-

Posts

422 -

Joined

-

Last visited

Posts posted by GARDRB

-

-

Just convert it to mild hybrid and use the alternatory/drive thing to start it rather than dicking around with starters. Then you can run KERS too

-

4wd MarkX is for when you add two turbos and want to do helis

-

2

2

-

-

2 hours ago, shrike said:

You can also look to go remote oil filter, probably worth adding an oil cooler as well.

Is the oil filter built into the sump?

Front/custom sump maybe the way to go. Could you 3d print a sump and then get sheet metal etc to weld one up?

https://www.ebay.com/itm/325352398654

is this one different from yours?

Actually how different is the bolt pattern on the sump if you wanted to run it backwards, (could always modify the pickup)

Modify or use and adapter to run the sump as a front instead of a rear?

I feel like they fucked up with that ebay listing, that sump looks identical to Dave's one.

I've been toying with making an adapter for my 1uz to run one of these SR20 pans https://www.trademe.co.nz/a/motors/car-parts-accessories/performance/other/listing/3995918987

-

55 minutes ago, Roman said:

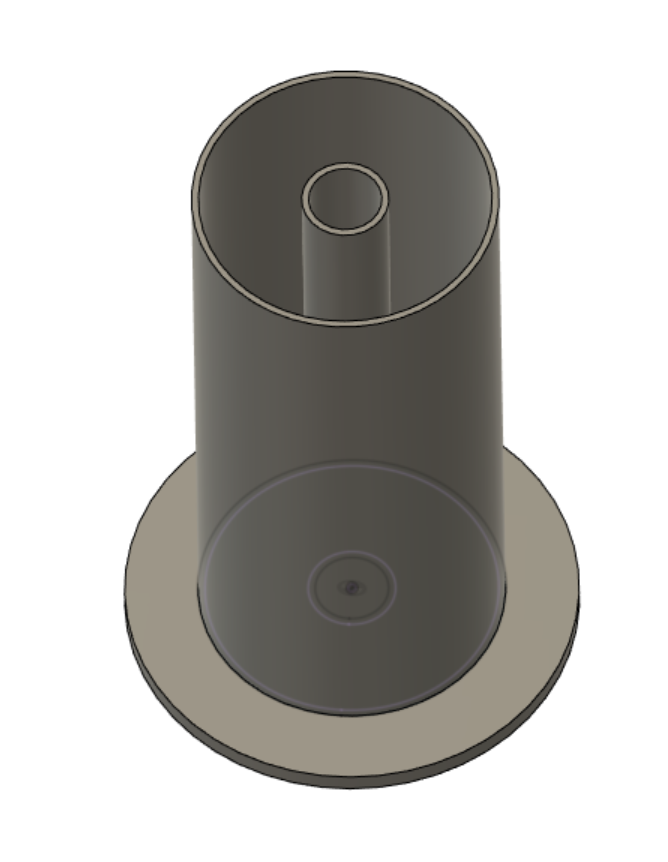

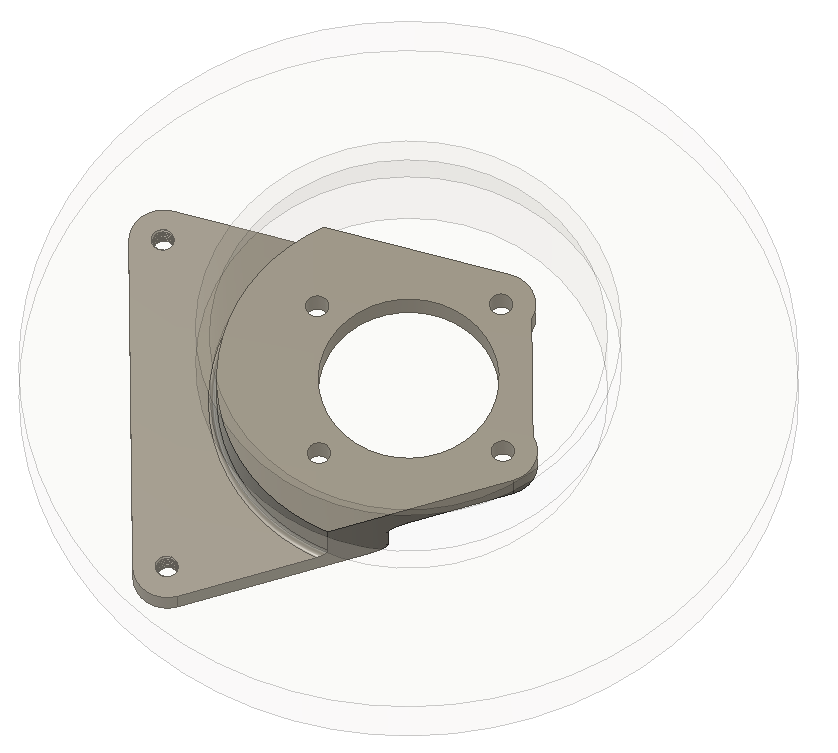

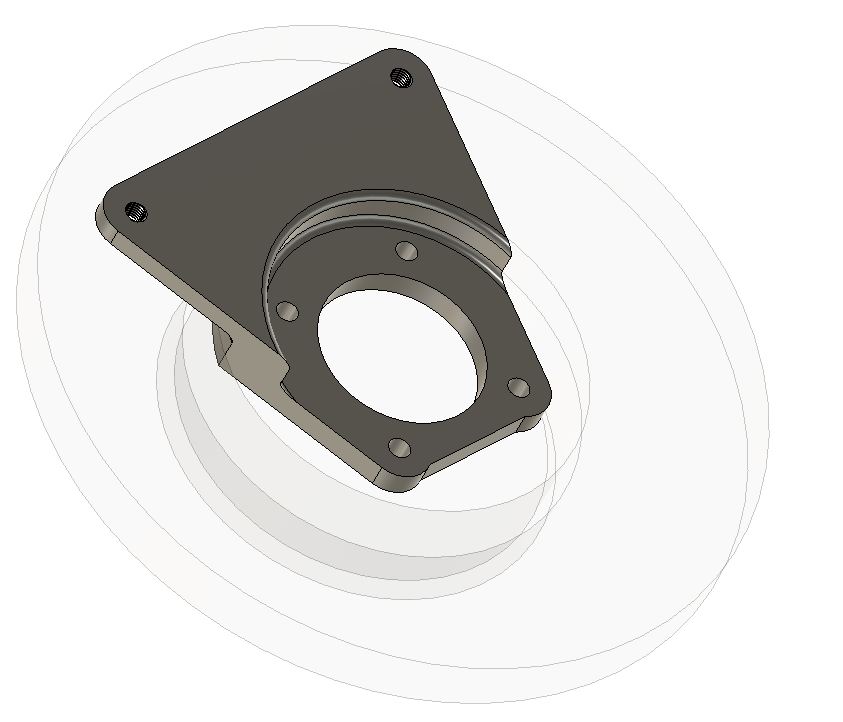

So will make some engine mounts, get it in the right place then start drawing up a sump.What filament are you gonna print the sump with? Carbon moooshed overtop of it?

-

14 hours ago, Roman said:

Yeah i guess it shouldnt be such a surprise that its huge, the whole reason this motor has a rod/stroke etc that is appealing is because small displacement in a stupidly big block.

At this point ive got nothing to lose by giving it a test fit in the engine bay, with a gearbox sorta bolted on.

But id be interested to get it on the scales. Back of the wagon sunk a whole lot when the forklift lowered it in...

For some reason the listed service weight of the 2500cc motor is 20kg heavier than 3500cc motor. But that might be because of some of the random extra bits that arent relevant to this.

If it looks like I need to chop up the engine bay to make it fit. Maybe I should test the concept in a Mark x first,to be sure its worth it.

If I can fit a 1uz in a corolla without modifying the firewall or ditching the swaybar, you can make this work.

If the motor is the hilux bolt pattern rather than the 2gr bolt pattern you could always go to an R154/R151??Otherwise let's see a 2gr echo

-

1

1

-

-

I'm assuming Dave has already read much of this, but this was where I got my info about the blocks.

https://www.toymods.org.au/forums/threads/65328-2GRFE-Conversion-any-inputs -

Is the 4gr the same block and crank pattern as the 1gr? I know when I was looking at 2gr RWD conversions the 1GR truck motor was quite different

-

12 hours ago, Roman said:

Dunno, does 1UZ and 1MZ have the same PCD?

I think I'm going to need to keep the geometry of the Altezza flywheel in order to make everything work with least potential hassle.

Have been looking into the idea of using CNC machine to redrill the flywheel bolts on the Toda altezza flywheel I've got.

3S PCD is 70mm, 4GR is 85mm.

Which from the front looks like it would work. But on the back face of the light flywheel it's only got a 90mm mounting surface.

It could potentially "work" but not keen to buzzsaw my legs off at high rpm if I can help it.1uz appears to be 80mm, so closer than 3s, but still not right. What's the PCD on the 1MZ? With my 3s flywheel on the 1uz we took the 1uz ring gear and machined the diameter of the flywheel down to match then fitted the 1uz ring gear for the engine side engagement of the starter.

-

If 1mz Flywheel is the way to go a 1uz flywheel may work?

-

-

1 hour ago, mjb.nz said:

Go Billy! Anyone have any 2LQQSE photos? I remember seeing it at Ash road back in the days. . Was impressive.

Just acquired these off Facebook, is this the right car?

-

6

6

-

-

41 minutes ago, kicker said:

^ that owned by a guy called Russell who has a lisp?

Yeth

-

1

1

-

1

1

-

7

7

-

-

- Popular Post

- Popular Post

If I could afford one of these I'd probably have one

-

12

12

-

But but but.... how did you mount the wing?

-

3 hours ago, Roman said:

However there's another one on 28th January. Hoping to get to that.

Looks to be sold out??

-

-

Keep the mounts in the middle, they won't stand out too much, and you could always work out a way to make a feature of them

-

- Popular Post

- Popular Post

https://www.trademe.co.nz/a/motors/cars/daihatsu/sirion/listing/3874023970

I want this more than you could ever understand, who wants a 2JZ Altezza Gita?

-

11

11

-

A couple of Prius engines would fetch a premium 10 days out from OS Drags

-

1

1

-

1

1

-

4

4

-

-

18 minutes ago, h4nd said:

Can I humbly suggest you do another crowd funding before drags? If you have $$/unaccountable slushfunds in unmarked Colombian pesos which definitely don't smell of bananas/spare block on the bench at home, I reckon that'll translate to 0.177 @RUNAMUCKunits of reduced mechanical sympathy, probably good for about

, yeah, about 9.5ms per gear. I for one would throw beer money at that, just for the repeat ensuing shits and giggles, like aiming for actual real max RPM analysis.

, yeah, about 9.5ms per gear. I for one would throw beer money at that, just for the repeat ensuing shits and giggles, like aiming for actual real max RPM analysis.

There needs to be a romandave patreon

-

1

1

-

-

4 minutes ago, Roman said:

Yeah

Maybe @cletus idea of a solid spacer with a shorter bump stop is a better plan than what I'm thinking.

This way can have a cone shape or whatever be more effective.

I'm trying Shore A 60 simply because that's what I bought a while back to fill my engine mounts. Might be a little on the soft side for a bump stop.

Also it might be a disaster and impossible to get out of the mould. haha.

The ones I've ordered are this sort of shape, 85mm long uncompressed. So probably compress down to smaller than I'd like.

Dude those are sex toys, not bumpstops, you're on the wrong part of aliexpress again

-

1

1

-

-

- Popular Post

- Popular Post

My brother is in a similar situation with a car he bought. A previous owner put the rego on hold, he bought it under the impression he was going to have to revin, and the testing station said, "nah that's in the system on hold". They said to have a yarn to the cops about it and the cops said "Get new plates for it, you bought the car, if he wants to complain he's admitting to something illegal"

-

13

13

-

1 hour ago, Roman said:

I'm also going to have a go at casting some bump stops from polyurethane with a 3d printed mould.

As I figure it might just be fun to do, then makes it easy to try some variations later on if it works well.

So I'm just printing a very thin walled tube. So then I'll use lots of mould release wax on it, then after pouring hopefully I'll be able to just break it off.

Doesn't making them cone shaped make them progressive? Maybe taper the mould out from the bottom??

-

On 17/11/2022 at 12:43, zep said:

I'm not sure if you're worried about manufacturing cost, but it may be cheaper to make those from two laser cut pieces of plate that bolt together like Barry does with his MRP caliper brackets then getting them machined from a single piece. You'd want to make sure @cletus is ok with it of course.

Nissan March (micra) K11 appreciation thread

in General Car Chat

Posted

Thanks @yoeddynz that used up a good hour or so of my day