrough it didn't like the intake pipe to the carb to be in-line, I ended up using the ulgy boxy thing off the mg factory setup, it changed the airflow path and had slots around the side, I dug it out and took a pic for you, I might strip it down later and get a pic of the inside... when I later changed to the downdraft Aisan factory turbo carb from a daihatsu charade I added a plenum box on the top and also had a diffuser plate on the inlet

-

awesome toy man! and good to see you realized with the variable vane you have to wind them open a little bit, took me a few days to figure that out on my first variable vane turbo install! I'm not sure exactly which turbo you are using but i've done draw-through before and learnt a lesson you might be interested in... you need a turbo with carbon seals to do draw through properly, if you use a normal turbo then the vacuum is too high across the compressor when you shut the throttle, and it kills the oil seal after a few hundred km's, however there is abit of info out there saying if you add a second throttle in-line and have it ever so slightly more closed that the SU throttle then it moves the high vacuum area to the first throttle rather than the turbo... I ended up using a SU carb from a mg montego which is factory blow-through after seizing the first turbo running draw-through, no risky fuel pooling in turbo inlet then aswell.

-

All the clutch's i've seen on factory superchargers are a on-off type of deal, I think any pulsing of this signal would cause the clutch to die very quickly... I see the s/c as being a restriction even when it's turned off and free-wheeling so I would use the wastegate(on cooler piping) to bypass the s/c which will also help with the transition as it will open more and more as the turbo really takes over. If your seriously considering 10k revs and 400hp (atw?) then I would recommend doing the calcs for air required at engine for those specs then look at comp maps, the G25's claim big numbers but real world seems to require high pressures to acheive... however the 60mm comp wheels are generally torque monsters for their size so if you can get the flow to match then it'd make for a nice driver

-

I'd use a decent sized turbo and blow it into a cooler and then into the supercharger, I would also add a decent sized wastegate after cooler + before the s/c, that bypasses the s/c once enough boost is achieved (say 15 to 20psi) letting the turbo take over in the top range but still giving s/c down low torque and twin charged in the mid-range, hopefully the factory s/c has the normal clutch pulley you can turn off at mid revs, making it sequential, and of course i'd use e85, maybe water/meth but e85 would be easier IMO

-

Next up was the gearbox... It had a sight level that was so dirty I thought the glass was stained, so I popped the top off and had a look, to my surprise the insides looked perfect, except the oil and a slight black grime on the outer edges of the oil level line, so I drained it out and emptied 4 or 5 cans of brake clean in there and got it looking decent, also got the sight glass good enough to see through, I figured out the ~equivalent oil needed was the typical tractor type oil so found a 20L container on trademe with only 2-3L missing for cheap so snapped that up and filled her up with fresh oil, took about 10L, again no pics but I found this one on the internet that is the same, ignore the writing... Next up it was time for a power source, I hunted around and found this water pump controller that also stepped 1PH to 3PH and was rated for 3hp, it was being $1 reserved on trademe so I took the gamble and got it for $25, at this point I was super dubious, but after a quick look through the china manual it seemed like it would do the job, and now it works a treat, I do have to run it in maintenance mode because it wants a pressure sensor or some such, but specs are unknown so I plan to try use this later as a safety cut-out. mean score and way better than using Emily's vsd on the other side of the garage. By now I had the basics sussed and had read the Colchester manual to try and figure out how things went... so I started playing with levers etc and noticed the clutch wouldn't disengage, luckily on the back there was some description of it's Matrix clutch so I pulled it apart and measured and cleaned and reset it, got it going but ended up changing specs slightly to reduce drag when disengaged, this old stuff is made to last!

-

Whipped the back off and snapped a couple of pics of the china 3hp power machine, can see the 12.9 grade m10 bolt used for locking to the keyway, the end being ground down to 6mm? to suit (that reminds me, I should make a proper one with the lathe! planned to change the pulley size but quite happy with it now)

-

I hunted high and low for the old pickup pics of Charlotte but think they are lost, I have one corrupted hard-drive left to try, but for now you'll have to suffice with my words... I've always wanted a lathe, probably more so than a mill, about a year after getting Emily I spotted a old Colchester roundhead on trademe that wasn't too far from my house, so I went and checked it out (knowing nothing about lathes haha) and fell in love with the shape and style, it was a $1 auction on trademe and bids were only at ~$60 so the place selling it got annoyed and chucked it outside in the rain thinking it was now going to scrap :/ I dried it best i could, got part numbers and wrapped in a tarp, waited till the end of the auction and thought i'd get it for sub $500, but of course there was a bidding war... I ended up getting for around $960 if I remember right. I quickly sold off a bunch of old JZ engines in the corner of my garage to make some space and then took Julie (my nissan atlas truck from the first post) to pickup the new lump of metal, they had a forkhoist so it was a simple pickup. My new addition is a 1964 Colchester Triumph 7.5" Roundhead and was apparently 1045kg's, I got a PDF scan of the manual for free from a friendly chap in England which was pretty handy! So now i was home, i had some room to store her but didn't know how to get off my truck and into the garage, so I called my buddy who's always up for one of my crazy missions and he as normal said he was keen,(wes, some of you will know him as 1ofaknd?) he came round after work and we used a engine crane/hoist to lift her just enough to drive the truck out of the way and drop to the ground, this was super sketchy! (and trust me i've done my fair share of sketchy things with helicopters and jet engines!) at one point I thought we'd lost it and it was gonna wreak the truck on it's way down, But we got lucky and then shoehorned her into my garage... (she's wider than the door so had to do a spiny twirl move to get her in place) Now for the fun bit! getting her going, I knew the drive gears for the autofeed and thread cutting were missing so that side of the machine will be ignored for now as I need to learn the basic's first. I removed the old motor, was meant to be a 5hp or at worst a 3hp, but what I found was a really old 1.5hp that was physically massive and had no provisions for running at 230V, it also had a small pulley so was driving the machine much slower than the speeds on the front plate. This was removed and a 3hp/2.2kw modern chinese motor brought from trademe ($160?), second hand but didn't look like it was ever used, once I had it home and inspected I found it had lots of end float (like 2mm), so stripped it down and shimmed it up so the spring washer was actually controlling the end float now, pretty happy with such a easy fix! Next up a brought a brand new double-A V-belt pulley(rare for me to buy new bits!) from bearingandengineering.co.nz but of course the center hole needed to be enlarged to the 28mm?? shaft, a job super easy on the lathe, but it didn't go yet, so i strapped it down to my rotary table and tried the best I could to get center then drilled out, was close enough lol, then instead of cutting a keyway I drilled a hole and tapped a thread, then using a high tensile bolt wound in from outside to locate it to the keyway Then i mounted the motor to the factory plate, and realized i'd need to buy new longer belts to suit my new pulley size, and I'm too cheap for that when I didn't even know if the machine worked at this stage! so I then made some 3" spacer blocks to raise motor and use the old belts, was abit messy but it worked.

-

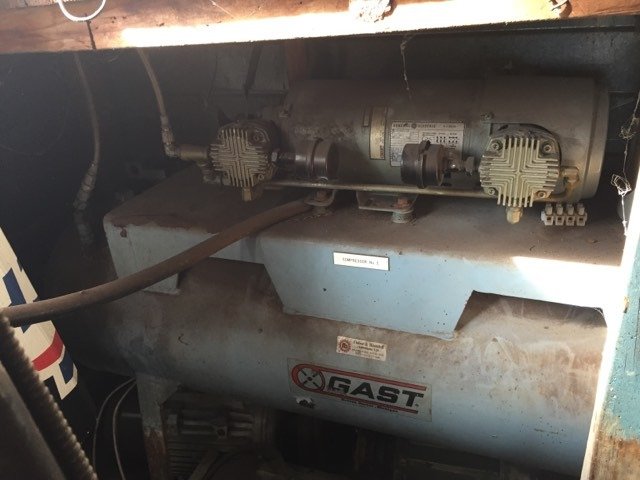

Yep bridegports are gold! When i was hunting around I found alot of copies of the classic bridgeport and all of them just seemed to change the taper for the tooling so I thought getting the real deal was a pretty safe bet! It's truly amazing what you can make it do when you get it right! Today's yarn is what I call my subaru compressor (it's not subaru at all) but it has a electric motor in the middle with a shaft/crank out each end which spins 2 horizontally opposed pistons each, got it free from a mall that was upgrading the plant room, no idea what it was actually used for but think it was more a backup unit for starting a generator or something... anyway it shares the VSD with Emily and currently has no over-pressure cut-off but does seem to stop making boost around 120psi which is perfect, also think it might have a cracked piston because pressure can leak back through one of them, more future repairs /piston welding one day... next yarn up is my round making mate Charlotte the Colchester, just trying to find old pics from the trip home, but I think they are lost :/

- 14 replies

-

- 12

-

-

I'm not so good at taking pics, might try again later with better camera and better lighting. Here's how she sits now, clocked many hours of slinging chips and twirling spirals, brought what tools I could afford along the way, shattered a few china tools and blunted a few english ones! Nikon DRO is so analog I love it, but has skipped on me before and made me have to restart which sucks, the last pic shows a extra 3phase connector, this runs off to my compressor which shares the VSD with Emily because it's rare I need them both at the same time. She's still got play and I haven't tried the auto downfeed function so still lots of future repairs and maintenance when I figure out how

- 14 replies

-

- 16

-

-

-

So i couldn't find a 'proper' motor, so next I looked for a flange mounted 2.2kw motor to mod up, but didn't find anything suitable in a decent price range so I went to my brothers air conditioning work and talked them into letting me hunt through there old motors, I found a 1hp Horizontal mount TECO NZ motor with a adjustable belt pulley, which they kindly donated to me... So then I went about making a horizontal motor conversion mount to run vertical, I had a drill, a grinder and a welder to work with... so I mainly used 50x5mm angle iron and made a cage of sorts to mount it and spread the load the best I could, then I undid the adjustable pulley and wound it as wide as it would go then welded it solid, this was then just wide enough to fit the factory belt which by luck was still in the head of the mill! Then I wired it up and added a front mounted potentiometer for speed control, not realizing that Emily had 2 gears (high+low) and they run in opposite direction to each other so would require forwards+reverse, my VSD is mounted at the rear and quite hard to access so rather than mess with that I wired in 2 3phase plugs on the side and swapped to suit direction wanted, this got old really quick so I hunted out a NOS 3ph forward/reverse switch and fitted that, it's amazing how often you need to switch gears! Recently I added the clear lexan cover for the wiring on the motor so I can show the kids about 3phase (the old cast one was about 1.5kg's!) I did end up buying a more suited 3hp vertical motor but never fitted it because the 1hp I can stall out if something goes really wrong, but i think the 3hp would cause more damage... one day if i have a job that needs power i'll fit it but until then i'm happy with the 1hp.

-

Was enjoying reading Adoom's Meuser lathe thread and it dawned on me that I should post up some of my machines, but because I live the no phone life I rarely have a camera near to take pics, but I'll try harder... First of all I'm no machinist, I am completely self learning the good old kiwi way, I buy old machines, cram them into my garage and use trail and error, and there sure is alot of ways to discover error when 0.1mm makes a huge difference hahaha First up is Emily my 1973 Bridgeport mill with a not so 2J head... I brought this machine with no motor, normally they have a motor with a spring loaded CVT-type pulley with a fat belt so you can adjust the speed across a large range, the old motor had burnt out and the quote to re-wind was too high so machine then left in the corner and the motor missing, I offered cash and then picked up a week later with my little truck It came with Piccodrive 2.2kw VSD and Nikon Digital readout, power feed on one axis, but I had no idea of wear, and couldn't find a replacement motor in NZ, But I was stoked to finally have a mill, next I sectioned off a area in my shed and poured some self leveling concrete for a base, moved it in using a engine crane and stuck it to the ground with windscreen urethane, sorry no pics as this was a couple years ago now

-

School me on frequency convertors and VSDs please

drftnmaz replied to moparmuppet's topic in Tech Talk

Yea sorry, mistype on the star/delta thing... Most VSD will go from 1ph 230v to 3ph 230V, If you want 400V then it will also need a step-up transformer, but going up voltage and to 3ph would cause massive current draws due to losses in the conversion and likely max out your available shed wiring. So check if your motor has Delta 230V option and if so then you can wire it to suit and run off a normal 230v vsd, most vsd's have input triggers, IE my Picodrive unit has option for external reverse trigger (but i've never used it) however I have wired in a external potentiometer so I can change speed on demand form the front of the machine while working, it also has current limits and start frequency and ramp rate (I have this set low, but if i plug into my compressor when it's already got pressure then it can't re-start it) As mentioned above there are other more ghetto ways to make it work but they will draw huge current and make low torque so don't seem suitable to your requirements, (caps added to run, or using a bigger dummy 3ph motor to create the extra phases) I had a friend try a vsd on a hoist but said it would barely lift the car so then he fitted a replacement single phase motor, I never asked how well it works now, but know he uses it daily. -

School me on frequency convertors and VSDs please

drftnmaz replied to moparmuppet's topic in Tech Talk

I'm no expert but I run a few of my machines on VSD's, as above you need to check the motor can be wired for both delta(400v) and star (230V), most modern stuff is and you can see it on the name plate, like this pic below. All my VSD's i've got from trademe, mine are all 2.2kw so popular size and harder to find, but you see the smaller ones pop up on trademe from time to time for cheap($100ish), having a full ramp and setting up a reverse switch should work how you want, but i'd oversize the unit a little because start-up torque could draw higher current than nameplate suggests and I never want my electrical equipment sitting on the limit. Depends on how the machine is setup but have you considered swapping the motor out for a single phase? the second hand sub 1kw motors don't seem to hold much value... -

I use a gt2056V(same as yours but bigger 1.0 ex housing) on my td27+T with a 10psi actuator on the vanes, and no wastegate, fuel controls amount of boost and i set that to ~18psi, I really like it, only tricky part is setting the vanes open enough that highway cruising is still good when at low boost, used to have a external gate fitted aswell, waste of time and money that was haha

-

Dunno if your interested but i have a column shift gearbox from a mazda e2200 van, that i brought to use in my column shift ute, which is gone now so box is up for grabs if your interested? then could use mazda/ford F/FE series of engines...

-

When i used to work at the airport we had 1000L containers of 'old jet a1' some helicopters had to have the whole tank drained to remove the fuel lift pump, but of course you weren't allowed to put it back in the helicopter so we would sell most of it to the local growers with greenhouses that burnt it for heating, but we also used to use in our trucks, would mix 50/50 with normal diesel fine and but the old boys were always going on about how harsh it was on the diesel pump and stuff, never saw any of them die tho, i guess a tiny bit of 2stroke oil in the mix would soften it up Never heard of the atf trick, but that could be handy as if your stuck somewhere with low gas!

-

yea it's size is borderline, but it was off a 3.3L volvo boat so it's the biggest spec of the 2056's in the 1.0 ex housing, the rear end can flow way more than the 0.48 t25/t28's found factory on the qd32, most 2056v's I see are 0.64 ex housing and smaller inducer compressors. I have a gt3063klv with 0.74 housing that will go on next, it's quite similar to the 2860, but smaller compressor inlet, smaller a/r on the compressor housing and larger 10blade gt30 turbine, but most importantly the strong shaft so compound won't worry me For motorway cruise i have made a accumulator canister and couple of air control solenoids so i can hold open the valve while motorway cruising, but haven't got round to installing or testing yet, rust is keeping me busy atm

-

yea hx40 is just a frame size, but i would like to be using one of the larger compressors(but have a smaller one here that may get used until i find a new turbo guy) so yea crazy for a td27 on it's own but when you do the calc's for compound turbo the big turbo needs about 2.5x the flow of the little turbo, I'm not shooting for high boost, more for decent airflow at acceptable temps so 25psi but only 12-13psi each turbo, and with little exhaust restriction. I think when driving unloaded it may not even make that much boost, but once you've got a full truck and trailer then it will come into it's own. it's my first compound turbo so I might get it all wrong haha

-

Yea im using a 10psi actuator aswell, works well except if you have the vanes too closed then off-throttle motorway cruise can be abit jerky, but easily adjusted

-

Anyone else use variable vane turbo's on their diesels? I use a garrett gt2056 with 1.0 housing on my td27+T with actuator to control the vanes, Works quite well, want to compound charge next but worried about small shaft size of little turbo so probably change to gt3063 as the small turbo and hx40 as big