-

Posts

481 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by HumberSS

-

I'd be busting out the tig

-

Humber SS's 4V Century V8 powered Dyna Camper

HumberSS replied to HumberSS's topic in Projects and Build Ups

- 61 replies

-

- 21

-

-

Humber SS's 4V Century V8 powered Dyna Camper

HumberSS replied to HumberSS's topic in Projects and Build Ups

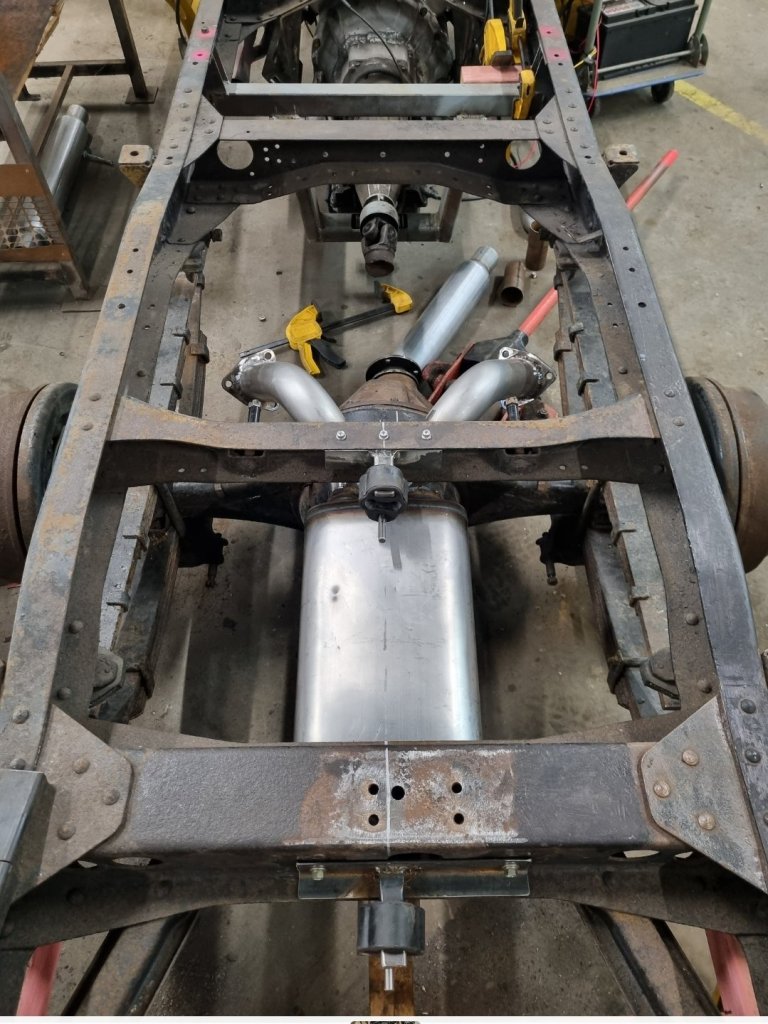

Work in progress of exhaust being built. Will take me a while at this pace but chunking little bits at a time, as is the order of the day. To save you using your imagination.. -

Discuss here about Yoeddynz's little Imp project...

HumberSS replied to yoeddynz's topic in Project Discussion

Worth a crack anyway while idling/revving? -

Nice personalized plate too

-

That spoiler and rear tail light bog job though...

-

Discuss here about Yoeddynz's little Imp project...

HumberSS replied to yoeddynz's topic in Project Discussion

Can you not do the old 'spray a bit of engine start around the place' trick to see if it idles up a little?? -

Coach painting refers to the process. The topcoat will be enamel paint. For primer you are probably best to stick to 1k primer, brushing on is probably best avoided for primers unless you like sanding.

-

All the old cars, I guess pre ww1 predominently?? Were brush painted - its called coach painting. You can get a really good finish using enamel, usually you warm the paint to make it flow out. Check youtube for tips,eg.. probably the only word of warning is make sure your work underneath is good if you're going to come back and spray properly later, and also if you go the enamel route it will ideally need to be sanded off if you go to a different paint sytem later on like 2k. It can remain however if your brushing you'll have to flatten it off to prime to seal up the enamel, which may not be super fun either. All doable and if you're coming back to it it's a future you problem.

-

I thought the solution to wife problems in Hawney Hills was the generous offering of your third leg? Two tiny cars must make that thing massive. Perhaps you could make an x1/9 love seat from the remains for your beloved?

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

HumberSS replied to RUNAMUCK's topic in Project Discussion

I'll give you $20k. You can give your ex half. We can negotiate buyback once the dust settles. -

FYI for those keen on evaporust but wanting to save pennies, there is this. According to the youtuber it's better, and about 1000% cheaper. I'm gonna give it a whirl as I share my workshop with a girl that makes soap, and hence can get the soda.

-

Pinto escorts are a lot of fun. I had a panelvan years ago that used to piss the skyline brigade off up to about a hundy.... balanced, cam, single side draft etc ... then the max boosts would reel you in.

-

Humber SS's 4V Century V8 powered Dyna Camper

HumberSS replied to HumberSS's topic in Projects and Build Ups

As promised, time to start making headway again after far too many distractions. Had a good couple nights on this over the weekend in pursuit of exhaust nirvana. Of course, ran out of/underestimated bends needed. So will grab another 2.5" this week some time. Made a couple of brackets to sling the main muffler off the xmembers. The trainspotters will notice I bent a prong the wrong way. It made sense in my head. Bending it back is probably not going to happen, I'm comfortable with accepting my failures. I also dropped the muffler at least twice. Dents upwards it is.. Started putting tube on, need to go up and out rather than just coming out at the 45. It would prob be ok but I don't want to risk diff head vs exhaust. This angle is a bit tight as it runs close to the shock so need to massage a little more along with deviating upwards. Will sling resonator next then connect the dots. Exhaust systems are harder than they look to get nice, muchos respect. Furthermore, cut my handbrake disk on the plasma and owing to selling my big lathe, I had the shop that brought it spin the necessary detail in to it to spigot between driveshaft and pinion flange. Need to chuck it on the mill and pitch out to holes, then set it up properly to start mounting calipers and weld mounts to diff housing.- 61 replies

-

- 20

-

-

I like the cavity wax idea. I do not like the spray foam idea. I'm sure it matters what I think. Mostly here to ensure my ballsack avatar infects your thread. Aforementioned vision of you and T attempting copulation in the X made me think of a plate for you. It was the only combo available. Fitting. Thank you

-

I dunno, at a guess about 30-40 a side. Just to be clear the truck is on WOF so would not require LT400. Agree would suck to have to backtrack later, maybe I need to talk to my cert guy who's covering off the engine swap stuff?

-

Thanks man. I'd rather fully deal to it while it's apart. Is what I'm proposing ok?

-

Looking at my Dyna chassis it got early signs of heave. Given how deep I am I'm thinking about separating the double skinned areas, there is a not inconsiderable about of rivets to do so. The double skinned areas runs effectively from gearbox xmember to radiator cross brace and fron shock pickups. I've spoken to a mate who works on trucks all day doing lt400 work, he's just a gopher not qualified in any way. He has assured me that if I separate the skins to clean up/treat/ paint etc that I can reassemble with grade 8.8 bolts. I've tried to find info on this but can't find anything definitive, seems to be common practice though. I would rather do once and do right... Can anyone confirm this for me?

-

Just turn your stereo up. When did you start caring about such things? It's prob factory.

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

HumberSS replied to RUNAMUCK's topic in Project Discussion

Guts. Also have this t-shirt. Get good advice, hang out with good friends, don't get bent over and reamed. All the best mate -

Humber SS's 4V Century V8 powered Dyna Camper

HumberSS replied to HumberSS's topic in Projects and Build Ups

- 61 replies

-

- 22

-

-

Humber SS's 4V Century V8 powered Dyna Camper

HumberSS replied to HumberSS's topic in Projects and Build Ups

The cadence has been poor on this one. Many distractions. Many more pressing things, unfortunately. However in the spirit of making me feel better with all your likes, and hopefully kicking my ass into gear, I thought perhaps an update is in order. I did work on this thing for the first time in two months last night, so that's a start. Winding back, I obvs got it going, which necessitated finishing the radiator pipework, i kept the rad in the factory posi, so needed to pipe it accordingly. No issues with bleeding air given the relative height diffs, which is good. Also got some sweet mufflers/resos from rock auto. 2.5" spiral flow resos, 18" long, and a nice 2 into one muffler. The prices are stupidly cheap compared to here, even with freight. Brought tube and hangers locally as that didn't compute. Also got some 7mm ply floor glued into the front of the camper body. And finished off the ally flashing to cap off the hole, which is partially visible above. Yesterday started finishing off collector. Tapering to 2" for a bit then step up into 2.5" resos and then into the muffler. Will add more muffler if it needs it thereafter. My old starlet turned up for a visit this week too. I restored this about 5 years ago, it's holding up pretty well.- 61 replies

-

- 19

-

-

Random slightly cool stuff you built but not worth its own thread, thread

HumberSS replied to h4nd's topic in Other Projects

-

Random slightly cool stuff you built but not worth its own thread, thread

HumberSS replied to h4nd's topic in Other Projects

Cheers man, yeah it's a bit if a marathon. Got some blackness on it tonight, will be a week or so until I attack the white though as I'm painting in enamel and it will take a while until it's dry enough to mask the black off. -

Random slightly cool stuff you built but not worth its own thread, thread

HumberSS replied to h4nd's topic in Other Projects

All other project have ceased due to lots of distractions. Distraction number 1 has been the cnc plasma, which is an excellent distraction. However distraction number 2 has been my digger requiring one hell of a birthday. It was my old man's, I inherited when he died a few years ago. It had been running hot forever and his solution was to add an electric fan, which is kindof great as we got many hundreds more hours of work out of it. Anyway, inevitable happens and it finally released the smoke, so I found a Kubota ride on with the same little d722 3 cylinder diesel in it, @ThePog kindly collected from somewhere local to him, only 1200 hours on it which was perfect. The old motor was so farked. Cracked head, piston slap, run bearings etc. It actually still ran, surprisingly. So out with the old, in with the new Have then spent last 4 evenings and the weekend prepping and painting. Will blow a fresh coat on this week. The factory paint job was obviously shit as it was flaking and surface rusting very randomly. I'm hopinh it will come up a treat.