-

Posts

2,350 -

Joined

-

Last visited

-

Days Won

2

Everything posted by Kimjon

-

I suspect it brakes in the sharp bend. I was toying with the idea of backing it up with a fillet weld, so this is convenient timing talking about possible cracking issues...so I will do that now as cheap insurance.

-

How did they fail? Did they crack along a stress line? How did you remedy it? Keen to hear about your situation and how you solved it. I was going to lathe up some round plugs and bend some round bar kind of like this: But by the time I found somewhere for the choke to go, it seemed a waste of time. I may still go down this route, but I'm obsessing over small stuff that really doesn't matter.

-

Hot metal glue gun action... Bolts are for pussy's!!! Functional, but far from sexy. That probably describes most kiwi woman...and this bracket falls into that category too. I'll get it chromed and it should disappear and not draw attention to itself.

-

Impala parts. And another angle grinder and a drill...cause I keep breaking them, because they just don't make em like they used to!

-

Kumeu was still pretty awesome. And I got the swap meet parts I actually needed to buy for once instead of buying random shit I didn't need. But fuck me it was hot! I'm way to ginger to be in the sun all day, think I got my years supply of vitamin D all in one day...

-

I have that same led stop/indicating light strip and was wondering if it's okay for wofs in nz? I haven't fitted it yet because I have doubts...but keen to hear if it's okay?

-

I've seen some hard out riders in nz, a dude the other day was doing stand up burnouts down Greenwood street in Hamilton, on his Harley... middle of the day, wildly crossing both lanes and passing cars while smoking the tyres for hundreds of meters up the road! Moments like that I wish I had an SD card in my eyes so I could download it and share it with other people. This dude (YouTube below) gives zero fucks too and shows that often it's more about the rider than the bike. Though I'm sure he could do it even faster on an R1. He's probably dead by now, but fuck he showed commitment!

-

I'll probably cut the pipes a bit more. But I'd like something like the pipe to touch first (if it was to ever happen) to give me an early indication that its been pushed beyond its limits, rather than contacting the frame or something solid with no give. Once again, think I'm worried about shit that's never going to happen.

-

Fucking around with my exhausts. They are the lowest part of my bike, so I trimmed as much off as possible without ruining the ceramic coated heat shields. The bit sticking out the lower pipe (marked by vivid line in photo above) is now gone. I then measured how much the bike could lean before touching and its approaching 30° from vertical. Doesn't sound much, but then I Google searched a few images and noticed something. This superbike is hard out cornering with a knee down, but the bike itself is probably 45° max from vertical, maybe not even that much? So 30° doesn't seem too bad for a cruiser. But when I do my final assembly I'll look at it again and may get a bit more aggressive with the angle grinder if need be.

-

Thanks @cletus that's what I thought, but didn't want to be true. I'll machine up a spacer between the carb and manifold and put a hose barb in it to provide the vaccum required. This is an opportunity to make a plastic spacer to help with a slight fuel evaporation issue I have. So maybe kill two birds with one stone.

-

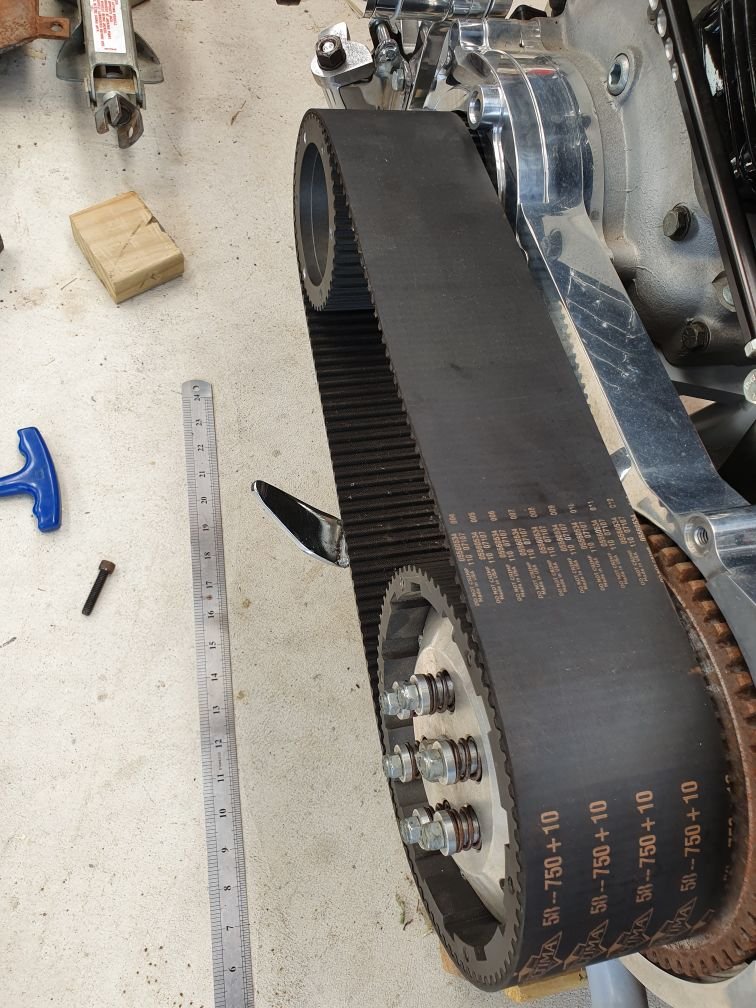

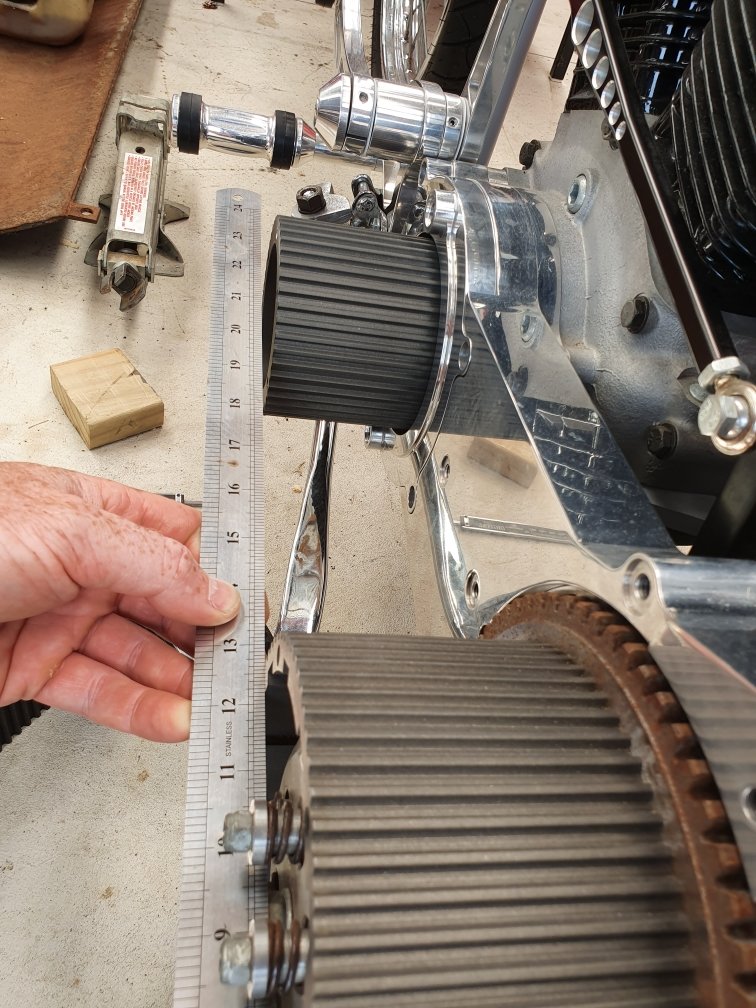

I put this outrigger on. I think for certification I need to guard the belt drive? Then, I rolled it outside and it stood for the first time in its life on it's own. As a father of 3, I can say that this emotional experience far eclipsed watching my own kids takes their first steps. So close, yet so far away for starting it up.

- 299 replies

-

- 15

-

-

-

Is it okay to run the exit end to the air filter above the carburetor? Or do I need to find a port below the carburetor? My air filter has a convenient hole in the bottom lid already that I'd like to use.

-

Same boat as you. I have knowledge, but no understanding. There's a couple systems. Race car = catch the oil, passively vent the gas through the breather. Or road car; from what I know, at high rpm engines dont make inlet vaccum anymore, so in turn at high rpm the pcv valve stops working, as theres no sucky sucky...so the breather on the catch can, then takes care of this by providing an escape route for the gases to go. At low to mid rpm range like 90% of road cars will drive in, the inlet vaccum will suck these gases through and burn them in the motor, this passage is through the pcv valve. Pcv valves are just one way valves, so flow is restricted in one direction only, it can't go backwards like an open pipe. But yeah, knowing how shit work versus actually having done it are two different things. I've never had to do it...so you're reading the ramblings of a moron.

-

-

My vaccum line on the carb is already in use, so I'm struggling to see an obvious place to plumb the pcv valve. If I ran the exit line out the downdraft hole, through the catch can, the to the air filter above the carb with a pcv inline between catch can and air filter...would this do? I'll try sketch it and add a photo to this soon.

-

The brass plate is an original feature left behind from the cars illustrious past. It was a government owned vehicle, used as a dignitarys car. They were manufactured in Canada, exported to New Zealand as parts, and assembled in either Thames or Wellington. Well that's what I've been told by an enthusiast. The factory righthand drive was a huge appeal to me. Left hook is okay, but righthand drive is just so much better.

-

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

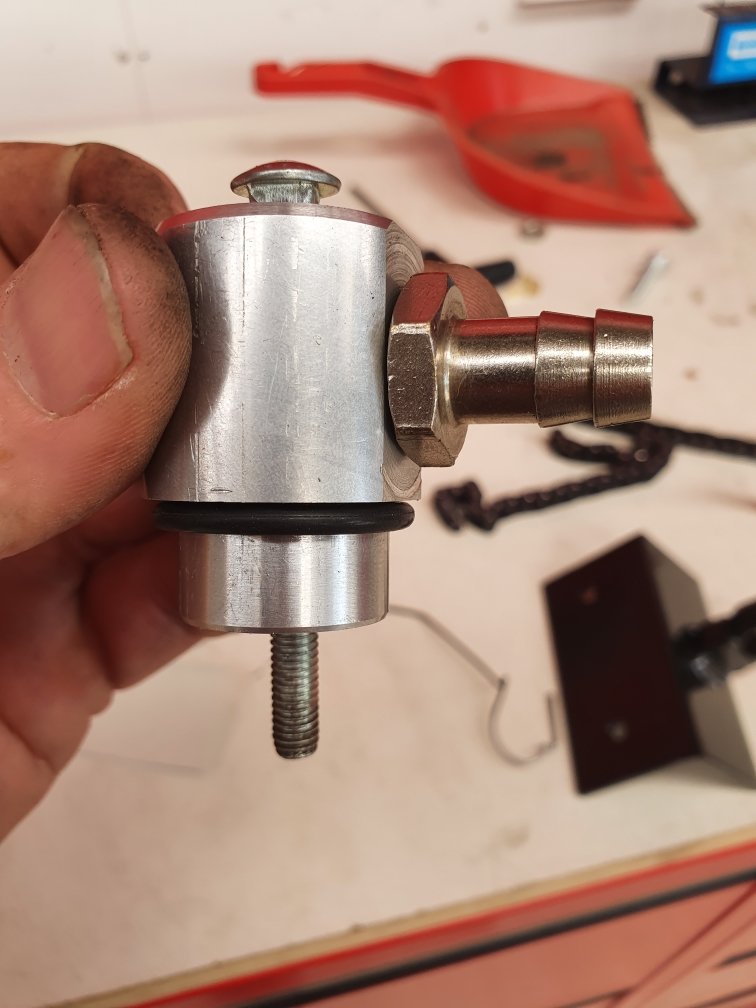

This is what was floating around the valley of my motor: The 3x little chunks were lose inside the valley under the inlet manifold. The larger "seal" was just flopping around on top, in the hole pictured in the above post. No wonder it was leaking oil eh! This part will replace all that shittyness. Its held down by a through bolt (this isn't the bolt I'll actually use, so stand down internet warriors). There's already a threaded hole for it in the block, left from the origonal down draft tube that's supposed to be there...very convenient, so that's what it will bolt down on and then the o-ring creates the seal. -

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

Just brought this. Did a bit of Google searching and it looks like it's going to do the job. I'll install my machined fitting into this hole, by the distributor. There was a "down draft tube" here on the original motor, basically the predecessor to a PCV system. It was a simple tube that runs back and exits out by the transmission to atmosphere (aka dumps oil on the road, drive, shed floor). As you drive air rushing past creates a venturi effect and sucks out blow by gases and any oil mist. My motor had the down draft tube cut and bent around for clearance purposes on the firewall. The seal has fallen to bits and it wasn't connected to anything, so blow by was exiting here and causing an annoying oil drip. The catch can will collect and separate the oil, and vent the gasses. -

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

Machining. More machining.. WTF??? You crazy cunt, it's in sideways!!! Oh, not so crazy after all. Pretty... Mmmmm PCV valve goodness. Just going my part for the environment (like I'd really lose sleep over fake news like man made climate change). I'm just sick of it leaking oil on my shed floor. Just gotta hook up a catch can or route it into my intake vaccum to get rid of my crankcase vapour and problem solved. -

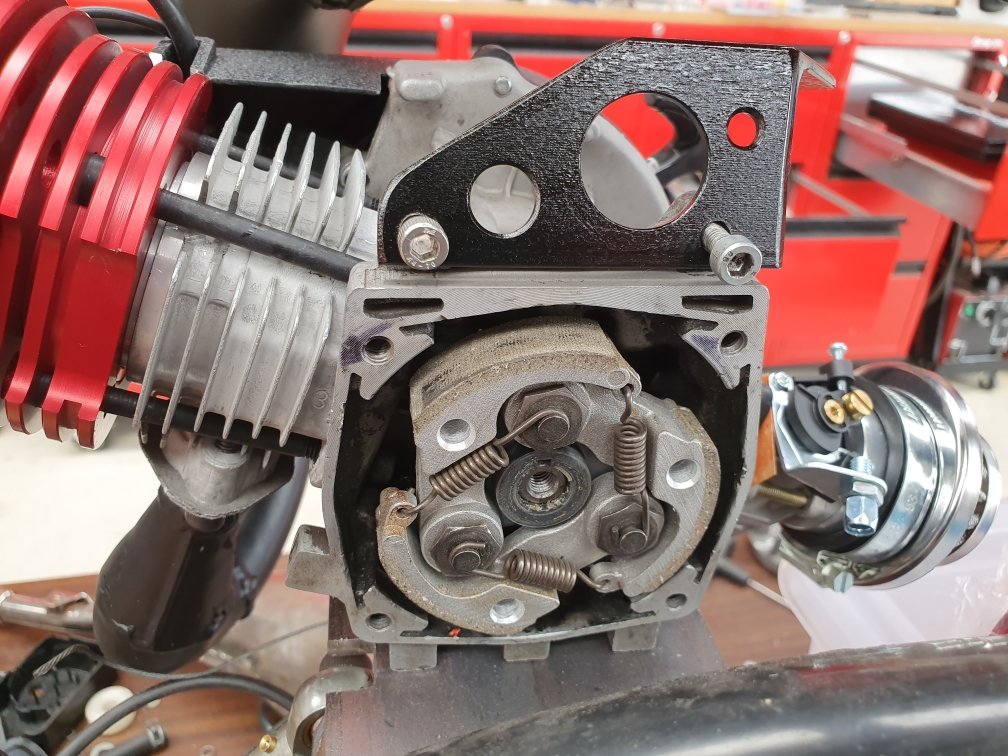

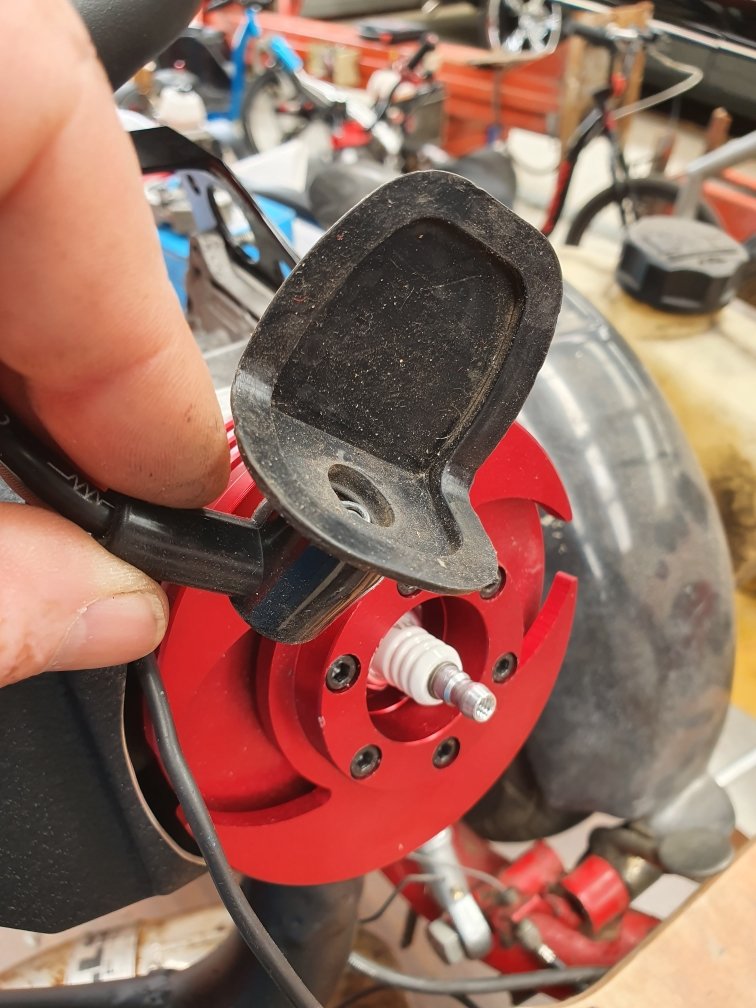

Clutch sorted Note the holes drilled in it, this is to lighten the arms and in turn raise the stall/engagement rpm. This makes a world of difference in acceleration and driveability. And before and after of spark plug boot.

-

Squish is a shade loose at 0.82mm Tested with solder. I only turned the motor over for one stroke, so possibly a bit of spring back in this measurement? If I pulled it over a couple times I may get closer to the 0.7mm I was hoping for? But it's so close that I can't be fucked changing it right now. At 0.82mm it's still going to be awesome, and it wont brake shit like pull start cords etc like my last one does (with insane compression). I can also use pump gas without detonating. So maybe a mildly conservative (conservative is a relative term, like saying a 2JZ "is only running 32psi boost or something like that") squish band setting isn't a bad thing? I'm pretty confident that if I tested it again and pulled the motor over a few times it would further squish the solder closer to the 0.7mm, so I actually think that's more likely the number than my half-arsed test. The main thing I've confirmed is that the piston has clearance to actually rotate and not strike the head, plus the squish is a lot tighter than factory 1.5mm, so I'm happy.

-

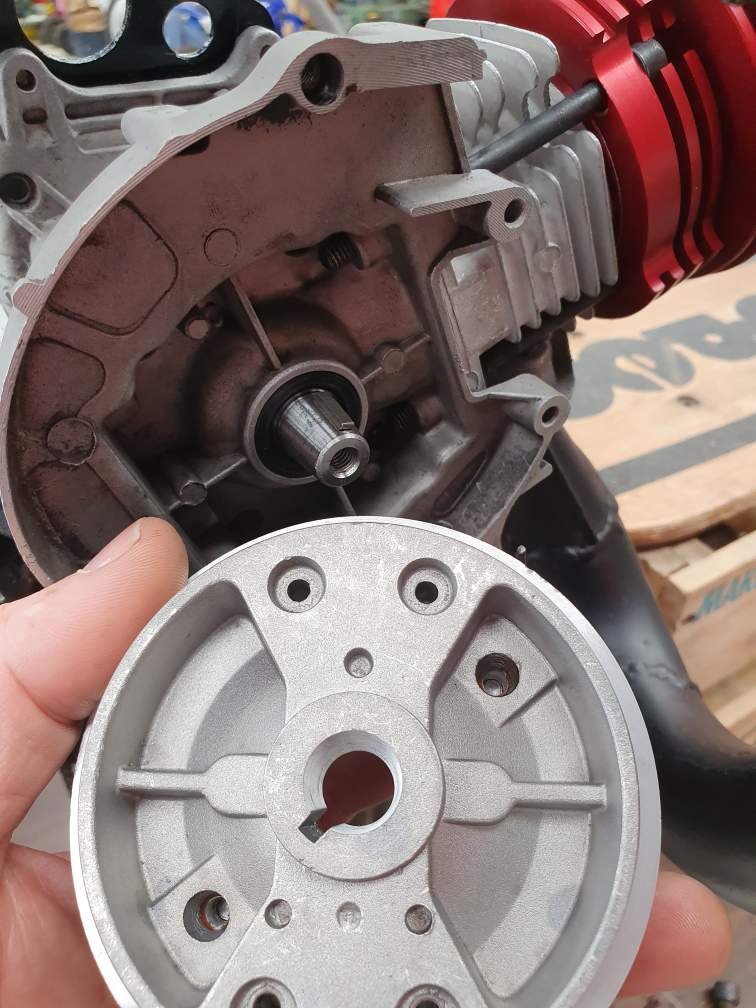

Got home and found an aliexpress package...best day ever! My woodruff keys arrived, so no fucking around...lets get some shit finished! Okay, not so awesome. Problems... The flywheel I'm using is supposed to convert it to easy pull start by shifting the leverage outward, thus increasing torque on the pull start. This certainly works...but there's not enough clearance to simply bolt on the pull start. This is how much clearance I need, so I'll space it with washers "for now, cough cough". And make a proper aluminum spacer plate for it later. #shitthatwillneverhappen #washersforlifemofos Makes me wonder how normal customers get on with this type of purchase. Not everyone buying cheap parts of ebay or Amazon etc have access to a lathe or milling machine to then make said cheap parts actually fit. Then a bit of clutch bell restoration. I've put it all back together and it's now ready to start.

-

Nowhere near enough to even remotely trouble it. They're 1340cc capacity and an unimpressive 70hp stock. The low hp figure is because they only rev about the same as a small block chevy, so say around 5700rpm if it was screaming Vs sportbike 18000rpm. My motor has been freshly rebuild with an Andrew's camshaft and all new parts etc...it will put out a little more than that, but it's no hayabusa for sure.

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

My parents asked if I could build them a shade house. Sure...no problem. Think my parents are planning on growing dope to fund their retirement? (***this may or may not be true***) Makes good use of a wasted space (sloping ground above septic system). May not tick council boxes for step backs from boundary, but I'm sure they have bigger issues to worry about than chasing someone whose nearly 80 years old. They're going to wrap it in shade cloth in their own time, so think my job is done. -

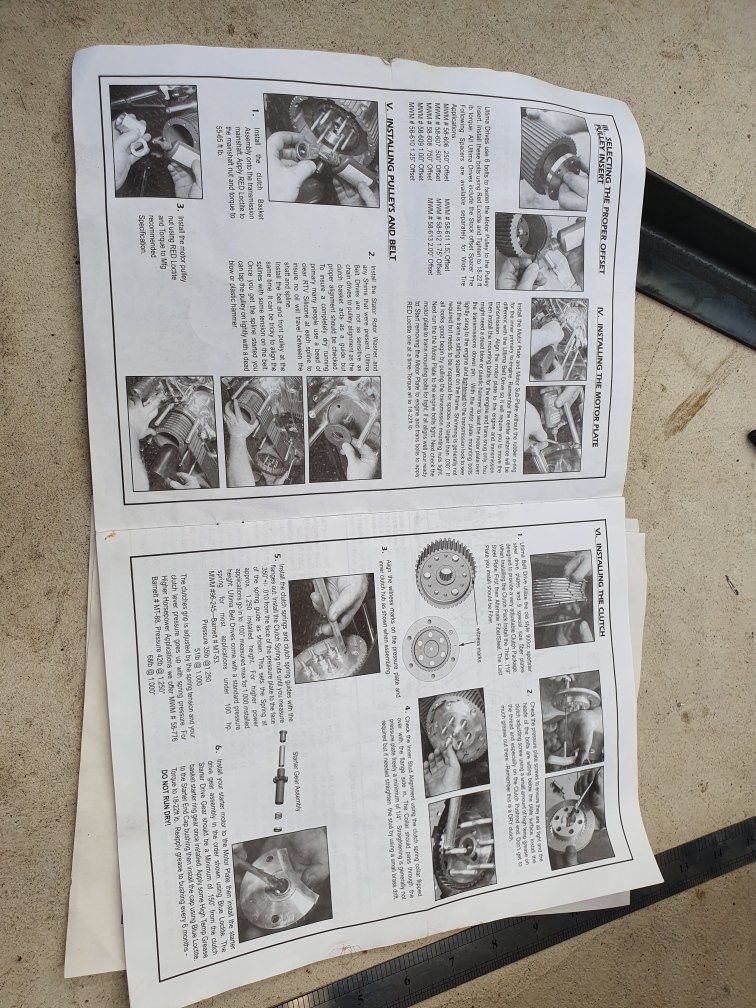

This is a job I've been putting off for a longtime. The pulleys didn't align correctly. Theres a 4.8mm difference between front and rear. Hmmm...yadda, yadda, yadda...something about using shims and a stator washer...yadda, yadda, yadda...blah, blah, blah. Instructions weren't a lot of use. What fucking shims? What fucking washers other than those already normally used on the motor??? Certainly would be helpful if they supplied these parts if you need them to make their kit work, one would think? But alas nothing like that came with it. However, as I've mentioned before; no problems just solutions... And test fitting after much time spent machining this up... Fuck yeah, like a glove!

- 299 replies

-

- 12

-

.jpeg.3359f7aabfbb3db3fa43b14ab4b55c66.jpeg)

.jpeg.7dbde483b963e88ca5bb2c4549d1ecec.jpeg)

.jpeg.72143cb0a39a3b39ce8ba5ef56b667f3.jpeg)

.jpeg.b61611690522628d2bf47af8d2d5a688.jpeg)