-

Posts

933 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by GARDRB

-

This is the only tool you need for rust work. The @Dudley 1000. He's a little hard on the gear though

-

Ok dumb computer guy question for the day. I'm in the process of re-routing my brake line for the rear in my ke70 and found the brake proportioning value in the weekend. I've switched from factory drums in the rear to AE92 FXGT calipers and I have MRP Wilwoods in the front. I'm running the factory master as this is what Barry at MRP has matched the WIlwoods to. I've got a single in single out proportioning valve which looks a lot like an AE86 proportioning valve. I've seen some people suggest gutting the factory proportioning valve. Does anyone know if Toyota used the same housing with a different spring pressure in the valve across different models? I'm almost tempted to go to an adjustable valve, but would rather not buy more things for the system if I don't need to. Any suggestions about what to do RE prop valve I'm all ears. @Dudley might even be convinced to give me his Wilwood one for free

-

The SZ engines are more of a Daihatsu thing, the 2SZ is a K3-DE, which means you could probably technically turbo Townace with a K3-VET, but that doesn't help with the 1nz RWD bellhousing. The way to do the 1NZ would be a milled and adapted J160

-

Non-car friend in Mornington needs some car help.

GARDRB posted a topic in Lower North Island Region

Hello Wellington GCs, I have a good friend who has just moved to Wellington who isn't a car person. She's got a Holden Cruze and has just had a bunch of thermostat stuff done up here. She's now moved to Welly and has a check light and code 89 which appears to relate to the sensor in the thermostat. Is anyone around that area that would be happy to have a look or can someone point me in the direction of a good workshop? She's been recommended Kilbirnie Motors but was hoping to find someone closer. If anyone has any suggestions or wants a new Wellington friend sing out. She and her fiance are into board games and TTRPG stuff. -

that's what she said

- 418 replies

-

I think this is the setup I'm gonna end up with. I'm gonna try and heat the hose a bit to get a little bit of a curve into it

-

Yeah kinda worried about what Dr Dre has been teaching him at the High Penetration Academy

- 418 replies

-

- 3

-

-

Ramen all the air into the engine

- 418 replies

-

- 14

-

-

-

600mm is gonna be pretty big for most printers, but someone like PCBway might be able to do it? You could also look at SLS Nylon or something through them and have a finished part to run with? https://www.pcbway.com/rapid-prototyping/3d-printing/

- 418 replies

-

So I'm no @Roman or @kpr and I know you've already fiddled with your inlet manifold, but now that Dave has proven we can 3d print metal easily and cheaply enough, could you do a curved runner behind the throttle body that lowers the throttle a little to get a nice entry angle? Would this leave you with atomised fuel pelting into the runner wall, or will the airflow suck the fuel round the corner? I've been playing with the sheet metal tool in Fusion and thoroughly enjoyed it. Could be a good next move after cardboard and then order a cut and folded box? Could you do silicone connectors between the throttles and the airbox to reduce the effect of vibration and put the bell mouths in the back wall of the box? Old mate in Kaiwaka with the widebody GTR fronted Stagea has been doing 3D printed modular moulds and producing composite parts off them (OMG just posted my first spoiler and it worked)

- 418 replies

-

I really like the idea of this, but you have to drill a hole in your brake res, and so if there wasn't enough fall to the clutch cylinder you might be in for a bad time https://www.chasebays.com/collections/universal-chase-bays/products/chase-bays-clutch-feed-adapter-for-brake-booster-eliminator

-

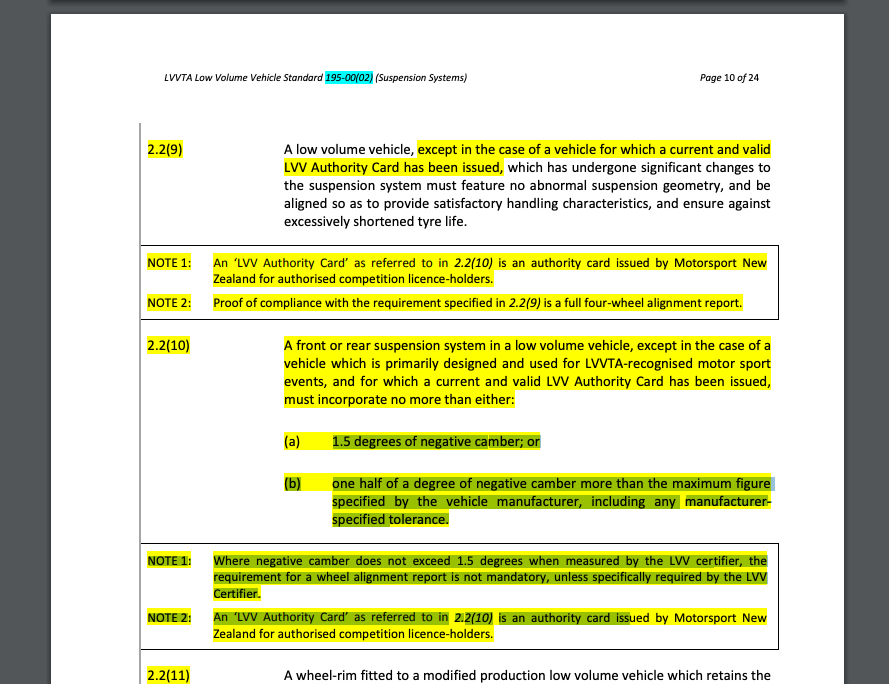

So I went looking for the camber thing. Here you go, 1.5degrees neg or half a degree more than maximum camber specified by the manufacturer.

-

Haha I'm in the crusty bilstein crew, but I think the keeper springs on mine might ruin any potential to be a criminal

-

Because I have a spicy brain I'm going to make you all suffer through 12 years of out of order updates based on which photos I find first. The diesel wagon comes factory with a larger s-series diff compared to the normal KE70, but this still wasn't going to cut the mustard because V8 and because I wanted an easy LSD option. I looked at options, first was G-Series Hilux, which I decided was heavier than what I needed, and settled on an F-Series. Now I needed to find one. Some of you may have heard of a Crown foamer called @sheepers, @Snoozin suggested I hit him up about a housing, and he supplied me with an MS85 drum brake diff. Somehow it made it's way to me and I turned it from a 5-stud, 3-link drum brake diff into a 4-stud, leaf sprung diff with AE92 FXGT calipers and S14 discs. We drew up some caliper adapters on paper and got them laser cut (I'll probably make better ones now that I have skills and shit) and an engineer a friend in Silverdale uses welded and redrilled the axles before I chucked some Landcruiser studs in them. The amount of time it took to get the axles done really makes me scared of breaking one, but we will see how we go. The LSD was bought off someone on Facebook and is an Altezza A-series torsen of a forgotten ratio, most likely 4.1, my same SIlverdale friend sent it to our mate Kayne Barrie for a bit of a freshen up and to be put into the Crown carrier. It's got a solid pinion spacer and he has really high standards and attention to detail, so I'm sure it will be a nice diff. I set about making some really ugly brake lines which was a learning experience and I have just recently found out how dumb I am, because they run through where the bump stop needs to land, so I'll probably redo them, maybe even with braided line if I get super lazy. Keep in mind I'm a computer guy, and that this is my first rear wheel drive car.

- 31 replies

-

- 17

-

-

Yeah it’s sold as Copper Nickel, it’s from Ali Express though so I’m a little dubious

-

Also in "Today stuff shows up for my Corolla" @di0n received the thread for my interior today The plan is to do my door cards in a similar fashion to these FJ45 ones he did, but black and with the orange stitching to match the FXGT steering wheel. I'll design and cut the cards and get him to deal with the stitching side. I've got some ideas for map pockets and armrests too so I'll see how I go. I'm thinking I'll do a detail section with a black basketweave vinyl too

- 31 replies

-

- 14

-

-

Max showed up this afternoon with my sump which he has had modified to fix a leak and clear the steering rack better. I've drawn the lower pan flange in fusion and I'm going to try and design a wider slimmer winged pan to give me some more ground clearance and try and get the sump up in line with the crossmember. He's also had a 4age throttle body flange welded onto his 2T intake manifold so we can use the 4age throttle and it's corresponding TPS so I'll update his thread soon hopefully

-

I've messaged @KKtrips with the solution for that. He said they were looking into it. It will be in your spam

-

Posted in the wrong thread coz I'm dumb

-

This is where I asked Clint

-

Yeah I think remote is gonna be the way to go. Just have to work out the cheapest way to do it.

-

Leeeeegend, @Dudley created a movement and he's a bit of a force

-

-

Yeah good point, I misread the instructions, it didn't make sense to me that that could be an inlet, must have been their use of "rear" on what I would consider to be the front of the cylinder because it's facing forward. Back to the drawing board.

-

Also, because Toyota so kindly put my rear brake line and my fuel lines down my tunnel, nice and high and out of the way of the road, and I have a fast spinning driveshaft in there that could explode and destroy everything in it's path, I've got to move my hard lines for cert. So I've bought a tube bender and a roll of copper brake line and just need to get fuel line. In their infinite wisdom, Toyota decided to have the passenger's rear floor pan stick down lower than the chassis rail, so it looks like I'm going to have to run the lines out through the side of the engine bay and down the outside of the chassis rail next to the pinch weld to avoid the dip in the floor and keep them up nice and high